Abstract

The laboratory synthesis of pure PVA and PVA–ZnO nanocomposites of varying concentrations was synthesized via co-precipitation and in situ techniques, respectively. The formation of PVA and PVA–ZnO nanocomposites and the corresponding changes in their structural properties were examined using X-ray diffraction (XRD) and Fourier transform infrared (FTIR) spectroscopic techniques. The FESEM images displayed regular distribution of ZnO nanowires in PVA matrix. The UV–Vis absorption spectra showed that the direct band gap (E g) decreased with the increase in ZnO concentration. The UV–Vis spectra also indicated the shifting towards blue–green region for higher ZnO concentrations. The optimized direct band gap was estimated around 2.985 eV duly associated with the p-type conductivity. The photoluminescence (PL) study revealed optimum intensity for 5:2 ratio of PVA:ZnO nanocomposites and blue emission (470 nm) varied with the increase in ZnO concentration. The atomic force microscopy (AFM) study showed that RMS roughness of the nanocomposites increased with the increase in ZnO concentration. The enhanced current density (~ 237.83%) in the visible region and reduced optical band gap with relatively higher electron–hole non-radiative recombination rate was in good agreement with the data for electron transport layer material for organic light emitting diode (OLED) application.

Similar content being viewed by others

Introduction

The doping of inorganic nanoparticles into conductive polymer matrix can provide high performance and efficient novel materials that find applications in dye-sensitized solar cells, short-wavelength organic light emitting diodes, transparent conductors, gas sensors and piezo-electric materials, etc. [1]. In recent years much research efforts have been directed towards the investigation on conductive polymers. As a consequence, conductive polymers have grown to be very important in various applications such as fuel cells, electrochemical cells, display devices, memories and sensors [2]. It is reported that the incorporation of inorganic nanoparticles into polymers matrix enhances the optical, structural as well as electrical properties. Reduction of the gas permeability and humidity of the conductive polymer matrix is also observed [3]. The development of nanostructured materials for its uses in nanoscale devices has been extensively expanding [4]. Because of the quantum confinement and increment of surface to volume ratio, it can show the properties of nanomaterials that are drastically different from the bulk counterparts [5]. The presence of inorganic nanoscaled additives in polymer matrix has been proved to enhance the optical and electrical properties [6].

Polyvinyl alcohol (PVA) is a polymer with exceptional properties such as high dielectric strength (> 1000 kV/mm), water solubility, biodegradability, biocompatibility, non-toxicity, good charge storage capacity, dopant-dependent electrical property and non-carcinogenity that possesses the capability to form hydrogels by different methods [7,8,9,10]. The outstanding chemical resistance, physical properties, and complete biodegradability of PVA pave the path for its broad practical applications [11]. As a consequence, PVA has grown to be important in various applications, such as electrochemical cells, fuel cells, display devices, memories and sensors [12,13,14]. PVA film can be easily prepared by solution casting method due to its water solubility property [15].

On the other hand, Zinc oxide (ZnO) is basically a II–VI group semiconducting material with wide band gap energy 3.2–3.4 eV [16, 17] at room temperature. ZnO has been the subject of enormous studies in the last few decades because of its exciting properties, such as resistivity control, direct band gap, transparency in the visible wavelength region, high electrochemical stability, absence of toxicity and abundantly available in nature [18]. In this context, zinc oxide (ZnO) nanostructured materials have gained much of interest as it shows good electrical and optical properties which have led to its wide use in a variety of industrial and technological applications in chemical sensors, piezo-electric films, surface acoustic wave devices, catalytic action and photovoltaic applications [19, 20].

Polyvinyl alcohol (PVA), a degradable polymer, is easily dissolved in solvents [21] like distilled water and ethanol. Also the synergistic combination of ZnO nanoparticles and PVA results in improved structural, electrical, and optical properties. This is probably due to its effective functional group and the backbone structure of PVA–ZnO composite [22]. ZnO-based PVA nanocomposites prepared by various physical and chemical methods such as solvent or solution casting, in situ method, chemical vapor deposition, vapor–liquid–solid growth process, melt processing methods have been extensively employed to design, fabricate and obtain the desired matrix of PVA–ZnO nanocomposites [23, 24].

