Abstract

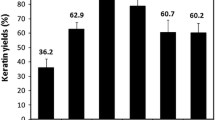

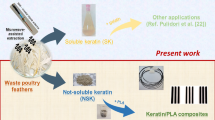

Feathers biomass from poultry industry is considered as an important waste product, which creates serious environmental problems. In this study, keratin was extracted from waste chicken feathers using sodium sulfide as a reducing agent under optimized conditions. The extracted keratin particles were used to develop a bioploymeric film by adding microcrystalline cellulose as nano-additive agent. The calculated yield of 80.2% was obtained for keratin from feathers dry weight 25 g (w/w). The extracted keratin was characterized using Fourier transform infrared spectroscopy, scanning electron microscopy (SEM), thermogravimetric analysis, differential scanning calorimetry, wide-angle X-ray diffraction. The physiochemical characteristics of the feathers were compared with the keratin powder. The regenerated keratin particles preserved their chemical composition, thermal strength and stability after chemical extraction. The extracted keratin particles showed 10–20-µm spongy porous microparticles in SEM analysis. The keratin powder was used to synthesize a bioplastic film using glycerol (3.5%) and microcrystalline cellulose (0.2%) in NaOH for 48 h at 60 °C. The calculated thickness of bioplastic film was 1.12 × 10−4 mm with tensile strength of 3.62 ± 0.6 MPa. The Young’s modulus and break elongation for synthesized bioplastic film were 1.52 ± 0.34 MPa and 15.8 ± 2.2%, respectively. The feather and keratin showed maximum similarity index of 64.74% (l-alanyl, l-alanyl, l-alanine, p-nitroanilide) and 64.32% with d-pantethine, respectively, using OMNIC Specta software. Overall, the study presented a highly efficient method to convert the waste feather biomass into a bioplastic film which can be used in biopolymer, biomedical and pharmaceutical industries.

Similar content being viewed by others

References

Sharma S et al (2016) Extraction and characterization of keratin from chicken feather waste biomass: a study

Aluigi A, Zoccola M, Vineis C, Tonin C, Ferrero F, Canetti M (2007) Study on the structure and properties of wool keratin regenerated from formic acid. Int J Biol Macromol 41:266–273

Aluigi A, Vineis C, Varesano A, Mazzuchetti G, Ferrero F, Tonin C (2008) Structure and properties of keratin/PEO blend nanofibres. Eur Polym J 44:2465–2475

Arai KM, Takahashi R, Yokote Y, Akahane K (1983) Amino-acid sequence of feather keratin from fowl. Eur J Biochem 132:501–507

Barone JR (2009) Lignocellulosic fiber-reinforced keratin polymer composites. J Polym Environ 17:143–151

Barone JR, Schmidt WF (2005) Polyethylene reinforced with keratin fibers obtained from chicken feathers. Compos Sci Technol 65:173–181

Bertsch A, Coello N (2005) A biotechnological process for treatment and recycling poultry feathers as a feed ingredient. Biores Technol 96:1703–1708

Brandelli A, Sala L, Kalil SJ (2015) Microbial enzymes for bioconversion of poultry waste into added-value products. Food Res Int 73:3–12

Cao J (2000) Is the α–β transition of keratin a transition of α-helices to β-pleated sheets? Part I. In situ XRD studies. J Mol Struct 553:101–107

Cavello I, Cavalitto S, Hours R (2012) Biodegradation of a keratin waste and the concomitant production of detergent stable serine proteases from Paecilomyces lilacinus. Appl Biochem Biotechnol 167:945–958

Dahl KH, McKinley-McKee JS (1981) The reactivity of affinity labels: a kinetic study of the reaction of alkyl halides with thiolate anions—a model reaction for protein alkylation. Bioorg Chem 10:329–341

Edwards H, Hunt D, Sibley M (1998) FT-Raman spectroscopic study of keratotic materials: horn, hoof and tortoiseshell. Spectrochim Acta Part A Mol Biomol Spectrosc 54:745–757

