Abstract

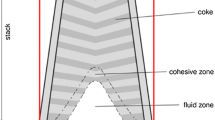

The computational fluid dynamics–discrete element method approach, supported by an averaging technique, has been employed to quantitatively investigate the stress distributions of solid flow in a model blast furnace (BF). The results indicate that large normal stresses are mainly observed in the lower central part of the BF, whilst small normal stresses in the vicinity of the raceway. In the upper part, the vertical normal stress varies little horizontally in the central region but reduces a bit near the wall, whereas the horizontal normal stress has a relatively uniform distribution on the whole cross section. The shear stress has its largest magnitude in two symmetrical regions close to the stagnant zone. The couple stress can be ignored except for the regions close to the walls. The stress and couple stress are both affected by gas flow rate. In particular, increasing gas flow rate will decrease the magnitude of the stress and couple stress. The internal friction coefficient is not dependent on the inertial number for the solid flow in a BF, but it may rely on the inertial number in some specific flow regions for the cases without gas and with low gas flow rates.

Similar content being viewed by others

References

Yagi J.I.: Mathematical modelling of the flow of four fluids in a packed bed. ISIJ Int. 33, 619–639 (1993). doi:10.2355/isijinternational.33.619

Dong X.F., Yu A.B., Yagi J.I., Zulli P.: Modelling of multiphase flow in a blast furnace: Recent developments and future work. ISIJ Int. 47, 1553–1570 (2007). doi:10.2355/isijinternational.47.1553

Khodak L., Borisov Y.: Velocity and pressure distributions of moving granular materials in a model of a shaft kiln. Powder Technol. 4, 187–194 (1970/1971). doi:10.1016/0032-5910(71)80034-7

Takahashi H., Komatsu N.: Cold model study on burden behaviour in the lower part of blast furnace. ISIJ Int. 33, 655–663 (1993). doi:10.2355/isijinternational.33.655

Inada T., Matsukura Y., Yaeda M., Matsumura S.I., Komatsu S., Yamamoto T., Onishi M.: Behavior of stress field in packed bed of Kokura No. 2 Blast Furnace during filling and after blow-in. ISIJ Int. 43, 1376–1383 (2003). doi:10.2355/isijinternational.43.1376

Zhang S.J., Yu A.B., Zulli P., Wright B., Tuzun U.: Modelling of the solids flow in a blast furnace. ISIJ Int. 38, 1311–1319 (1998). doi:10.2355/isijinternational.38.1311

Takahashi H., Kawai H., Suzuki Y.: Analysis of stress and buoyancy for solids flow in the lower part of a blast furnace. ISIJ Int. 57, 215–226 (2002)

Zaimi S.A., Akiyama T., Guillot J.B., Yagi J.I.: Validation of a blast furnace solid flow model using reliable 3-D experimental results. ISIJ Int. 40, 332–341 (2000). doi:10.2355/isijinternational.40.332

Zhou Z.Y., Yu A.B., Zulli P.: A simplified mathematical model for gas–solid flow in a blast furnace. Prog. Comput. Fluid Dyn. 4, 39–45 (2004). doi:10.1504/PCFD.2004.003786

Zaimi S.A., Akiyama T., Guillot J.B., Yagi J.I.: Sophisticated multi-phase multi-flow modelling of the blast furnace. ISIJ Int. 40, 322–331 (2000). doi:10.2355/isijinternational.40.322

Jackson R.: The Dynamics of Fluidized Particles. Cambridge University Press, Cambridge (2000)

Tsuji Y., Kawaguchi T., Tanaka T.: Discrete particle simulation of 2-dimensional fluidized-bed. Powder Technol. 77, 79–87 (1993). doi:10.1016/0032-5910(93)85010-7

Xu B.H., Yu A.B.: Numerical simulation of the gas–solid flow in a fluidized bed by combining discrete particle method with computational fluid dynamics. Chem. Eng. Sci. 52, 2785–2809 (1997). doi:10.1016/S0009-2509(97)00081-X

Zhu H.P., Zhou Z.Y., Yang R.Y., Yu A.B.: Discrete particle simulation of particulate systems: Theoretical developments. Chem. Eng. Sci. 62, 3378–3396 (2007). doi:10.1016/j.ces.2006.12.089

