Abstract

Carbon capture and storage is an emerging technology to mitigate carbon dioxide (CO2) emissions from industrial sources such as power plants. Post-combustion capture based on aqueous amine scrubbing is one of the most promising technologies for CO2 capture currently. This technology, however, possesses a number of shortcomings, including high regeneration energy requirement, high solvent loss, degradation of solvent, etc. To overcome these limitations, researchers suggested different solvents and alternative technologies to replace the current amine scrubbing technique. Ionic liquids (ILs) are the most potential substitute among all. This is mainly because they have negligible vapour pressure and high thermal stability, which reduce solvent loss. However, there are up to a million possible combinations of cation and anion that may make up the ILs, which makes experimental works very time consuming and costly. In this work, optimal IL solvents specifically for carbon capture purpose are designed using computer-aided molecular design approach. This approach utilises group contribution method to estimate the thermophysical properties of ILs, and UNIFAC model to predict CO2 solubility in the ILs. Structural constraints are included to ensure that the synthesised ILs structure will satisfy the bonding requirement. This work focuses on design of ILs based on a physical absorption mechanism, and hence no chemical reaction is involved. The results show that the designed ILs are capable of capturing CO2 and their predicted properties are in good agreement with properties as determined through experimental works.

Similar content being viewed by others

Abbreviations

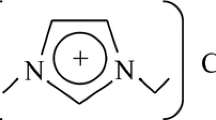

- [MIm]+ :

-

Methylimidazolium cation

- [Im]+ :

-

Imidazolium cation

- [BF4]− :

-

Tetrafluoroborate anion

- [PF6]− :

-

Hexafluorophosphate anion

- [Cl]− :

-

Chloride anion

- i :

-

Component (i = 1, 2, …, p)

- j :

-

Organic functional groups (j = 1, 2, …, r)

- k :

-

Groups (k = 1, 2, …, q)

- m :

-

Cation groups (m = 1, 2, …, s)

- n :

-

Anion groups (n = 1, 2, …, t)

- a :

-

Coefficient in the model equation for the density

- a mn :

-

UNIFAC group interaction parameter between group m and n

- A i :

-

Constant for group I in Antoine equation

- A k,μ :

-

Contribution of group k to parameter A

- b :

-

Coefficient in the model equation for the density

- B i :

-

Constant for group i in Antoine equation

- B k,μ :

-

Contribution of group k to parameter B

- c :

-

Coefficient in the model equation for the density

- C i :

-

Constant for group i in Antoine equation

- G CH3, m :

-

Number of CH3 groups in cation m

- N :

-

Avogadro constant

- n k :

-

Free bond number of group k

- P :

-

System pressure (MPa)

- Q k , Q m , Q n :

-

Group surface area parameter in the UNIFAC model

- R k :

-

Group volume parameter in the UNIFAC model

- T :

-

System temperature (K)

- V k :

-

Molecular volume of group k

- A :

-

Coefficient in the model equation for the viscosity

- B :

-

Coefficient in the model equation for the viscosity

- F i :

-

Auxiliary property for component i (surface fraction/mole fraction)

- g CH3 :

-

Number of CH3 groups in the selected cation

- M :

-

Molecular weight (g mol−1)

- \(P_{i}^{S}\) :

-

Saturated vapour pressure of component i (MPa)

- q i :

-

Parameter relative to the molecular van der Waals surface areas of pure component i

- r i :

-

Parameter relative to the molecular van der Waals volumes of pure component i

- V :

-

Molecular volume (Å3)

- V i :

-

Auxiliary property of component i

- v k , v m :

-

Number of group k or m

- \(v_{k}^{(i)}\), \(v_{m}^{(i)}\) :

-

Number of group k or m in component i

- x i :

-

Mole fraction of component i in gas phase

- x j :

-

Mole fraction of group j in the mixture

- X m , X n :

-

Fraction of group m or n in the mixture

- y i :

-

Mole fraction of component i in liquid phase

- α m :

-

Binary variable representing cation m

- β n :

-

Binary variable representing anion n

- μ :

-

Viscosity (Pa.s)

- ρ :

-

Density (g cm−3)

- ρ c :

-

Critical density (g cm−3)

- δ :

-

Reduced density

- ϕ r :

-

Reduced dimensionless Helmholtz function

- \(\phi_{\delta }^{r}\) :

-

Derivative of reduced dimensionless Helmholtz function

- φ i :

-

Gas-phase fugacity coefficient of component i

- γ i :