Endo R, Kamei K, Iida I, Kawahara Y (2008) Dimensional stability of waterlogged wood treated with hydrolyzed feather keratin. J Archaeol Sci 35:1240–1246

Eslahi N, Dadashian F, Nejad NH (2013) An investigation on keratin extraction from wool and feather waste by enzymatic hydrolysis. Prep Biochem Biotechnol 43:624–648

Fang Y, Catron B, Zhang Y, Zhao L, Caruso J, Hu Q (2010) Distribution and in vitro availability of selenium in selenium-containing storage protein from selenium-enriched rice utilizing optimized extraction. J Agric Food Chem 58:9731–9738

Feughelman M, Lyman D, Willis B (2002) The parallel helices of the intermediate filaments of α-keratin. Int J Biol Macromol 30:95–96

Fu K, Griebenow K, Hsieh L, Klibanov AM, Langera R (1999) FTIR characterization of the secondary structure of proteins encapsulated within PLGA microspheres. J Controll Release 58:357–366

Garrido T, Leceta I, de la Caba K, Guerrero P (2018) Chicken feathers as a natural source of sulphur to develop sustainable protein films with enhanced properties. Int J Biol Macromol 106:523–531

Guo Y, Tang H, Li G, Xie D (2014) Effects of cow dung biochar amendment on adsorption and leaching of nutrient from an acid yellow soil irrigated with biogas slurry. Water Air Soil Pollut 225:1820

Ha S-W, Tonelli AE, Hudson SM (2005) Structural studies of Bombyx mori silk fibroin during regeneration from solutions and wet fiber spinning. Biomacromolecules 6:1722–1731

Happey F, Wormell R (1949) 53—Regenerated keratin fibres from wool. J Text Inst Trans 40:T855–T869

He M, Zhang B, Dou Y, Yin G, Cui Y (2017) Blend modification of feather keratin‐based films using sodium alginate. J Appl Polym Sci 134:44680

Idris A, Vijayaraghavan R, Rana UA, Fredericks D, Patti A, MacFarlane D (2013) Dissolution of feather keratin in ionic liquids. Green Chem 15:525–534

Idris A, Vijayaraghavan R, Patti A, MacFarlane D (2014) Distillable protic ionic liquids for keratin dissolution and recovery. ACS Sustain Chem Eng 2:1888–1894

Ji Y, Chen J, Lv J, Li Z, Xing L, Ding S (2014) Extraction of keratin with ionic liquids from poultry feather. Sep Purif Technol 132:577–583

Jones CB, Mecham D (1943) The dispersion of keratins. I. Studies on the dispersion and degradation of certain keratins by sodium sulfide. Arch Biochem 2:209

Kamarudin NB, Sharma S, Gupta A, Kee CG, Chik SMSBT, Gupta R (2017) Statistical investigation of extraction parameters of keratin from chicken feather using design-expert. 3 Biotech 7:127

Khosa MA, Ullah A (2014) In-situ modification, regeneration, and application of keratin biopolymer for arsenic removal. J Hazard Mater 278:360–371

Lasekan A, Bakar FA, Hashim D (2013) Potential of chicken by-products as sources of useful biological resources. Waste Manag 33:552–565

Lee H et al (2015) Human hair keratin-based biofilm for potent application to periodontal tissue regeneration. Macromol Res 23:300–308

Ma B, Qiao X, Hou X, Yang Y (2016) Pure keratin membrane and fibers from chicken feather. Int J Biol Macromol 89:614–621

Ma B, Chen W, Qiao X, Pan G, Jakpa W, Hou X, Yang Y (2017) Tunable wettability and tensile strength of chitosan membranes using keratin microparticles as reinforcement. J Appl Polym Sci 134:44667

Martelli SM, Moore G, Paes SS, Gandolfo C, Laurindo JB (2006a) Influence of plasticizers on the water sorption isotherms and water vapor permeability of chicken feather keratin films. LWT Food Sci Technol 39:292–301

