Abstract

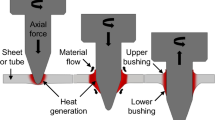

Friction drilling is one of the most promising methods for hole making in thin sheets of conventional structural alloy materials (aluminum, steel, copper, titanium, etc.) and novel polymer composites. Despite almost a hundred year history of studying friction drilling, it is still highly relevant and is actively developed. The aim of the present review is to cover as fully as possible all aspects of this technology. The paper analyzes the advantages and disadvantages of friction drilling, discusses the influence of technological parameters on the drilled hole quality. The technological parameters considered are not only the feed rate and spindle speed, but also the tool configuration. The quality of the holes refers to their strength, inner surface hardness, hole geometry and roughness, bushing geometry, and so on; therefore, they are also analyzed. From a fundamental point of view, frictional drilling is interesting in that it causes structural changes in the material as a result of severe plastic deformation, which is discussed in a separate section. Approaches for the process modeling are considered which quite accurately predict the material behavior. A technically more advanced technology of a new generation is discussed, namely flow drill screwdriving. A general conclusion is that despite the widespread use of friction drilling, including by well-known engineering companies, the technology continues to develop with regard to the changing needs of the industry and the market and strengthens its position in the industry.

Similar content being viewed by others

Data availability

Not applicable

References

Streppel AH, Kals HJJ (1983) Flowdrilling: a preliminary analysis of a new bush-making operation. Annals CIRP 32(1):167–171

Boopathi M, Shankar S, Kanish T (2017) Investigation of surface texture generated by friction drilling on Al2024-T6. Mech Mater Sci Eng 9. https://doi.org/10.2412/mmse.1.19.706

Pereira O, Urbikain G, Rodrigues A, Calleja A, Ayesta I, Lopez de Lacalle LN (2019) Process performance and life cycle assessment of friction drilling on dual-phase steel. J Cleaner Prod 213:1147–1156

Sobotova L, Kralikova R, Badida M (2015) The analysis of chosen material properties at thermal drilling. Key Eng Mater 635:35–40

Dekkers GJ (1993) Flowdrill technical guide. Flowdrill, Holland

Enghauser WL (1929) Method of forming manifolds, US patent #1906953.

Leroy A (1957) Procédé et outil de formation de collets, et collets résultant de ce proceed, French patent #1189384.

Van Geffen JA (1974) Piercing tools, US patent #3939683.

Hoogenboom AJ (1982) Flow drill for the provision of holes in sheet material, US patent #4454741.

Dekkers GJ (1984) Flowdrill, particularly adapted to be used in a hand drilling machine, European patent #0150518 A1.

Head GD Jr, Le Master WC, Bredesky LP Jr, Winter DC (1982) Flow drilling process and tool therefor, US patent #4428214.

El-Bahloul SA, El-Shourbagy HE, Al-Makky MY, El-Midany TT (2013) Thermal friction drilling: (a review). 15th International Conference on Aerospace Sciences & Aviation Technology, ASAT – 15.

Alphonse M, Raja VKB, Logesh K, Nachippan MN (2017) Evolution and recent trends in friction drilling technique and the application of thermography. IOP Conf. Series: Mater Sci Eng 197:012058

Gajjarkar B, Kamble N, Kamble Y (2017) A comprehensive review on influence of process parameters by a novel method form drilling technique. J Emerg Technol Innovative Res 4(6):16–20

Kerkhofs M, Van Stappen M, D’Olieslaeger M, Quaeyhaegens C, Stals LM (1994) The performance of (Ti,Al)N-coated flowdrills. Surf Coat Technol 68(69):741–746

Prabhu T, Arulmurugu A (2014) Experimental and analysis of friction drilling on aluminium and copper. Int J Mech Eng Technol 5(5):130–139

Alphonse M, Bupesh Raja VK, Rama Chandra LV, Venkata Subbaiah B, Sai Uday Kiran R, Gopala Krishna V (2021) Experimental investigation and optimization of surface treated and coated friction drilling tool for AZ31B magnesium alloy. Mater Today Proc 44(5):3760–3766

Mutalib MZA, Ismail MIS, Jalil NAA, As’arry A (2018) Characterization of tool wear in friction drilling. Jurnal Tribologi 17:93–103

Miller SF (2006) Experimental analysis and numerical modeling of the friction drilling process. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2006.