-

Activity coefficient of component i

- \(\gamma_{i}^{C}\) :

-

Combinatorial contribution to the activity coefficient of component i

- \(\gamma_{i}^{R}\) :

-

Residual contribution to the activity coefficient of component i

- Γ K :

-

Residual activity coefficient of group k

- \(\varGamma_{K}^{(i)}\) :

-

Residual activity coefficient of group k in pure component i

- θ m :

-

Fraction of group m in a mixture of the liquid phase

- ψ mk :

-

Group interaction parameter

References

Abu-Zahra MRM, Abbas Z, Singh P, Feron P (2013) Carbon dioxide post-combustion capture: solvent technologies overview, status and future directions. In: Mendez-Vilas A (ed) Materials and processes for energy: communicating current research and technological developments. Formatex Research Center, Badajoz, pp 923–934

Anthony JL, Aki SNVK, Maginn EJ, Brennecke JF (2004) Feasibility of using ionic liquids for carbon dioxide capture. Int J Environ Technol Manage 4:105–115

Anthony JL, Anderson JL, Maginn EJ, Brennecke JF (2005) Anion effects on gas solubility in ionic liquids. J Phys Chem B 109:6366–6374

Aroonwilas A, Veawab A (2004) Characterization and comparison of the CO2 absorption performance into single and blended alkanolamines in a packed column. Ind Eng Chem Res 43:2228–2237

Baltus RE, Culbertson BH, Dai S et al (2004) Low-pressure solubility of carbon dioxide in room-temperature ionic liquids measured with a quartz crystal microbalance. J Phys Chem B 108:721–727

Bandyopadhyay A (2011) Amine versus ammonia absorption of CO2 as a measure of reducing GHG emission: a critical analysis. Clean Technol Environ Policy 13:269–294

Bardow A, Steur K, Gross J (2010) Continuous-molecular targeting for integrated solvent and process design. Ind Eng Chem Res 49:2834–2840

Basavaraj RJ, Jayanti S (2014) Syngas-fueled, chemical-looping combustion-based power plant lay-out for clean energy generation. Clean Technol Environ Policy 17:237–247

Bates ED, Mayton RD, Ntai I, Davis JH (2002) CO2 capture by a task-specific ionic liquid. J Am Chem Soc 124:926–927

Billard I, Marcou G, Ouadi A, Varnek A (2011) In silico design of new ionic liquids based on quantitative structure-property relationship models of ionic liquid viscosity. J Phys Chem B 115:93–98

Blanchard LA, Hancu D, Beckman EJ, Brennecke JF (1999) Green processing using ionic liquids and CO2. Nature 399:28–29

Bonhôte P, Dias A-P, Armand M et al (1996) Hydrophobic, highly conductive ambient-temperature molten salts. Inorg Chem 35:1168–1178

Breckenridge WAH, Ong JOY, Sharp C (2000) Use of SELEXOL® process in coke gasification to ammonia project. Laurance Reid Gas Conditioning Conference. The University of Oklahoma Norman, Oklahoma, pp 1–17

Burr B, Lyddon L (2008) A comparison of physical solvents for acid gas removal. Gas Processors’ Association Convention, Grapevine

Chávez-Islas LM, Vasquez-medrano R, Flores-tlacuahuac A (2011) Optimal molecular design of ionic liquids for high-purity bioethanol production. Ind Eng Chem Res 50:5153–5168

Chremos A, Forte E, Papaioannou V et al (2013) Modelling the fluid phase behaviour of multifunctional alkanolamines and carbon dioxide using the SAFT-γ approach. Chem Eng Trans 35:427–432

Coutinho JAP, Carvalho PJ, Oliveira NMC (2012) Predictive methods for the estimation of thermophysical properties of ionic liquids. RSC Advances 2:7322–7346

Damartzis T, Papadopoulos AI, Seferlis P (2014) Optimum synthesis of solvent-based post-combustion CO2 capture flowsheets through a generalized modeling framework. Clean Technol Environ Policy 16:1363–1380

Eslick JC, Shulda SM, Spencer P, Camarda KV (2010) Optimization-based approaches to computational molecular design. In: Adjiman CS, Galindo A (eds) Molecular Systems Engineering. Wiley-VCH, Weinheim, pp 173–194

Figueroa JD, Fout T, Plasynski S et al (2008) Advances in CO2 capture technology—the US department of energy’s carbon sequestration program. Int J Greenhouse Gas Control 2:9–20

