Abstract

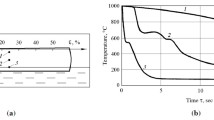

A computer model was developed and a study of the cold rolling modes of 1580 alloy sheets was carried out. The model provided for the achievement of the maximum total degree of reduction in cold rolling of 60% in the minimum number of passes, the rolling force should not exceed 90% of the maximum allowable for the rolling mill, and the Cockcroft-Latham criterion was not reach value 1, so that cracks do not occur along the edges of the rolled products. The simulation results were tested on a billet cut from a large-sized ingot cast at an industrial enterprise by the method of semi-continuous casting. Hot rolling was carried out on a two-roll mill with a roll diameter of 330 mm and a barrel length of 520 mm. For cold rolling a two-roll mill with a roll diameter of 200 mm and a barrel length of 400 mm was used. Based on the simulation results, cold rolling was carried out, as a result of which a 2-mm-thick strip without cracks along the edges was obtained from a hot-rolled billet 5-mm-thick in 8 passes. At the same time in all passes, the rolling force values did not exceed 90% of the allowable for the rolling mill, and the Cockcroft-Latham criterion was less than 1. Thus, it is shown that computer modeling allows to optimize the rolling route of thin sheets of alloy 1580 and to carry out cold rolling with a total reduction rate of 60% for a minimum number of passes to obtain high-quality sheet semi-finished products.

Similar content being viewed by others

References

Wang R, Jiang S, Chen B, Zhu Z (2020) Size effect in the Al3Sc dispersoid-mediated precipitation and mechanical/electrical properties of Al-Mg-Si-Sc alloys. J Mater Sci Technol 57:78–84

Mansurov YN, Gusarov M (1988) Dependence of mechanical properties of alloys of the Al - Mg system with increased content of impurities on the rate of cooling during crystallization. Tsvetnye Metally 2:69–71

Mansurov YN, Letyagin NV, Finogeyev AS, Rakhmonov JU (2018) Influence of impurity elements on the casting properties of Al-Mg based alloys. Non-Ferrous Met 44(1):24–29

Tang H-P, Wang Q-D, Luo C, Lei C, Liu T-W, Li Z-Y, Jiang H-Y, Ding W-J, Fang J, Zhang J-W (2020) Effects of aging treatment on the precipitation behaviors and mechanical properties of Al-5.0Mg-3.0Zn-1.0Cu cast alloys. J Alloys Compd 842:155707

Mansurov YN, Kurbatkina EI, Buravlev IY, Reva VP (2015) Features of structure’s formation and properties of composite aluminum alloy ingots. Non-ferrous Met 39(2):48–45

Avtokratova E, Sitdikov O, Latypova O, Markushev M (2020) Effect of the bimodal structure processed by ecap and subsequent rolling on static strength and superplasticity of Al-Mg-Sc-Zr alloy. Facta Universitatis, Ser: Mechan Eng 18(2):255–267

Ahmed M, Shrivastava A, Kumar DR, Nabi MU (2020) Optimisation of process parameters for energy-efficient electro-hydraulic forming of Al-Mg alloy sheets. Adv Mater Proc Technol 6(3):620–636

Kishchik MS, Kotov AD, Demin DO, Kishchik AA, Aksenov SA, Mikhaylovskaya AV (2020) The effect of multidirectional forging on the deformation and microstructure of the Al–Mg alloy. Phys Met Metallogr 121(6):597–603

Filatov YA (2014) Al–Mg–Sc aluminium alloys for welded and brazed structures. Tsvetnye Metally 1:80–86

Bronz AV, Efremov VI, Plotnikov AD, Chernyavskiy AG (2014) Kosmicheskaya tekhnika i tekhnologii [Space Eng Technol] 4(7):62–67

Filatov YA, Plotnikov AD (2011) Structure and properties of deformed semi-finished products from aluminum alloy 01570C of the Al–Mg–Sc system for the RSC «Energia» product. Tekhnologiya legkikh splavov [Light Alloy Technol] 2:15–26

Shi C, Liang Z, Wu G, Zhang X, Chen A, Tao J (2017) Effects of Sc addition on the microstructure and mechanical properties of cast Al-3Li-1.5Cu-0.15Zr alloy. Mater Sci Eng А680:232–238

Pereiraa PHR, Wang YC, Huang Y, Langdon TG (2017) Influence of grain size on the flow properties of an Al-Mg-Sc alloy over seven orders of magnitude of strain rate. Mater Sci Eng А685:367–376

Mondol S, Alamb T, Banerjee R, Kumar S, Chattopadhyay K (2017) Development of a high temperature high strength Al alloy by addition of small amounts of Sc and Mg to 2219 alloy. Mater Sci Eng А687:221–231

Malopheyev S, Kulitskiy V, Kaibyshev R (2017) Deformation structures and strengthening mechanisms in an Al–Mg–Sc–Zr alloy. J Alloys Compd 698:957–966

Li M, Pan Q, Shi Y, Xue S, Xiang H (2017) High strain rate superplasticity in an Al–Mg–Sc–Zr alloy processed via simple rolling. Mater Sci Eng А687:298–305

Buranova Y, Kulitskiy V, Peterlechner M, Mogucheva A, Kaibyshev R, Divinski SV, Wilde G (2017) Al3(Sc, Zr) - based precipitates in AlMg alloy: effect of severe deformation. Acta Mater 124:210–224

