Abstract

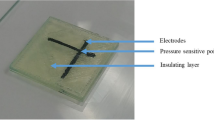

One of the methods, to improve the uniformity of a microhotplate is to provide an insulation layer of optimum dimensions between the heater and gas sensor. In this paper, two insulation layer material, silicon nitride and silicon carbide, are investigated. Simulation studies are carried out to find the optimum dimension of insulation layer, required for a targeted uniformity of 0.22 K/μm, a value comparable to the reported literature. With 8 μm thick silicon nitride layer, a thermal uniformity of 0.18 K/μm is obtained whereas the same is achieved with a 1.5 μm thick silicon carbide layer. Therefore, the deposition time in the whole process will significantly reduce by employing silicon carbide layer while retaining similar uniformity. It has been established that, the proposed method not only serves the purpose of providing electrical insulation and improve thermal uniformity but also improves the mechanical stability. The silicon carbide is compared with silicon nitride layer in terms of performance parameters and a table is also listed, highlighting the practical aspects involved in the choice of these two insulation layer materials.

Similar content being viewed by others

References

(2001) NSM Archive - Silicon Carbide (SiC). http://www.ioffe.rssi.ru/SVA/NSM/Semicond/SiC/, [Online]. [April-2013]

(2013) coventor.com. http://www.coventor.com/mems-solutions/products/coventorware/, [Online]. [April-2013]

Ahmed A, Dennis J, Saad M, Talah W (2008) Design and simulation of a high temperature MEMS micro-hotplate for application in trace gas detection, pp 153–157. doi:10.1109/SMELEC.2008.4770297

Arata H, Rondelez Y, Noji H, Fujita H (2005) Temperature alternation by an on-chip microheater to reveal enzymatic activity of β-galactosidase at high temperatures. Anal Chem 77(15):4810–4814

Briand D (2001) Thermally isolated microelectronic devices for gas sensing applications. PhD thesis, University of Neuchâtel

Briand D, Pham P, De Rooij N (2007) Reliability of freestanding polysilicon microheaters to be used as igniters in solid propellant microthrusters. Sens Actuators A 135(2):329–336

Chung GS, Jeong JM (2010) Fabrication of micro heaters on polycrystalline 3C-SiC suspended membranes for gas sensors and their characteristics. Microelectron Eng 87(11):2348–2352. doi:10.1016/j.mee.2010.04.005. http://www.sciencedirect.com/science/article/pii/S0167931710001309

Dennis J, Ahmed A, Mohamad N (2010) Design, simulation and modeling of a micromachined high temperature microhotplate for application in trace gas detection. Int J Eng Technol 10(02):89–96

Fu X, Dunning JL, Zorman CA, Mehregany M (2005) Measurement of residual stress and elastic modulus of polycrystalline 3C-SiC films deposited by low-pressure chemical vapor deposition. Thin Solid Films 492:195–202. doi:10.1016/j.tsf.2005.07.236. http://www.sciencedirect.com/science/article/pii/S0040609005009879

Kang T, Kim S, Cho Y (2002) High-impulse, low-power, digital microthrusters using low boiling temperature liquid propellant with high viscosity fluid plug. Sens Actuators A 97:659–664

Kim J, Chung J, Lee D, Kim Y, Kim J, Hwang S, Ju B, Yun S, Park H (2009) Development of temperature feedback control system for piezo-actuated display package. Sens Actuators A 151(2):213–219

Lam L, Sakakihara S, Ishizuka K, Takeuchi S, Arata H, Fujita H, Noji H (2008) Loop-mediated isothermal amplification of a single DNA molecule in polyacrylamide gel-based microchamber. Biomed Microdevices 10(4):539–546

Lee J, Spadaccini CM, Mukerjee EV, King WP (2009) Suspended membrane single crystal silicon micro hotplate for fifferential scanning calorimetry. In: Proceedings of the 22nd international conference on micro electro mechanical systems, IEEE, pp 852–855

Li T, Wu L, Liu Y, Wang L, Wang Y, Wang Y (2006) Micro-heater on membrane with large uniform-temperature area. In: 5th IEEE conference on sensors, 2006, pp 571–575. doi:10.1109/ICSENS.2007.355532

Liu F, Carraro C, Chu J, Maboudian R (2009) Residual stress characterization of polycrystalline 3c-sic films on si (100) deposited from methylsilane. J Appl Phys 106(1):013505–013505

Lu C, Setiadi D, Udrea F, Milne W, Covington J, Gardner J (2000) 3D Thermo-electro-mechanical simulations of gas sensors based on SOI membranes. Power [W] 500:600

Mele L, Rossi T, Riccio M, Iervolino E, Santagata F, Irace A, Breglio G, Creemer J, Sarro P (2011) Electro-thermal analysis of MEMS microhotplates for the optimization of temperature uniformity. Procedia Eng 25(0):387–390. doi:10.1016/j.proeng.2011.12.096. http://www.sciencedirect.com/science/article/pii/S1877705811057651

Mele L, Santagata F, Iervolino E, Mihailovic M, Rossi T, Tran A, Schellevis H, Creemer J, Sarro P (2012) A molybdenum MEMS microhotplate for high-temperature operation. Sens Actuators A 188(0):173–180. doi:10.1016/j.sna.2011.11.023. http://www.sciencedirect.com/science/article/pii/S0924424711006820