Thus, using polymeric PVA–ZnO nanocomposites, one can successfully fabricate novel hybrid materials with low band gap, high dielectric permittivity, high breakdown voltages and energy storage density for applications in sensors, OLEDs and capacitors as electric energy storage devices. Investigation on the incorporation of inorganic particle into polymer matrix has been developed by many researchers. Hemalatha et al. reported the structural and optical properties of PVA–ZnO nanocomposites [25]. They also discussed about the luminescence properties of films with different excitation wavelengths. Further B. Karthikeyan et al. studied the time resolved photoluminescence of PVA–ZnO nanocomposite films [26]. Concentration-dependent structure, optical and electrical properties of PVA–ZnO nanocomposite films prepared via in situ techniques have not been investigated in detail. The present study reports the synthesis, characterization and concentration-dependent performance evaluation of the structural, optical and electrical properties of PVA–ZnO nanocomposite films as electron transport material, synthesized in the laboratory.

Experimental

Materials

Poly vinyl acetate (Molecular weight ~ 124,800) (Merck) with high purity, sodium sulfate (Na2SO4) (molecular mass = 142.05 g/mol) (Merck), sulfuric acid (H2SO4) (Merck) (molecular mass = 98.08 g/mol), zinc nitrate hexahydrate (molecular mass = 297.47 g/mol) (Merck) and sodium hydroxide (molecular mass = 39.99 g/mol) (Merck) were procured for synthesis purpose. Deionised water and methanol (Merck) were used as solvents during chemical processing.

Synthesis of PVA

PVA powder was prepared via co-precipitation technique. In this method, polyvinyl acetate was coagulated from its emulsion using a solution of sodium sulfate in the presence of methanol as solvent and distilled water. 100 mg of polyvinyl acetate emulsion (60% by weight solid content) was stirred with 25 ml methanol, and it was dissolved in the aqueous solution of sodium sulfate salt (100 mg Na2SO4 and 100 ml distilled water) and 1 ml sulfuric acid in a conical flask. The mixture was stirred for 2 h at temperature in the range 30–50 °C. The reaction mixture was allowed to settle for about 1 h at room temperature. The polyvinyl acetate was coagulated and three layers were formed: the top layer was emulsifiers, the intermediate (middle) layer was liquid phase (water, dissolved salt, and methanol), and the bottom layer was the precipitated polymer. The collected precipitate was then washed three times with distilled water and filtered. The resulting polymer consisted of 75–80% polymer and 20–25% water. The polymer mixture was dried in an oven at 50 °C for 24 h to obtain the PVA powder.

Synthesis of PVA–ZnO nanocomposites

In situ method was used for the fabrication of nanocomposite films. Firstly, 5 mg PVA stock solution was prepared by dissolving PVA powder into 15 ml distilled water under constant heating up to 75 °C for 2.5 h. The ZnO:PVA nanocomposites were prepared in varying concentrations of zinc nitrate hexahydrate (1,2 and 3 mg) by dispersing it into 5 mL of double distilled water separately and then NaOH or KOH (0.5 M) was added to the solution. The solution was mixed under continuous stirring for 5 h. Afterwards, 5 g PVA stock solution was added to it and stirred vigorously using magnetic stirrer until transparent PVA–ZnO multicomponent dispersion was obtained. Each concentration of PVA–ZnO composite was poured in a petri dish and was dried in a dust-free chamber at room temperature for about 72 h to obtain the nanocomposite films. The schematic representation of as-synthesized PVA and PVA–ZnO nanocomposite has been shown in Fig. 1.

Characterization

The as-synthesized PVA and PVA–ZnO nanocomposites were characterized by X-ray diffractometry (XRD-GBCMMA, Cu-Kα radiation, λ = 1.5406 Å). The XRD patterns were recorded in the 2θ angular range 10°–70°. The FTIR spectroscopic (Perkin Elmer-RX1) analysis of PVA and PVA–ZnO composites was carried out in the frequency range 4000–400 cm−1 using KBr pellet techniques. Field emission scanning electron microscopy (ZEISS, SUPRA-55) was used to investigate the surface morphology of these films. Optical absorbance and band gap of these films were examined by UV–Vis spectroscopic technique (CARY-5000) in the wavelength range 200–800 nm. The thickness of these films was measured by US Mprobe VIS spectroscopic reflectometer (Mprobe-20 series). The photoluminescence spectra were recorded using fluorescence spectrophotometer (Hitachi F-2500 Fluorescence Spectrophotometer) at the excitation wavelength of 250 nm. The Film roughness and surface morphology of pure PVA and PVA–ZnO composites of varying concentrations were examined by atomic force microscopy (Bruker) using tapping mode. The J–V characteristics of the said films were studied by source meter (KEITHLEY 2400).

Results and discussion

XRD analysis

To examine the structure of the polymer composite films, X-ray diffraction spectroscopic technique was employed. Figure 2 shows the XRD spectra for pristine PVA and PVA–ZnO nanocomposite films of varying concentrations. The XRD spectra for pristine PVA shown in Fig. 2a revealed the relatively strong broad diffraction peak located at 2θ = 20.04°. This corresponded to (101) reflection plane of PVA and a greater peak at 41.9° indicated the semi-crystalline nature of PVA [27,28,29,30]. There was a strong intermolecular interaction between PVA chains through hydrogen bond which confirmed the semi-crystalline nature of PVA [31].

