Abstract

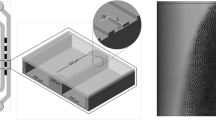

Uniformly sized droplets of soybean oil, MCT (medium-chain fatty acid triglyceride) oil and n-tetradecane with a Sauter mean diameter of d 3,2 = 26–35 μm and a distribution span of 0.21–0.25 have been produced at high throughputs using a 24 × 24 mm silicon microchannel plate consisting of 23,348 asymmetric channels fabricated by photolithography and deep reactive ion etching. Each channel consisted of a 10-μm diameter straight-through micro-hole with a length of 70 μm and a 50 × 10 μm micro-slot with a depth of 30 μm at the outlet of each channel. The maximum dispersed phase flux for monodisperse emulsion generation increased with decreasing dispersed phase viscosity and ranged from over 120 L m−2 h−1 for soybean oil to 2,700 L m−2 h−1 for n-tetradecane. The droplet generation frequency showed significant channel to channel variations and increased with decreasing viscosity of the dispersed phase. For n-tetradecane, the maximum mean droplet generation frequency was 250 Hz per single active channel, corresponding to the overall throughput in the device of 3.2 million droplets per second. The proportion of active channels at high throughputs approached 100% for soybean oil and MCT oil, and 50% for n-tetradecane. The agreement between the experimental and CFD (Computational Fluid Dynamics) results was excellent for soybean oil and the poorest for n-tetradecane.

Similar content being viewed by others

Abbreviations

- A m :

-

Active cross-sectional area of microchannel plate (m2)

- Ca :

-

Capillary number

- d :

-

Droplet diameter (m)

- d10, d50, d90:

-

Droplet diameters corresponding to 10, 50, and 90% cumulative undersize mass (m)

- d 3,2 :

-

Sauter mean diameter of droplets (m)

- d ch :

-

Diameter of microchannel (m)

- k :

-

Fraction of active microchannels

- h :

-

Height of gap between microchannel plate and cover slip (m)

- N 0 :

-

Total number of microchannels in plate

- Q :

-

Volume flow rate (m3 s−1)

- U :

-

Velocity of disperse phase in microchannel (m s−1)

- \( \bar{U} \) :

-

Mean velocity of disperse phase in active microchannels (m s−1)

- W :

-

Width of gap between MC plate and cover slip (m)

- We :

-

Weber number

- γ :

-

Interfacial tension (N m−1)

- η :

-

Viscosity (Pa s)

- ρ :

-

Density (kg m−3)

- τ :

-

Shear stress (Pa)

- c:

-

Continuous phase

- cr:

-

Critical conditions

- d:

-

Disperse phase

References

Abate AR, Weitz DA (2009) High-order multiple emulsions formed in poly(dimethylsiloxane) microfluidics. Small 18:2030–2032

Abrahamse AJ, van Lierop R, van der Sman RGM, van der Padt A, Boom RM (2002) Analysis of droplet formation and interactions during cross-flow membrane emulsification. J Membr Sci 204:125–137

Anna SL, Bontoux N, Stone HA (2003) Formation of dispersions using ‘flow-focusing’ in microchannels. Appl Phys Lett 82:364–366

Egidi E, Gasparini G, Holdich RG, Vladisavljević GT, Kosvintsev SR (2008) Membrane emulsification using membranes of regular pore spacing: droplet size and uniformity in the presence of surface shear. J Membr Sci 323:414–420

Holdich RG, Dragosavac MM, Vladisavljević GT, Kosvintsev SR (2010) Membrane emulsification with oscillating and stationary membranes. Ind Eng Chem Res 49:3810–3817

Kawakatsu T, Kikuchi Y, Nakajima M (1997) Regular-sized cell creation in microchannel emulsification by visual microprocessing method. J Am Oil Chem Soc 74:317–321

Kikuchi Y, Sate K, Ohki H, Kaneko T (1992) Optically accessible microchannels formed in a single-crystal silicon substrate for studies of blood rheology. Microvasc Res 44:226–240

Kobayashi I, Nakajima M, Chun K, Kikuchi Y, Fujita H (2002) Silicon array of elongated through-holes for monodisperse emulsion droplets. AIChE J 48:1639–1644

Kobayashi I, Nakajima M, Mukataka S (2003) Preparation characteristics of oil-in-water emulsions using differently charged surfactants in straight-through microchannel emulsification. Colloids Surf A: Physicochem Eng Asp 229:33–41

Kobayashi I, Mukataka S, Nakajima M (2004) Effect of slot aspect ratio on droplet formation from silicon straight-through microchannels. J Colloid Interface Sci 279:277–280

Kobayashi I, Mukataka S, Nakajima M (2005a) Production of monodisperse oil-in-water emulsions using a large silicon straight-through microchannel plate. Ind Eng Chem Res 44:5852–5856

Kobayashi I, Mukataka S, Nakajima M (2005b) Novel asymmetric through-hole array microfabricated on a silicon plate for formulating monodisperse emulsions. Langmuir 21:7629–7632

Kobayashi I, Uemura K, Nakajima M (2007) Formulation of monodisperse emulsions using submicron-channel arrays. Colloids Surf A: Physicochem Eng Asp 296:285–289

