Abstract

The oil-film interferometry skin-friction technique is described and applied to flows in some of the NASA Ames large wind tunnel facilities. Various schemes for applying the technique are discussed. Results are shown for tests in several wind tunnels that illustrate the oil film's ability to measure a variety of flow features such as shock waves, separation, and three-dimensional flow.

Similar content being viewed by others

Abbreviations

- c :

-

airfoil chord

- C f :

-

skin-friction coefficient

- h :

-

oil thickness

- M :

-

Mach number

- n :

-

index of refraction

- q :

-

dynamic pressure

- Re :

-

free-stream Reynolds number based on airfoil chord

- t :

-

time

- x :

-

axial coordinate from the oil leading edge

- λ :

-

light wavelength

- ρ :

-

density

- θ i :

-

incidence angle

- θ r :

-

refraction angle

- τ :

-

skin friction

- ξ :

-

distance along model surface from oil leading edge

- μ :

-

absolute viscosity of oil

- ν :

-

kinematic viscosity of oil

- f:

-

fringe

- o:

-

oil

- ref:

-

reference condition

- run:

-

duration of run

- x :

-

x-direction

- z :

-

z-direction

- ∞:

-

free-stream condition

References

Dow Corning (1994) Information about Dow Corning silicone fluids. Dow Corning Corp, Midland, MI

Drake A, Kennelly RA Jr (1999) Oil film interferometry for skin friction measurement on an aircraft in flight. J Aircraft 36:723–725

Garrison TJ, Ackman M (1998) Development of a global interferometer skin-friction meter. AIAA J 36:62–68

Kennelly RA Jr, Westphal RV, Mateer GG, Seelen J (1995) Surface oil film interferometry on a swept wing model in supersonic flow. In: Crowder JP (ed) Flow visualization VII, Proceedings of the 7th international symposium on flow visualization. Begell House, New York, pp 302–307

Monson DJ, Mateer GG, Menter FR (1993) Boundary-layer transition and global skin friction measurement with an oil-fringe imaging technique. SAE paper 932550

Monson DJ (1983) A nonintrusive laser interferometer method for measurement of skin friction. Exp Fluids 1:15–22

Naughton JW, Brown JL (1996) Surface interferometric skin-friction measurement technique. AIAA paper 96–2183

Tanner LH, Blows LG (1976) A study of the motion of oil films on surfaces in air flow, with application to the measurement of skin friction. J Phys E 9:194–202

Wadcock AJ, Yamauchi GK, Driver DM (1999) Skin friction measurements on a rotor in hover. J Am Helicopter Soc 44:312–319

Zilliac GG (1996) Further developments of the fringe-imaging skin friction technique. NASA TM 110425

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A. Oil-flow equation derivation

This section provides the derivation of the final equation offered by Monson et al. (1993). Starting with the differential form of the one-dimensional thin-film equation in which the effects of gravity and surface tension are neglected

where h is the thickness of the oil, μ o is the oil's viscosity, and τ is the shear stress. This equation can be integrated using separation of variables. By letting h(x,t)=T(t)X(x), and substituting this into Eq. (2), we obtain

Rearranging terms, dividing by q ∞ (the free-stream dynamic head), and defining C fx≡τ x /q gives \( - \left( {{{\mu _{\rm{o}} } \over {qT^2 }}} \right){{{\rm{d}}T} \over {{\rm{d}}t}} = {1 \over 2}X^{ - 1} {{\rm{d}} \over {{\rm{d}}x}}\left( {X^2 C_{{\rm{f}}x} } \right) \). Since the right side is only a function of x, and the left side is only a function of t, the two sides of the equation can be solved separately. By defining A=(2X)−1 d(X 2 C fx )/dx and rearranging terms, we can integrate with respect to time to obtain

where t o is the time at which the oil starts to flow. Using the definition h(x,t)≡T(t)X(x), we obtain 1/T(t o)=X/h(x,t o) at the lower limit. At time t o the oil is very thick (assumed to be infinitely thick), making it possible to neglect 1/T(t o) at the lower limit of integration, yielding