Mendoza-Acevedo S, Reyes-Barranca M (2011) Study for the micromachining optimization of micro hotplates used in MEMS-CMOS gas sensors. In: Proceedings of the 8th international conference on electrical engineering computing science and automatic control (CCE), IEEE, pp 1–6

Mo Y, Okawa Y, Inoue K, Natukawa K (2002) Low-voltage and low-power optimization of micro-heater and its on-chip drive circuitry for gas sensor array. Sens Actuators A 100(1):94–101. doi:10.1016/S0924-4247(02)00145-0. http://www.sciencedirect.com/science/article/pii/S0924424702001450

Naumann F, Ebert M, Hildenbrand J, Moretton E, Peter C, Wollenstein J (2009) Thermal and mechanical design optimisation of a micro machined mid-infrared emitter for optical gas sensing systems. In: Proceedings of the 10th international conference on thermal, mechanical and multi-physics simulation and experiments in microelectronics and microsystems, IEEE, pp 1–5

Rossi C, Temple-Boyer P, Esteve D (1998) Realization and performance of thin SiO2/SiNx membrane for microheater applications. Sens Actuators A 64(3):241–245. doi:10.1016/S0924-4247(97)01627-0. http://www.sciencedirect.com/science/article/pii/S0924424797016270

Saddow SE, La Via F, Severino A, Anzalone R, D’Arrigo G, Locke C, Volinsky A, Piluso N, Carballo J (2010) Growth rate effect on 3C-SiC film residual stress on (100) Si substrates. Mater Sci Forum Trans Tech Publ 645:143–146

Saxena G, Paily R (2012) Simulation study of power loss components in a microheater. In: 1st International conference on power and energy in NERIST (ICPEN), pp 1–5. doi:10.1109/ICPEN.2012.6492333

Saxena G, Paily R (2013a) Analytical modeling of square microhotplate for gas sensing application. Sens J IEEE 13(12):4851–4859 doi:10.1109/JSEN.2013.2275951

Saxena G, Paily R (2013b) Effect of membrane to heater ratio on the performance of square microhotplate. In: 2013 Annual international conference on emerging research areas and 2013 international conference on microelectronics, communications and renewable energy (AICERA/ICMiCR), pp 1–5. doi:10.1109/AICERA-ICMiCR.2013.6575982

Schmid U, Seidel H (2008) Effect of high temperature annealing on the electrical performance of titanium/platinum thin films. Thin Solid Films 516(6):898–906. doi:10.1016/j.tsf.2007.04.128. http://www.sciencedirect.com/science/article/pii/S0040609007007353

Smith R, Collins S (1990) Thick films of silicon nitride. Sens Actuators A Phys 23(1–3):830–834. doi:10.1016/0924-4247(90)87041-G. http://www.sciencedirect.com/science/article/pii/092442479087041G

Solzbacher F, Imawan C, Steffes H, Obermeier E, Eickhoff M (2001) A highly stable SiC based microhotplate NO2 gas-sensor. Sens Actuators B 78(1–3):216–220. doi:10.1016/S0925-4005(01)00815-2. http://www.sciencedirect.com/science/article/pii/S0925400501008152

Swart N, Nathan A (1994) Design optimisation of integrated microhotplates. Sens Actuators A 43(1–3):3–10

Velmathi G, Ramshanker N, Mohan S (2010) Design, electro-thermal simulation and geometrical optimization of double spiral shaped microheater on a suspended membrane for gas sensing. In: Proceedings of the 36th annual conference on IEEE industrial electronics society, pp 1258–1262. doi:10.1109/IECON.2010.5675550

Visvanathan K, Gianchandani Y (2011) Microheaters based on ultrasonic actuation of piezoceramic elements. J Micromech Microeng 21:085030

Vrinceanu I, Danyluk S (2002) Measurement of residual stress in single crystal silicon wafers. In: Proceedings of 8th international symposium on advanced packaging materials, 2002, pp 297–301. doi:10.1109/ISAPM.2002.990402

Xu L, Li T, Gao X, Wang Y (2011a) Development of a reliable micro-hotplate with low power consumption. Sens J IEEE 11(4):913–919. doi:10.1109/JSEN.2010.2064765

Xu L, Xu J, Wang B, Zhang W (2011b) Pool boiling heat transfer on the microheater surface with and without nanoparticles by pulse heating. Int J Heat Mass Transf 54(15):3309–3322

Yoon D, Cho YK, Oh K, Kim S, Kim Y, Han J, Lim G (2006) A microfluidic gel valve device using reversible sol–gel transition of methyl cellulose for biomedical application. Microsyst Technol 12:238–246

Acknowledgments

The authors are thankful to NPMASS, Government of India, for equipping the National MEMS Design Center IIT Guwahati with MEMS design softwares which were used for carrying out this work. The authors gratefully acknowledge Mr. Vijay S. Duryodhan of IIT Bombay and Mr. Dushyant Singh Raghuvanshi of IIT Delhi (India) for their valuable discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saxena, G., Paily, R. Choice of insulation materials and its effect on the performance of square microhotplate. Microsyst Technol 21, 393–399 (2015). https://doi.org/10.1007/s00542-013-2022-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-2022-6