Abstract

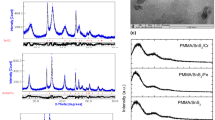

In the present study, hybrid organic–inorganic composites were fabricated from epoxy–TEOS (tetraethyl orthosilicate, Si(OC2H5)4) with various ratios (0–10 wt%) of multiwall carbon nanotubes (MWCNTs) as reinforcing nanofillers by the sol–gel method. The effect of the MWCNTs ratios on the structural, optical and mechanical characteristics and the thermal conductivity of the epoxy–TEOS/MWCNTs composites is investigated. The X-ray diffraction (XRD) analysis reveals that the pure epoxy-TEOS is amorphous, while epoxy–TEOS/MWCNTs composites are crystalline with an orthorhombic crystal structure that has an average crystallite size of 3.9 ± 0.15 nm. In addition, thermal stability and thermal conductivity were improved by adding TEOS and MWCNTs, whereas the exothermic peak temperature decreases compared with pure epoxy-TEOS. Similarly, the hardness Shore-D and tensile strength reach the optimum value at 4 wt% MWCNTs content. The significant improvement in the mechanical and thermal properties of the prepared composites could be attributed to the synergistic effect of MWCNTs and epoxy–TEOS which was emphasized by Fourier transform infrared (FTIR) spectroscopy. Moreover, epoxy-TEOS sample has high optical transmittance (T) within the visible region, but the composites samples are transparent at λ < 800 nm and have a lower value of T. The indirect optical band gap decreases from 3.59 to 2.91 eV with an increase in MWCNTs fractions from 0 to 10 wt%, respectively. However, the glass transition reflects the onset of decomposition temperatures was also considerably increased. The acquired outcomes such as a large increase in thermal conductivity and tensile stress coupled with reduced T make the composites readily applicable for a variety of applications.

Graphic abstract

Similar content being viewed by others

References

Yemam D, Kim B-J, Moon J-Y, Yi C (2017) Mechanical properties of epoxy resin mortar with sand washing waste as filler. Materials 10(3):246

Hussein SI, Abd Elnaiem AM, Asafa TB, Jaafar HI (2018) Effect of incorporation of conductive fillers on mechanical properties and thermal conductivity of epoxy resin composite. Appl Phys A 124(7):475

Zeng S, Shen M, Yang L, Xue YC, Lu F, Chen S (2018) Self-assembled montmorillonite–carbon nanotube for epoxy composites with superior mechanical and thermal properties. Compos Sci Technol 162(7):131–139

Burger N, Laachachia A, Ferriolb M, Lutzc M, Toniazzoa V, Ruch D (2016) Review of thermal conductivity in composites: mechanisms, parameters and theory. Prog Polym Sci 61:1–28

Shen D, Zhan Z, Liu Z, Cao Y, Zhou L, Liu Y, Dai W (2017) Enhanced thermal conductivity of epoxy composites filled with silicon carbide nanowires. Sci Rep 7(1):2606

Fei-Peng D, Tang H, Huang D-Y (2013) Thermal conductivity of epoxy resin reinforced with magnesium oxide coated multiwalled carbon nanotubes. Int J Polym Sci 2013:Article ID 541823

Congliang H, Zhen W, Huang Z, Luo D (2018) Thermal and electrical conductivities of epoxy resin-based composites incorporated with carbon nanotubes and TiO2 for a thermoelectric application. Appl Phys A 24(1):38

Backesa EH, Senea TS, Passadorb FR, Pessan LA (2018) Electrical, thermal and mechanical properties of epoxy/CNT/calcium carbonate nanocomposites. Mater Res 21(1):e20170801

Dresselhaus MS, Dresselhaus G, Eklund PC, Rao AM (2000) Carbon nanotubes. In: Andreoni W (ed) The physics of fullerene-based and fullerene-related materials. Springer, Netherlands, pp 331–379

Campbell FC (2010) Structural composite materials. ASM international, Cleveland

Ahmadi Z (2019) Epoxy in nanotechnology: a short review. Prog Org Coat 132:445–448