Ku W, Chow H, Lin Y, Wang D, Yang L (2011) Optimization of thermal friction drilling using grey relational analysis. Adv Mater Res 154(155):1726–1738

El-Bahloul SA, El-Shourbagy HE, El-Bahloul AM, El-Midany TT (2018) Experimental and thermo-mechanical modeling optimization of thermal friction drilling for AISI 304 stainless steel. CIRP J Manuf Sci Technol 20:84–92

El-Bahloul SA, El-Shourbagy HE, El-Midany TT (2016) Effect of tool geometry, feed rate, and rotational speed of thermal friction drilling process on AISI 304 stainless steel. Mansoura Eng J 41(1):9–15

Krishna PVG, Kishore K, Satyanarayana VV (2010) Some investigations in friction drilling AA6351 using high speed steel tools. ARPN J Eng Appl Sci 5(3):11–15

Oezkaya E, Hannich S, Biermann D (2019) Development of a three-dimensional finite element method simulation model to predict modified flow drilling tool performance. Int J Mater Form 12:477–490

Bustillo A, Urbikain G, Perez JM, Pereira OM, de Lacalle LNL (2018) Smart optimization of a friction-drilling process based on boosting ensembles. J Manuf Sys 48:108–121

Krasauskas P (2011) Experimental and statistical investigation of thermo-mechanical friction drilling process. Mechanika 17(6):681–686

Boopathi M, Shankar S, Manikandakumar S, Ramesh R (2013) Experimental investigation of friction drilling on brass, aluminium and stainless steel. Procedia Eng 64:1219–1226

Demir Z, Ozek C (2013) Investigate the friction drilling of aluminium alloys according to the thermal conductivity. TEM J 2(1):93–101

Pantawane PD, Ahuja BB (2014) Parametric analysis and modelling of friction drilling process on AISI 1015. Int J Mechatronics Manuf Sys 7(1):60–79

Rao KH, Gopichand A, Kumar NP, Jitendra K (2017) Optimization of machining parameters in friction drilling process. Int J Mech Eng Technol 8(4):242–254

Dogru N, Ozler L, Tosun N (2013) Experimental and statistical evaluation on surface roughness and temperature in friction drilling. European conference in technology and society EuroTecS-2013 243-250.

Pantawane PD, Ahuja BB (2011) Experimental investigations and multi-objective optimization of friction drilling process on AISI 1015. Int J Appl Eng Res 2(2):448–461

Ku W, Hung C, Lee S, Chow H (2011) Optimization in thermal friction drilling for SUS 304 stainless steel. Int J Adv Manuf Technol 53:935–944

Biermann D, Walther F, Hannich S, Wittke P (2017) Front face flow drilling of lightweight cast materials. Procedia Eng 207:956–961

Dehghan S, Ismail MIS, Ariffin MKA, Baharudin BTHT (2018) Experimental investigation on friction drilling of titanium alloy. Eng Solid Mech 6(2):135–142

Somasundaram G, Boopathy SR (2010) Fabrication and friction drilling of aluminum silicon carbide metal matrix composite. Frontiers in Automobile and Mechanical Engineering -2010, Chennai 21–6.

Aslan F, Langlois L, Balan T (2019) Experimental analysis of the flow drill screw driving process. Int J Adv Manuf Technol 104:2377–2388

Sato YS, Kokawa H (2003) Friction stir welding (FSW) process. Weld Inter 17:852–855

Hynes NRJ, Kumar R, Sujana JAJ (2017) Optimum bushing length in thermal drilling of galvanized steel using artificial neural network coupled with genetic algorithm. Mater Technol 51(5):813–822

Shalamov PV, Kazantseva JV (2017) Thermal drilling with force-feed tool. Procedia Eng 206:985–990

Demir Z, Ozek C, Bal M (2018) An experimental investigation on bushing geometrical properties and density in thermal frictional drilling. Appl Sci 8/12:2658

Shalamov PV, Kulygina IA, Yaroslavova EN (2016) ANSYS software-based study of thermal drilling process. Procedia Eng 150:746–752

Fernández A, Lopez de Lacalle LN, Lamikiz A (2011) Friction drilling of stainless steels pipes. AIP Conf Proc 1315:1187

