Abstract

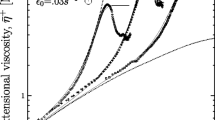

The influence of extrusion under strong slip conditions on the extensional properties of linear low-density polyethylene was studied in this work. The material was extruded at two different temperatures under strong slip and no slip conditions, and was subsequently subjected to uniaxial elongational flow by means of a Rheotens device. Strong slip was evident through the elimination of sharkskin distortions and the stick-slip instability, as well as by the electrification of the extrudates. The extrudate swell was smaller in the presence of slip when comparing with no slip conditions at constant apparent shear rate, but it was found to be a unique function of the shear stress if comparison was performed at constant stress. The draw ratio and melt strength of the filaments obtained under slip conditions were larger compared to those without slip. In addition, draw resonance was postponed to higher draw ratios during the extrusion with strong slip at constant apparent shear rate. It is suggested that slip of the polymer at the die wall decreases the shear stress in the bulk, and therefore, restricts the disentanglement and orientation of macromolecules during flow, which subsequently produces the increase in draw ratio and melt strength during stretching.

Similar content being viewed by others

References

Bernnat A, Wagner MH (1999) Effect of wall slip on Rheotens master curves for linear PE melts. Int Polym Proc XIV:336–341

Bernnat A, Wagner MH, Chai CK (2000) Assessment of LDPE melt strength by use of Rheotens mastercurves. Int Polym Proc XV:268–272

Denn MM (2001) Extrusion instabilities and wall slip. Ann Rev Fluid Mech 33:265–297

Done DS, Baird DG, Everage AE (1983) The influence of porous media on the flow of polymer melts in capillaries. Chem Eng Commun 21:293–309

Ghanta VG, Riise BL, Denn MM (1999) Disappearance of extrusion instabilities in brass capillary dies. J Rheol 43:435–442

Goutille Y, Guillet J (2002) Disentanglement of polymer melts flowing through porous medium before entering a capillary die. J Rheol 46:1307–1323

Graessley WW, Glasscok SD, Crawley RL (1970) Die swell in molten polymers. J Rheol 14:519–544

Hatzikiriakos SG, Dealy JM (1993) Effects of interfacial conditions on wall slip and sharkskin melt fracture of HDPE. Int Polym Proc 8:36–44

Hatzikiriakos SG, Hong P, Ho W, Stewart CW (1995) The effect of Teflon coatings in polyethylene capillary extrusion. J Appl Polym Sci 55:595–603

Hyun JC (1999) Draw resonance in polymer processing: a short chronology and a new approach. Korea-Austr Rheol J 11:279–285

Jay P, Piau JM, El Kissi N, Cizeron J (1998) The reduction of viscous extrusion stresses and extrudate swell computation using slippery surfaces. J Non-Newtonian Fluid Mech 79:599–617

Kharchenko SB, McGuiggan PM, Migler KB (2003) Flow induced coating of fluoropolymer additives: development of frustrated total internal reflection imaging. J Rheol 47:1523–1545

Liang RF, Mackley MR (2001) Gas assisted extrusion of molten polyethylene. J Rheol 45:211–226

Migler KB, Lavallée C, Dillon MP, Woods SS, Gettinger CL (2001) Visualizing the elimination of sharkskin through fluoropolymer additives: coating and polymer-polymer slippage. J Rheol 45:565

Mooney M (1931) Explicit formulas for slip and fluidity. J Rheol 2:210–222

Pérez-González J (2001) Exploration of the slip phenomenon in the capillary flow of linear low-density polyethylene via electrical measurements. J Rheol 45:845–853

Pérez-González J, Denn MM (2001) Flow enhancement in the continuous extrusion of linear low-density polyethylene. Ind Eng Chem Res 40:4309–4316

Pérez-González J, de Vargas L (2002) Quantification of the slip phenomenon and the effect of shear thinning in the capillary flow of linear polyethylenes. Polym Eng Sci 42:1231–1237

Pérez-González J, de Vargas L, Pavlínek V, Hausnerová B, Sáha P (2000) Temperature dependent instabilities in the capillary flow of a metallocene linear low density polyethylene melt. J Rheol 44:441–451

Pérez-Trejo L, Pérez-González J, de Vargas L, Moreno E (2004) Triboelectrification of molten linear low-density polyethylene under continuous extrusion. Wear 257:329–337

Piau JM, El Kissi N (1994) Measurement and modelling of friction in polymer melts during macroscopic slip at the wall. J Non-Newtonian Fluid Mech 54:121–142

Piau JM, El Kissi N, Toussaint F, Mezghani A (1995) Distortions of polymer melt extrudates and their elimination using slippery surfaces. Rheol Acta 34:40–57

Piau JM, Nigen S, El Kissi N (2000) Effect of die entrance filtering on mitigation of upstream instability during extrusion of polymer melts. J Non-Newtonian Fluid Mech 91:37–57

Ramamurthy AV (1986) Wall slip in viscous fluids and influence of materials of construction. J Rheol 30:337–357

Reiner M (1931) Slippage in a non-Newtonian liquid. J Rheol 2:338–349

Robens G, Winter HH (1974) Kapillaryrheometrie: Abschätzen und Verkleinern des Dissipationseinflusses. Kunststofftechnik 13:61–64

Rosenbaum EE, Hatizikiriakos SG (1997) Wall slip in the capillary flow of molten polymers subject to viscous heating. AIChE J 43:598–608

Schallamach A (1963) A theory of dynamic rubber friction. Wear 6:375–382

Wagner MH, Bernat A, Shulze V (1998) The rheology of the Rheotens test. J Rheol 42:917–928

Wang SQ (1999) Molecular transitions and dynamics at polymer/wall interfaces: origins of flow instabilities and wall slip. Adv Polym Sci 138:239

Acknowledgements

This research was supported by CGPI-IPN (20010565, 2003-0555) and CONACYT (34971-U). T. J. G-M has CONACYT and PIFI-IPN scholarships. J. P-G and L. de V. are COFFA-EDI fellows. We wish to acknowledge the reviewers for very useful comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guadarrama-Medina, T.d.J., Pérez-González, J. & de Vargas, L. Enhanced melt strength and stretching of linear low-density polyethylene extruded under strong slip conditions. Rheol Acta 44, 278–286 (2005). https://doi.org/10.1007/s00397-004-0409-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-004-0409-0