Abstract

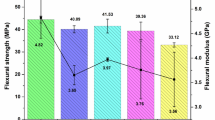

The arising trend of using natural fibres in the composite materials has stimulated the continuous exploration of their mechanical properties. The positive environmental behaviours of natural fibres are the driving factor that allows them to gain their wide acceptance in industries. However, the mechanical behaviour of natural fibre-based composites is still not fully explored. In this research study, the mechanical properties of composite materials with different types of natural fibre and various fibre compositions were investigated. The polypropylene-based composite materials were fabricated through hot press compression moulding method using a hydraulic hot press machine. The composites were then subjected to mechanical tests to study the tensile, flexural and impact properties of such materials. The results demonstrated that the tensile strength and flexural strength of pineapple leaf fibre (PALF)-based composites were 7.83% and 54.23% higher than kenaf-based composites at a fibre content of 30 wt%. Moreover, the impact strength of PALF-reinforced composites was 3.08% and 5.56% higher than kenaf fibre-reinforced composites in the flatwise and edgewise impact orientations. Overall, composites with 30 wt% evidenced the top most mechanical properties irrespective of types of plant fibre.

Similar content being viewed by others

References

Pickering KL, Efendy MGA, Le TM (2016) A review of recent developments in natural fibre composites and their mechanical performance. Compos Part A Appl Sci Manuf 83:98–112. https://doi.org/10.1016/j.compositesa.2015.08.038

Habibi M, Laperrière L, Hassanabadi HM (2018) Influence of low-velocity impact on residual tensile properties of nonwoven flax/epoxy composite. Compos Struct 186:175–182. https://doi.org/10.1016/j.compstruct.2017.12.024

Feng NL, Malingam SD, Jenal R, Mustafa Z, Subramonian S (2018) A review of the tensile and fatigue responses of cellulosic fibre-reinforced polymer composites. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2018.1489086

Zahedi M, Khanjanzadeh H, Pirayesh H, Saadatnia MA (2015) Utilization of natural montmorillonite modified with dimethyl, dehydrogenated tallow quaternary ammonium salt as reinforcement in almond shell flour-polypropylene bio-nanocomposites. Compos Part B Eng 71:143–151. https://doi.org/10.1016/j.compositesb.2014.11.009

Subramaniam K, Malingam SD, Feng NL, Bapokutty O (2017) The effects of stacking configuration on the response of tensile and quasi-static penetration to woven kenaf/glass hybrid composite metal laminate. Polym Compos. https://doi.org/10.1002/pc.24691

Martin N, Davies P, Baley C (2016) Evaluation of the potential of three non-woven flax fiber reinforcements: spunlaced, needlepunched and paper process mats. Ind Crops Prod 83:194–205. https://doi.org/10.1016/j.indcrop.2015.10.008

Feng NL, Malingam SD (2019) Monotonic and fatigue responses of fiber-reinforced metal laminates. In: Jawaid M, Thariq M, Saba N (eds) Mechanical and physical testing of biocomposites, fibre-reinforced composites and hybrid composites, 1st edn. Elsevier, Amsterdam. https://doi.org/10.1016/B978-0-08-102292-4.00016-3

Faruk O, Bledzki AK, Fink HP, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37:1552–1596. https://doi.org/10.1016/j.progpolymsci.2012.04.003

Feng NL, DharMalingam S, Zakaria KA, Selamat MZ (2017) Investigation on the fatigue life characteristic of kenaf/glass woven-ply reinforced metal sandwich materials. J Sandw Struct Mater. https://doi.org/10.1177/1099636217729910

Ramesh M (2016) Kenaf (Hibiscus cannabinus L.) fibre based bio-materials: a review on processing and properties. Prog Mater Sci 78–79:1–92. https://doi.org/10.1016/j.pmatsci.2015.11.001

Cieh NL, Sulaiman S, Mokhtar MN, Naim MN (2017) Bleached kenaf microfiber as a support matrix for cyclodextrin glucanotransferase immobilization via covalent binding by different coupling agents. Process Biochem 56:81–89. https://doi.org/10.1016/j.procbio.2017.02.025

Ng LF, Sivakumar D, Zakaria KA, Bapokutty O, Sivaraos S (2017) Influence of kenaf fibre orientation effect on the mechanical properties of hybrid structure of fibre metal laminate. Pertanika J Sci Technol 25:1–8

Rashdi AAA, Sapuan SM, Ahmad MMHM, Abnan K (2009) Review of kenaf fiber reinforced polymer composites. Polimery 54:777–780

Babatunde OE, Yatim JM, Ishak MY, Masoud R, Meisam R (2015) Potentials of kenaf fibre in bio-composite production: a review. J Teknol 77:23–30. https://doi.org/10.11113/jt.v77.6304

Asim M, Abdan K, Jawaid M et al (2015) A review on pineapple leaves fibre and its composites. Int J Polym Sci 2015:1–16. https://doi.org/10.1155/2015/950567

Radzi AM, Sapuan SM, Jawaid M, Mansor MR (2017) Influence of fibre contents on mechanical and thermal properties of roselle fibre reinforced polyurethane composites. Fibers Polym 18:1353–1358. https://doi.org/10.1007/s12221-017-7311-8