Martelli SM, Moore GRP, Laurindo JB (2006b) Mechanical properties, water vapor permeability and water affinity of feather keratin films plasticized with sorbitol. J Polym Environ 14:215–222

Martinez-Hernandez AL, Velasco-Santos C, De Icaza M, Castano VM (2005) Microstructural characterisation of keratin fibres from chicken feathers. Int J Environ Pollut 23:162–178

Menefee E, Yee G (1965) Thermally-induced structural changes in wool. Text Res J 35:801–812

Mohanty AK, Misra M, Drzal LT (2005) Natural fibers, biopolymers, and biocomposites. CRC Press, Boca Raton

Mokrejs P, Svoboda P, Hrncirik J, Janacova D, Vasek V (2010) Processing poultry feathers into keratin hydrolysate through alkaline-enzymatic hydrolysis. Waste Manag Res 29(3):260–267

Moore GRP, Martelli SM, Gandolfo C, do Amaral Sobral PJ, Laurindo JB (2006) Influence of the glycerol concentration on some physical properties of feather keratin films. Food Hydrocoll 20:975–982

Moritz J, Latshaw J (2001) Indicators of nutritional value of hydrolyzed feather meal. Poult Sci 80:79–86

Nishikawa N, Tanizawa Y, Tanaka S, Horiguchi Y, Asakura T (1998) Structural change of keratin protein in human hair by permanent waving treatment. Polymer 39:3835–3840

Onifade A, Al-Sane N, Al-Musallam A, Al-Zarban S (1998) A review: potentials for biotechnological applications of keratin-degrading microorganisms and their enzymes for nutritional improvement of feathers and other keratins as livestock feed resources. Biores Technol 66:1–11

Pavia DL, Lampman GM, Kriz GS, Vyvyan JA (2008) Introduction to spectroscopy. Cengage Learning, Boston

Pillai C (2010) Challenges for natural monomers and polymers: novel design strategies and engineering to develop advanced polymers. Des Monomers Polym 13:87–121

Poole AJ, Church JS (2015) The effects of physical and chemical treatments on Na2S produced feather keratin films. Int J Biol Macromol 73:99–108

Poole AJ, Church JS, Huson MG (2008) Environmentally sustainable fibers from regenerated protein. Biomacromolecules 10:1–8

Poole AJ, Lyons RE, Church JS (2011) Dissolving feather keratin using sodium sulfide for bio-polymer applications. J Polym Environ 19:995–1004

Popescu C, Augustin P (1999) Effect of chlorination treatment on the thermogravimetric behaviour of wool fibres. J Therm Anal Calorim 57:509–515

Rad ZP, Tavanai H, Moradi A (2012) Production of feather keratin nanopowder through electrospraying. J Aerosol Sci 51:49–56

Ramakrishnan N, Sharma S, Gupta A, Alashwal BY (2018) Keratin based bioplastic film from chicken feathers and its characterization. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2018.01.037

Rao DR, Gupta V (1992) Crystallite orientation in wool fibers. J Appl Polym Sci 46:1109–1112

Reddy N, Yang Y (2007) Structure and properties of chicken feather barbs as natural protein fibers. J Polym Environ 15:81–87

Schrooyen PM, Dijkstra PJ, Oberthür RC, Bantjes A, Feijen J (2000) Partially carboxymethylated feather keratins. 1. Properties in aqueous systems. J Agric Food Chem 48:4326–4334

Schrooyen PM, Dijkstra PJ, Oberthür RC, Bantjes A, Feijen J (2001a) Partially carboxymethylated feather keratins. 2. Thermal and mechanical properties of films. J Agric Food Chem 49:221–230

Schrooyen PM, Dijkstra PJ, Oberthür RC, Bantjes A, Feijen J (2001b) Stabilization of solutions of feather keratins by sodium dodecyl sulfate. J Colloid Interface Sci 240:30–39

