Abstract

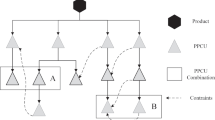

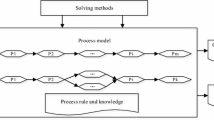

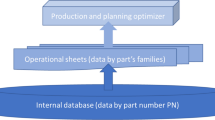

Configuration design is a process of composing customized product from a set of predefined component types with a set of well-defined rules which decide how items can be selected and combined. The configuration solving process is to instantiate all component types into instances. However, the configurator faces the problem of how to determine the instantiation order of component types in the configuration solving process. An unreasonable instantiation order may reduce the accuracy of the configuration result and extend the time required to finish the configuration. In response to the above problem, a heuristic configuration solving process planning method by imitating the crystal crystallization process (CCP) was proposed. According to the product configuration rules, the frequent itemset mining algorithm was used to mine the correlation between the attribute parameters of the product configuration unit. By imitating the CCP and utilizing the calculated coupling strength, the configurator will determine a suitable instantiation sequence for component types. This method has been applied in the GB10 elevator produced by Canny Elevator. It is found that the configuration accuracy has been improved and the consumption of time has been reduced.

Similar content being viewed by others

References

Wei W, Fan W, Li Z (2014) Multi-objective optimization and evaluation method of modular product configuration design scheme. Int J Adv Manuf Technol 75(9):1527–1536

Kott A, Agin G, Fawcett D (1992) Configuration Tree Solver - a Technology for Automated Design and Configuration. J Mech Design 114(1):187–195

Yang D, Dong M, Miao R (2008) Development of a product configuration system with an ontology-based approach. Comput Aided Design 40(8):863–878

Steward DV (1981) The Design Structure-System - a Method for Managing the Design of Complex-Systems. Ieee T Eng Manage 28(3):71–74

Mcdermott J (1982) R1 - a Rule-Based Configurer of Computer-Systems. Artif Intell 19(1):39–88

Soloway E, Bachant J, Jensen K (1987) Assessing the maintainability of XCON-in-RIME: coping with the problems of a VERY large rule-base. In: Proceedings of the sixth National conference on Artificial intelligence - Volume 2. Seattle, Washington, pp 824–829

Felfernig A, Hotz L, Bagley C, Tiihonen J (2014) Knowledge-based Configuration: From Research to Business Cases. Morgan Kaufmann Publishers Inc, San Francisco

Mittal S, Frayman F (1989) Towards a generic model of configuraton tasks. In: the Proceedings of the 11th international joint conference on Artificial intelligence - Volume 2, Detroit, Michigan, pp 1395-1401.

Mailharro D (1998) A classification and constraint-based framework for configuration. Ai Edam 12(4):383–397

Amilhastre J, Fargier H, Marquis P (2002) Consistency restoration and explanations in dynamic CSPs-Application to configuration. Artif Intell 135(1-2):199–234

Wang P, Gong Y, Xie H, Liu Y (2016) SOMEDGRA: A case retrieval method for machine tool product configuration design. J Mech Sci Technol 30(7):3283–3293

Zeng FS, Jin Y (2007) Study on product configuration based on product model. The International Int J Adv Manuf Technol 33(7):766–771

Lee J, Han S (2010) Knowledge-based configuration design of a train bogie. J Mech Sci Technol 24(12):2503–2510

Dong M, Yang D, Su LY (2011) Ontology-based service product configuration system modeling and development. Expert Syst Appl 38(9):11770–11786

Yassine A, Falkenburg D, Chelst K (1999) Engineering design management: an information structure approach. Int J Prod Res 37(13):2957–2975

Srour IM, Abdul-Malak MAU, Yassine AA, Ramadan M (2013) A methodology for scheduling overlapped design activities based on dependency information. Autom Constr 29:1–11

Lin J, Qian YJ, Yassine AA, Cui WT (2012) A fuzzy approach for sequencing interrelated activities in a DSM. Int J Prod Res 50(23):7012–7025

Spinner M (1989) Improving project management skills and techniques. Prentice Hall, Englewood Cliffs, N.J

Shishko R. AR, and Cassingham R.C (1995) NASA Systems Engineering Handbook. National Aeronautics and Space Administration, Washington, D.C.