Lee JH, Rhee KY, Park SJ (2011) Effect of silane modification and temperature on tensile and fractural behaviours of carbon nanotube/epoxy nanocomposites. J Nanosci Nanotechnol 11:275–80

Avilés F, Cauich-Rodríguez JV, Rodríguez-González JA, May-Pat A (2011) Oxidation and silanization of MWCNTs for MWCNT/vinyl ester composites. Express Polym Lett 9:766–776

Wang S, Liang Z, Liu T, Wang B, Zhang C (2006) Effective aminofunctionalization of carbon nanotubes for reinforcing epoxy polymer composites. Nanotechnology 17(6):1551–1557

Shen JF, Huang W, Wu L, Hu Y, Ye M (2007) The reinforcement role of different amino-functionalized multi-walled carbon nanotubes in epoxy nanocomposites. Compos Sci Technol 67(15–16):3041–3150

Chen W, Auad ML, Williams RJ, Nutt SR (2006) Improving the dispersion and flexural strength of multiwalled carbon nanotubes–stiff epoxy composites through β-hydroxyester surface functionalization coupled with the anionic homopolymerization of the epoxy matrix. Eur Polym J 42:2765–72

Meng H, Sui G, Fang P, Yang R (2008) Effects of acid-and diamine-modified MWNTs on the mechanical properties and crystallization behavior of polyamide 6. Polymer 49(2):610–620

Wang X, Zhao Y, Jin J, Song M (2017) A comparative study on the effect of carbon fillers on electrical and thermal conductivity of a cyanate ester resin. Polym Test 60:293–298

Pumera M, Merkoçi A, Alegret S (2006) Carbon nanotube-epoxy composites for electrochemical sensing. Sens Actuators B Chem 113:617–622

Yun Y-H, Shanov V, Schulz MJ, Narasimhadevara S, Subramaniam S, Hurd D, Boerio FJ (2005) Development of novel single-wall carbon nanotube–epoxy composite ply actuators. SMART Mater Struct 14:1526–1532

Sumio I (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Arash B, Wang Q, Varadan VK (2014) Mechanical properties of carbon nanotube/polymer composites. Sci Rep (Nature Publisher Group) 4:6479

Hadavand BS, Javid KM, Gharagozlou M (2013) Mechanical properties of multi-walled carbon nanotube/epoxy polysulfide nanocomposite. Mater Des 50:62–67

Sapiai N, Jumahat A, Mahmud J (2018) Mechanical properties of functionalised CNT filled kenaf reinforced epoxy composites. Mater Res Express 5(4):045034

Jinho H, Jeongwoo L, Chang H, Sang S (2010) Improvement of thermal conductivity of poly (dimethyl siloxane) using silica-coated multi-walled carbon nanotube. J Therm Anal Calorim 101(1):297–302

Jiaxi G, Saha P, Liang J, Saha M, Grady BP (2013) Multi-walled carbon nanotubes coated by multi-layer silica for improving thermal conductivity of polymer composites. J Therm Anal Calorim 113(2):467–474

Z. Jinchao, F. Du, W. Cu, P. Zhu, X. Zhou and X. Xie., Effect of silica coating thickness on the thermal conductivity of polyurethane/SiO2 coated multiwalled carbon nanotube composites, Composites Part A: Applied Science and Manufing, vol. 58, pp. 1–6, 2014.

An L, Zhang C, Zhang Y-F (2017) Thermal conductivity of graphene-polymer composites: Mechanisms, properties, and applications. Polymers 9(9):437

Kim P, Shi L, Majumdar A, McEuen P (2001) Thermal transport measurements of individual multi-walled nanotubes. Phys Rev Lett 87:215502

Gonnet P, Liang Z, Choi E, Kadambala R, Zhang C, Brooks J et al (2006) Thermal conductivity of magnetically aligned carbon nanotube buckypapers and nanocomposites. Curr Appl Phys 6:119–122

Hone J, Llaguno M, Nemes N, Johnson A, Fischer J, Walters D et al (2000) Electrical and thermal transport properties of magnetically aligned single wall carbon nanotube films. Appl Phys Lett 77:666–668