The X-ray diffraction pattern of PVA–ZnO nanocomposites has been shown in the Fig. 2c–e. The corresponding diffraction peaks matched with the diffraction peak of PVA and standard PDF database (JCPDS 36-1451) of ZnO wurtzite hexagonal crystal structure [32]. These diffraction peaks confirmed the formation of PVA–ZnO nanocomposite with the increase in crystallinity of PVA matrix with the embodiment of ZnO nanofiller. There were some additional peaks instead of PVA and ZnO peaks. This structural deformation was due to the variation in inter-planar spacing, lattice parameters, concentration of defects, development of micro-strain and crystallite size in crystal structure due to the host PVA matrix [33]. Lattice parameter and unit cell volume of PVA–ZnO nanocomposites were calculated and shown in Table 1.

Relation of d-spacing and crystallite size as function of concentration ratio

The crystallite size of the synthesized nanocomposites was calculated using Scherer’s formula [34] as shown by the relation:

where D is the average crystallite size, λ is the wave length of X-ray (1.5416 Å), B is the full-width of half-maximum of a diffraction peak in radian, θ is the diffraction angle, and K is the Scherrer’s constant of the order of unity for usual crystal (0.9). The d spacing (d) of the lattice was calculated by the Bragg’s law as shown by the following relation [35]:

The concentration-dependent study of d-spacing and crystallite size of PVA–ZnO nanocomposites has been shown in Fig. 3a. A meager shifting of peak was observed towards lower scattering angle for all the concentrations. The highest optimized crystallographic lattice (~ 2.37 Å) was found for the PVA:ZnO (5:2) ratio due to fair dispersion of the ZnO nanofillers in the polymeric surface, which led to an increase in interfacial adhesion between the filler and polymeric matrix [36]. The crystallite size of nanocomposites was increased due to decrease in the peak width or FWHM (full-width half-maxima) value. The highest optimized crystallite size was observed for the PVA:ZnO (5:2) ratio due to the relative increase in ZnO nanofillers population during crystallization process.

Relation of FWHM (full-width half-maxima) and crystallinity (%) with PVA and PVA:ZnO nanocomposites

The crystallinity (%) of polymeric nanocomposite was calculated by the following relation [37]:

Figure 3b presents the correlation of FWHM (full-width half-maxima) and crystallinity index with respect to pure PVA and PVA:ZnO nanocomposites of varying concentrations. The pristine PVA showed the broad diffraction. With the incorporation of ZnO fillers in PVA polymeric matrix, a relatively lower value of FWHM was examined due to the reduction of point defect in pristine PVA [38]. The optimized lowest value of FWHM (~ 0.9411°) was observed for PVA:ZnO (5:2) ratio due to the proper alignment of ZnO on the PVA surface. There was small change in crystallinity index observed with the incorporation of ZnO nanofillers and optimized higher crystallinity (%) (~ 61.94) was observed for PVA:ZnO (5:2) ratio, due to the well distribution of ZnO nanofillers on PVA surface.

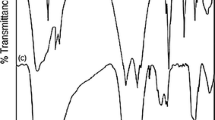

FTIR analysis

The FTIR spectrum for pure poly vinyl alcohol and PVA–ZnO nanocomposites has been depicted in Fig. 4. The FTIR transmission spectra confirmed the interaction between polymer and metal oxide over the wave number range 500–4000 cm−1 in KBr medium. The peaks appeared in the higher wavenumber side were ascribed to the vibration of organic compounds of PVA matrix. Absorption peaks in the wave number around 500 cm−1 in the PVA–ZnO nanocomposites occurred due to Zn–O stretching which was not observed in the pure PVA film. This confirmed the presence of ZnO in PVA matrix. The absorption peaks recorded at 1444, 1108 and 840 cm−1 were assigned to the vibrations of CH2, C–C and C–H modes, respectively. The peak recorded around 1570 and 1660 cm−1 could be assigned due to the C=C bond and C=O stretching vibration, respectively. Whereas absorption peak at 1440 cm−1 was related to C–H deformation mode. Peaks around 2935, 920 cm−1 are suggested to the characteristic –CH2 stretching and bending vibration bands of PVA, respectively. The peak around 1255 cm−1 was just because of C–C stretching or from wagging vibration of CH. The peaks having wavenumber 1065 cm−1 are due to (C–O) stretching vibration of the ether group. The peaks which were observed between 2918 and 2659 cm−1 were symmetric and asymmetric C–H2 bond’s osculation. A peak at 1023 cm−1 corresponded to C–O–C stretching of acetyl group present on PVA backbone. On comparing the absorption spectra of pure PVA and PVA–ZnO composites, the broad peak of pure PVA at 3432 cm−1 was shifted towards the higher wave number of about 3575–3587 cm−1. In the FTIR spectra of PVA:ZnO composite, the shift was due to the formation of intermolecular hydrogen bonds between O–H group of PVA with the surface of ZnO. This confirmed the light surface coating of PVA on ZnO nanoparticles.