Vergara J, Damm S, Villanueva J, Godoy J-M, Tikal F (2001) Bush making by thermal flow drilling in copper and brass. Int J Manuf Sci Prod 4(2):103–111

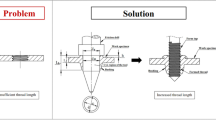

Su K, Welo T, Wang J (2018) Improving friction drilling and joining through controlled material flow. Procedia Manuf 26:663–670

Urbikain G, Perez JM, Lopez de Lacalle LN, Andueza A (2018) Combination of friction drilling and form tapping processes on dissimilar materials for making nutless joints. Proc Ins Mech Eng Part B: J Eng Manuf 232(6):1007–1020

Lopez De Lacalle LN, Urbikain Pelayo G, Azkona I, Verbitchi V, Cojocaru R, Botila L, Ciuca C, Perianu I, Vlascici M (2018) Functional layers of aluminium alloy on steel made by alternative friction processes, for elements of metal structures. Adv Mater Res 1146:106–114

El-Bahloul SA (2019) Friction drilling of cast aluminum alloy A380 without significant petal formation and radial fracture. Int J Precision Eng Manuf 20:45–52

France JE, Davison JB, Kirby PA (1999) Strength and rotational stiffness of simple connections to tubular columns using flowdrill connectors. J Constrl Steel Res 50:15–34

Miller SF, Blau PJ, Shih AJ (2005) Microstructural alterations associated with friction drilling of steel, aluminum, and titanium. J Mater Eng Perform 14:647–653

Chow H, Lee S, Yang L (2008) Machining characteristic study of friction drilling on AISI 304 stainless steel. J Mater Process Technol 207:180–186

Kumar R, Hynes NRJ (2019) Influence of rotational speed on mechanical features of thermally drilled holes in dual-phase steel. Proc Inst Mech Eng Part B: J Eng Manuf 233(5):1614–1625

Wittke P, Liu Y, Biermann D, Walther F (2015) Influence of the production process on the deformation and fatigue performance of friction drilled internal threads in the aluminum alloy 6060. Mater Test 57(4):281–288

Wittke P, Walther F (2016) Cyclic deformation behavior of friction drilled internal threads in AlSi10Mg and AZ31 profiles. Procedia Struct Integr 2:3264–3271

Fernández Landeta J, Fernández Valdivielso A, López de Lacalle LN, Girot F, Pérez Pérez JM (2015) Wear of form taps in threading of steel cold forged parts. J Manuf Sci Eng 137(3):031002

Wittke P, Teschke M, Walther F (2018) Mechanical characterization of friction drilled internal threads in AZ91 profiles. Int J Adv Manuf Technol 99:3111–3122

Engbert T, Heymann T, Biermann D, Zabel A (2011) Flow drilling and thread forming of continuously reinforced aluminium extrusions. Proc Inst Mech Eng Part B: J Eng Manuf 225(3):398–407

Eliseev AA, Fortuna SV, Kolubaev EA, Kalashnikova TA (2017) Microstructure modification of 2024 aluminum alloy produced by friction drilling. Mater Sci Eng A. 691:121–125

Eliseev AA, Kalashnikova TA, Fortuna SV (2017) Microstructure evolution of AA3005 in friction drilling. AIP Conf Proc 1909:020038

Eliseev AA, Kalashnikova TA, Fortuna SV (2017) Structure of AA5056 after friction drilling. AIP Conf Proc 1909:–020039

Fortuna SV, Kalashnikova TA, Kolubaev EA (2017) Structural and phase state evolution in friction drilling on AA2024. AIP Conf Proc 1909:020055

Bilgin MB, Gok K, Gok A (2017) Three-dimensional finite element model of friction drilling process in hot forming processes. Proc IMechE Part E: J Process Mech Eng 231(3):548–554

Qu J, Blau PJ (2008) A new model to calculate friction coefficients and shear stresses in thermal drilling. J Manuf Sci Eng 130:014502.