Itkis M, Borondics F, Yu A, Haddon R (2007) Thermal conductivity measurements of semitransparent single-walled carbon nanotube films by a bolometric technique. Nano Lett 7:900–904

Ya-nan M, Liang G, Gu A, Zhao F, Yuan L (2013) Thermally conductive aluminum nitride–multiwalled carbon nanotube/cyanate ester composites with high flame retardancy and low dielectric loss. Ind Eng Chem Res 52(9):3342–3353

Ali SS, Al-Muaikel NS (2010) Thermal properties of epoxy (DGEBA)/phenolic resin (NOVOLAC) blends. Arab J Sci Eng 35(1B):7–14

Ao L, Li W, Ling Y, Gan W, Brady MA, Wang C (2016) Effects of silica-coated carbon nanotubes on the curing behavior and properties of epoxy composites. RSC Adv 6(28):23318–23326

Jiang C, Zhang J, Lin S, Ju S, Jiang D (2015) Effects of free organic groups in carbon nanotubes on glass transition temperature of epoxy matrix composites. Compos Sci Technol 118:269–275

Gulotty R, Castellino M, Jagdale P, Tagliaferro A, Balandin AA (2013) Effects of functionalization on thermal properties of single-wall and multi-wall carbon nanotube–polymer nanocomposites. ACS Nano 7(6):5114–5121

Kareem AA (2018) Thermal and electrical properties of polyimide/PANI nanofiber composites prepared via in situ polymerization. Mater Sci Poland 36(2):283–287

Gojny FH, Wichmann MH, Fiedler B, Kinloch IA, Bauhofer W, Windle AH, Schulte K (2006) Evaluation and identification of electrical and thermal conduction mechanisms in carbon nanotube/epoxy composites. Polymer 47:2036–2045

Kargar F, Barani Z, Lewis JS, Debnath B, Salgado R, Aytan E, Lake R, Balandin AA (2018) Thermal percolation threshold and thermal properties of composites with high loading of graphene and boron nitride fillers. ACS Appl Mater Interfaces 10(43):37555–37565

Ibrahim SS, Ayesh AS (2015) Electrical and optical properties of functionalized multiwalled carbon nanotubes/poly (3-octylthiophene)/polystyrene composites. J Thermoplast Compos Mater 28(2):225–240

Che BD, Nguyen BQ, Nguyen L-TT, Nguyen HT, Nguyen VQ, Le TV, Nguyen NH (2015) The impact of different multi-walled carbon nanotubes on the X-band microwave absorption of their epoxy nanocomposites. Chem Cent J 9:10

Elimat ZM, Zihlif AM, Ragosta G (2010) Optical characterization of poly (ethylene oxide)/alumina composites. Physica B Condens Matter 405:3756–3760

Abu El-Fadl A, Soltan AS, Aashour AS, Nashaat AM (2018) Optical investigation of thermally evaporated Cu5GexTe95−x thin films. Mater Res Innov 22(2):69–78

Devangamath SS, Lobo B (2020) Optical parameters of epoxy-CoSO4.7H2O polymer hybrid material. Mater Res Innov 24:152–160

Al-Mudhaffer MF, Nattiq MA, Jaber MA (2012) Linear optical properties and energy loss function of Novolac: epoxy blend film. Arch Appl Sci Res 4(4):1731–7140

El-Rahman MA, Yassien KM, Yassene AA (2019) Effect of gamma irradiation on the optical properties of epoxy resin thin films. Optik 183:962–970

Xie A, Zhang K, Sun M, Xia Y, Fan Wu (2018) Facile growth of coaxial Ag@polypyrrole nanowires for highly tunable electromagnetic waves absorption. Mater Des 154:192–202

Ebrahimi I, Gashti MP (2016) Chemically reduced versus photo-reduced clay–Ag–polypyrrole ternary nanocomposites: comparing thermal, optical, electrical and electromagnetic shielding properties. Mater Res Bull 83:96–107