Zhu H.P., Zhou Z.Y., Yang R.Y., Yu A.B.: Discrete particle simulation of particulate systems: a review of major applications and findings. Chem. Eng. Sci. 63, 5728–5770 (2008). doi:10.1016/j.ces.2008.08.006

Latzel M., Luding S., Herrmann H.J.: Macroscopic material properties from quasi-static, microscopic simulations of a two-dimensional shear-cell. Granul. Matter 2, 123–135 (2000). doi:10.1007/s100350000048

Zhu H.P., Yu A.B.: Averaging method of granular materials. Phys. Rev. E Stat. Nonlin. Soft Matter Phys. 66, 021302 (2002). doi:10.1103/PhysRevE.66.021302

Zhou Z.Y., Zhu H.P., Yu A.B., Wright B., Pinson D., Zulli P.: Discrete particle simulation of solid flow in a model blast furnace. ISIJ Int. 45, 1828–1837 (2005). doi:10.2355/isijinternational.45.1828

Zhou Z.Y., Zhu H.P., Yu A.B., Wright B., Zulli P.: Discrete particle simulation of gas–solid flow in a blast furnace. Comput. Chem. Eng. 32, 1760–1772 (2008). doi:10.1016/j.compchemeng.2007.08.018

Katayama K., Wakabayashi S., Inada T., Takatani K., Yamaoka H.: Stress analysis of the packed bed in blast furnace. Tetsu-to-Hagane 83, 91–96 (1997)

Nouchi T., Sato T., Sato M., Takeda K., Ariyama T.: Stress field and solid flow analysis of coke packed bed in blast furnace based on DEM. ISIJ Int. 45, 1426–1431 (2005). doi:10.2355/isijinternational.45.1426

Zhu H.P., Yu A.B.: The effects of wall and rolling resistance on the couple stress of granular materials in vertical flow. Phys. A-Stat. Mech. Its Appl. 325, 347–360 (2003). doi:10.1016/S0378-4371(03)00143-2

Xu B.H., Yu A.B., Chew S.J., Zulli P.: Numerical simulation of the gas–solid flow in a bed with lateral gas blasting. Powder Technol. 109, 13–26 (2000). doi:10.1016/S0032-5910(99)00223-5

Di Felice R.: The voidage function for fluid–particle interaction systems. Int. J. Multiph. Flow 20, 153–159 (1994). doi:10.1016/0301-9322(94)90011-6

Cundall P.A., Strack O.D.L.: A discrete numerical model for granular assemblies. Geotechnique 29, 47–65 (1979)

Patankar S.V.: Numerical Heat Transfer and Fluid Flow. Hemisphere, New York (1980)

Zhu H.P., Yu A.B.: Steady-state granular flow in a 3D cylindrical hopper with flat bottom: macroscopic analysis. Granul. Matter 7, 97–107 (2005). doi:10.1007/s10035-004-0191-9

Moreea S.B.M., Nedderman R.M.: Exact stress and velocity distributions in a cohesionless material discharging from a conical hopper. Chem. Eng. Sci. 51, 3931–3942 (1996). doi:10.1016/0009-2509(96)00248-5

Gremaud, P.A., Matthews, J.V., Shearer, M.: Similarity solutions for granular materials in hoppers. In: Bona J., Saxton K., Saxton R. (eds.) Nonlinear PDE’s, Dynamics, and Continuum Physics, Contemporary Mathematics, vol. 255, pp. 79–95. AMS, Providence (2000)

Potapov A.V., Campbell C.S.: Computer simulation of hopper flow. Phys. Fluids 8, 2884–2894 (1996). doi:10.1063/1.869069

Jop P., Forterre Y., Pouliquen O.: A constitutive law for dense granular flows. Nature 441, 727–730 (2006). doi:10.1038/nature04801

Luding S.: The effect of friction on wide shear bands. Particul. Sci. Technol. 26, 33–42 (2008). doi:10.1080/02726350701759167

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, H.P., Zhou, Z.Y., Yu, A.B. et al. Stress fields of solid flow in a model blast furnace. Granular Matter 11, 269–280 (2009). https://doi.org/10.1007/s10035-008-0123-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-008-0123-1