Abstract

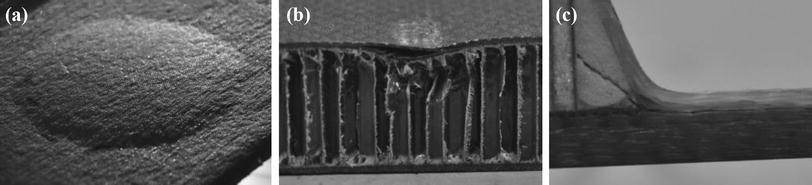

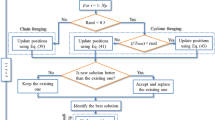

Damage detection methods are an important field of engineering and crucial in terms of structural safety. However, in many practical cases, the process of monitoring and identifying damage is extremely difficult or even impractical due to the conditions of access and operation of a given component/structure. In this study, an inverse algorithm based on strain fields for damage identification in composite plate structures is presented. The inverse analyses combine experimental tests and digital image correlation (DIC) with numerical models based on finite element update method with great advantage of being a non-contact method. The proposed technique identifies the location and dimension of damages in a CFRP plate using static strains formulated as an objective function to be minimized. By model updating, the discrepancies between the experimental and the numerical results are minimized. For the success of the model updating, the efficiency of the optimization algorithm is essential. A powerful new metaheuristic sunflower optimization (SFO) is employed to update the unknown model parameters. Experimental results showed the excellent efficiency in the combined use of DIC, numerical modeling and SFO optimization to accurately identify the location of damage in numerical and experimental tests. The obtained results indicate that the proposed method can be used to determine efficiently the location and dimension of structural damages in mechanical structures.

Similar content being viewed by others

References

Balageas D, Fritzen C-P, Güemes A (2010) Structural health monitoring, vol 90. Wiley, Hoboken

Feng D, Feng MQ (2017) Experimental validation of cost-effective vision-based structural health monitoring. Mech Syst Signal Process 88:199–211

Gomes GF, Mendéz YAD, da Silva Lopes Alexandrino P, da Cunha SS Jr, Ancelotti AC Jr (2018) The use of intelligent computational tools for damage detection and identification with an emphasis on composites – A review. Compos Struct 196:44–54. https://doi.org/10.1016/j.compstruct.2018.05.002

Samir K, Brahim B, Capozucca R, Wahab MA (2018) Damage detection in cfrp composite beams based on vibration analysis using proper orthogonal decomposition method with radial basis functions and cuckoo search algorithm. Compos Struct 187:344–353

de Sousa BS, Gomes GF, Jorge AB, da Cunha SS Jr, Ancelotti AC Jr (2018) A modified topological sensitivity analysis extended to the design of composite multidirectional laminates structures. Compos Struct 200:729–746

de Souza A, Gomes GF, Peres EP, Isaías JC, Ancelotti AC (2019) A numerical-experimental evaluation of the fatigue strain limits of cfrp subjected to dynamic compression loads. Int J Adv Manuf Technol 103(1–4):219–237

Di Benedetto RM, Botelho EC, Gomes GF, Junqueira DM, Ancelotti Junior AC (2019) Impact energy absorption capability of thermoplastic commingled composites. Compos B Eng 176:107307

Bhudolia SK, Perrotey P, Joshi SC (2018) Mode i fracture toughness and fractographic investigation of carbon fibre composites with liquid methylmethacrylate thermoplastic matrix. Compos B Eng 134:246–253

Diniz CA, Cunha SS, Gomes GF, Ancelotti AC (2019) Optimization of the layers of composite materials from neural networks with tsai-wu failure criterion. J Fail Anal Prev 19(3):709–715

