Abstract

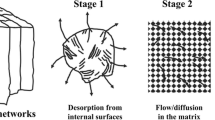

The influence of gas diffusion behavior on gas flow and permeability evolution in coal seams is evaluated in this paper. Coalbed methane (CBM) reservoirs differ from conventional porous media and fractured gas reservoirs due to certain unique features, which lead to two distinct gas pressures: one in fractures and the other in the coal matrix. The latter pressure, also known as the sorption pressure, will be used in calculating sorption-based volume changes. The effective stress laws for single-porosity media is not suitable for CBM reservoirs, and the effective stress laws for multi-porosity media need to be applied. The realization of the above two points is based on the study of the two-phase state of gas migration (involving Fickian diffusion and Darcy flow) in a coal seam. Then, a general porosity and permeability model based on the P-M model is proposed to fit this phenomenon. Moreover, the Klinkenberg effect has been taken into account and set as a reference object. Finally, a coupled gas flow and coal deformation model is proposed and solved by using a finite element method. The numerical results indicate that the effects of gas diffusion behavior and Klinkenberg behavior can have a critical influence on the gas pressure, residual gas content, and permeability evolution during the entire methane degasification period, and the impacts of the two effects are of the same order of magnitude. Without considering the gas diffusion effect, the gas pressure and residual gas content will be underestimated, and the permeability will be overestimated.

Similar content being viewed by others

Abbreviations

- \(p_{\text{f}}\) :

-

Pressure in the fractures (Pa)

- \(p_{\text{m}}\) :

-

Pressure in the matrix blocks (Pa)

- \(\sigma_{\text{c}}\) :

-

Coal matrix block shape factor (m−2)

- \(L\) :

-

Spacing between fractures (m)

- \(Q_{\text{s} }\) :

-

Gas exchange rate per volume of coal matrix (kg m−3 s−1)

- \(D\) :

-

Gas diffusion coefficient (m2 s−1)

- \(c_{\text{m}}\) :

-

Concentration of gas in the matrix blocks (kg m−3)

- \(c_{\text{f} }\) :

-

Concentration of gas in the fractures (kg m−3)

- \(Mc\) :

-

Molar mass of methane (kg mol−1)

- \(R\) :

-

The universal gas content (8.314 J mol−1 K−1)

- \(T\) :

-

Temperature (K)

- \(\tau\) :

-

Sorption time (s)

- \(m_{\text{m}}\) :

-

Quantity of adsorbed gas and free gas per volume of coal matrix blocks (kg m−3)

- \(V_{\text{L} }\) :

-

Maximum adsorption capacity of coal (kg m−3)

- \(P_{\text{L} }\) :

-

Langmuir pressure constant (Pa)

- \(\varepsilon_{\text{L}}\) :

-

Langmuir volumetric strain at infinite pore pressure

- \(\rho_{\text{c}}\) :

-

Coal density (kg m−3)

- \(\rho_{\text{gs}}\) :

-

Gas density under standard condition (kg m−3)

- \(\rho_{\text{g}}\) :

-

Gas density (kg m−3)

- \(\phi_{\text{m}}\) :

-

Coal matrix porosity

- \(\phi_{\text{f}}\) :

-

Fracture porosity

- \(V_{\text{M}}\) :

-

Molar volume of methane under standard condition (m3 mol−1)

- \(V\) :

-

Gas velocity in fractures (m s−1)

- \(k_{\text{e}}\) :

-

Effective gas permeability (m2)

- \(k_{\infty }\) :

-

Absolute gas permeability (m2)

- \(k_{\text{f}}\) :

-

Permeability of fractures (m2)

- \(k_{\text{m}}\) :

-

Permeability of coal matrix (m2)

- \(\mu\) :

-

Methane viscosity (Pa s)

- \(b\) :

-

Klinkenberg factor (Pa)

- \(\sigma_{ij}^{\text{e}}\) :

-

The effective stress

- \(\sigma_{ij}\) :

-

The total stress

- \(\delta_{ij}\) :

-

The Kronecker delta (1 for \(i = j\) and 0 for \(i \ne j\))

- \(\beta_{\text{m}}\) :

-

Effective stress coefficient for pore

- \(\beta_{\text{f}}\) :

