Abstract

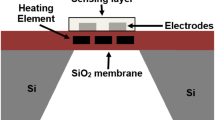

This paper reports a low power miniaturized MEMS based integrated gas sensor with 36.84 % sensitivity (ΔR/R0) for as low as 4 ppm (NH3) gas concentration. Micro-heater based gas sensor device presented here consumes very low power (360 °C at 98 mW/mm2) with platinum (Pt) micro-heater. Low powered micro-heater is an essential component of the metal oxide based gas sensors which are portable and battery operated. These micro-heaters usually cover less than 5 % of the gas sensor chip area but they need to be thermally isolated from substrate, to reduce thermal losses. This paper elaborates on design aspects of micro fabricated low power gas sensor which includes ‘membrane design’ below the microheater; the ‘cavity-to-active area ratio’; effect of silicon thickness below the silicon dioxide membrane; etc. using FEM simulations and experimentation. The key issues pertaining to process modules like fragile wafer handling after bulk micro-machining; lift-off of platinum and sensing films for the realization of heater, inter-digitated-electrodes (IDE) and sensing film are dealt with in detail. Low power platinum microheater achieving 700 °C at 267 mW/mm2 are fabricated. Temperature calculations are based on experimentally calculated thermal coefficient of resistance (TCR) and IR imaging. Temperature uniformity and localized heating is verified with infrared imaging. Reliability tests of the heater device show their ruggedness and repeatability. Stable heater temperature with standard deviation (σ) of 0.015 obtained during continuous powering for an hour. Cyclic ON–OFF test on the device indicate the ruggedness of the micro-heater. High sensitivity of the device for was observed for ammonia (NH3), resulting in 40 % response for ~4 ppm gas concentration at 230 °C operating temperature.

Similar content being viewed by others

References

Agbor NE, Petty MC, Monkman AP (1997) An optical gas sensor based on polyaniline Langmuir-Blodgett films. Sens Actuators B Chem 41:137–141

Anothainart K et al (2003) Light enhanced NO2 gas sensing with tin oxide at room temperature: conductance and work function measurements. Sens Actuators B Chem 93(1–3):580–584

Baroncini M et al (2004) Thermal characterization of a microheater for micromachined gas sensors. Sens Actuators B Chem 115(1):8–14

Creemer JF et al (2008) Microhotplates with TiN heaters. Sens Actuators A 148(2):416–421

Hwang WJ et al (2011) Development of micro-heaters with optimized temperature compensation design for gas sensors. Sensors (Basel) 11(3):2580–2591

Laconte J, Dupont C, Flandre D, Raskin JP (2004) SOI CMOS compatible low-power microheater optimization for the fabrication of smart gas sensors. IEEE Sens J 4(5):670–680

Lee DD, Chung WY, Choi MS, Baek JM (1996) Low-power micro gas sensor. Sens Actuators B Chem 33:147–150

Moon SE et al (2014) Low power consumption micro C2H5OH gas sensor based on micro-heater and ink jetting technique. Sens Actuators B Chem 217:146–150

Pavelko RG et al (2009) Comparative study of nanocrystalline SnO2 materials for gas sensor application: thermal stability and catalytic activity. Sens Actuators B Chem 137(2):637–643

Prajesh R, Jain N, Khanna VK, Gupta V, Agarwal A (2014) MEMS based integrated gas sensor for NO2 and NH3. J ISSS 3(2):1–6

Rossi C, Temple-Boyer P, Esteve D (1998) Realization and performance of thin SiO2/SiNx membrane for microheater applications. Sens Actuators A 64:241–245

Saxena G, Paily R (2013) Analytical modeling of square microhotplate for gas sensing application. IEEE Sens J 13(12):4851–4859

Sheng LY, Tang Z, Wu J, Chan PC, Sin JK (1998) A low-power CMOS compatible integrated gas sensor using maskless tin oxide sputtering. Sens Actuators B Chem 49:81–87

Tabata S et al (2005) A micromachined gas sensor based on a catalytic thick film/SnO2 thin film bilayer and a thin film heater. Sens Actuators B Chem 109(2):190–193

Vereshchagina E et al (2015) Low power micro-calorimetric sensors for analysis of gaseous samples. Sens Actuators B Chem 206:772–787

Xu L, Li T, Gao X, Wang Y (2011) Development of a Reliable Micro-Hotplate with low power consumption. IEEE Sens J 11(4):913–919

Xu L, Li T, Gao X, Wang Y (2012) A high-performance three-dimensional microheater-based catalytic gas sensor. IEEE Electron Device Lett 33(2):284–286

Acknowledgments

Authors would like to acknowledge Director, CSIR-CEERI for providing the infrastructure for the project and Head, MEMS and Microsensors group, for continuous encouragement. Authors also want to thank Dr. Vinay Gupta and his team for their constant technical support. Authors are also thankful to the technical staff of MEMS and Microsensors group, CSIR-CEERI for their wonderful support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prajesh, R., Jain, N. & Agarwal, A. Low power highly sensitive platform for gas sensing application. Microsyst Technol 22, 2185–2192 (2016). https://doi.org/10.1007/s00542-015-2609-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2609-1