Ebrahimi I, Gashti MP (2018) Polypyrrole–MWCNT–Ag composites for electromagnetic shielding: comparison between chemical deposition and UV-reduction approaches. J Phys Chem Solids 118:80–87

Kim K-S, Kim I-J, Park S-J (2010) Influence of Ag doped graphene on electrochemical behaviors and specific capacitance of polypyrrole-based nanocomposites. Synth Met 160(21–22):2355–2360

Aradhanaa R, Mohanty S, Nayak SK (2018) High performance epoxy nanocomposite adhesive: effect of nanofillers on adhesive strength, curing and degradation kinetics. Int J Adhes Adhes 84:238–249

Li Y, Kessler MR (2013) Liquid crystalline epoxy resin based on biphenyl mesogen: effect of magnetic field orientation during cure. Polymer 54:5741–5746

Lavorgna M, Romeo V, Martone A, Zarrelli M, Giordano M, Buonocore GG, Qu MZ, Fei GX, Xia HS (2013) Silanization and silica enrichment of multiwalled carbon nanotubes: synergistic effects on the thermal-mechanical properties of epoxy nanocomposites. Eur Polym J 49(2):428–438

AL-Hassani E (2010) Effect of UV radiation on dielectric constant and thermal conductivity in epoxy phenol blends. Eng Tech J 28:1982–1989

Hussein S, Abd-Elnaiem A, Nadia A, Mebed A (2020) Enhanced thermo-mechanical properties of poly(vinyl alcohol)/poly(vinyl pyrrolidone) polymer blended with nanographene. Curr Nanosci. https://doi.org/10.2174/1573413716666200310121947

Timoshenko S, Goodier JN (1970) Theory of elasticity. McGraw-Hill, New York

Łączka M, Cholewa-Kowalska K, Kulgawczyk K, Klisch M, Mozgawa W (1999) Structural examinations of gel-derived materials of the CaO–P2O5–SiO2 system. J Mol Struct 511:223–231

Czarnobaj K (2008) Preparation and characterization of silica xerogels as carriers for drugs. Drug Deliv 15(8):485–492

Sahmetlioglu ER, Mart H, Yuruk H, Surme Y (2006) Synthesis and characterization of oligosalicylaldehyde-based epoxy resins. Chem Pap 60(1):65–68

Du X, Yu ZZ, Dasari A, Ma J, Mo M, Meng Y, Mai YW (2008) New method to prepare graphite nano-composites. Chem Mater 20:2066–2068

Khare KS, Khabaz F, Khare R (2014) Effect of carbon nanotube functionalization on mechanical and thermal properties of cross-linked epoxy–carbon nanotube nanocomposites: role of strengthening the interfacial interactions. ACS Appl Mater Interfaces 6:6098–6110

Gojny FH, Nastalczyk J, Roslaniec Z, Schulte K (2003) Surface modified multi-walled carbon nanotubes in CNT/epoxy-composites. Chem Phys Lett 370(5–6):820–824

Ma P-C, Mo S-Y, Tang B-Z, Kim J-K (2010) Dispersion, interfacial interaction and re-agglomeration of functionalized carbon nanotubes in epoxy composites. Carbon 48(6):1824–1834

Zeng S, Shen M, Duan P, Xue Y, Wang Z (2018) Effect of silane hydrolysis on the interfacial adhesion of carbon nanotubes/glass fiber fabric-reinforced multiscale composites. Text Res J 88:379–391

Ketan SK, Rajesh K (2013) Effect of carbon nanotube dispersion on glass transition in cross-linked epoxy–carbon nanotube nanocomposites: role of interfacial interactions. J Phys Chem 117(24):7444–7454

Peterson RE, Anderson AC (1973) The kapitza thermal boundary resistance. J Low Temp Phys 11:639–665

Liu H, Dong M, Huang W, Gao J, Dai K, Guo J, Zheng G, Liu C, Shena C, Guo Z (2017) Lightweight conductive graphene/thermoplastic polyurethane foams with ultrahigh compressibility for piezoresistive sensing. J Mater Chem C 5:73–83