-

Effective stress coefficient for fracture

- \(K\) :

-

Bulk modulus of coal (MPa)

- \(K_{\text{m}}\) :

-

Bulk modulus of coal grains (MPa)

- \(K_{\text{s}}\) :

-

Bulk modulus of coal skeleton (MPa)

- \(E\) :

-

Young’s modulus of coal (MPa)

- \(E_{\text{m}}\) :

-

Young’s modulus of coal grains (MPa)

- \(\upsilon\) :

-

Poisson’s ratio of coal

- \(M\) :

-

Constrained axial modulus (MPa)

- \(\varepsilon_{ij}\) :

-

Component of the total strain tensor

- \(\varepsilon_{\text{v}}\) :

-

Volumetric strain of coal matrix

- \(F_{i}\) :

-

Component of the body force in the i-direction

- \(u_{i}\) :

-

Component of the displacement in the i-direction

- \(f\) :

-

A fraction (0–1)

- \(\gamma\) :

-

Grain compressibility (Pa−1)

- \(r_{\text{c}}\) :

-

Radius of the analyzed zone (m)

- \(r_{{\text{w}} }\) :

-

Radius of the injection well (m)

- \(h\) :

-

Thickness of the analyzed zone (m)

- \(d\varepsilon_{\text{g}}\) :

-

Incremental grain volume strain

- \(d\varepsilon_{\text{r}}\) :

-

Incremental rock volume strain

- \(d\varepsilon_{\text{p}}\) :

-

Incremental pore volume strain

- 0:

-

Initial value of the variable

- m:

-

Matrix

- f:

-

Fracture

- c:

-

Coal

- g:

-

Gas

References

Al-Hussainy R, Ramey HJ Jr, Crawford PB (1966) The flow of real gases through porous media. J Petrol Technol 18(5):624–636

An F-H, Cheng Y-P, Wang L, Li W (2013) A numerical model for outburst including the effect of adsorbed gas on coal deformation and mechanical properties. Comput Geotech 54:222–231

Biot MA (1935) Le problème de la consolidation des matières argileuses sous une charge. Ann Soc Sci Bruxelles B 55:110–113

Biot MA (1941) General theory of three-dimensional consolidation. J Appl Phys 12(2):155–164

Chen D, Pan Z, Liu J, Connell LD (2012a) Characteristic of anisotropic coal permeability and its impact on optimal design of multi-lateral well for coalbed methane production. J Petrol Sci Eng 88–89:13–28. doi:10.1016/j.petrol.2012.04.003

Chen Z, Liu J, Pan Z, Connell LD, Elsworth D (2012b) Influence of the effective stress coefficient and sorption-induced strain on the evolution of coal permeability: model development and analysis. Int J Greenhouse Gas Control 8:101–110

Chilingar GV (1964) Relationship between porosity, permeability, and grain-size distribution of sands and sandstones. Dev Sedimentol 1:71–75

COMSOL AB (2008) COMSOL Multiphysics, version 3.5a. User’s Guide. COMSOL AB

Detournay E, Cheng AH-D (1993) Fundamentals of poroelasticity. In: Hudson JA (ed) Comprehensive rock engineering. Pergamon Press, Oxford

Durucan S, Ahsanb M, Shia J-Q (2009) Matrix shrinkage and swelling characteristics of European coals. Energy Procedia 1(1):3055–3062

Flores RM (1998) Coalbed methane: from hazard to resource. Int J Coal Geol 35(1):3–26

Gilman A, Beckie R (2000) Flow of coal-bed methane to a gallery. Transp Porous Media 41(1):1–16

Gray I (1987) Reservoir engineering in coal seams: Part 1—The physical process of gas storage and movement in coal seams. SPE Reserv Eng 2(1):28–34

He T-C, Qin Y, Zhang X-M, Wng D (2007) CBM exploration and exploitation technology. China University of Mining and Technology Press, Xuzhou

Hu G, Wang H, Fan X, Yuan Z, Hong S (2009) Mathematical model of coalbed gas flow with Klinkenberg effects in multi-physical fields and its analytic solution. Transp Porous Media 76(3):407–420

Jones FO, Owens WW (1980) A laboratory study of low-permeability gas sands. J Petrol Technol 32(9):1631–1640

