Abstract

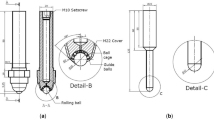

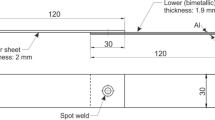

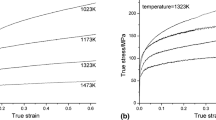

The recent advance of the single-point incremental forming (SPIF) was possible by flexibility with used the Computer Numeric Control (CNC) machine and increase manufacture. The objective of this study is to investigate correlation between the limit angle, work-hardening, stress coefficient, and thickness in two alloys, an aluminum EN AW-1100 and magnesium AZ31-B. For this study, tests were on aluminum and magnesium plates with thickness 1 mm for stamping of cones, with a roller ball tool for conditions, spindle speeds 0 RPM, feed rate 1500 mm/min, and increment 0.01 mm/rot. The study points to a phenomenon with few observations so far, which is adhesion at the tip of the tool and influences the fracture in the material. The experimental results show that an adhesion is an indicator of premature fracture in the material, and favors the conformation of the material the increase of strength coefficient, and the reduction of the strain-hardening exponent of the hooloning equation favors the conformation of the material.

Similar content being viewed by others

References

Durante M, Formisano A, Lambiase F (2018) Incremental forming of polycarbonate sheets. J Mater Process Technol 253:57–63. https://doi.org/10.1016/j.jmatprotec.2017.11.005

Zha GC, Shi XF, Zhao W, Gao L, Wu ML (2016) Experimental research of incremental sheet forming based on fastened pre-tensioning. Int J Adv Manuf Technol 82:711–717. https://doi.org/10.1007/s00170-015-7411-9

Jeswieta J, Micarib F, Hirtc G, Bramleyc A, Dufloue JA (2005) Asymmetric single point incremental forming of sheet metal. CIRP Ann 54:88–114

Duflou JR, Behera AK, Vanhove H, Bertol LS (2013) Manufacture of accurate titanium cranio-facial implants with high forming angle using single point incremental forming. Key Eng Mater 549:223–230. https://doi.org/10.4028/www.scientific.net/kem.549.223

Mirnia MJ, Shamsari M (2017) Numerical prediction of failure in single point incremental forming using a phenomenological ductile fracture criterion. J Mater Process Technol 244:17–43. https://doi.org/10.1016/j.jmatprotec.2017.01.029

Henry SD, Davidson GM, Lampman SR, Reidenbach F, Boring RL, Scott WW Jr (1996) Fatigue data book: light structural alloys. ASM Int 33:33–5731. https://doi.org/10.5860/choice.33-5731

Song L, Wu B, Zhang L, du X, Wang Y, Esling C (2018) Twinning characterization of fiber-textured AZ31-B magnesium alloy during tensile deformation. Mater Sci Eng A 710:57–65. https://doi.org/10.1016/j.msea.2017.10.055

Min J, Kuhlenkötter B, Shu C, Störkle D, Thyssen L (2018) Experimental and numerical investigation on incremental sheet forming with flexible ort from metallic foam. J Manuf Process 31:605–612. https://doi.org/10.1016/j.jmapro.2017.12.013

Bagudanch I, Lozano-Sánchez LM, Puigpinós L, Sabater M, Elizalde LE, Elías-Zúñiga A, Garcia-Romeu ML (2015) Manufacturing of polymeric biocompatible cranial geometry by single point incremental forming. Procedia Eng 132:267–273. https://doi.org/10.1016/j.proeng.2015.12.494

Lu H, Kearney M, Li Y, Liu S, Daniel WJT, Meehan PA (2016) Model predictive control of incremental sheet forming for geometric accuracy improvement. Int J Adv Manuf Technol 82:1781–1794. https://doi.org/10.1007/s00170-015-7431-5

Gatea S, Ou H, McCartney G (2016) Review on the influence of process parameters in incremental sheet forming. Int J Adv Manuf Technol 87:479–499. https://doi.org/10.1007/s00170-016-8426-6

Hussain G, Gao L, Hayat N, Cui Z, Pang YC, Dar NU (2007) Tool and lubrication for negative incremental forming of a. J Mater Process Technol 3:193–201. https://doi.org/10.1016/j.jmatprotec.2007.10.043

Diabb J, Rodríguez CA, Mamidi N, Sandoval JA, Taha-Tijerina J, Martínez-Romero O, Elías-Zúñiga A (2017) Study of lubrication and wear in single point incremental sheet forming (SPIF) process using vegetable oil nanolubricants. Wear 376–377:777–785. https://doi.org/10.1016/j.wear.2017.01.045

Patel A, Guo H, Iglesias P (2018) Study of the lubricating ability of protic ionic liquid on an aluminum-steel contact. Lubricants 6. https://doi.org/10.3390/lubricants6030066

Dakhli M, Boulila A, Tourki Z (2017) Effect of generatrix profile on single-point incremental forming parameters. Int J Adv Manuf Technol 93:2505–2516. https://doi.org/10.1007/s00170-017-0598-1

Hussain G, Gao L (2007) A novel method to test the thinning limits of sheet metals in negative incremental forming. Int J Mach Tools Manuf 47:419–435. https://doi.org/10.1016/j.ijmachtools.2006.06.015

Bai L, Yang M, Cui F et al (2018) Study on thickness thinning ratio of the forming parts in single point incremental forming process. Adv Mater Sci Eng 2018:1–11. https://doi.org/10.1155/2018/2927189

McAnulty T, Jeswiet J, Doolan M (2017) Formability in single point incremental forming: a comparative analysis of the state of the art. CIRP J Manuf Sci Technol 16:43–54. https://doi.org/10.1016/j.cirpj.2016.07.003

Kumar A, Gulati V (2018) Experimental investigations and optimization of forming force in incremental sheet forming. Sadhana 43:43. https://doi.org/10.1007/s12046-018-0926-7

Dong C, Sun J, Cheng Z, Hou Y (2019) Preparation and tribological properties of a microemulsion for magnesium alloy warm rolling. Ind Lubr Tribol 71:74–82. https://doi.org/10.1108/ILT-06-2018-0222

Acknowledgments

The authors would like to thank the institutions PUC-MG, CNPQ, FAPEMIG for the support and encouragement of technological research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Castro Maciel, D., da Silva, G.C. & de Quadros, L.M. Incremental stamping forming with use of roller ball tool in aluminum and magnesium alloy. Int J Adv Manuf Technol 108, 455–462 (2020). https://doi.org/10.1007/s00170-020-05425-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05425-4