Freemantle M (2010) An introduction to ionic liquids. The Royal Society of Chemistry, Cambridge

Gani R (2004a) Chemical product design: challenges and opportunities. Comput Chem Eng 28:2441–2457

Gani R (2004b) Computer-aided methods and tools for chemical product design. Chem Eng Res Des 82:1494–1504

Gani R, Brignole EA (1983) Molecular design of solvents for liquid extraction based on UNIFAC. Fluid Phase Equilib 13:331–340

Gardas RL, Coutinho JAP (2008a) A group contribution method for viscosity estimation of ionic liquids. Fluid Phase Equilib 266:195–201

Gardas RL, Coutinho JAP (2008b) Extension of the Ye and Shreeve group contribution method for density estimation of ionic liquids in a wide range of temperatures and pressures. Fluid Phase Equilib 263:26–32

Gutkowski K, Shariati A, Peters CJ (2006) High-pressure phase behavior of the binary ionic liquid system 1-octyl-3-methylimidazolium tetrafluoroborate + carbon dioxide. J Supercrit Fluids 39:187–191

Hada S, Herring RH, Eden MR (2013) Design of ionic liquids using property clustering and decomposition techniques. In: Kraslawski A, Turunen I (eds) 23rd European symposium on computer aided process engineering. Elsevier, Amsterdam, pp 955–960

Han K, Ahn CK, Lee MS et al (2013) Current status and challenges of the ammonia-based CO2 capture technologies toward commercialization. Int J Greenh Gas Control 14:270–281

Hasaneen R, Elsayed NA, Barrufet MA (2014) Analysis of the technical, microeconomic, and political impact of a carbon tax on carbon dioxide sequestration resulting from liquefied natural gas production. Clean Technol Environ Policy 16:1597–1613

Hasib-ur-Rahman M, Siaj M, Larachi F (2010) Ionic liquids for CO2 capture—development and progress. Chem Eng Process 49:313–322

Hetland J (2009) Assessment of pre-combustion decarbonisation schemes for polygeneration from fossil fuels. Clean Technol Environ Policy 11:37–48

IEA (2013) World energy outlook special report 2013: redrawing the energy climate map, Paris

IPCC (2007) Climate change 2007: mitigation. contribution of working group III to the fourth assessment report of the intergovernmental panel on climate change

Karunanithi AT, Mehrkesh A (2013) Computer-aided design of tailor-made ionic liquids. AIChE J 59:4627–4640

Karunanithi AT, Achenie LEK, Gani R (2005) A new decomposition-based computer-aided molecular/mixture design methodology for the design of optimal solvents and solvent mixtures. Ind Eng Chem Res 44:4785–4797

Karunanithi AT, Achenie LEK, Gani R (2006) A computer-aided molecular design framework for crystallization solvent design. Chem Eng Sci 61:1247–1260

Kenarsari SD, Yang D, Jiang G et al (2013) Review of recent advances in carbon dioxide separation and capture. RSC Advances 3:22739–22773

Kuhlmann E, Himmler S, Giebelhaus H, Wasserscheid P (2007) Imidazolium dialkylphosphates—a class of versatile, halogen-free and hydrolytically stable ionic liquids. Green Chem 9:233–242

Lei Z, Zhang J, Li Q, Chen B (2009) UNIFAC model for ionic liquids. Ind Eng Chem Res 48:2697–2704

Lei Z, Dai C, Wang W, Chen B (2013) UNIFAC model for ionic liquid-CO2 systems. AIChE J 60:716–729

Li J-R, Ma Y, McCarthy MC et al (2011) Carbon dioxide capture-related gas adsorption and separation in metal-organic frameworks. Coord Chem Rev 255:1791–1823

Liebmann B, Friedl A, Carvalho Rodrigues JF (2012) Lignocellulosic biomass dissolution and fractioning using ionic liquids as a solvent. Chem Eng Trans 29:553–558

Mac Dowell N, Pereira FE, Llovell F et al (2011) Transferable SAFT-VR models for the calculation of the fluid phase equilibria in reactive mixtures of carbon dioxide, water, and n-alkylamines in the context of carbon capture. J Phys Chem B 115:8155–8168

Macchietto S, Odele O, Omatsone O (1990) Design of optimal solvents for liquid–liquid extraction and gas-absorption processes. Chem Eng Res Des 68:429–433

MacFarlane DR, Tachikawa N, Forsyth M et al (2014) Energy applications of ionic liquids. Energy Environ Sci 7:232–250

