Abstract

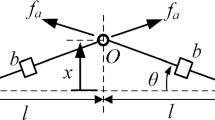

This paper presents an analytical analysis and optimization of vibration-induced fatigue in a generalized, linear two-degree-of-freedom inerter-based vibration isolation system. The system consists of a source body and a receiving body, coupled through an isolator. The isolator consists of a spring, a damper, and an inerter. A broadband frequency force excitation of the source body is assumed throughout the investigation. Optimized system, in which the kinetic energy of the receiving body is minimized, is compared with sub-optimal systems by contrasting the fatigue life of a receiving body helical spring with several alternative isolator setup cases. The optimization is based on minimizing specific kinetic energy, but it also increases the number of cycles to fatigue failure of the considered helical spring. A significant portion of this improvement is due to the inclusion of an optimally tuned inerter in the isolator. Various helical spring deflection and stress correction factors from referent literature are discussed. Most convenient spring stress and deflection correction factors are adopted and employed in conjunction with pure shear governed proportional stress in the context of high-cycle fatigue.

Similar content being viewed by others

References

Rao, S.S.: Mechanical Vibrations, 5th edn. Prentice Hall, New York (2010)

Smith, M.C.: Synthesis of mechanical networks: the inerter. IEEE Trans. Autom. Control 47(10), 1648–1662 (2002)

Steinberg, D.S.: Vibration Analysis for Electronic Equipment, Third edn. Wiley, New York (2000)

Bishop, N.W.M., Sherratt, F.: Finite Element Based Fatigue Calculations. NAFEMS, Farnham (2000)

Lee, Y., Barkey, M.E., Kang, H.: Metal Fatigue Analysis Handbook. Practical Problem-Solving Techniques for Computer-Aided Engineering. Elsevier, Waltham (2012)

Wahl, A.M.: Helical compression and tension springs. ASME paper A-38. J. Appl. Mech. 2(1), A-35–A-37 (1935)

Wahl, A.M.: Mechanical Springs, 1st edn. Penton, Cleveland (1944)

DIN EN 2089-1-1963-01 (1963) Helical Springs Made From Round Wire and Rod—Calculation and Design of Compression Springs

DIN EN 2089-1-1963-02 (1963) Helical Springs Made From Round Wire and Rod—Calculation and Design of Tension Springs

Din EN 13906-1: Cylindrical Helical Springs Made From Round Wire and Bar—Calculation and Design—Part 1: Compression Springs. BeuthVerlag, Berlin (2002)

Din EN 13906-2: Cylindrical Helical Springs Made From Round Wire and Bar—Calculation and Design—Part 2: Extension Springs. BeuthVerlag, Berlin (2002)

Ancker Jr., C.J., Goodier, J.N.: Pitch and curvature correction for helical springs. ASME J. Appl. Mech. 25(4), 466–470 (1958)

Dym, C.L.: Consistent derivations of spring rates for helical springs. ASME J. Mech. Des. 131(7), 1–5 (2009)

Research Committee on the Analysis of Helical Spring: Report of research committee on the analysis of helical spring. Trans. Jpn. Soc. Spring Eng. 2004(49), 35–75 (2004)

Society of Automotive Engineers (SAE): Spring Design Manual. Ae Series. Society of Automotive Engineers Inc., Warrendale (1990)

Hearn, E.J.: Mechanics of Materials, Volume 1, An Introduction to the Mechanics of Elastic and Plastic Deformation of Solids and Structural Materials, 3rd edn. Butterworth-Heinemann, Oxford (1997)

Meissner, M., Schorcht, H.-J., Kletzin, U.: Metallfedern: Grundlagen, Werkstoffe, Berechnung, Gestaltung und Rechnereinsatz, 3rd edn. Springer, Berlin (2015)

Shimoseki, M., Hamano, T., Imaizumi, T.: FEM for Springs. Springer, Berlin (2003)

Timoshenko, S.P.: Strength of Materials, Part I, Elementary Theory and Problems, 2nd edn. D. Van Nostrand, New York (1940)

Timoshenko, S.P.: Strength of Materials, Part II, Advanced Theory and Problems, 2nd edn. D. Van Nostrand, New York (1940)

Timoshenko, S.P., Goodier, J.N.: Theory of Elasticity, 2nd edn. McGraw-Hill, New York (1951)