King GR, Ertekin T, Schwerer F (1986) Numerical simulation of the transient behavior of coal-seam degasification wells. SPE Form Eval 1(2):165–183

Klinkenberg LJ (1941) The permeability of porous media to liquids and gases. Paper presented at the API 11th Mid-year Meeting, Tulsa, Oklahoma, May 1941

Kriz I, Pultr A (2013) Multivariable differential calculus. In: Introduction to mathematical analysis. Springer, New York, pp 65–95

Levine JR (1996) Model study of the influence of matrix shrinkage on absolute permeability of coal bed reservoirs. Geol Soc Lond Spec Publ 109(1):197–212

Lim KT, Aziz K (1995) Matrix–fracture transfer shape factors for dual-porosity simulators. J Petrol Sci Eng 13(3):169–178

Liu H-L, Wang H-Y, Zhang J-B (2000) Calculation of coal bed gas resorption time and analysis of its influential factors. Exp Petrol Geol 22(4):365–367

Liu J, Chen Z, Elsworth D, Qu H, Chen D (2011) Interactions of multiple processes during CBM extraction: a critical review. Int J Coal Geol 87(3–4):175–189. doi:10.1016/j.coal.2011.06.004

Liu S, Harpalani S, Pillalamarry M (2012) Laboratory measurement and modeling of coal permeability with continued methane production: Part 2—Modeling results. Fuel 94:117–124

Mian C, Zhida C (1999) Effective stress laws for multi-porosity media. Appl Math Mech 20(11):1207–1213

Mitra A, Harpalani S, Liu S (2012) Laboratory measurement and modeling of coal permeability with continued methane production: Part 1—Laboratory results. Fuel 94:110–116

Moore TA (2012) Coalbed methane: a review. Int J Coal Geol 101:36–81

Mora CA, Wattenbarger RA (2009) Analysis and verification of dual porosity and CBM shape factors. J Can Pet Technol 48(2):17–21

Nie R-S, Meng Y-F, Guo J-C, Jia Y-L (2012) Modeling transient flow behavior of a horizontal well in a coal seam. Int J Coal Geol 92:54–68

Pabst W, Gregorová E, Tichá G (2006) Elasticity of porous ceramics—a critical study of modulus–porosity relations. J Eur Ceram Soc 26(7):1085–1097

Palmer I (2009) Permeability changes in coal: analytical modeling. Int J Coal Geol 77(1–2):119–126. doi:10.1016/j.coal.2008.09.006

Palmer I, Mansoori J (1998) How permeability depends on stress and pore pressure in coalbeds: a new model. SPE Reservoir Eval Eng 1(6):539–544

Pan Z, Connell LD (2012) Modelling permeability for coal reservoirs: a review of analytical models and testing data. Int J Coal Geol 92:1–44. doi:10.1016/j.coal.2011.12.009

Pillalamarry M, Harpalani S, Liu S (2011) Gas diffusion behavior of coal and its impact on production from coalbed methane reservoirs. Int J Coal Geol 86(4):342–348

Purl R, Evanoff J, Brugler M (1991) Measurement of coal cleat porosity and relative permeability characteristics. In: SPE Gas Technology Symposium, Houston, Texas, January 1991

Reda DC (1985) Slip-flow experiments in welded tuff: the Knudsen diffusion problem. Sandia National Laboratories, Albuquerque

Rice JR, Cleary MP (1976) Some basic stress diffusion solutions for fluid-saturated elastic porous media with compressible constituents. Rev Geophys 14(2):227–241

Rudnicki J (1985) Effect of pore fluid diffusion on deformation and failure of rock. In: Bažant ZP (ed) Mechanics of geomaterials. Wiley, New York, pp 315–347

Seidle JP, Huitt LG (1995) Experimental measurement of coal matrix shrinkage due to gas desorption and implications for cleat permeability increases. In: International Meeting on Petroleum Engineering, Beijing, China, November 1995

Shi JQ, Durucan S (2004) Drawdown induced changes in permeability of coalbeds: a new interpretation of the reservoir response to primary recovery. Transp Porous Media 56(1):1–16

