Abstract

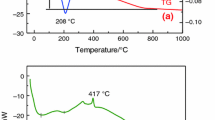

CuCo2O4 spinel nanopowders were synthesized by sol–gel method. The optimal values of pH and molar ratio of citric acid to metal ions (RC), and the influence of the calcination temperature and time were investigated. As-prepared materials were characterized by XRD, TGA, DSC, FE-SEM and electrical and coefficient of thermal expansion (CTE) measurements. It was found that pH = 4.5 and RC = 1 are the optimum conditions to produce pure CuCo2O4 nanopowders. The electrical conductivity was increased remarkably from 15.2 to 27.5 S cm−1 with an increase in temperature from 500 to 800 °C. Over the temperature range of 25–800 °C, the CTE of CuCo2O4 was 11.4 × 10−6 K−1 which is very close to the CTE of ferritic stainless steel (~12 × 10−6 K−1) used as solid oxide fuel cell interconnect.

Similar content being viewed by others

References

B.A. Pint, The Long-Term Performance of Model Austenitic Alloys in Humid Air. NACE Corrosion (2004)

J.H. Zhu, Y. Zhang, A. Basu, Z.G. Lu, M. Paranthaman, D.F. Lee, E.A. Payzant, Surf. Coat. Technol. 177, 65–72 (2004)

C. Lee, J. Bae, Thin Solid Films 516, 6432–6437 (2008)

C.-L. Chu, J.-Y. Wang, S. Lee, Int. J. Hydrog. Energy 33, 2536–2546 (2008)

S. Lee, C.-L. Chu, M.-J. Tsai, J. Lee, Appl. Surf. Sci. 256, 1817–1824 (2010)

E.A. Lee, S. Lee, H.J. Hwang, J.-W. Moon, J. Power Sources 157, 709–713 (2006)

N. Shaigan, D.G. Ivey, W. Chen, J. Power Sources 185, 331–337 (2008)

N. Shaigan, D.G. Ivey, W. Chen, J. Power Sources 183, 651–659 (2008)

Z. Yang, G.-G. Xia, X.-H. Li, J.W. Stevenson, Int. J. Hydrog. Energy 32, 3648–3654 (2007)

H. Ebrahimifar, M. Zandrahimi, Surf. Coat. Technol. 206, 75–81 (2011)

B. Hua, W. Zhang, J. Wu, J. Pu, B. Chi, L. Jian, J. Power Sources 195, 7375–7379 (2010)

W. Zhang, J. Pu, B. Chi, L. Jian, J. Power Sources 196, 5591–5594 (2011)

Z.H. Bi, J.H. Zhu, J.L. Batey, J. Power Sources 195, 3605–3611 (2010)

A. Petric, H. Ling, J. Am. Ceram. Soc. 90, 1515–1520 (2007)

P. Paknahad, M. Askari, M. Ghorbanzadeh, J. Power Sources 266, 79–87 (2014)

P. Stefanov, I. Avramova, D. Stoichev, N. Radic, B. Grbic, T. Marinova, App. Surf. Sci. 245, 65–72 (2005)

W.M. Shaheen, A.A. Ali, Mater. Res. Bull. 36, 1703–1716 (2001)

M. Wojciechowska, M. Zielinski, A. Malczewska, W. Przystajko, M. Pietrowski, Appl. Catal. A: Gen. 298, 225–231 (2006)

J.P. Singh, R.N. Singh, J. N. Mater. Electrochem. Syst. 3, 131–139 (2000)

A.L. Rosa-Toro, R. Berenguer, C. Quijada, F. Montilla, E. Morallon, J.L. Vazquez, J. Phys. Chem. B 110, 24021–24029 (2006)

R. Ning, J. Tian, A.M. Asiri, A.H. Qusti, A.O. Al-Youbi, X. Sun, Am. Ceram. Soc. 29, 13146–13151 (2013)

E. Alizadeh-Gheshlaghi, B. Shaabani, A. Khodayari, Y. Azizian-Kalandaragh, R. Rahimi, Powder Technol. 217, 330–339 (2012)

W. Wei, W. Chen, D.G. Ivey, Chem. Mater. 20, 1941–1947 (2008)

P. Boldrin, A.K. Hebb, A.A. Chaudhry, L. Otley, B. Thiebaut, P. Bishop, J.A. Darr, Ind. Eng. Chem. Res. 46, 4830–4838 (2007)

T. Baird, K.C. Campbell, P.J. Holliman, R.W. Hoyle, M. Huxam, D. Stirling, B.P. Williams, M. Morris, J. Mater. Chem. 9, 599–605 (1999)

G.Z. Gassan–zedeh, S.F. Seyidbayova, Appl. Catal. B 42, 359–367 (2003)

B. Cui, H. Lin, J.B. Li, X. Li, J. Yang, J. Tao, Adv. Func. Mater. 18, 1440–1472 (2008)

B. Chi, H. Lin, J. Li, N. Wang, J. Yang, Int. J. Hydrog. Energy 31, 1210–1214 (2006)

J.F. Marco, J.R. Gancedo, M. Gracia, J.L. Gautier, E. Ríos, F.J. Berry, J. Solid State Chem. 153, 74–81 (2000)

J.F. Marco, J.R. Gancedo, M. Gracia, J.L. Gautier, E.I. Ríos, H.M. Palmer, C. Greaves, F.J. Berry, J. Mater. Chem. 11, 3087–3309 (2001)

Y. Sharma, N. Sharma, G.V. Subba Rao, B.V.R. Chowdari, Adv. Func. Mater. 17, 2855–2861 (2007)

Z. Haijun, J. Xiaolin, Y. Yongjie, L. Zhanjie, Y. Daoyuan, L. Zhenzhen, Mater. Res. Bull. 39, 839–850 (2004)

P. Lavela, J.L. Tirado, C. Vidal-Abarca, Electrochim. Acta 52, 7986–7995 (2007)

X. Tan, G. Li, Y. Zhao, C. Hu, J. Alloy. Compd. 493, 55–63 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Paknahad, P., Askari, M. & Ghorbanzadeh, M. Characterization of nanocrystalline CuCo2O4 spinel prepared by sol–gel technique applicable to the SOFC interconnect coating. Appl. Phys. A 119, 727–734 (2015). https://doi.org/10.1007/s00339-015-9021-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9021-7