Budynas, R.G., Nisbett, J.K.: Shigley’s Mechanical Engineering Design, 10th edn. McGraw-Hill, New York (2015)

Ugural, A.C.: Mechanical Design of Machine Components, 2nd edn. CRC Press, Boca Raton (2015)

Stephens, R.I., Fatemi, A., Stephens, R.R., Fuchs, H.O.: Metal Fatigue in Engineering, 2nd edn. Wiley, New York (2005)

Roessle, M.L., Fatemi, A.: Strain-controlled fatigue properties of steels and some simple approximations. Int. J. Fatigue 22(6), 495–511 (2000)

Bannantine, J.A., Comer, J.J., Handrock, J.L.: Fundamentals of Metal Fatigue Analysis. Prentice Hall, Englewood Cliffs (1990)

Romanowicz, P.: Numerical assessment of fatigue load capacity of cylindrical crane wheel using multiaxial high-cycle fatigue criteria. Arch. Appl. Mech. 87, 1707–1726 (2017)

Berger, C., Kaiser, B.: Result of very high cycle fatigue tests on helical compression springs. Int. J. Fatigue 28, 1658–1663 (2006)

Kaiser, B., Berger, C.: Fatigue behaviour of technical springs. Mater. Werkst. 36(11), 685–696 (2005)

Del Llano-Vizcaya, L., Rubio-González, C., Mesmacque, G., Cervantes-Hernandez, T.: Multiaxial fatigue and failure analysis of helical compression springs. Eng. Fail. Anal. 13(8), 1303–1313 (2006)

Pyttel, B., Ray, K.K., Brunner, I., Tiwari, A., Kaoua, S.A.: Investigation of probable failure position in helical compression springs used in fuel injection system of diesel engines. IOSR J. Mech. Civil Eng. 2(3), 24–29 (2012)

Rivera, R., Chiminelli, A., Gómez, C., Núñez, J.L.: Fatigue failure analysis of a spring for elevator doors. Eng. Fail. Anal. 17(4), 731–738 (2010)

Ružička, M., Doubrava, K.: Loading regimes and designing helical coiled springs for safe fatigue life. Res. Agr. Eng. 51(2), 50–55 (2005)

Kamal, M., Rahman, M.M.: Finite element-based fatigue behaviour of springs in automobile suspension. Int. J. Autom. Mech. Eng. 10, 1910–1919 (2014)

Kuznetsov, A., Mammadov, M., Sultan, I., Hajilarov, E.: Optimization of improved suspension system with inerter device of the quarter-car model in vibration analysis. Arch. Appl. Mech. 81, 1427–1437 (2011)

Cowper, G.R.: The shear coefficients in Timoshenko’s beam theory. ASME J. Appl. Mech. 33(2), 335–340 (1966)

Mlikota, M., Schmauder, S., Božić, Ž., Hummel, M.: Modelling of overload effects on fatigue crack initiation in case of carbon steel. Fatigue Fract. Eng. Mater. Struct., Special Issue: 16th International Conference on New Trends in Fatigue and Fracture (NT2F16) 40(8):1182–1190 (2017)

Alujević, N., Čakmak, D., Wolf, H., Jokić, M.: Passive and active vibration isolation systems using inerter. J. Sound Vib. 418, 163–183 (2018)

Alujević, N., Wolf, H., Gardonio, P., Tomac, I.: Stability and performance limits for active vibration isolation using blended velocity feedback. J. Sound Vib. 330, 4981–4997 (2011)

Alujević, N., Gardonio, P., Frampton, K.D.: Smart double panel for the sound radiation control: blended velocity feedback. AIAA J. 49(6), 1123–1134 (2011)

Caiazzo, A., Alujević, N., Pluymers, B., Desmet, W.: Active control of turbulent boundary layer-induced sound transmission through the cavity-backed double panels. J. Sound Vib. 422, 161–188 (2018)

James, H.M., Nichols, N.B., Phillips, R.S.: Theory of Servomechanisms. MIT Radiation Laboratory Series, vol. 25, First edn. McGraw-Hill, New York (1947)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Čakmak, D., Wolf, H., Božić, Ž. et al. Optimization of an inerter-based vibration isolation system and helical spring fatigue life assessment. Arch Appl Mech 89, 859–872 (2019). https://doi.org/10.1007/s00419-018-1447-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-018-1447-x