FESEM analysis

The surface morphology for pure PVA and PVA–ZnO nanocomposites has been shown in Fig. 5. The PVA–ZnO nanocomposites revealed the inclusion of ZnO nanowires on the surface of PVA. The FESEM image of PVA–ZnO nanocomposites confirmed that with the increase in the concentration of ZnO, crystallites were initiated and grown in the immediate vicinity of the surface. It also showed uniform dispersion of ZnO nanowires, whereas with the increase in the ZnO concentration, more compactness and aggregation existed. This showed the higher crystalline nature of the sample and the surface of the sample was more rough as compared to pure PVA supporting the observation of XRD and AFM analysis. The EDX (energy dispersive X-ray spectroscopy) spectrum of PVA–ZnO composite confirmed the successful incorporation of ZnO nanowires into polymer matrix.

Optical properties

UV–Vis spectroscopy analysis

UV–Vis absorption spectroscopic technique was employed to examine the optical properties of nano-sized particles and nanocomposite films. The absorption spectra of pure PVA and PVA–ZnO composites were recorded using double beam UV–Vis spectrometer and these have been shown in Fig. 6a.

a UV–Vis spectra for PVA and PVA–ZnO nanocomposites of varying concentrations. b The plot between (αhυ)2 versus hυ for PVA and PVA–ZnO nanocomposites of varying concentrations. c The plot between (αhυ)1/2 versus hυ for PVA and PVA–ZnO nanocomposites of varying concentrations. d Optical dielectric loss versus photon energy (hυ) for PVA and PVA–ZnO nanocomposites of varying concentrations

The absorption peak of pure PVA was recorded with broad absorption band at 210 nm. This band arose due to semi-crystalline nature of PVA. Another reason was the presence of un-hydrolyzed acetate group and carbonyl containing structure which was connected to the PVA polymer matrix [25, 39]. These bands corresponded to the electronic transitions n–π* and π–π*, respectively [40]. The optical absorption spectra of PVA–ZnO composites film showed two bands appeared at 280 nm and further at 370 nm with less intensity which corresponded to the presence of ZnO in the film [41]. These bands were referred to the absorption of PVA and excitons of ZnO nanoparticles. The absorption edge of ZnO nanoparticle was 10 nm blue shift in comparison to the characteristic ZnO at room temperature. Such blue shift occurred due to the reduction in the crystallite size [42, 43]. As indicated in the UV absorption spectra, the higher the concentration of ZnO into PVA matrix, the better the absorbance of PVA host in the UV–Vis region. Thus, the absorption edge shifted towards the lower energy or higher wavelength associated with the blue–green region of the visible spectral range with increasing concentration of the nano-sized ZnO particle.

Determination of optical band gap

Optical band gap is the appropriate way to define the optical transition in nanocomposites film using Tauc’s plot [44]. The frequency-dependent absorption Coefficient has been shown by the relation:

where α is the absorption coefficient, hυ is the energy of incident photon, B is the constant that depends on the inter band transition probability, E g is the optical band gap and n is the index characterizing the nature of the electronic transition which causes the optical absorption. We can take n as the value \( \frac{1}{2} \), \( \frac{3}{2} \), 2, 3 for direct allowed, direct forbidden, indirect allowed and indirect forbidden electronic transitions, respectively. The absorption coefficient α is calculated using Beer–Lambert’s relation [45] as shown by the relation.