Maginn EJ (2007) Design and evaluation of ionic liquids as novel CO2 absorbents. pp 1–17

Maranas CD (1996) Optimal computer-aided molecular design : a polymer design case study. Ind Eng Chem Res 35:3403–3414

Marsh KN, Boxall JA, Lichtenthaler R (2004) Room temperature ionic liquids and their mixtures—a review. Fluid Phase Equilib 219:93–98

Matsuda H, Yamamoto H, Kurihara K, Tochigi K (2007) Computer-aided reverse design for ionic liquids by QSPR using descriptors of group contribution type for ionic conductivities and viscosities. Fluid Phase Equilib 261:434–443

McLeese SE, Eslick JC, Hoffmann NJ et al (2010) Design of ionic liquids via computational molecular design. Comput Chem Eng 34:1476–1480

Miyafuji H (2013) Liquefaction of wood by ionic liquid treatment. In: Kadokawa J (ed) Ionic liquids—New aspects for the future. InTech, pp 299–314

Olajire AA (2010) CO2 capture and separation technologies for end-of-pipe applications—a review. Energy 35:2610–2628

Palomar J, Gonzalez-Miquel M, Polo A, Rodriguez F (2011) Understanding the physical absorption of CO2 in ionic liquids using the COSMO-RS method. Ind Eng Chem Res 50:3452–3463

Papadopoulos AI, Stijepovic M, Linke P (2010) On the systematic design and selection of optimal working fluids for organic rankine cycles. Appl Therm Eng 30:760–769

Papadopoulos AI, Badr S, Chremos A et al (2014) Efficient screening and selection of post-combustion CO2 capture solvents. Chem Eng Trans 39:211–216

Pereira FE, Keskes E, Galindo A et al (2011) Integrated solvent and process design using a SAFT-VR thermodynamic description: high-pressure separation of carbon dioxide and methane. Comput Chem Eng 35:474–491

Plechkova NV, Seddon KR (2008) Applications of ionic liquids in the chemical industry. Chem Soc Rev 37:123–150

Qureshi ZS, Deshmukh KM, Bhanage BM (2013) Applications of ionic liquids in organic synthesis and catalysis. Clean Technol Environ Policy 16:1487–1513

Rai G, Kumar A (2013) Calorimetric elucidation of ionic interactions in room temperature ionic liquid solutions. Clean Technol Environ Policy 16:1529–1536

Ramdin M, de Loos TW, Vlugt TJH (2012) State-of-the-art of CO2 capture with ionic liquids. Ind Eng Chem Res 51:8149–8177

Rochelle GT (2009) Amine scrubbing for CO2 capture. Science 325:1652–1654

Rockström J, Steffen W, Noone K et al (2009) A safe operating space for humanity. Nature 461:472–475

Rogers RD, Seddon KR (2003) Ionic liquids—solvents of the future? Science 302:792–793

Roughton BC, Christian B, White J et al (2012) Simultaneous design of ionic liquid entrainers and energy efficient azeotropic separation processes. Comput Chem Eng 42:248–262

Sahinidis NV, Tawarmalani M, Yu M (2003) Design of alternative refrigerants via global optimization. AIChE J 49:1761–1775

Salazar J, Diwekar U, Joback K et al (2013) Solvent Selection for Post-Combustion CO2 Capture. Energy Procedia 37:257–264

Satyanarayana KC, Abildskov J, Gani R et al (2010) Computer aided polymer design using multi-scale modelling. Braz J Chem Eng 27:369–380

Seddon KR (1997) Ionic liquids for clean technology. J Chem Technol Biotechnol 68:351–356

Shariati A, Peters CJ (2004) High-pressure phase behavior of systems with ionic liquids. J Supercrit Fluids 30:139–144

Shiflett MB, Yokozeki A (2005) Solubilities and diffusivities of carbon dioxide in ionic liquids: [bmim][PF6] and [bmim][BF4]. Ind Eng Chem Res 44:4453–4464

Shiflett MB, Yokozeki A (2006) Solubility and diffusivity of hydrofluorocarbons in room-temperature ionic liquids. AIChE J 52:1205–1219

Skjold-Jørgensen S, Kolbe B, Gmehling J, Rasmussen P (1979) Vapor-liquid equilibria by UNIFAC group contribution. Revision and extension. Ind Eng Chem Process Des Dev 18:714–722

Song J, Song H (2008) Computer-aided molecular design of environmentally friendly solvents for separation processes. Chem Eng Technol 31:177–187