Li H, Chen L, Zhang C, Li Z (2018) An improved drilling force model in friction drilling AISI 321. IOP Conf. Series: J Phys: Conf. Series 1074:012147

Raju BP, Swamy MK (2012) Finite element simulation of a friction drilling process using deform-3D. Int J Eng Res Appl 2(6):716–721

Dehghan S, Ismail MIS, Ariffin MKA, Baharudin BTHT, Sulaiman S (2017) Numerical simulation on friction drilling of aluminum alloy. Mat.-wiss. u. Werkstofftech 48:241–248

Dehghan S, Ismail MISB, Souri E (2020) A thermo-mechanical finite element simulation model to analyze bushing formation and drilling tool for friction drilling of difficult-to-machine materials. J Manuf Process 57:1004–1018

Kumar R, Hynes NRJ (2018) Finite-element simulation and validation of material flow in thermal drilling process. J Brazilian Soc Mech Sci Eng 40:162

Freis AK (2013) Method of flow drill screwing parts, US patent #0195579 A1.

Skovron J, Mears L, Ulutan D, Detwiler D, Paolini D, Baeumler B, Claus L (2015) Characterization of flow drill screwdriving process parameters on joint quality. SAE Int J Mater Manf 8(1):35–44

Sonstabo JK, Holmstrom PH, Morin D, Langseth M (2015) Macroscopic strength and failure properties of flow-drill screw connections. J Mater Process Technol 222:1–12

Scholz CS, Kopp G, Friedrich HE (2016) Influence of corrosive conditions on the mechanical performance of flow drill screw joints between light metals. Mater Sci Forum 879:1725–1730

Huang C-P, Chen W-N, Sung S-J, Pan J (2018) Mechanical strength and failure mode of flow drill screw joints in coach-peel specimens of aluminum 6082-T6 sheets of different thicknesses and processing conditions. SAE Technol Paper 01:0116

Aslan F, Langlois L, Mangin P, Balan T (2018) Identification of drilling parameters during the flow drill screw driving process. Key Eng Mater 767:465–471

Meschut G, Janzen V, Olfermann T (2014) Innovative and highly productive joining technologies for multi-material lightweight car body structures. J Mater Eng Perform 23:1515–1523

Skovron JD, Rohan Prasad R, Ulutan D, Mears L, Detwiler D, Paolini D, Baeumler B, Claus L (2015) Effect of thermal assistance on the joint quality of Al6063-T5A during flow drill screwdriving. ASME J Manuf Sci Eng 137/5:051019

Nagel P, Meschut G (2017) Flow drill screwing of fibre-reinforced plastic-metal composites without a pilot hole. Weld World 61:1057–1067

Szlosarek R, Karal T, Enzinger N, Hahne C, Meyer C, Berger A (2016) Experimental and numerical investigations on the punching failure of carbon fiber-reinforced plastics. Mater Test 58(7):617–621

Sonstabo JK, Morin D, Langseth M (2018) Static and dynamic testing and modelling of aluminium joints with flow-drill screw connections. Int J Impact Eng 115:58–75

Pan J, Chen W-N, Sung S-J, Su X, Friedman P (2018) Failure mode and fatigue behavior of flow drill screw joints in lap-shear specimens of aluminum 6082-T6 sheets of different thicknesses. SAE Technol Paper 01:1239

Milner JL, Gnaeupel-Herold T, Skovron JD (2016) Residual stresses in flow drill screwdriving of aluminum alloy sheets. Proceedings of the ASME 2016 International Manufacturing Science and Engineering Conference.

Grujicic M, Snipes J, Ramaswami S (2016) Process and product-performance modeling for mechanical fastening by flow drilling screws. Int J Struct Integr 7(3):370–396

Grujicic M, Snipes J, Ramaswami S (2017) Process modeling, joint virtual testing and construction of joint connectors for mechanical fastening by flow-drilling screws. Proc Inst Mech EngPart B: J Eng Manuf 231(6):1048–1061

Graf M, Sikora SP, Roider CS (2018) Macroscopic modeling of thin-walled aluminum-steel connections by flow drill screws. Thin-Walled Structures 130:286–296

Funding

The work was performed according to the Government research assignment for ISPMS SB RAS, project FWRW-2021-0006.

Author information

Authors and Affiliations

Contributions

Alexander Eliseev was responsible for the literature search and text writing. Evgeny Kolubaev was responsible for the concept of the paper, its structure, and proofreading.

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent to publish

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Eliseev, A., Kolubaev, E. Friction drilling: a review. Int J Adv Manuf Technol 116, 1391–1409 (2021). https://doi.org/10.1007/s00170-021-07544-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07544-y