Labunov VA, Basaev AS, Shulitski BG, Shaman YP, Komissarov I, Prudnikava AL, Tay BK, Shakerzadeh M (2012) Growth of few-wall carbon nanotubes with narrow diameter distribution over Fe–Mo–MgO catalyst by methane/acetylene catalytic decomposition. Nanoscale Res Lett 7:102

Peng-Cheng M, Shan-Yin M, Ben-Zhong T, Jang-Kyo K (2010) Dispersion, interfacial interaction and re-agglomeration of functionalized carbon nanotubes in epoxy composites. Carbon 48:1824–1834

Ramirez S, Chan K, Hernandez R, Recinos E, Hernandez E, Salgado R, Khitun A, Garay J, Balandin A (2017) Thermal and magnetic properties of nanostructured densified ferrimagnetic composites with graphene-graphite fillers. Mater Des 118:75–80

Saadah M, Hernandez E, Balandin AA (2017) Thermal management of concentrated multi-junction solar cells with graphene-enhanced thermal interface materials. Appl Sci 7:589

Ci L, Bai J (2006) The reinforcement role of carbon nanotubes in epoxy composites with different matrix stiffness. Compos Sci Technol 66:599–603

Fox M (2001) Optical properties of solids. Oxford University, New York

Hongbing Z, Chan Z, Wenzhe C, Minquan W (2005) Characterization and nonlinear optical property of a multi-walled carbon nanotube/silica xerogel composite. Chem Phys Lett 411:373–377

García V, Guerrero L, Nair MTS, Nair PK (1999) Effect of thermal processing on optical and electrical properties of copper selenide thin films. Superficies y Vacío 9:213–218

Yakuphanoglu F, Cukurovali A, Yilmaz I (2004) Single oscillator model and determination of optical constants of some optical thin film materials. Phys B Condens Matter 353:210–216

Abbady G, Qasem A, Abd-Elnaiem AM (2020) Optical parameters and electronic properties for the transition of the amorphous-crystalline phase in Ge20Te80 thin films. J Alloy and Compd 842:155705. https://doi.org/10.1016/j.jallcom.2020.155705

Abd‑Elnaiem AM, Hassan RM, Alamri HR, Assaedi HS (2020) Comparative investigation of linear and nonlinear optical properties of As-70 at.% Te thin films: influence of Ga content. J Mater Sci Mater Electron. https://doi.org/10.1007/s10854-020-03872-z

Koizhaiganova R, Kim H, Vasudevan T, Lee M (2009) Double-walled carbon nanotube (DWCNT)–poly (3-octylthiophene)(P3OT) composites: electrical, optical and structural, investigations. Synth Met 159:2437–2442

Tauc J (1974) Optical properties of amorphous semiconductors. Amorphous and liquid semiconductors. Springer, Boston, pp 159–220

Mott NF, Davis EA (1979) Electronic processes in non-crystalline materials. Oxford University Press, New York

Bishop SG, TL Reinecke, U Strom, PC Taylor and CC Klick (1977) International conference on amorphous and liquid semiconductors (7th) at Edinburgh. No. ONRL-C-13-77. Office of naval research London (England)

Venkatachalam S, Mangalaraj D, Narayandass SK, Kim K, Yi J (2005) Structure, optical and electrical properties of ZnSe thin films. Phys B Condens Matter 358(1–4):27–35

Kale RB, Lokhande CD (2005) Influence of air annealing on the structural, morphological, optical and electrical properties of chemically deposited ZnSe thin films. Appl Surf Sci 252(4):929–938

Venkatachalam S, Mangalaraj D, Narayandass SK (2007) Characterization of vacuum-evaporated ZnSe thin films. Phys B Condens Matter 393(1–2):47–55

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abd-Elnaiem, A.M., Hussein, S.I., Assaedi, H.S. et al. Fabrication and evaluation of structural, thermal, mechanical and optical behavior of epoxy–TEOS/MWCNTs composites for solar cell covering. Polym. Bull. 78, 3995–4017 (2021). https://doi.org/10.1007/s00289-020-03301-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03301-5