Senoz E, Wool RP (2010) Microporous carbon–nitrogen fibers from keratin fibers by pyrolysis. J Appl Polym Sci 118:1752–1765

Sharma S, Gupta A (2016) Sustainable management of keratin waste biomass: applications and future perspectives. Braz Arch Biol Technol 59:e16150684

Sharma S, Gupta A, Chik S, Kee CG, Mistry BM, Kim DH, Sharma G (2017a) Characterization of keratin microparticles from feather biomass with potent antioxidant and anticancer activities. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2017.06.015

Sharma S, Gupta A, Chik SMSBT, Kee CYG, Poddar PK (2017b) Dissolution and characterization of biofunctional keratin particles extracted from chicken feathers. In: IOP conference series: materials science and engineering, vol 1. IOP Publishing, p 012013

Tanabe T, Okitsu N, Tachibana A, Yamauchi K (2002) Preparation and characterization of keratin–chitosan composite film. Biomaterials 23:817–825

Tesfaye T, Sithole B, Ramjugernath D, Chunilall V (2017) Valorisation of chicken feathers: characterisation of physical properties and morphological structure. J Clean Prod 149:349–365

Tiwary E, Gupta R (2010) Medium optimization for a novel 58 kDa dimeric keratinase from Bacillus licheniformis ER-15: biochemical characterization and application in feather degradation and dehairing of hides. Biores Technol 101:6103–6110

Touaibia D, Benayada B (2005) Removal of mercury (II) from aqueous solution by adsorption on keratin powder prepared from Algerian sheep hooves. Desalination 186:75–80

Ullah A, Vasanthan T, Bressler D, Elias AL, Wu J (2011) Bioplastics from feather quill. Biomacromolecules 12:3826–3832

Vasconcelos A, Freddi G, Cavaco-Paulo A (2008) Biodegradable materials based on silk fibroin and keratin. Biomacromolecules 9:1299–1305

Wang Y-X, Cao X-J (2012) Extracting keratin from chicken feathers by using a hydrophobic ionic liquid. Process Biochem 47:896–899

Wojciechowska E, Włochowicz A, Wesełucha-Birczyńska A (1999) Application of Fourier-transform infrared and Raman spectroscopy to study degradation of the wool fiber keratin. J Mol Struct 511:307–318

Xu W, Ke G, Wu J, Wang X (2006) Modification of wool fiber using steam explosion. Eur Polym J 42:2168–2173

Yamauchi K, Yamauchi A, Kusunoki T, Kohda A, Konishi Y (1996) Preparation of stable aqueous solution of keratins, and physiochemical and biodegradational properties of films. J Biomed Mater Res 31:439–444

Yin X-C, Li F-Y, He Y-F, Wang Y, Wang R-M (2013) Study on effective extraction of chicken feather keratins and their films for controlling drug release. Biomater Sci 1:528–536

Zhang J et al (2013) Isolation and characterization of biofunctional keratin particles extracted from wool wastes. Powder Technol 246:356–362

Zhang Y, Zhao W, Yang R (2015) Steam flash explosion assisted dissolution of keratin from feathers. ACS Sustain Chem Eng 3:2036–2042

Zoccola M, Aluigi A, Tonin C (2009) Characterisation of keratin biomass from butchery and wool industry wastes. J Mol Struct 938:35–40

Acknowledgment

Authors are thankful to University Malaysia Pahang (UMP) for proving facilities and financial support; author [SS] is thankful to UMP for providing Doctoral Scholarship Scheme (DSS) scholarship as financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest among all authors.

Rights and permissions

About this article

Cite this article

Sharma, S., Gupta, A., Kumar, A. et al. An efficient conversion of waste feather keratin into ecofriendly bioplastic film. Clean Techn Environ Policy 20, 2157–2167 (2018). https://doi.org/10.1007/s10098-018-1498-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-018-1498-2