Tabatabaei M, Zhu D (2010) Generalized inflow performance relationships for horizontal gas wells. J Nat Gas Sci Eng 2(2):132–142

Terzaghi Kv (1923) Die berechnung der durchlassigkeitsziffer des tones aus dem verlauf der hydrodynamischen spannungserscheinungen. Sitzungsber Akad Wiss Wien 132(3–4):125–138

Thararoop P, Karpyn ZT, Ertekin T (2012) Development of a multi-mechanistic, dual-porosity, dual-permeability, numerical flow model for coalbed methane reservoirs. J Nat Gas Sci Eng 8:121–131

Tuncay K, Corapcioglu MY (1995) Effective stress principle for saturated fractured porous media. Water Resour Res 31(12):3103–3106

Valliappan S, Zhang W (1996) Numerical modelling of methane gas migration in dry coal seams. Int J Numer Anal Meth Geomech 20(8):571–593

Wang JG, Kabir A, Liu J, Chen Z (2012) Effects of non-Darcy flow on the performance of coal seam gas wells. Int J Coal Geol 93:62–74

Wu Y-S, Pruess K (1998) Gas flow in porous media with Klinkenberg effects. Transp Porous Media 32(1):117–137

Wu Y, Liu J, Elsworth D, Chen Z, Connell L, Pan Z (2010) Dual poroelastic response of a coal seam to CO2 injection. Int J Greenhouse Gas Control 4(4):668–678

Zahner B (1997) Application of material balance to determine ultimate recovery of a San Juan Fruitland coal well. In: SPE Annual Technical Conference and Exhibition, October, San Antonio, Texas

Zhang J (2002) Dual-porosity approach to wellbore stability in naturally fractured reservoirs. University of Oklahoma, Norman

Zhang J (2013) Borehole stability analysis accounting for anisotropies in drilling to weak bedding planes. Int J Rock Mech Min Sci 60:160–170

Zhang J, Roegiers J-C (2005) Double porosity finite element method for borehole modeling. Rock Mech Rock Eng 38(3):217–242. doi:10.1007/s00603-005-0052-9

Zhang J, Bai M, Roegiers J-C (2003) Dual-porosity poroelastic analyses of wellbore stability. Int J Rock Mech Min Sci 40(4):473–483. doi:10.1016/s1365-1609(03)00019-4

Zhang J, Roegiers J-C, Bai M (2004) Dual-porosity elastoplastic analyses of non-isothermal one-dimensional consolidation. Geotech Geol Eng 22(4):589–610

Zhang J, Bai M, Roegiers J-C (2006) On drilling directions for optimizing horizontal well stability using a dual-porosity poroelastic approach. J Petrol Sci Eng 53(1):61–76

Zhang H, Liu J, Elsworth D (2008) How sorption-induced matrix deformation affects gas flow in coal seams: a new FE model. Int J Rock Mech Min Sci 45(8):1226–1236. doi:10.1016/j.ijrmms.2007.11.007

Zhao Y, Hu Y, Zhao B, Yang D (2004) Nonlinear coupled mathematical model for solid deformation and gas seepage in fractured media. Transp Porous Media 55(2):119–136

Zhu WC, Liu J, Sheng JC, Elsworth D (2007) Analysis of coupled gas flow and deformation process with desorption and Klinkenberg effects in coal seams. Int J Rock Mech Min Sci 44(7):971–980

Zuber M, Sawyer W, Schraufnagel R, Kuuskraa V (1987) The use of simulation and history matching to determine critical coalbed methane reservoir properties. In: Low Permeability Reservoirs Symposium, Denver, Colorado, May 1987

Zutshi A, Harpalani S (2004) Matrix swelling with CO2 injection in a CBM reservoir and its impact on permeability of coal. In: International Coalbed Methane Symposium, University of Alabama, Tuscaloosa, Alabama, May 2004, pp 12–14

Acknowledgments

This work was supported by the Natural Science Foundation for the Youth of China (no. 51204173), the National Basic Research Program of China (973 Program, no. 2011CB201204), the Natural Science Foundation of China (no. 51004106), and the National Science Foundation for the Youth of China (no. 41202118).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A

