Abstract

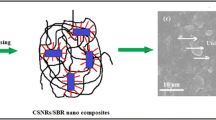

With the increasing difficulty in exploitation of low-permeability, high water content and other unconventional reservoirs, a new kind of proppants that possess not only ultra-light weight and high strength and but also hydrophobic performances have attracted more and more interests. Here, this kind of proppants were designed and prepared successfully in the form of polymer microspheres. What's more is that the polymer microspheres (named O-MSDBs) showing high strength and stable hydrophobicity were prepared by a one-step suspension polymerization between styrene, divinyl benzene and γ-methacryloxypropyl-trimethoxy silane accompanying with the formation of silica through sol–gel process. When compared with reported ultra-lightweight proppants (ULWPs), the O-MSDBs not only perform better in ultra-lightweight (0.9917 g·cm−3) and are comparable in high strength (low crushing ratio of 0.89–2.53% at 55–69 MPa), but also show new hydrophobic function. The water contact angle on the surface of O-MSDBs is 140.7° that keeps about more than 80% after mechanical abrasion or acid dissolution. The one-step facile preparation method and brilliant performances make O-MSDBs very promising to large-scale preparation and widely applied in fracturing technology as proppants.

Graphical Abstract

Similar content being viewed by others

References

Osiptsov AA (2017) Fluid mechanics of hydraulic fracturing: a review. J Pet Sci Eng 156:513–535

Barbati AC, Desroches J, Robisson A (2016) Complex fluids and hydraulic fracturing. In: PRAUSNITZ J M. Annual review of chemical and biomolecular engineering 7: 415–453

Barati R, Liang J-T (2014) A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J Appl Polym Sci 131:40735

Tang Y, Ranjith PG, Perera MSA (2018) Major factors influencing proppant behaviour and proppant-associated damage mechanisms during hydraulic fracturing. Acta Geotech 13:757–780

Liang C, Luo W, Yan C et al (2016) Ultra-lightweight proppant synthesized from PMMA/pine bark composite: low-cost material and outstanding properties. Chem Lett 45:994–996

Xu Y, Chen T, Hu J et al (2014) Study on preparation and properties of PMMA composite microspheres as the matrix of low density proppant. Appl Mech Mater 457–458:116–119

Chen T, Wang Y, Yan C et al (2015) Preparation of heat resisting poly(methyl methacrylate)/graphite composite microspheres used as ultra- lightweight proppants. J Appl Polym Sci 132:41924

Zhang Y, Yan C, Chen T et al (2016) Ultra-lightweight composite proppants prepared via suspension polymerization. J Compos Mater 50:2823–2831

Liang T, Yan C, Zhou S et al (2017) Carbon black reinforced polymethyl methacrylate (PMMA)-based composite particles: Preparation, characterization, and application. J Geophys Eng 14:1225–1232

Wang Y, Chen T, Yan C (2015) Reinforced performances of polymethyl methacrylate/silica fume composite spherical particles used as ultra-lightweight proppants. J Reinf Plast Compos 34:672–683

Liang T, Yan C, Zhou S et al (2017) Silica fume reinforced polystyrene-based composite particles used as ultra-light weight proppants in hydraulic fracturing. Mater Res Express 4:115306

Han X, Cheng Q, Bao F et al (2014) Synthesis of low-density heat-resisting polystyrene/graphite composite microspheres used as water carrying fracturing proppants. Polym Plast Technol Eng 53:1647–1653

Tasque JE, Vega IN, Marco S et al (2021) Ultra-light weight proppant: synthesis, characterization, and performance of new proppants. J Nat Gas Sci Eng 85:103717

Markovic G, Visakh (2017) PM. 1 - polymer blends: State of art. In: Visakh P M, Markovic G, Pasquini D. Recent developments in polymer macro, micro and nano blends. Woodhead Publishing. 1–15

Yong J, Chen F, Yang Q et al (2017) Superoleophobic surfaces. Chem Soc Rev 46:4168–4217

Ren X, Hu Q, Liu X et al (2019) Nanoparticles patterned ceramsites showing super-hydrophobicity and low crushing rate: the promising proppant for gas and oil well fracturing. J Nanosci Nanotechnol 19:905–911

Wang S, Liu K, Yao X et al (2015) Bioinspired surfaces with superwettability: new insight on theory, design, and applications. Chem Rev 115:8230–8293

Hench LL, West JK (1990) The sol-gel process. Chem Rev 90:33–72

Li X, Liu C, Gou K et al (2015) Effects of residual double bonds on the catalytic activity and stability of Pt/SDB hydrophobic catalysts. Rsc Adv 5:45420–45425

Al-Oweini R, El-Rassy H (2009) Synthesis and characterization by FTIR spectroscopy of silica aerogels prepared using severa Si(OR)4 and R’’Si(OR’)3 precursors. J Mol Struct 919:140–145

Tan L, Tan B (2017) Hypercrosslinked porous polymer materials: design, synthesis, and applications. Chem Soc Rev 46:3322–3356

Brooks BW (2010) Suspension polymerization processes. Chem Eng Technol 33:1737–1744

Zhang S, So LLC, Faucher S et al (2016) Polymer coating over solid particles with in situ thermal curing. Ind Eng Chem Res 55:5574–5584

Pangilinan KD, de Leon ACC, Advincula RC (2016) Polymers for proppants used in hydraulic fracturing. J Pet Sci Eng 145:154–160

Zoveidavianpoor M, Gharibi A, Binjaafar MZ (2018) Experimental characterization of a new high-strength ultra-lightweight composite proppant derived from renewable resources. J Pet Sci Eng 170:1038–1047

Ma R, Han X, Bao F et al (2016) Preparation and characterization of polymeric ultra-low-density proppants: Epoxy/phenolic resin-coated polystyrene/graphite microspheres. J Polym Mater 33:259–270

Funding

This work is supported by the Science and Technology Plan Project of Sichuan Province [2021YJ0348], Southwest University of Science and Technology of the Startup Foundation for Doctors [16ZX7139] and the Longshan Talent Program [17LZX675, 18LZXT01].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, L., Yuan, H., Gong, Y. et al. High-strength and long-term durable hydrophobic polystyrene microsphere: a promising ultra-lightweight proppant for fracturing technology. Polym. Bull. 79, 3665–3679 (2022). https://doi.org/10.1007/s00289-021-03683-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03683-0