Span R, Wagner W (1996) A new equation of state for CO2 covering the fluid region from the triple point temperature to 1100 K at pressures up to 800 MPa. J Phys Chem Ref Data 25:1509–1596

Spigarelli BP, Kawatra SK (2013) Opportunities and challenges in carbon dioxide capture. J CO2 Util 1:69–87

Stavrou M, Lampe M, Bardow A, Gross J (2014) Continuous molecular targeting–computer-aided molecular design (CoMT–CAMD) for simultaneous process and solvent design for CO2 capture. Ind Eng Chem Res 53:18029–18041

Thee H, Suryaputradinata YA, Mumford KA et al (2012) A kinetic and process modeling study of CO2 capture with MEA-promoted potassium carbonate solutions. Chem Eng J 210:271–279

Torralba-Calleja E, Skinner J, Gutiérrez-Tauste D (2013) CO2 capture in ionic liquids: a review of solubilities and experimental methods. J Chem 2013:1–16

US Energy Information Administration (2013) International Energy Outlook 2013. Washington, DC, USA

Vaidyanathan R, El-Halwagi MM (1996) Computer-aided synthesis of polymers and blends with target properties. Ind Eng Chem Res 35:627–634

Valencia-marquez D, Flores-tlacuahuac A, Vasquez-medrano R (2012) Simultaneous optimal design of an extractive column and ionic liquid for the separation of bioethanol-water mixtures. Ind Eng Chem Res 51:5866–5880

Varun Bhat IK, Prakash R (2009) LCA of renewable energy for electricity generation systems—a review. Renew Sustain Energy Rev 13:1067–1073

Wappel D, Gronald G, Kalb R, Draxler J (2010) Ionic liquids for post-combustion CO2 absorption. Int J Greenh Gas Control 4:486–494

Weisser D (2007) A guide to life-cycle greenhouse gas (GHG) emissions from electric supply technologies. Energy 32:1543–1559

Welton T (1999) Room-temperature ionic liquids. Solvents for synthesis and catalysis. Chem Rev 99:2071–2084

Ye C, Shreeve JM (2007) Rapid and accurate estimation of densities of room-temperature ionic liquids and salts. J Phys Chem A 111:1456–1461

Yu C-H, Huang C-H, Tan C-S (2012) A review of CO2 capture by absorption and adsorption. Aerosol Air Qual Res 12:745–769

Zaman M, Lee JH (2013) Carbon capture from stationary power generation sources: a review of the current status of the technologies. Korean J Chem Eng 30:1497–1526

Zhou F, Liang Y, Liu W (2009) Ionic liquid lubricants: designed chemistry for engineering applications. Chem Soc Rev 38:2590–2599

Acknowledgments

The financial support from Faculty of Engineering Dean’s Ph.D. scholarship and NPRP Grant No 6-678-2-280 from the Qatar National Research Fund (a member of Qatar Foundation) are both gratefully acknowledged. The statements made herein are solely the responsibility of the authors.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

UNIFAC model is a well-established method to estimate activity coefficient and it is expressed as a function of composition and temperature, as shown in Eqs. (30)–(37). The model consists of a combinatorial contribution, ln \(\gamma_{i}^{C}\), which is essentially due to the differences in size and shape of the molecules, and a residual contribution, ln \(\gamma_{i}^{R}\), which is due to energetic interactions (Skjold-Jørgensen et al. 1979).

The combinatorial contribution can be determined using Eqs. (31)–(32).

where x j is the mole fraction of group j.

Pure component parameters r i and q i are relative to molecular van der Waals volumes and to molecular surface areas, respectively. They are calculated as the total of the group volume and group area parameters, R k and Q k , as shown in Eq. (33).

Residual contribution of the component can be determined as follows:

where Γ K is the residual activity coefficient of group k, and \(\varGamma_{k}^{(i)}\) is the residual activity of group k in reference solution containing only molecules of type i. These can be determined using Eqs. (35) and (36).

where X m is the fraction of group m in the mixture. The group interaction parameter ψ mk is defined by Eq. (37).

Parameter a nm characterises the interaction between groups n and m. For each group–group interaction, there are two parameters a nm and a mn , which are not the same.

Rights and permissions

About this article

Cite this article

Chong, F.K., Foo, D.C.Y., Eljack, F.T. et al. Ionic liquid design for enhanced carbon dioxide capture by computer-aided molecular design approach. Clean Techn Environ Policy 17, 1301–1312 (2015). https://doi.org/10.1007/s10098-015-0938-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-015-0938-5