Abstract

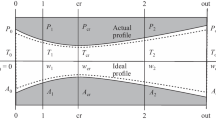

The flow behavior of the shielding gas has been a key factor to improve the quality of products manufactured by the selective laser melting (SLM) technology as it is a major mechanism to remove the ejected metal particles away from the working plane. In this study, to obtain a proper flow field, computational fluid dynamics (CFD) with the application of the Taguchi method was employed to investigate the flow field across the working chamber, with the variations in the geometries of the blowing nozzle, the widths of the suction tunnel, the suction-to-plane distances, and the Reynolds numbers of the blowing flow. The simulation was first verified with experimental measurements. The ejecting motions of the metal powders were also taken into consideration to study the interactions between the shielding gas and the ejected particles. The results demonstrated that axis switching as well as the suction-to-plane distance are the important factors for improving the particle removal efficiency during the SLM operation.

Similar content being viewed by others

References

WOHLERS, Wohlers associates, 2017

Borbás L (2013) Economical investigation of rapid prototyping, vol 3

Ladewig A, Schlick G, Fisser M, Schulze V, Glatzel U (2016) Influence of the shielding gas flow on the removal of process by-products in the selective laser melting process. Addit Manuf 10:1–9

Kuo T-Y, Lin Y-D (2007) Effects of different shielding gases and power waveforms on penetration characteristics and porosity formation in laser welding of Inconel 690 alloy. Mater Trans 48:219–226

Qiu C, Panwisawas C, Ward M, Basoalto HC, Brooks JW, Attallah MM (2015) On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater 96:72–79

Dai D, Gu D (2014) Thermal behavior and densification mechanism during selective laser melting of copper matrix composites: simulation and experiments. Mater Des 55:482–491

Ferrar B, Mullen L, Jones E, Stamp R, Sutcliffe C (2012) Gas flow effects on selective laser melting (SLM) manufacturing performance. J Mater Process Technol 212:355–364

Ly S, Rubenchik AM, Khairallah SA, Guss G, Matthews MJ (2017) Metal vapor micro-jet controls material redistribution in laser powder bed fusion additive manufacturing. Sci Rep 7:4085

Bidare P, Bitharas I, Ward R, Attallah M, Moore A (2018) Fluid and particle dynamics in laser powder bed fusion. Acta Mater 142:107–120

Chen X-X, Tzeng S-J, Wang W-C (2019) Numerical and experimental observations of the flow field inside a selective laser melting (SLM) chamber through computational fluid dynamics (CFD) and particle image velocimetry (PIV). Powder Technol

Zhao W, Kumar K, Mujumdar AS (2004) Flow and heat transfer characteristics of confined noncircular turbulent impinging jets. Dry Technol 22:2027–2049

Aleyasin SS, Tachie MF, Koupriyanov M (2017) Statistical properties of round, square, and elliptic jets at low and moderate Reynolds numbers. J Fluids Eng 139:101206

Reodikar SA, Meena HC, Vinze R, Prabhu SV (2016) Influence of the orifice shape on the local heat transfer distribution and axis switching by compressible jets impinging on flat surface. Int J Therm Sci 104:208–224

Elicer-Cortés J, Demarco R, Valencia A, Pavageau M (2009) Heat confinement in tunnels between two double-stream twin-jet air curtains. Int Commun Heat Mass Transfer 36:438–444

Wang LL, Zhong Z (2014) An approach to determine infiltration characteristics of building entrance equipped with air curtains. Energy Build 75:312–320

Masmoudi A, Bolot R, Coddet C (2015) Investigation of the laser–powder–atmosphere interaction zone during the selective laser melting process. J Mater Process Technol 225:122–132

Calignano F, Manfredi D, Ambrosio EP, Iuliano L, Fino P (August 01 2013) Influence of process parameters on surface roughness of aluminum parts produced by DMLS. Int J Adv Manuf Technol 67:2743–2751

S. Kumar, A. K. S. Choudhary, J. Anwar, and V. Sharma, Optimization of process parameters in direct metal deposition technique using Taguchi method, 2016

Wang W-C, Chang C-Y (2017) Flow analysis of the laminated manufacturing system with laser sintering of metal powder. Part I: flow uniformity inside the working chamber. Int J Adv Manuf Technol 92:1299–1314

Romano J, Ladani L, Razmi J, Sadowski M (2015) Temperature distribution and melt geometry in laser and electron-beam melting processes – a comparison among common materials. Addit Manuf 8:1–11

Khairallah SA, Anderson AT, Rubenchik A, King WE (2016) Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108:36–45

Khayrullina A, van Hooff T, Blocken B, van Heijst G (2017) PIV measurements of isothermal plane turbulent impinging jets at moderate Reynolds numbers. Exp Fluids 58:31

Chen X-X (2018) Flow field analysis with the application of particle image velocimetry (PIV) system inside the selective laser melting (SLM) chamber, MS Thesis, Department of Aeronautics and Astronautics, National Cheng Kung University

Sforza PM, Steiger MH, Trentacoste N (1966) Studies on three-dimensional viscous jets. AIAA J 4:800–806

Acknowledgments

This project was supported by the Ministry of Science and Technology, Taiwan, through grant 107-2622-E-006-012-CC3.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tzeng, SJ., Chen, XX. & Wang, WC. Numerical studies of metal particle behaviors inside the selective laser melting (SLM) chamber through computational fluid dynamics (CFD). Int J Adv Manuf Technol 107, 4677–4686 (2020). https://doi.org/10.1007/s00170-020-05351-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05351-5