Abstract

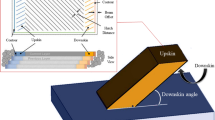

The actual geometrical design of micro milling tools has been adopted from macro tools, assuming that the effects during the milling process are analogical. Experience has also proved that micro tools respond to influences in a very different way than macro tools do. So it is very important to achieve a comprehensive understanding of the entire process by taking a structural, mechanical and cutting technological approach to micro milling tools in order to be able to optimize them. Oftentimes, structural details such as the rake angle and the twist angle impede further miniaturization and are impossible to achieve with conventional manufacturing techniques. This paper deals with an alternative method to manufacture structural optimized milling tools, namely Electro Discharge Machining (EDM). The present state of research already puts the deficits of the currently available tools on display. Manufacturing tolerances of ±10 μm on a micro tool are insufficient to ensure constant cutting conditions for the commonly used lateral infeed or feed per tooth of a few micrometers. Sometimes, only one cutting edge is engaged, which results in increased wear, increased cutting forces, minor surface quality and a higher risk of milling cutter breakage. That is why a single-edged micro milling tool has been developed. It guarantees clear adjustment of the process parameters, feed per edge and lateral infeed. For that purpose, stability analyses of simple stylus geometries have been conducted by means of FEM simulations. Corresponding to the results of the simulation the geometry of this tool was optimized in several steps. The resulting tool with a diameter down to 30 μm was machined on the EDM-machine (Sarix SX 100) at the wbk—Institute of Production Science. Initial tests have been carried out and showed the ability of these tools to optimize cutting process.

Similar content being viewed by others

References

Fleischer J, Masuzawa T, Schmidt J, Knoll M (2004) New applications for micro-EDM, Euspen

Fleischer J, Schmidt J, Haupt S, Halvadjiysky G, Kotschenreuther J (2005) Mikroformeinsätze in gehärteten Stählen, wt Werkstattstechnik online

Hesselbach J, Raatz A, Wrege J, Herrmann H, Weule H, Buchholz C, et al (2003) “mikroPRO—untersuchung zum internationalen Stand der Mikroproduktionstechnik”, wt Werkstattstechnik online, 93, Nr.3T

Schmidt J, Fleischer J, Knoll M (2003) Electrodes for micro-EDM. In: EUSPEN international topical conference on precision engineering, micro technology, measurement techniques and equipment 2003, vol 1, Seiten, pp 177–179, ISBN: 3-926832-30-4

Schmidt J, Simon M, Tritschler H, Ebner R (2001) “μ-Fräsen und μ-Erodieren für den Formenbau”, wt Werkstattstechnik online, Jahrgang 91, H. 12 S. 743 ff

Acknowledgments

The authors wish to thank the German Research Foundation (DFG) for their support. “Structuring guidelines and machining procedures for micro milling tools”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fleischer, J., Deuchert, M., Ruhs, C. et al. Design and manufacturing of micro milling tools. Microsyst Technol 14, 1771–1775 (2008). https://doi.org/10.1007/s00542-008-0652-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-008-0652-x