where A is the absorbance and d is the thickness of the sample. The average thickness ‘d’ of nanocomposite films was calculated and shown in Table 2. Figure 6b, c shows the direct and indirect band gap value using the plots between (αhυ)2 versus hυ and (αhυ)1/2 versus hυ for pure PVA and PVA–ZnO nanocomposites, respectively. By extrapolating the line segment of the spectra to x axis, one can determine the optical band gap. The acquired values of band gap (E g) for both the electronic transition have been tabulated in Table 3. In the case of organic–inorganic mixture, nature of electronic transition was rather difficult to predict. The optical dielectric loss was another precise method to examine the exact value of optical band gap which confirmed direct or indirect nature of band gap [46] due to the direct response to incident photon to electronic transition [47]. The optical dielectric loss was calculated using imaginary part of dielectric constant (ɛ i ) using the following relation [48]:

where K is the extinction coefficient (\( \frac{\alpha \lambda }{4\pi } \)), α is the absorption coefficient, λ is the wavelength and n is the refractive index \( \left( { R = \frac{{\left( {n - 1} \right)^{2 } + K^{2} }}{{(n + 1)^{2} + K^{2} }}} \right) \), where R is the reflectance. Figure 6d shows the intersection of linear segment of optical dielectric loss on photon energy and it was almost matched with the direct band gap values. As a result, the direct allowed electronic transition \( \left( {n = \frac{1}{2}} \right) \) is possible for PVA and PVA–ZnO nanocomposites films.

It was confirmed from Fig. 6b that with the addition of ZnO nanoparticle in PVA matrix, direct optical energy gap decreased due to the p-type conductivity of nanocomposite film and the optimized band gap of sample 5:2 was about 2.985 eV. This occurred due to the formation of reinnovative new level in the band gap, and began to promote the electron move through valance band to local level to the conduction band. As a result, the band gap decreased and conductivity increased [49]. Another reason was the formation of donor level in the bottom of the conduction band which resulted in the tensile strain developed in the nanocomposite films [50].

Photoluminescence analysis

The photoluminescence emission spectra for pure PVA and PVA–ZnO nanocomposites under 250 nm excitation using xenon arc lamp as excitation source have been shown in Fig. 7. These exhibited luminescence emission in the blue region. There were two identifiable emission peaks appearing at near about 390 and 470 nm due to the radiative and non-radiative recombination of electron–hole pair in the nanocomposite film [51]. The emission peak observed at 390 was attributed to the band edge exciton radiative recombination of ZnO [52]. The emission peak near about 470 nm occurred due to the phonon-assisted transition [53]. Intense blue spectrum was ejected from the ZnO nanoparticle. From the photoluminescence spectra, the optimum luminescence intensity was found for 5:2 ratio of PVA–ZnO nanocomposites due to the increase in the electron–hole recombination rate. Although for 5:1 and 5:3 PVA:ZnO ratio, the emission intensity was lower. This occurred due to the self absorption of light and it was quite relevant to the data of UV–Vis absorption spectroscopy. Thus, the photoluminescence properties of nanocomposite films specified that it could be possibly used in organic light emitting diode as an organic electron transport layer.

AFM analysis

The AFM technique reveals 3D profile of the surface on a nanoscale, by measuring forces between a sharp probe (< 10 nm) and surface at very short distance (0.2–10 nm probe-sample separation). It was basically used to evaluate the surface roughness, grain size of nanocomposite thin film and nanoscale topology [54].

Figure 8 shows the height sensing atomic force microscopy image of PVA and PVA–ZnO nanocomposites. The height of the tor was observed in micrometer range. It indicated the micro-domain structure of the surface. From Fig. 8, a clear heterogeneous structure was observed in the nanocomposite films due to the presence of crystalline materials in the semi-crystalline composite phase.

The height parameters calculated from the AFM image have been shown in the Table 4. From the above data, it was observed that with the increase in the concentration of ZnO nanoparticles, the average and RMS (root mean square) roughness increased and at the same time average length of the peak also increased. This occurred due to the strong interaction between the ZnO nanoparticle and PVA polymer macromolecule that eventually grasped the surface polymer chain to produce a renovated compact structure [55].

Electrical properties

J–V measurement

The conductivity behavior of PVA and PVA–ZnO nanocomposite film of varying concentrations was measured at room temperature in the potential range − 10.0 to + 10.0 V as represented in Fig. 9. Figure 9 shows that the current increased linearly with increase in the applied voltage. This occurred due to the electron mobility which was completely based on electron–hole recombination process. There was an increase in minority charge carrier (hole) as compared to the majority charge carrier (electron) with the embodiment of ZnO into the PVA matrix. Based on this explanation, the conduction mechanism for these conducting polymer nanocomposites was quite different from that of intrinsic semiconductors [56]. The sample ratio of PVA:ZnO (5:2) exhibited the optimized higher current density of 12.1 µA/cm2. This occurred due to the increased neck particle size in PVA:ZnO (5:2) sample which formed wider neck between adjacent particles; hence, resistivity was decreased and recombination rate was increased. It is quite favorable for good electron transport due to the transfer of electrons from one particle to another through larger path width [57]. The enhancement of current density for optimized PVA:ZnO (5:2) ratio sample was observed 237.83% compared to pure PVA. These electrical properties specified that the said PVA–ZnO nanocomposite film could be used as an electron transport layer in OLED application.