Gomes GF, Mendéz YAD, Simões S, da Cunha, Antônio CA (2018) A numerical-experimental study for structural damage detection in cfrp plates using remote vibration measurements. J Civ Struct Health Monit 8(1):33–47

da Silva P, Alexandrino L, Gomes GF, Jr Sebastião Simões C (2020) A robust optimization for damage detection using multiobjective genetic algorithm, neural network and fuzzy decision making. Inverse Prob Sci Eng 28(1):21–46

Heslehurst RB (2014) Defects and damage in composite materials and structures. CRC Press, Boca Raton

Gomes GF, de Almeida FA, da Silva Lopes Alexandrino P, da Cunha SS Jr, de Sousa BS, Ancelotti AC Jr (2018) A multiobjective sensor placement optimization for SHM systems considering Fisher information matrix and mode shape interpolation. Eng Comput 35(2):519–535. https://doi.org/10.1007/s00366-018-0613-7

Gopalakrishnan S, Ruzzene M, Hanagud S (2011) Computational techniques for damage detection, classification and quantification. In: Computational techniques for structural health monitoring. Springer, New York, pp 407–461

Yun-Lai Z, Maia Nuno MM, Sampaio Rui PC, Abdel WM (2017) Structural damage detection using transmissibility together with hierarchical clustering analysis and similarity measure. Struct Health Monit 16(6):711–731

Gillich G-R, Furdui H, Wahab MA, Korka Z-I (2019) A robust damage detection method based on multi-modal analysis in variable temperature conditions. Mech Syst Signal Process 115:361–379

Zhou Y-L, Wahab MA (2017) Cosine based and extended transmissibility damage indicators for structural damage detection. Eng Struct 141:175–183

Zhou Y-L, Maia NMM, Wahab MA (2018) Damage detection using transmissibility compressed by principal component analysis enhanced with distance measure. J Vib Control 24(10):2001–2019

Khatir S, Wahab MA, Boutchicha D, Khatir T (2019) Structural health monitoring using modal strain energy damage indicator coupled with teaching-learning-based optimization algorithm and isogoemetric analysis. J Sound Vib 448:230–246

Ribeiro Junior RF, de Almeida FA, Gomes GF (2020) Fault classification in three-phase motors based on vibration signal analysis and artificial neural networks. Neural Comput Appl. https://doi.org/10.1007/s00521-020-04868-w

Barbosa LCM, Santos M, Oliveira TLL, Gomes GF, Ancelotti AC Jr (2019) Effects of moisture absorption on mechanical and viscoelastic properties in liquid thermoplastic resin/carbon fiber composites. Polymer Eng Sci 59(11):2185–2194

Barbosa LCM, Gomes G, Junior ACA (2019) Prediction of temperature-frequency-dependent mechanical properties of composites based on thermoplastic liquid resin reinforced with carbon fibers using artificial neural networks. Int J Adv Manuf Technol 105(5–6):2543–2556

Chandarana N, Sanchez D, Soutis C, Gresil M (2017) Early damage detection in composites during fabrication and mechanical testing. Materials 10(7):685

Kessler SS, Mark Spearing S, Atalla MJ, Cesnik CES, Soutis C (2002) Damage detection in composite materials using frequency response methods. Compos B Eng 33(1):87–95

Cantwell WJ, Morton J (1992) The significance of damage and defects and their detection in composite materials: a review. J Strain Anal Eng Des 27(1):29–42

Pearson MR, Eaton MJ, Featherston CA, Holford KM, Pullin R (2011) Impact damage detection and assessment in composite panels using macro fibre composites transducers. J Phys Conf Ser 305:012049

Gomes GF, Pereira JVP (2020) Sensor placement optimization and damage identification in a fuselage structure using inverse modal problem and firefly algorithm. Evol Intell 1–21

François H, Jean-Noël P, Stéphane R (2015) Evaluating damage with digital image correlation: C. applications to composite materials. In: Handbook of damage mechanics: nano to macro scale for materials and structures, pp 1301–1322

Caminero MA, Lopez-Pedrosa M, Pinna C, Soutis C (2014) Damage assessment of composite structures using digital image correlation. Appl Compos Mater 21(1):91–106

