Abstract

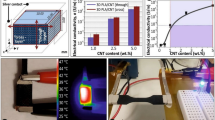

Fusion of the transduction mechanism in micro and macro nanopores of porous silicon (PS) was employed to fabricate an MEMS-based aliphatic alcohol impedance sensor. The presence of a nanopore network on silicon was confirmed by the SEM image. The morphology of the PS nanopores was roughly distributed in a uniform manner. The performance of the sensor was studied using Impedance spectroscopy at room temperature. Electrochemical impedance spectroscopy and an equivalent circuit analysis of the small amplitude (± 10 mV) AC impedance measurements (frequency range 0.1 Hz–1 kHz) at ambient temperature were carried out. The Sensing layer consists of nanopores (45.30–71.13 nm), micropores (0.95–5 µm), and comb type alumina electrodes with the micro PS layer having a thickness of about 0.2 µm and the macro PS layer having a thickness of about 4 µm. These results were used to assess the effect of the micro PS and macro PS of the particulate layer on the conductivity of the given aliphatic gases. The measured impedance was approximately 2.3e5 for the micro PS, and 3.22e5 macro PS for 8 ppm of gas injected into the gas chamber. The grain boundary resistance increases with an increase in the concentration of butane, benzene, and methane, which ranges from 2 to 16 ppm.

Similar content being viewed by others

References

Badilla JP, Rojas DC, Lopez V, Fahlman BD, Ramirez-Porras A (2011) Development of organic vapour sensor based on functionalized porous silicon. Phys Status Solidi A 208(6):1458–1461

du Plessis M (2007) Properties of porous silicon nano-explosive devices. Sens Actuators A 135:666–674

Dusheiko M, Ilchenko V, Obukhova T, Stepanova M (2017) Sensors on FET with porous silicon. In: 37th International conference on electronics and nanotechnology (ELNANO). IEEE, Kiev, Ukraine. https://doi.org/10.1109/ELNANO.2017.7939739

Escorcia-Garcia J, Martinez OS, Gracia-Jimenez JM, Agarwal V (2009) Porous silicon photonic devices using pulsed anodic etching of lightly doped silicon. J Phys D Appl Phys 42:145101–145108

Gessner T et al (2000) Metal oxide gas sensor for high temperature application. Microsyst Technol 6:169–174

Kanungo J, Basu S (2014) Ohmic and rectifying contacts to porous silicon. In: Canham L (ed) Handbook of porous silicon. Springer, Cham. https://doi.org/10.1007/978-3-319-04508-5_72-1

Kanungo J, Pramanik C, Bandopadhyay S, Gangopadhyay U, Das L, Saha H, Gettens RT (2006) Improved contacts on a porous silicon layer by electroless nickel plating and copper thickening. Semicond Sci Technol 21:964

Kanungo J, Maji S, Saha H, Basu S (2009) Stable aluminium ohmic contact to surface modified porous silicon. Solid State Electron 53(6):663–668

Karacali T, Hasar UC, Ozbek IY, Oral EA, Efeoglu H (2013) Novel design of porous silicon based sensor for reliable and feasible chemical gas vapor detection. J Lightwave Technol 31(2):295–305

Losic D, Santos A (2015) Electrochemically engineered nanoporous materials. Springer Series in Materials Science. Springer, Berlin, p 220

Mabrook M, Ray A, Ghassemlooy Z, Brown S (1995) Electrical characteristics of metal contacts on porous silicon. In: IEE colloquium on materials for displays. London, UK. https://doi.org/10.1049/ic:19950981

Ogata YH, Koyama A, Harraz FA, Salem MS, Sakkaa T (2007) Electrochemical formation of porous silicon with medium-sized pores. Electrochemistry 75(3):270–272

Palzer S, Moretton E, Ramirez FH, Romano-Rodriguez A, Wöllenstein J (2008) Nano-and microsized metal oxide thin film gas sensors. Microsyst Technol 14:645–651

Pérez EX (2008) Design, fabrication and characterization of porous silicon multilayer optical devices. Universitat Rovira i Virgili, Chicago

Sailor MJ (2012) Fundamentals of porous silicon preparation. In: Porous silicon in practice: preparation, characterization and applications. Wiley-VCH Verlag GmbH & Co. KGaA, pp 1–42. https://doi.org/10.1002/9783527641901.ch1

Selvakumar VS, Sujatha L (2019) A parametrical study of porous silicon for volatile organic chemical sensor applications. Sens Lett 17(5):405–410

Selvakumar VS, Sujatha L, Suganthi S, Kumar SS (2019) Fabrication of nanoparticles based nanoporous silicon sensor for detection of volatile organic compounds. Sens Lett 17:423–430

Sujatha L, Bhattacharya E (2007a) Composite silicon/porous silicon membranes for low pressure sensors, IUMRSICAM

Sujatha L, Bhattacharya E (2007b) Sensitivity and stress in pressure sensors with composite silicon/macroporous silicon membranes. In: International workshop on physics of semiconductor devices. IEEE, Mumbai, India. https://doi.org/10.1109/IWPSD.2007.4472626

Valera E, Casals O, Vetter M, Rodriguez A (2007) Micro porous silicon gas sensor based on inter digitated micro electrodes, 1-4244-0869-5/07 IEEE. pp 197–200

Vinod PN (2005) Specific contact resistance of the porous silicon and silver metal Ohmic contact structure. Semicond Sci Technol 20(9):966

Wang YH, Lee CY, Lin CH, Fu LM (2008) Enhanced sensing characteristics in MEMS-based formaldehyde gas sensors. Microsyst Technol 14:995–1000

Zhang GX (2005) Porous silicon: morphology and formation mechanisms, modern aspects of electrochemistiy, vol 39. Springer, New York

Zhang D, Wang K, Tong J, Xia B (2014) Characterization of layer-by-layer nano self-assembled carbon nanotube/polymer film sensor for ethanol gas sensing properties. Microsyst Technol 20:379–385

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Selvakumar, V.S., Sujatha, L. Fast response and recovery of nano-porous silicon based gas sensor. Microsyst Technol 26, 823–834 (2020). https://doi.org/10.1007/s00542-019-04622-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-019-04622-w