Salman SD, Leman Z, Sultan MTH et al (2016) Influence of fiber content on mechanical and morphological properties of woven kenaf reinforced pvb film produced using a hot press technique. Int J Polym Sci 2016:1–11. https://doi.org/10.1155/2016/7828451

El-Shekeil YA, Sapuan SM, Jawaid M, Al-Shuja’a OM (2014) Influence of fiber content on mechanical, morphological and thermal properties of kenaf fibers reinforced poly(vinyl chloride)/thermoplastic polyurethane poly-blend composites. Mater Des 58:130–135. https://doi.org/10.1016/j.matdes.2014.01.047

Thwe MM, Liao K (2002) Effects of environmental aging on the mechanical properties of bamboo-glass fiber reinforced polymer matrix hybrid composites. Compos Part A Appl Sci Manuf 33:43–52. https://doi.org/10.1016/S1359-835X(01)00071-9

Bax B, Müssig J (2008) Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Compos Sci Technol 68:1601–1607. https://doi.org/10.1016/j.compscitech.2008.01.004

Sivakumar D, Ng LF, Chew RM, Bapokutty O (2017) Investigation on failure strength of bolted joints woven fabric reinforced hybrid composite. Int Rev Mech Eng 11:138–143. https://doi.org/10.15866/ireme.v11i2.10897

Khanjanzadeh H, Pirayesh H, Salari A (2013) Long term hygroscopic characteristics of polypropylene based hybrid composites with and without organo-modified clay. Eur J Wood Wood Prod 71:211–218. https://doi.org/10.1007/s00107-012-0661-4

Khan MZR, Srivastava SK, Gupta MK (2018) Tensile and flexural properties of natural fiber reinforced polymer composites: a review. J Reinf Plast Compos. https://doi.org/10.1177/0731684418799528

Dittenber DB, GangaRao HVS (2012) Critical review of recent publications on use of natural composites in infrastructure. Compos Part A Appl Sci Manuf 43:1419–1429. https://doi.org/10.1016/j.compositesa.2011.11.019

Abilash N, Sivapragash M (2016) Optimizing the delamination failure in bamboo fiber reinforced polyester composite. J King Saud Univ Eng Sci 28:92–102. https://doi.org/10.1016/j.jksues.2013.09.004

Ramli R, Yunus RM, Beg MDH, Prasad DMR (2011) Oil palm fiber reinforced polypropylene composites: effects of fiber loading and coupling agents on mechanical, thermal, and interfacial properties. J Compos Mater 46:1275–1284. https://doi.org/10.1177/0021998311417647

Mohanty S, Verma SK, Nayak SK (2006) Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos Sci Technol 66:538–547. https://doi.org/10.1016/j.compscitech.2005.06.014

Sivakumar D, Ng LF, Selamat MZ, Sivaraos S (2017) Investigation on fatigue life behaviour of sustainable bio-based fibre metal laminate. J Mech Eng 1:123–140

Sultana Mir S, Hasan M, Hasan SMN et al (2015) Effect of chemical treatment on the properties of coir fiber reinforced polypropylene and polyethylene composites. Polym Compos 38:1259–1265. https://doi.org/10.1002/pc.23690

Yallew TB, Kumar P, Singh I (2016) Mechanical behavior of nettle/wool fabric reinforced polyethylene composites. J Nat Fibers 13:610–618. https://doi.org/10.1080/15440478.2015.1093576

Sangthong S, Pongprayoon T, Yanumet N (2009) Mechanical property improvement of unsaturated polyester composite reinforced with admicellar-treated sisal fibers. Compos Part A Appl Sci Manuf 40:687–694. https://doi.org/10.1016/j.compositesa.2008.12.004

Caminero MA, Rodríguez GP, Muñoz V (2016) Effect of stacking sequence on Charpy impact and flexural damage behavior of composite laminates. Compos Struct 136:345–357. https://doi.org/10.1016/j.compstruct.2015.10.019

Yahaya R, Sapuan SM, Jawaid M et al (2015) Effect of layering sequence and chemical treatment on the mechanical properties of woven kenaf–aramid hybrid laminated composites. Mater Des 67:173–179. https://doi.org/10.1016/j.matdes.2014.11.024

Alomayri T, Assaedi H, Shaikh FUA, Low IM (2014) Effect of water absorption on the mechanical properties of cotton fabric-reinforced geopolymer composites. J Asian Ceram Soc 2:223–230. https://doi.org/10.1016/j.jascer.2014.05.005

Acknowledgements

The authors would like to thank Universiti Teknikal Malaysia Melaka for their continuous support to this research project. The authors also wish to express their gratitude towards Skim Zamalah UTeM provided by Universiti Teknikal Malaysia Melaka and Grant FRGS/1/2017/STG07/FKM-CARE/F00339 from Ministry of Education Malaysia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ng, L.F., Dhar Malingam, S., Selamat, M.Z. et al. A comparison study on the mechanical properties of composites based on kenaf and pineapple leaf fibres. Polym. Bull. 77, 1449–1463 (2020). https://doi.org/10.1007/s00289-019-02812-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02812-0