Smith RP, Eppinger SD (1997) A predictive model of sequential iteration in engineering design. Manag Sci 43(8):1104–1120

Huang JQ, Li YP, Chu XN, Chu DX (2015) An integrated top-down design process evaluation approach of complex products and systems based on hierarchical design structure matrix. Int J Comput Integ M 28(10):1015–1029

Chen L, Ding ZD, Li S (2005) A formal two-phase method for decomposition of complex design problems. J Mech Design 127(2):184–195

Chen L, Macwan A, Li S (2007) Model-based rapid redesign using decomposition patterns. J Mech Design 129(3):283–294

Jafari MH, Kosari A, Fakoor M (2019) A new heuristic method for improved structuring of the Work Transformation Matrix (WTM). Sci Iran 26(4):2506–2523

Zhiliang W, Yunxia W, Yun L (2011) Primary Exploration of Optimization Theory and Method for Ordering Coupled Tasks. Chin J Mech Eng(Chs Ei) 22(12):1444–1449

Lee DM, Drake PR (2010) A portfolio model for component purchasing strategy and the case study of two South Korean elevator manufacturers. Int J Prod Res 48(22):6651–6682

Lawler EL (1976) Combinatorial optimization : networks and matroids. Holt, Reinhardt and Winston, New York

Warfield JN (1973) Binary Matrices in System Modeling. Ieee T Syst Man Cyb Smc 3(5):441–449

Sharman DM, Yassine AA (2004) Characterizing complex product architectures. Syst Eng 7(1):35–60

Gebala D, Eppinger S (1991) Methods for Analyzing Design Procedures. Nabu Press, Germany

Kosztyán ZT (2015) Exact Algorithm for Matrix-Based Multilevel Project Planning Problems. In: Innovations and Advances in Computing. Networking and Engineering. Springer International Publishing, Informatics, Systems Sciences, pp 487–493

Rogers J (1990) Knowledge-Based Tool for Decomposing Complex Design Problems. J Comput Civ Eng 4(4):298–312

English KW, Bloebaum CL (2008) Visual Dependency Structure Matrix for Multidisciplinary Design Optimization Tradeoff Studies. J Aerosp Comput Inf Commun 5(9):274–297

Abdelsalam HME, Bao HP (2006) A simulation-based optimization framework for product development cycle time reduction. Ieee T Eng Manage 53(1):69–85

Altus SS, Kroo IM, Gage PJ (1996) A genetic algorithm for scheduling and decomposition of multidisciplinary design problems. J Mech Design 118(4):486–489

Sun L, An J, Yu H (2016) The Application of Design Structure Matrix Optimization Method Based on Genetic Algorithm. In: the International Conference on Communications, Information Management and Network Security, Kuala Lumpur, Malaysia 271-273

Funding

This work has been funded by the National Key R&D Program of China (2018YFB1700700), the National Natural Science Foundation of China (51905476), and the Jiangsu Province Science and Technology Achievement Transforming Fund Project (BA2018083).

Author information

Authors and Affiliations

Contributions

Shuyou Zhang: Funding acquisition, data curation, formal analysis, project administration, resources, supervision, visualization, roles/writing - original draft

Wenqi Ge: Conceptualization, formal analysis, methodology, investigation, roles/writing - original draft, software, visualization

Zili Wang: Funding acquisition, project administration, formal analysis, supervision, visualization, writing - review and editing

Lemiao Qiu: Data curation, project administration

Huifang Zhou: Investigation, resources

Corresponding author

Ethics declarations

Ethical approval

No applicable

Consent to participate

No applicable

Consent to publish

Authors consent to publish this article

Conflict of interest

The authors declare no competing interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shuyou, Z., Wenqi, G., Zili, W. et al. A heuristic configuration solving process planning method for mechanical product configuration by imitating the crystal crystallization process. Int J Adv Manuf Technol 116, 611–628 (2021). https://doi.org/10.1007/s00170-021-07462-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07462-z