Conclusion

Polyvinyl alcohol (PVA) and PVA–ZnO nanocomposites of varying concentrations were successfully synthesized in the laboratory by co-precipitation and in situ methods, respectively. The XRD analysis showed confinement of ZnO in polymer matrix. The peak narrowing and peak shift associated with the XRD study exhibited crystallite size variation due to the structure deformation and growth of micro-strain. The FTIR studies confirmed the successful formation of PVA–ZnO nanocomposites. The FESEM images showed the appropriate size distribution of ZnO nanowires into the PVA polymeric surface, and smaller sizes of ZnO nanowires in lower concentration nanocomposites.

The UV–Vis measurements showed two bands at 280 and 370 nm which were attributed to the absorption of PVA and excitons of ZnO nanoparticles. The optical direct band gap decreased with the addition of ZnO nanoparticle and the optimum band gap was found 2.985 eV as inferred from the optical dielectric loss curve. The study showed that the light emitting property of ZnO was completely controlled by PVA through surface passivation. The film showed the optimum increases in PL (photoluminescence) intensity for (5:2) of PVA:ZnO ratio and exhibited ultraviolet luminescence and enhanced the optical property for OLED devices. The AFM analysis confirmed the heterogeneous structure in nanocomposites. It also showed that RMS roughness increased with the increase in concentration of ZnO. The electrical properties showed enhancement in current density (237.83%) as compared to pristine PVA and the optimized current density was found to be sample of PVA:ZnO (5:2) ratio due to the highest electron hole recombination rate which led to its application for OLED device fabrication as an electron transport layer.

References

Fortunato EMC, Barquinha PMC, Pimentel ACMBG, Goncalves AMF, Marques AJS, Pereira LMN, Martins RFP (2005) Fully transparent ZnO thin-film transistor produced at room temperature. Adv Mater 17:590–594

Filoti G, Kuncser V, Franke H, Kardinahl T, Manivannan G (1995) Optical induced modifications in thin films of Fe:PVA. J Radioanal Nucl Chem 190:315–320

Lee J, Bhattacharya D, Easteal AJ, Metson JB (2008) Properties of nano-ZnO/poly(vinyl alcohol)/poly(ethylene oxide) composite thin films. Curr Appl Phys 8:42–47

Aricò AS, Bruce P, Scrosati B, Jean-Marie Tarascon J-M, Walter van Schalkwijk WV (2005) Nanostructured materials for advanced energy conversion and storage devices. Nature 4:366–377

Chaudhry Q, Scotter M, Blackburn J (2008) Applications and implications of nanotechnologies for the food sector. Food Addit Contam 25:241–258

Godovsky DY (2000) Device applications of polymer-nanocomposites. Adv Polym Sci 153:163–205

Hassan CM, Peppas NA (2000) Structure and applications of poly (vinyl alcohol) hydrogels produced by conventional crosslinking or by freezing/thawing methods. Adv Polym Sci 153:37–65

Scotchford CA, Cascone MG, Downes S, Giusti P (1998) Osteoblast responses to collagen-PVA bioartificial polymers in vitro: the effects of cross-linking method and collagen content. Biomater 19:1–11

Chowdhury MN, Alam AK, Dafader NC, Haque ME, Akhtar F, Ahmed MU, Rashid H, Begum R (2006) Radiation processed hydrogel of poly (vinyl alcohol) with biodegradable polysaccharides. Bio-Med Mater Eng 16(3):223–228

Abdullah OG, Aziz SB, Omer KM, Salih YM (2015) Reducing the optical band gap of polyvinyl alcohol (PVA) based nanocomposite. J Mater Sci: Mater Electron 26:5303–5309

Arunkumar Basavaraja S, Bedre M, Venkataraman A (2009) Metal oxide dispersed in polyvinyl alcohol nano composites. J Metall Mater Sci 51:297–306

Aziz SB (2016) Modifying poly (vinyl alcohol) (PVA) from insulator to small bandgap polymer: a novel approach for organic solar cells and optoelectronic devices. J Electron Mater 45:736–745

Aziz SB, Ahmed HM, Hussein AM, Fathulla AB, Wsw RM, Hussein RT (2015) Tuning the absorption of ultraviolet spectra and optical parameters of aluminum doped PVA based solid polymer composites. J Mater Sci: Mater Electron 26:8022–8028

Kokabi M, Sirousazar M, Hassan Z (2007) PVA–clay nanocomposite hydrogels for wound dressing. Eur Polym J 43:773–781

Nagura M, Hamano T, Ishikawa H (1989) Structure of poly (vinyl alcohol) hydrogel prepared by repeated freezing and melting. Polymer 30:762–765