Fister Jr I, Yang X-S, Fister I, Brest J, Fister D (2013) A brief review of nature-inspired algorithms for optimization. arXiv preprint arXiv:1307.4186

Yang X-S, Xingshi H (2016) Nature-inspired optimization algorithms in engineering: overview and applications. Nature-inspired computation in engineering. Springer, New York, pp 1–20

Gomes GF, Mendez YAD, Alexandrino Patrícia da Silva L, da Cunha SS, Ancelotti AC (2018) A review of vibration based inverse methods for damage detection and identification in mechanical structures using optimization algorithms and ann.In: Archives of computational methods in engineering, pp 1–15

Zenzen R, Belaidi I, Khatir S, Wahab MA (2018) A damage identification technique for beam-like and truss structures based on frf and bat algorithm. Comptes Rendus Mécanique 346(12):1253–1266

Tran-Ngoc H, De Samir Khatir G, Roeck T, Bui-Tien LN-N, Wahab MA (2018) Model updating for nam o bridge using particle swarm optimization algorithm and genetic algorithm. Sensors 18(12):4131

Khatir S, Abdel Wahab M (2019) Fast simulations for solving fracture mechanics inverse problems using pod-rbf xiga and jaya algorithm. Eng Fract Mech 205:285–300

Samir Khatir and Magd Abdel Wahab (2019) A computational approach for crack identification in plate structures using xfem, xiga, pso and jaya algorithm. Theor Appl Fract Mech 103:102240

Gomes GF, Simões S, da Cunha A, Ancelotti C (2019) A sunflower optimization (sfo) algorithm applied to damage identification on laminated composite plates. Eng Comput 35(2):619–626

Caminero MA, Pavlopoulou S, Lpez-Pedrosa M, Nicolaisson BG, Pinna C, Soutis C (2012) Digital image correlation analysis applied to monitor damage evolution of composite plates with stress concentrations and bonded patch repairs. In: Proceedings of the 15th European conference on composite materials, Venice, Italy, pp 24–28

Memmolo V, Monaco E, Boffa ND, Maio L, Ricci F (2018) Guided wave propagation and scattering for structural health monitoring of stiffened composites. Compos Struct 184:568–580

Zuo H, Yang Z, Xu C, Tian S, Chen X (2018) Damage identification for plate-like structures using ultrasonic guided wave based on improved MUSIC method. Compos Struct 203:164–171. https://doi.org/10.1016/j.compstruct.2018.06.100

Yang Z-B, Radzienski M, Kudela P, Ostachowicz W (2017) Damage detection in beam-like composite structures via chebyshev pseudo spectral modal curvature. Compos Struct 168:1–12

Xingwu Z, Gao Robert X, Ruqiang Y, Xuefeng C, Chuang S, Zhibo Y (2016) Multivariable wavelet finite element-based vibration model for quantitative crack identification by using particle swarm optimization. J Sound Vib 375:200–216

Yang Z-B, Radzienski M, Kudela P, Ostachowicz W (2017) Fourier spectral-based modal curvature analysis and its application to damage detection in beams. Mech Syst Signal Process 84:763–781

Stepinski T, Uhl T, Staszewski W (2013) Advanced structural damage detection: from theory to engineering applications. Wiley, Hoboken

Worden K, Staszewski W, Manson G, Ruotulo A, Surace C (2008) Optimization techniques for damage detection. In: Encyclopedia of structural health monitoring. Wiley. https://doi.org/10.1002/9780470061626.shm057

Rytter A (1993) Vibrational based inspection of civil engineering structures. PhD thesis, Dept. of Building Technology and Structural Engineering, Aalborg University

Shi D, Xiao X (2018) An enhanced continuum damage mechanics model for crash simulation of composites. Compos Struct 185:774–785

