Abstract

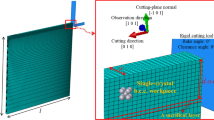

In this study, micro-machining of f.c.c. single-crystal materials was investigated based on a hybrid modelling approach combining smoothed particle hydrodynamics and continuum finite element analysis. The numerical modelling was implemented in the commercial software ABAQUS/Explicit by employing a user-defined subroutine VUMAT for a crystal plasticity formulation to gain insight into the underlying mechanisms that drive a plastic response of materials in high deformation processes. The numerical studies demonstrate that cutting force variations in different cutting directions are similar for different f.c.c. crystals even though the magnitudes of the cutting forces are different.

Similar content being viewed by others

References

Okazaki Y., Mishima N., Ashida K.: Microfactory: concept, history, and developments. J. Manuf. Sci. Eng. 126(4), 837–844 (2004)

Masuzawa T.: State of the art of micromachining. CIRP Ann. Manuf. Technol. 49(2), 473–488 (2000)

Zahedi S.A., Demiral M., Roy A., Silberschmidt V.V.: FE/SPH modelling of orthogonal micro-machining of f.c.c. single crystal. Comput. Mater. Sci. 78, 104–109 (2013)

Zahedi S.A., Roy A., Silberschmidt V.V.: Modeling of micro-machining single-crystal f.c.c. metals. Proc. CIRP 8, 346–350 (2013)

Sato M., Kato Y., Aoki S., Ikoma A.: Effects of crystal orientation on the cutting mechanism of the aluminum single crystal: 2nd report: on the (111) plane and the (112) end cutting. Bull. JSME 26(215), 890–896 (1983)

Lee W., Yang W.: Methodology and applications of mesoplasticity in manufacturing sciences. Int. J. Mech. Sci. 35(12), 1079–1095 (1993)

Lee W.B., To S., Sze Y.K, Cheung C.F.: Effect of material anisotropy on shear angle prediction in metal cutting—a meso-plasticity approach. Int. J. Mech. Sci. 45(10), 1739–1749 (2003)

Shirakashi T., Yoshino M., Kurashima H.: Study on cutting mechanism of single crystal based on simple shear plane model. Int. J. Jpn. Precis. Eng. 25(2), 96–97 (1991)

Lawson B.L., Kota N., Ozdoganlar O.B.: Effects of crystallographic anistropy on orthogonal micromachining of single-crystal aluminium. Tran. ASME-B-J. Manuf. Sci. Eng. 130(3), 316–319 (2008)

Chunhui J., Jing S., Zhanqiang L., Yachao W.: Comparison of tool–chip stress distributions in nano-machining of mono-crystalline silicon and copper. Int. J. Mech. Sci. 77, 30–39 (2013)

Komanduri R., Chandrasekaran N., Raff L.: MD simulation of exit failure in nanometric cutting. Mater. Sci. Eng. A 311(1), 1–12 (2001)

Cai M.B., Li X.P., Rahman M.: Study of the mechanism of nano-scale ductile mode cutting of silicon using molecular dynamics simulation. Int. J. Mach. Tools Manuf. 47, 75–80 (2007)

Hutchinson J.: Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. Lond. A. Math. Phys. Eng. Sci. 348, 101–127 (1976)

Peirce D., Asaro R.J., Needleman A.: An analysis of nonuniform and localized deformation in crystalline solids. Acta. Metal. 30, 1087–1093 (1982)

Huang, Y.: A User-Material Subroutine Incorporating Single Crystal Plasticity in the ABAQUS Finite Element Program. Harvard University Press, Cambridge (1991)

Kysar, J.: Addendum to a user-material subroutine incorporating single crystal plasticity in the ABAQUS finite element program. Mech. Report 178. Division of engineering and applied sciences, Harvard University, Cambridge, MA (1997)

Zahedi, S.A.: Crystal plasticity modelling of machining, Ph.D. thesis, Loughborough University (2014)

Zahedi S.A., Demiral M., Roy A., Babitsky V.I., Silberschmidt V.V.: Indentation in fcc single crystals. Solid State Phenom. 188, 219–225 (2012)

Demiral, M.: Enhanced gradient crystal-plasticity study of size effects in b.c.c. metal, Ph.D. thesis (2012)

Wang Y., Raabe D., Klüber C., Roters F.: Orientation dependence of nanoindentation pile-up patterns and of nanoindentation microtextures in copper single crystals. Acta Mater. 52(8), 2229–2238 (2004)

Groh S., Marin E., Horstemeyer M., Zbib H.: Multiscale modelling of the plasticity in an aluminum single crystal. Int. J. Plast. 25(8), 1456–1473 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abolfazl Zahedi, S., Roy, A. & Silberschmidt, V.V. Variation of cutting forces in machining of f.c.c. single crystals. Acta Mech 227, 3–9 (2016). https://doi.org/10.1007/s00707-015-1418-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-015-1418-z