Roy AS, Gupta S, Sindhu S, Parveen A, Ramamurthy CP (2013) Dielectric properties of novel PVA/ZnO hybrid nanocomposite films. Compos B 47:314–319

Bouropoulos N, Psarras GC, Moustakas N, Chrissanthopoulos A, Baskoutas S (2008) Optical and dielectric properties of ZnO–PVA nanocomposites. Phys Status Solidi A 205:20332037

Kaur R, Singh AV, Sehrawat K, Mehra NC, Mehra RM (2006) Sol–gel derived yttrium doped ZnO nanostructures. J Non-Cryst Solids 352:2565–2568

Al-Salman HS, Abdullah MJ (2013) Effect of Co-doping on the structure and optical properties of ZnO nanostructure prepared by RF-magnetron sputtering. Superlattices Microstuct 60:349–357

Fu YS, Du XW, Kulinich SA, Qiu JS, Qin WJ, Li R, Sun J, Liu J (2007) Stable aqueous dispersion of ZnO quantum dots with strong blue emission via simple solution route. J Am Chem Soc 129:16029–16033

Aina A, Morris A, Gupta M (2014) Dissolution behavior of poly vinyl alcohol in water and its effect on the physical morphologies of PLGA scaffolds. UK J Pharm Biosci 2:1–6

Thomas P, Satapathy S, Dwarakanath K (2010) Dielectric properties of poly (viny lidene fluoride)/CaCu3Ti4O12 nanocrystal composite thick films. Express Polym Lett 4:632–643

Devi PI, Ramachandran K (2011) Dielectric studies on hybridised PVDF–ZnO nanocomposites. J Exp Nanosci 6:281–293

Qingshan LI, Wenjie GAO, Pengsheng MA (2009) Application of poly (vinylbutyral) nanocomposites in environment design. Adv Nat Sci 1:81–88

Hemalatha KS, Rukmani K, Suriyamurthy N, Nagabhushana BM (2014) Synthesis characterization and optical properties of hybrid PVA–ZnO nanocomposite: a composition dependent study. Mater Res Bull 51:438–446

Karthikeyan B, Pandiyarajan T, Mangalaraja RV (2016) Enhanced blue light emission in transparent ZnO:PVA nanocomposite free standing polymer films. Spectrochim Acta Part A Mol Biomol Spectrosc 152:485–490

Pal K, Banthia KA, Majumdar KD (2007) Preparation and characterization of polyvinyl alcohol-gelatin hydrogel membranes for biomedical applications. AAPS Pharm Sci Tech 8:142–145

Saleem M, Fang L, Wakeel A, Rashad M, Kong CY (2012) Simple preparation and characterization of nano-crystalline zinc oxide thin films by sol–gel method on glass substrate. World J Condens Matter Phys 2:10–15

Smith P, Lemstra PJ (1980) Ultrahigh-strength polyethylene filaments by solution spinning/drawing. J Mater Sci 15:505–514

Agrawal RC, Pandey GP (2008) Solid polymer electrolyte: materials designing and all-solid-state battery applications: an overview (topical review). J Phys D Appl Phys 41:223001

Chandrakala HN, Bommulu R, Shivakumaraiah Hatna S (2014) Optical properties and structural characteristics of zinc oxide, cerium oxide doped polyvinyl alcohol films. J Alloys Compd 586:333–342

Fernandes DM, Silva R, Hechenleitner AAW, Radovanovic E, Melo MAC, Pineda EAG (2009) Synthesis and characterization of ZnO, CuO and a mixed Zn and Cu oxide. Mater Chem Phys 115:110–115

Cullity BD (1970) Elements of X-ray diffraction. Addison-Wesley, Boston

Gupta V, Mansingh A (1996) Influence of post-deposition annealing on the structural and optical properties of sputtered zinc oxide film. J Appl Phys 80:1063–1073

Cullity BD, Stock SR (2001) Elements of X-ray diffraction, 3rd edn. Prentice Hall, New Jersey

Abdel-Aal N, El-Tantawy F, Al-Hajry A, Bououdina M (2008) Epoxy resin/plasticized carbon black composites. Part II. Correlation among network structure and mechanical properties. Polym Compos 29:804–808

Zhang WL, Liua YD, Hyoung JC (2011) Graphene oxide coated core—shell structured polystyrene microspheres and their electrorheological characteristics under applied electric field. J Mater Chem 21:6916–6921

Alam AKMM, Beg MDH, Yunus RM (2016) Micro structure and fractography of multiwalled carbon nanotube reinforced unsaturated polyester nanocomposites. Polym Compos. doi:10.1002/pc.23911