Soriano A, Díaz J (2018) Failure analysis of variable stiffness composite plates using continuum damage mechanics models. Compos Struct 184:1071–1080

Ben Sghaier R, Majed N, Ben Dali H, Fathallah R (2017) High cycle fatigue prediction of glass fiber-reinforced epoxy composites: reliability study. Int J Adv Manuf Technol 92(9–12):4399–4413

Sundararaman S, Adams DE, Rigas EJ (2005) Structural damage identification in homogeneous and heterogeneous structures using beamforming. Struct Health Monit 4(2):171–190

Reddy JN, Miravete A (2018) Practical analysis of composite laminates. CRC Press, Boca Raton

Sridharan S (2008) Delamination behaviour of composites. Elsevier, Amsterdam

Niemann H, Morlier J, Shahdin A, Gourinat Y (2010) Damage localization using experimental modal parameters and topology optimization. Mech Syst Signal Process 24(3):636–652

Montalvao D, Maia NMM, Ribeiro AMR (2006) A review of vibration-based structural health monitoring with special emphasis on composite materials. Shock Vib Digest 38(4):295–324

Zou Y, Tong LPSG, Steven GP (2000) Vibration-based model-dependent damage (delamination) identification and health monitoring for composite structures—a review. J Sound Vib 230(2):357–378

Liu PF, Zheng JY (2010) Recent developments on damage modeling and finite element analysis for composite laminates: A review. Mater Des 31(8):3825–3834

Chao X, Qi L, Cheng J, Tian W, Zhang S, Li H (2018) Numerical evaluation of the effect of pores on effective elastic properties of carbon/carbon composites. Compos Struct 196:108–116

Drach B, Tsukrov I, Trofimov A, Gross T, Drach A (2018) Comparison of stress-based failure criteria for prediction of curing induced damage in 3d woven composites. Compos Struct 189:366–377

Sokolnikoff IS (1956) Mathematical theory of elasticity. McGraw-Hill Book Company, New York

Malvern LE (1969) Introduction to the mechanics of a continuous medium (No. Monograph)

Ugural Ansel C, Fenster Saul K (2011) Advanced mechanics of materials and applied elasticity. Pearson Education, London

Pilkey Walter D, Pilkey Deborah F (2008) Peterson’s stress concentration factors. Wiley, Hoboken

Carlos AJA, Claudio PL, Marcelo BE, Dennis R (2010) Use of the mar-lin criteria to determine the influence of porosity on the iosipescu and short beam shear properties in carbon fiber polymer matrix composites. Mater Res 13(1):63–69

Ye L, Afaghi-Khatibi A, Lawcock G, Mai Y-W (1998) Effect of fibre/matrix adhesion on residual strength of notched composite laminates. Compos A Appl Sci Manuf 29(12):1525–1533

Tan Seng C (1994) Stress concentrations in laminated composites. CRC Press, Boca Raton

Chu TC, Ranson WF, Sutton MA (1985) Applications of digital-image-correlation techniques to experimental mechanics. Exp Mech 25(3):232–244

Orell O, Vuorinen J, Jokinen J, Kettunen H, Hytönen P, Turunen J, Kanerva M (2018) Characterization of elastic constants of anisotropic composites in compression using digital image correlation. Compos Struct 185:176–185

Tekieli M, De Santis S, de Felice G, Kwiecień A, Roscini F (2017) Application of digital image correlation to composite reinforcements testing. Compos Struct 160:670–688

Peters WH, Ranson WF (1982) Digital imaging techniques in experimental stress analysis. Opt Eng 21(3):213427

Sutton MA, Wolters WJ, Peters WH, Ranson WF, McNeill SR (1983) Determination of displacements using an improved digital correlation method. Image Vis Comput 1(3):133–139

Beberniss TJ, Ehrhardt DA (2017) High-speed 3d digital image correlation vibration measurement: Recent advancements and noted limitations. Mech Syst Signal Process 86:35–48

