Abstract

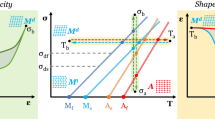

A coupling device for damping within a drive train is presented. For conventional damping couplings, damping is often realized by the dissipation of energy due to material damping or friction. In opposite to this, the damping effect of the presented coupling is based on the dissipated energy during the stress induced phase transformation of pseudoelastic NiTi shape memory alloys. In this contribution the design principles, experimental results, and a numerical simulation using the material law for shape memory alloys developed by Raniecki B. Lexcellent C. and Tanaka K. (Arch Mech 44(3:261–284)) are presented.

Similar content being viewed by others

References

Belytschko T., Liu W.K., Moran B. (2000) Nonlinear finite elements for continua and structures. Wiley, New York

Funakubo H. ed (1984) Shape memory alloys. Gordon & Breach, New York

Gadaj S.P., Nowacki W.K., Tobushi H. (1999) Temperature evolution during tensile test of TiNi shape memory alloy. Arch Mech 51(6): 649–663

Heckmann A. (2003) Mikrostruktur und Ermüdung von NiTi-Formgedächtnislegierungen. PhD thesis, Ruhr-Universität Bochum, Bochum, Germany

Heckmann, A., Hornbogen, E. On the interrelation of microstructure, localisation of transformational strain and strain rate in pseudo elastic fatigue of NiTi. In: Proceedings of SMST 2003, Pacific Grove, USA (2003)

Hill R. (1968) On constitutive inequalities for simple materials. Int J Mech Phys Solids 16, 229–242

Hodgson D.E., Brown J.W. (2000) Using nitinol alloys. Tech. rep., Shape Memory Applications, Inc. San Jose, CA, USA

Kestin J., Rice, J.R. A critical review of thermodynamics. In: Paradoxes in the application of thermodynamics to strained solids, pp 275–298 (1970)

Khan A.S., Huang S. (1995) Continuum theory of plasticity. Wiley, New York

Klönne M. (2004) Drehschwingungsdämpfung mit NiTi-Formgedächtnislegierungen – Grundlagen und Anwendung. PhD thesis, Ruhr-Universität Bochum, Bochum, Germany

Miyazaki S., Kimura S., Otsuka K., Suzuki Y. (1984) The habit plane and transformation strains associated with the martensitic transformation in Ti-Ni single crystals. Scr Met 18, 883–888

Müller C. (2003) Thermodynamic modeling of polycrystalline shape memory alloys at finite strains. Mitteilungen aus dem Institut für Mechanik. Ruhr-Universität Bochum, Bochum, Germany

Otsuka K., Wayman C.M. (1998). Introduction. In: Otsuka K., Wayman C.M. (eds). Shape memory materials. Cambridge University Press, Cambridge, pp. 1–26

Predki, W., Klönne, M. Superelastic NiTi alloys under torsional loading. In: Proceedings of ICOMAT 2002, ICOMAT, Helsinki, Finnland, pp 807–810 (2002)

Raniecki B., Lexcellent C., Tanaka K. (1992) Thermodynamic models of pseudoelastic behaviour of shape memory alloys. Arch Mech 44(3): 261–284

Shaw J.A. (2000) Simulations of localized thermo-mechanical behavior in a TiNi shape memory alloy. Int J Plast 16, 541–562

Simo, J.C., Hughes, T.J.R. Computational inelasticity. Interdiscip Appl Math 7 (1998)

Sittner P., Novák V. (2000) Anisotropy of martensitic transformations in modeling of shape memory alloy polycrystals. Int J Plast 16, 1243–1268

Truesdell C., Toupin R.A. (1960). The classical field theories. In: Flügge S. (eds). Handbuch der Physik, vol III/1, Springer, Berlin, Heidelberg New York

Xiao H., Bruhns O.T., Meyers A. (1997) Logarithmic strain, logarithmic spin and logarithmic rate. Acta Mech 124, 89–105

Xiao H., Bruhns O.T., Meyers A. (1998) Objective corotational rates and unified work-conjugacy relation between Eulerian and Lagrangean strain and stress measures. Arch Mech 50(6): 1015–1045

Xiao H., Bruhns O.T., Meyers A. (1998) On objective corotational rates and their defining spin tensors. Int J Solids Structures 35(30): 4001–4014

Xiao H., Bruhns O.T., Meyers A. (1998) Strain rates and material spins. J Elast 52, 1–41

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luig, P., Oberste-Brandenburg, C., Grabe, C. et al. Damping Couplings with Elements of Pseudoelastic NiTi Shape Memory Alloys. Arch Appl Mech 76, 75–87 (2006). https://doi.org/10.1007/s00419-006-0006-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-006-0006-z