Clemenson S, David L, Espuche E (2007) Structure and morphology of nanocomposite films prepared from polyvinyl alcohol and silver nitrate: influence of thermal treatment. J Polym Sci A 45:2657–2672

El-Khodary A (2010) Evolution of the optical, magnetic and morphological properties of PVA films filled with CuSO4. Phys B 405:3401–3408

Sabara DM, Dunne JS, Pedro AQH, Trifunović J, Idiatu BIO, Kotlicic O, Serrano A, István K (2011) Spectroscopic studies of naproxen and tryptophan immobilized in polyvinyl alcohol. Biotechnol Food Sci 75:39–49

Ramaiah KS, Bhatanagar AK, Pilkington RD, Hillard AE, Tomlinson RD (2000) The effect of sulfur concentration on the properties of chemical bath deposited CdS thin film. J Mater Sci: Mater Elect 11:269–277

Rana SB, Singh A, Kaur N (2013) Structural and optoelectronic characterization of prepared and Sb doped ZnO nanoparticles. J Mater Sci: Mater Electron 24:44–52

Prasad V, D’Souza C, Yadav D, Shaikh AJ, Vigneshwaran N (2006) Spectroscopic characterization of zinc oxide nanorods synthesized by solid-state reaction. Spectrochim Acta, Part A 65:173–178

Sahay PPR, Nath RK, Tewari S (2007) Optical properties of thermally evaporated CdS thin films. Cryst Res Technol 42:275–280

Aziz SB, Abdullah OG, Rasheed MA (2017) A novel polymer composite with a small optical band gap: new approaches for photonics and optoelectronics. J Appl Polym Sci 134:44847

Hossain FM, Sheppard L, Nowotny J, Murch GE (2008) Optical properties of anatase and rutile titanium dioxide: Ab initio calculations for pure and anion-doped material. J Phys Chem Solids 69:1820–1828

Aziz SB, Abdullah OG, Hussein AM, Abdulwahid RT, Rasheed MA, Ahmed HM, Abdalqadir SW, Mohammed AR (2017) Optical properties of pure and doped PVA:PEO based solid polymer blend electrolytes: two methods for band gap study. J Mater Sci: Mater Electron 28:7473–7479

Dutta S, Ganguly BN (2012) Characterization of ZnO nanoparticles grown in presence of folic acid template. J Nanobiotechnol 10:29

Kayathri J, RaniMeiyammai N, Rani S, Bhuvana KP, Palanivelu K, Nayak SK (2013) Study on the optoelectronic properties of UV luminescent polymer: ZnO nanoparticles dispersed PANI. J Mater. doi:10.1155/2013/473217

Vanheusden K, Warren WL, Seager CH, Tallant DR, Voigt JA, Gnade BE (1996) Mechanisms behind green photoluminescence in ZnO phosphor powders. J Appl Phys 79:7983

Talam S, Karumuri SR, Gunnam N (2012) Synthesis characterization and spectroscopic properties of ZnO nanoparticles. ISRN Nanotechnol. doi:10.5402/2012/372505

Reynolds DC, Look DC, Jogai B, Morkoc H (1997) Similarities in the band-edge and deep-center photoluminescence mechanisms of ZnO and GaN. Solid State Commun 101:643–646

Kumar D, Karan S, Pawan J, Khanna K, Vijayan N, Banerjee S (2012) Synthesis, characterization and studies of PVA/Co-doped ZnO nanocomposite films. Int J Green Nanotechnol 4:408–416

Chouhan S, Bhatt R, Bajpai AK, Bajpai J, Katare R (2015) Investigation of UV absorption and antibacterial behavior of zinc oxide containing poly(vinyl alcohol-g-acrylonitrile) (PVA-g-PAN) nanocomposites films. Fibers Polym 16:1243–1254

Reghu M, Cao Y, Moses D, Heeger AJ (1993) Counterion-induced processibility of polyaniline: transport at the metal-insulator boundary. Phys Rev Part B 47:1758–1764

Park K, Zhang Q, Myers D, Cao G (2013) Charge transport properties in TiO2 network with different particle sizes for dye sensitized solar cells. ACS Appl Mater Interfaces 5:1044–1052

Acknowledgements

Authors would like to express their sincere thanks to Prof. D.C. Panigrahi, Director Indian Institute of Technology (Indian school of Mines) Dhanbad for encouragement in this communication.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kandulna, R., Choudhary, R.B. Concentration-dependent behaviors of ZnO-reinforced PVA–ZnO nanocomposites as electron transport materials for OLED application. Polym. Bull. 75, 3089–3107 (2018). https://doi.org/10.1007/s00289-017-2186-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2186-9