Abstract

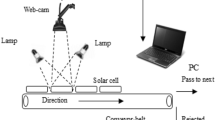

Automatic defect detection on reflective surfaces is a compelling process. In particular, detection of tiny defects is almost impossible for human eye or simple machine vision methods. Therefore, the need for fast and sensitive machine vision methods has gained importance. In this study, an effective defect detection method is presented for reflective surfaces such as glass, tile, and steel. Defects on the surface of the product are determined automatically without the need for human intervention. The proposed system involves illumination unit, digital camera, and defect detection algorithm. Firstly, color image is taken by digital camera. Then, properties of taken image are selected. At this stage, ambient condition of lighting devices is very important. Reflections are minimized thanks to the true lighting. Selected properties are: red, green, and blue values, and luminance value. These properties are applied to fuzzy inputs. Information from the inputs is evaluated according to determined rules. Finally, each pixel is classified as black or white. Thirty-two glass pieces are tested using the proposed system. The proposed method was compared with commonly used methods. The success rate of the proposed algorithm is 83.5% and is higher than that of other algorithms .

Similar content being viewed by others

References

Andersen AL, Nielsen K, Brunoe TD (2016) Prerequisites and barriers for the development of reconfigurable manufacturing systems for high speed ramp-up. Proc CIRP 51:7–12

Holmes RL (1983) Computer-assisted quality control in tree-ring dating and measurement. Tree-Ring Bull 43(1):69–78

Malamas EN, Petrakis EG, Zervakis M, Petit L, Legat JD (2003) A survey on industrial vision systems, applications and tools. Image Vis Comput 21(2):171–188

Bulnes FG, García DF, de la Calle FJ, Usamentiaga R, Molleda J (2016) A non-invasive technique for online defect detection on steel strip surfaces. J Nondestr Eval 35(4):54

Qu T, Zou L, Zhang Q, Chen X, Fan C (2016) Defect detection on the fabric with complex texture via dual-scale over-complete dictionary. J Text Inst 107(6):743–756

Chen X, Liu N, You B, Xiao B (2016) A novel method for surface defect inspection of optic cable with short-wave infrared illuminance. Infrared Phys Technol 77:456–463

Jin Y, Wang Z, Chen Y, Wang Z (2016) The online measurement of optical distortion for glass defect based on the grating projection method. Opt Int J Light Electron Opt 127(4):2240–2245

Cen YG, Zhao RZ, Cen LH, Cui LH, Miao ZJ, Wei Z (2015) Defect inspection for TFT-LCD images based on the low-rank matrix reconstruction. Neurocomputing 149:1206–1215

Liu Y, Yu F (2014) Automatic inspection system of surface defects on optical IR-CUT filter based on machine vision. Opt Lasers Eng 55:243–257

Öztürk Ş, Akdemir B (2015) Comparison of edge detection algorithms for texture analysis on glass production. Proc Soc Behav Sci 195:2675–2682

Chan CH, Pang GK (2000) Fabric defect detection by Fourier analysis. IEEE Trans Ind Appl 36(5):1267–1276

Xu J, Jia Y, Shi Z, Pang K (2016) An improved anisotropic diffusion filter with semi-adaptive threshold for edge preservation. Sig Process 119:80–91

Huang ZK, Ma YL, Lu L, Rao FX, Hou LY (2016) Chinese historic image threshold using adaptive K-means cluster and Bradley’s. In: International conference on intelligent computing, pp 171–179

Bulnes FG, Usamentiaga R, Garcia DF, Molleda J (2016) An efficient method for defect detection during the manufacturing of web materials. J Intell Manuf 27(2):431–445

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353

Adelson EH, Wang JY (1992) Single lens stereo with a plenoptic camera. IEEE Trans Pattern Anal Mach Intell 14(2):99–106

Fossum ER (1997) CMOS image sensors: electronic camera-on-a-chip. IEEE Trans Electron Devices 44(10):1689–1698

Boulkroune A (2016) A fuzzy adaptive control approach for nonlinear systems with unknown control gain sign. Neurocomputing 179:318–325

Sridhar B, Reddy KVVS, Prasad AM (2015) Mammographic image analysis based on adaptive morphological fuzzy logic CAD system. Int J Biomed Eng Technol 17(4):341–355

Zadeh LA (1997) Toward a theory of fuzzy information granulation and its centrality in human reasoning and fuzzy logic. Fuzzy Sets Syst 90(2):111–127

Perić N (2015) Fuzzy logic and fuzzy set theory based edge detection algorithm. Serbian J Electr Eng 12(1):109–116

Zadeh LA (1996) Fuzzy logic = computing with words. IEEE Trans Fuzzy Syst 4(2):103–111

Saravanan C (2010) Color image to grayscale image conversion. In: Second international conference on computer engineering and applications (ICCEA), 2010, IEEE, vol. 2. pp 196–199

Mamdani EH, Assilian S (1975) An experiment in linguistic synthesis with a fuzzy logic controller. Int J Man Mach Stud 7(1):1–13

Sugeno M, Kang GT (1988) Structure identification of fuzzy model. Fuzzy Sets Syst 28(1):15–33

Van Leekwijck W, Kerre EE (1999) Defuzzification: criteria and classification. Fuzzy Sets Syst 108(2):159–178

Canny J (1986) A computational approach to edge detection. IEEE Trans Pattern Anal Mach Intell 6:679–698

Bezdek JC, Ehrlich R, Full W (1984) FCM: the fuzzy c-means clustering algorithm. Comput Geosci 10(2–3):191–203

Otsu N (1975) A threshold selection method from gray-level histograms. Automatica 11(285–296):23–27

Vasicek Z, Mrazek V (2016) Trading between quality and non-functional properties of median filter in embedded systems. Genet Program Evol Mach 1–38. doi:10.1007/s10710-016-9275-7

Acknowledgements

This work was supported by the Scientific and Technological Research Council of Turkey (TUBITAK) with Project Number: 114E925.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Öztürk, Ş., Akdemir, B. Fuzzy logic-based segmentation of manufacturing defects on reflective surfaces. Neural Comput & Applic 29, 107–116 (2018). https://doi.org/10.1007/s00521-017-2862-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-017-2862-6