Abstract

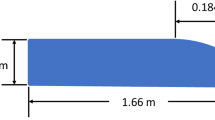

The contact surface tailoring conditions normally used for shock tubes do not apply to shock tubes with different driver and driven section diameters. A theoretical model is presented that predicts the contact surface tailoring condition for a convergent shock tube, designed to have a larger driver cross-section area than the driven section. The tailoring condition previously developed for shock tubes with uniform driver and driven diameters can be recovered from this model. Representative on- and off-model performance is verified experimentally in a high-pressure convergent shock. Tailoring conditions calculated with the model are also given for commonly used driven gases (Ar, N2 and air) and He–N2 driver mixtures as a function of driver/driven area ratio.

Similar content being viewed by others

References

Palmer H.B., Knox B.E.: Contact surface tailoring in a chemical shock tube. ARS J. 31, 826–828 (1961)

Napier D.H., Simonson J.R.: Attainment of interface matching in a chemical shock tube. ARS J. 32, 1736–1737 (1962)

Trass O., Mackay D.: Contact surface tailoring in a chemical shock tube. AIAA J. 1, 2161–2163 (1963)

Reddy N.M.: An analysis method for real gas tailoring in a shock tube. AIAA J. 9, 2458–2460 (1971)

Amadio A.R., Crofton M.W., Petersen E.L.: Test-time extension behind reflected shock waves using CO2-He and C3H8-He driver mixtures. Shock Waves 16, 157–165 (2006)

Alpher R.A., White D.R.: Flow in shock tubes with area change at the diaphragm section. J. Fluid Mech. 3, 457–470 (1958)

Resler E.L., Lin S., Kantrowitz A.: The production of high temperature gases in shock tubes. J. Appl. Phys. 23, 1390–1399 (1952)

Nishida M.: Shock tubes In: Handbook of shock waves, pp. 553–585. 1 edn. Academic, New York (2001)

Petersen E.L., Hanson R.K.: Nonideal effects behind reflected shock waves in a high-pressure shock tube. Shock Waves 10, 405–420 (2001)

Hong, Z., Pang, G.A., Vasu, S.S., Davidson, D.F., Hanson, R.K.: The use of driver inserts to reduce non-ideal pressure variations behind reflected shock waves. Shock Waves. doi:10.1007/s00193-009-0205-y

Hooker J.W.: Test time and contact-zone phenomena in shock-tube flow. Phys. Fluids 4, 1451–1463 (1961)

Polachek H., Seeger J.R.: On shock-wave phenomena: refraction of shock waves at a gaseous interface. Phys. Rev. 84, 922–930 (1952)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by H. Olivier.

Rights and permissions

About this article

Cite this article

Hong, Z., Davidson, D.F. & Hanson, R.K. Contact surface tailoring condition for shock tubes with different driver and driven section diameters. Shock Waves 19, 331–336 (2009). https://doi.org/10.1007/s00193-009-0212-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00193-009-0212-z