Crammond G, Boyd SW, Dulieu-Barton JM (2013) Speckle pattern quality assessment for digital image correlation. Opt Lasers Eng 51(12):1368–1378

Johanson K, Harper LT, Johnson MS, Warrior NA (2015) Heterogeneity of discontinuous carbon fibre composites: damage initiation captured by digital image correlation. Compos A Appl Sci Manuf 68:304–312

Speranzini E, Agnetti S (2014) The technique of digital image correlation to identify defects in glass structures. Struct Control Health Monit 21(6):1015–1029

Yoneyama S, Murasawa G (2009) Digital image correlation. Exp Mech 207

Gomes GF, da Cunha SS Jr, da Silva Lopes Alexandrino P, Silva de Sousa B, Ancelotti AC Jr (2018) Sensor placement optimization applied to laminated composite plates under vibration. Struct Multi Optim 58(5):2099–2118. https://doi.org/10.1007/s00158-018-2024-1

Khatir S, Dekemele K, Loccufier M, Khatir T, Wahab MA (2018) Crack identification method in beam-like structures using changes in experimentally measured frequencies and particle swarm optimization. Comptes Rendus Mécanique. 346(2):110–120

Braun CE, Chiwiacowsky LD, Gomez AT (2015) Variations of ant colony optimization for the solution of the structural damage identification problem. Procedia Comput Sci 51:875–884

Kim N-I, Kim S, Lee J (2019) Vibration-based damage detection of planar and space trusses using differential evolution algorithm. Appl Acoust 148:308–321

Bayraktar Z, Komurcu M, Bossard JA, Werner DH (2013) The wind driven optimization technique and its application in electromagnetics. IEEE Trans Antennas Propag 61(5):2745–2757

Yang X-S (2012) Flower pollination algorithm for global optimization. In: International conference on unconventional computing and natural computation. Springer, New York, pp 240–249

Richards SHANEA (1997) Completed richardson extrapolation in space and time. Commun Numer Methods Eng 13(7):573–582

Robert Frank G (2007) Sensor placement optimization under uncertainty for structural health monitoring systems of hot aerospace structures. PhD thesis, Citeseer

Ray-Chaudhuri S, Chawla K (2018) Stress and strain concentration factors in orthotropic composites with hole under uniaxial tension. Curved Layer Struct 5(1):213–231

Perumal L, Tso CP, Leng LT (2016) Analysis of thin plates with holes by using exact geometrical representation within xfem. J Adv Res 7(3):445–452

Taynara Incerti de Paula, Guilherme FG, José Henrique de Freitas G, Anderson Paulo de Paiva (2019) A mixture design of experiments approach for genetic algorithm tuning applied to multi-objective optimization. In: World Congress on Global Optimization. Springer, New York, pp 600–610

Qais MH, Hasanien HM, Alghuwainem S (2019) Identification of electrical parameters for three-diode photovoltaic model using analytical and sunflower optimization algorithm. Appl Energy 250:109–117

Shaheen MAM, Hasanien HM, Mekhamer SF, Talaat HEA (2019) Optimal power flow of power systems including distributed generation units using sunflower optimization algorithm. IEEE Access 7:109289–109300

Acknowledgements

The authors would like to acknowledge the financial support from the Brazilian agency CNPq - Conselho Nacional de Desenvolvimento Cientııfico e Tecnolígico, CAPES - Coordenação de Aperfeiçoamento de Pessoal de Nııvel Superior and FAPEMIG - Fundação de Amparo à Pesquisa do Estado de Minas Gerais (APQ-00385-18). The authors would like to acknowledge also the Tutorial Education Program (PET)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gomes, G.F., de Almeida, F.A., Ancelotti, A.C. et al. Inverse structural damage identification problem in CFRP laminated plates using SFO algorithm based on strain fields. Engineering with Computers 37, 3771–3791 (2021). https://doi.org/10.1007/s00366-020-01027-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-020-01027-6