Zhemchuzhnikova D, Kaibyshev R (2014) Effect of grain size on cryogenic mechanical properties of an Al–Mg–Sc alloy. Adv Mater Res 922:862–867

Marquis EA, Seidman EA (2001) Nanoscale structural evolution of Al3Sc precipitates in Al (Sc) alloys. Acta Mater 49:1909–1919

Fuller CB, Seidman DN (2005) Temporal evolution of the nanostructure of Al (Sc,Zr) alloys: Part II Coarsening of Al3(Sc1−xZrx) precipitates. Acta Mater 53(20):5415–5428

Ryset J, Ryum N (2005) Scandium in aluminum alloys. Int Mater Rev 50(1):19–44

Fujikawa S-I, Sakauchi S (1998) Kinetics of precipitation in Al–0,20 mass % Sc alloy. Aluminium Alloys. Their Physical and Mechanical Properties. Proc. of the 6th Int. Conf. on Aluminium Alloys, ICAA-6. Toyohashi, Japan. – The Japan Institute of Light Metals, 2:805–810

Koryagin YD, Il’in SI (2017) Recrystallization features of deformable aluminium-magnesium alloys with scandium. Bulletin of the South Ural State University. Series “Metallurgy”, 17:1, 65–72

Knipling KE, Seidman DN, Dunand DC (2011) Ambient- and high-temperature mechanical properties of isochronally aged Al–0.06Sc, Al–0.06Zr and Al–0.06Sc–0.06Zr (at.%) alloys. Acta Mater 59:943–954

Rajinikanth V, Vikas J, Akkimardi VG, Mainak G, Venkateswarlu K (2007) Transmission electron microscopy studies on the effect of strain on Al and Al–1% Sc alloy. Scr Mater 57:425–428

Lee S-L, Chang J-K, Cheng Y-C, Lee K-Y, Chen W-C (2011) Effects of scandium addition on electrical resistivity and formation of thermal hillocks in aluminum thin films. Mater Charact 519:3578–3581

Konstantinov IL, Baranov VN, Sidelnikov SB, Kulikov BP, Bezrukikh AI, Frolov VF, Orelkina TA, Voroshilov DS, Yuryev PO, Belokonova IN (2020) Investigation of the structure and properties of cold-rolled strips from experimental alloy 1580 with a reduced scandium content. Int J Adv Manuf Technol 109:443–450

Yashin VV, Aryshenskiy VY, Latushkin IA, Tepterev VS (2018) Substantiation of a manufacturing technology of flat rolled products from Al – Mg – Sc based alloys for the aerospace industry. Tsvetnye Metally 7:75–82

Dovzhenko NN, Rushchits SV, Dovzhenko IN, Yurev PO (2019) Understanding the behaviour of aluminium alloy Р-1580 sparingly doped with scandium under hot deformation. Tsvetnye Metally 9:80–86

Sidelnikov SB, Yakivyuk OV, Baranov VN, Zenkin EY, Dovzhenko IN (2020) Developing, simulating, and researching a production process of long deformed semi-fabricated aluminum–magnesium products with a varying scandium content. Russ J Non-Ferrous Met 61(1):51–59

Baranov VN, Zenkin EY, Konstantinov IL, Sidelnikov SB (2019) The research of the cold rolling modes for plates of aluminum alloy sparingly doped with scandium. Non-ferrous Met 47(2):48–52

Baranov V, Sidelnikov S, Voroshilov D, Yakivyuk O, Konstantinov I, Sokolov R, Belokonova I, Zenkin E, Frolov V (2018) Study of strength properties of semi-finished products from economically alloyed high-strength aluminium-scandium alloys for application in automobile transport and shipbuilding. Open Eng 8(1):69–76

Mann VK, Sidelnikov SB, Konstantinov IL, Baranov VN, Dovzhenko IN, Voroshilov DS, Lopatina ES, Yakivyuk OV, Belokonova IN (2019) Modeling and investigation of the process of hot rolling of large-sized ingots from aluminum alloy of the Al–Mg system, economically alloyed by scandium. Mater Sci Forum 943:58–65

Yakivyuk OV (2018) Development of a technology for obtaining longish deformed semi-finished products from alloys of the Al-Mg system doped with scandium, and investigation of their properties. Dissertation thesis for an academic degree candidate of technical sciences, Krasnoyarsk

Cockcroft MG, Latham DJ (1968) Ductility and the workability of metals. J Inst Met 96:33–39

Botkin AV, Valiev RZ, Stepin PS, Baymukhametov AK (2011) Assessment of metal damage during cold plastic deformation using the Cockcroft-Latham fracture model. Deforma Destruct Mater 7:17–22

Mondolfo L.F. Structure and properties of aluminum alloys. Metallurgiya. 1979

Funding

The research was carried out within the framework of the state assignment of the Ministry of Science and Higher Education of the Russian Federation (scientific theme code FSRZ-2020-0011).

Author information

Authors and Affiliations

Contributions

The authors declare that they are all participants in the work and none of them performed only administrative functions.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Ethical approval

The work contains no libelous or unlawful statements, does not infringe on the rights of others, or contains material or instructions that might cause harm or injury.

Consent to participate

The authors consent to participate.

Consent to publish

The authors consent to publish.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Konstantinov, I.L., Baranov, V.N., Sidelnikov, S.B. et al. Investigation of cold rolling modes of 1580 alloy by the method of computer simulation. Int J Adv Manuf Technol 112, 1965–1972 (2021). https://doi.org/10.1007/s00170-020-06570-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06570-6