A similar analytic solution for X can be obtained

Rearranging terms and integrating with respect to x starting at the oil's leading edge (x=x o) gives

Imposing the boundary condition at the leading edge of the oil (x=x o) h=0 and X=h/T=0 results in

Substituting this and the previous result for T(t) into the definition h(x,t)≡T(t)X(x) we obtain

If C fx is a constant then we get Monson et al.'s (1993) form of the equation

Thus, by measuring the height of the oil at some location x at time t and monitoring tunnel conditions throughout a run, the skin friction coefficient may be determined.

It is worth noting that one of the main assumptions is that the starting thickness of the oil is infinite. While it is not infinite, it is large (on the order of 100 λ), making this a reasonable assumption. The other assumption that C f is constant with time can be overcome if it is possible to obtain a pair of images spaced in time for use in computing the difference in oil thickness and the associated C f.

Appendix B. Numerical solution of thin film equation

Starting with the one-dimensional differential form of the thin film equation

it is possible to integrate with respect to time to obtain

Next, we take the central difference about the midpoint of x i and x i−1 to obtain

Alternatively, this numerical result could have been obtained by expanding the differential form of the equation about the point n+1/2 and i−1/2. Following Naughton and Brown (1996), we approximate (h 2)t+dt/2 by htht+dt and substitute into the above equation to obtain

Rearranging, we obtain

This equation is marched forward in time starting with an initial distribution of h, which is large. For example, a typical initial thickness is 100 times larger than the final thickness of the oil.

One of the concerns about the technique is the assumption that the oil is infinitely thick at the beginning of the run, which it is not. Furthermore, the surface downstream of the original spot of oil is often not wetted by oil until some time later in the run. How does this condition affect the final answer for skin friction?

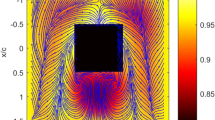

A numerical solution was obtained to answer this question. The solution was started with a thick blob of oil at the upstream position in the domain, and at time zero, shear was imposed on the oil. Figure 19 shows the thickness distribution of the oil film for various times during the run along with the thickness distribution from the Monson–Mateer equation (Eq. (6)). The simulation shows that the oil-film thickness distribution from the blob of oil follows very nearly the identical solution from Eq. (6). The difference between these two solutions (normalized by the local oil thickness) is shown in Fig. 20. The error diminishes with time and is roughly proportional to the ratio of the oil thickness and the initial oil thickness.

Numerical solution of oil-film height distribution compared to simplified oil-film Eq. (6). Numerical solution started with finite oil-film height

Difference between numerical solution and Eq. (6)

A second calculation was performed on an oil film with stepwise varying shear (a condition similar to that found in the vicinity of a shock wave). The shear was made to be 5 times higher over the initial 25% of the domain than it is over the remaining 75%. The resulting height distribution is shown in Fig. 21. After time T=1.0 the oil-film height distribution is seen to display two distinct regions with different slope. The upstream region has a slope that is predicted by Eq. (6), and the downstream region has a slope 5 times that of the upstream level. This implies that C f is a function of the local slope and that the oil is not influenced by what is flowing into it from upstream. This analysis is only valid for this stepwise varying shear situation. In cases where the shear continually changes along the oil path line, measurements should only be made near the leading edge of the oil using the approach outlined here. If the entire oil film is to be processed in regions of high shear, methods such as that of Garrison and Ackman (1998) or Naughton and Brown (1996) should be used.

Rights and permissions

About this article

Cite this article

Driver, D.M. Application of oil-film interferometry skin-friction measurement to large wind tunnels. Exp Fluids 34, 717–725 (2003). https://doi.org/10.1007/s00348-003-0613-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00348-003-0613-1