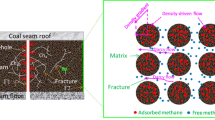

The common conceptual model applied to coal is that it is a dual-porosity reservoir, where gas is mostly stored in the coal matrix and Darcy fluid flow occurs in the natural fracture system (the contribution of flow in the coal matrix to Darcy flow can be neglected) (Purl et al. 1991; Pan and Connell 2012). The permeability of a coalbed is a function of its fracture system. Thus, many typical CBM reservoir models treat the CBM system as a dual-porosity, single-permeability scheme, with the implication that the coal matrix serves as storage and provides a source for the fracture network, while the fluids can only flow through the fractures (Thararoop et al. 2012; Palmer 2009; Pan and Connell 2012; Liu et al. 2011). In this paper, the CBM reservoir has also been treated as a dual-porosity, single-permeability scheme.

The derivation of P-M model starts from the following equation of linear elasticity for strain changes in porous rock (Palmer and Mansoori 1998):

where \(d\varepsilon_{\text{g}}\) is the incremental grain volume strain, \(d\varepsilon_{\text{r}}\) is the incremental rock volume strain, \(d\varepsilon_{\text{p}}\) is the incremental pore volume strain, and \(\phi\) is the natural fracture porosity [see the nomenclature of Palmer and Mansoori (1998)]. In this paper, \(\phi_{\text{f}}\) is used to denote the fracture porosity in order to distinguish between it and the matrix porosity, so in the following, \(\phi\) is replaced by \(\phi_{\text{f}} .\)

The theory of single-porosity poroelasticity has been used by Palmer and Mansoori (1998) to achieve the relation between porosity change and effective stress change:

where \(f\) is a fraction ranging from 0 to1, \(\gamma\) is the grain compressibility, Pa−1, \(\alpha\) is the grain thermal expansively, °F−1, and \((d\sigma - dp)\) denotes the change of the effective stress (\(\sigma_{\text{e}} = \sigma - \beta_{\text{p}} p ,\) where \(\beta_{\text{p}}\) ranges from 0 to 1, positive in compression), and it was obtained by using the effective stress law for a single-porosity system. As analyzed in the previous section, the effective stress law for dual-porosity media [see Eq. (16)] is more suitable for obtaining the effective stress changes; thus, the relation between porosity change and effective stress change can be obtained based on the dual-porosity poroelastic theory as:

According to Palmer and Mansoori (1998), the fracture porosity, \(\phi_{\text{f}} \ll 1 ,\) as is the case in coalbeds, and there is no change in overburden stress under uniaxial strain conditions, \(d\sigma = 0 ,\) and grain compressibility is set to zero, \(\gamma = 0\) [see Table 1 of Palmer and Mansoori (1998)]. The term \(dT =\) is a temperature expansion/contraction term; this is directly analogous to matrix shrinkage. And the pressure in coal matrix, \(p_{\text{m}} ,\) rather than the pressure \(p\) (without considering the effects of diffusion behavior), is used to calculate the matrix shrinkage. By direct analogy, for incremental rock volume strain (i.e., increase in strain per unit temperature or pressure change), we have:

and:

Equation (A5) can be easily converted to a total differential form:

Based on the theory of multivariable differential calculus (Kriz and Pultr 2013), we have:

Dividing by \(\phi_{\text{f}0}\) leads to:

Equation (A8) is the same as Eq. (23). It is clear that there is a relationship between fracture porosity, permeability, and the grain size distribution in porous media. Chilingar (1964) defined this relationship as:

where \(d_{\text{e}}\) is the effective diameter of grains. Based on this equation, we obtain the widely used cubic law as:

where \(k_{\infty }\) and \(k_{\infty 0}\) are the absolute permeability and initial absolute permeability, respectively. For the fracture porosity, \(\phi_{\text{f}} \ll 1 ,\) as is the case in coalbeds, we obtain:

Equation (A11) is the same as Eq. (24).

Appendix B

See Table 5.

Rights and permissions

About this article

Cite this article

Liu, Q., Cheng, Y., Zhou, H. et al. A Mathematical Model of Coupled Gas Flow and Coal Deformation with Gas Diffusion and Klinkenberg Effects. Rock Mech Rock Eng 48, 1163–1180 (2015). https://doi.org/10.1007/s00603-014-0594-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-014-0594-9