Kobayashi I, Takayuki T, Maeda R, Wada Y, Uemura K, Nakajima M (2008a) Straight-through microchannel devices for generating monodisperse emulsion droplets several microns in size. Microfluid Nanofluid 4:167–177

Kobayashi I, Wada Y, Uemura K, Nakajima M (2008b) Generation of uniform drops via through-hole arrays micromachined in stainless-steel plates. Microfluid Nanofluid 5:677–687

Kobayashi I, Wada Y, Uemura K, Nakajima M (2009) Production of monodisperse water-in-oil emulsions consisting of highly uniform droplets using asymmetric straight-through microchannel arrays. Microfluid Nanofluid 7:107–119

Kobayashi I, Wada Y, Uemura K, Nakajima M (2010) Microchannel emulsification for mass production of uniform fine droplets: integration of microchannel arrays on a chip. Microfluid Nanofluid 8:255–262

Link DR, Anna SL, Weitz DA, Stone HA (2004) Geometrically mediated breakup of drops in microfluidic devices. Phys Rev Lett 92:054503

McClements DJ (2004) Food emulsions: principles practices and techniques. CRC Press, Boca Raton

Nakashima T, Shimizu M, Kukizaki M (2000) Particle control of emulsion by membrane emulsification and its applications. Adv Drug Deliv Rev 45:47–56

Neves MA, Ribeiro HS, Butron Fujiu K, Kobayashi I, Nakajima M (2008) Formulation of controlled size PUFA-loaded oil-in-water emulsions by microchannel emulsification using β-carotene-rich palm oil. Ind Eng Chem Res 47:6405–6411

Nisisako T, Torii T (2006) Microfluidic large-scale integration on a chip for mass production of monodisperse droplets and particles. Lab Chip 8:287–293

Nisisako T, Torii T, Takahashi T, Takizawa Y (2006) Synthesis of monodisperse bicolored Janus particles with electrical anisotropy using a microfluidic co-flow system. Adv Mater 18:1152–1156

Steegmans ML, Schroën KGPH, Boom RM (2009) Characterization of emulsification at flat Y junctions. Langmuir 25:3396–3401

Sugiura S, Nakajima M, Kumazawa N, Iwamoto S, Seki M (2002a) Characterization of spontaneous transformation-based droplet formation during microchannel emulsification. J Phys Chem B 106:9405–9409

Sugiura S, Nakajima M, Seki M (2002b) Effect of channel structure on microchannel emulsification. Langmuir 18:5708–5712

Thorsen T, Roberts RW, Arnold FH, Quake SR (2001) Dynamic pattern formation in a vesicle-generating microfluidic device. Phys Rev Lett 86:4163–4166

Utada AS, Lorenceau E, Link DR, Kaplan PD, Stone HA, Weitz DA (2005) Monodisperse double emulsions generated from a microcapillary device. Science 308:537–541

Utada AS, Chu LY, Fernandez-Nieves A, Link DR, Holtze C, Weitz DA (2007) Dripping, jetting, drops, and wetting: the magic of microfluidics. MRS Bull 32:702–708

van Dijke KC, Veldhuis G, Schroën K, Boom R (2009a) Simultaneous formation of many droplets in a single microfluidic droplet formation unit. AIChE J 56:833–836

van Dijke K, Veldhuis G, Schroën K, Boom R (2009b) Parallelized edge-based droplet generation (EDGE) devices. Lab Chip 9:2824–2830

van Dijke K, Kobayashi I, Schroën K, Uemura K, Nakajima M, Boom R (2010) Effect of viscosities of dispersed and continuous phases in microchannel oil-in-water emulsification. Microfluid Nanofluid 9:77–85

Vladisavljević GT, Schubert H (2003a) Influence of process parameters on droplet size distribution in SPG membrane emulsification and stability of prepared emulsion droplets. J Membr Sci 225:15–23

Vladisavljević GT, Schubert H (2003b) Preparation of emulsions with a narrow particle size distribution using microporous α-alumina membranes. J Disper Sci Technol 24:811–819

Vladisavljević GT, Williams RA (2006) Manufacture of large uniform droplets using rotating membrane emulsification. J Colloid Interface Sci 299:396–402

Vladisavljević GT, Shimizu M, Nakashima T (2006) Production of multiple emulsions for drug delivery systems by repeated SPG membrane homogenization: influence of mean pore size, interfacial tension and continuous phase viscosity. J Membr Sci 284:373–383

Vladisavljević GT, Kobayashi I, Nakajima M (2008) Generation of highly uniform droplets using asymmetric microchannels fabricated on a single crystal silicon plate: effect of emulsifier and oil types. Powder Technol 183:37–45

Williams RA, Peng SJ, Wheeler DA, Morley NC, Taylor D, Whalley M, Houldsworth DW (1998) Controlled production of emulsions using a crossflow membrane. Part II. Industrial scale manufacture. Chem Eng Res Des 76:902–910

Xu Q, Nakajima M (2004) The generation of highly monodisperse droplets through the breakup of hydrodynamically focused microthread in a microfluidic device. Appl Phys Lett 83:3726–3728

Yobas L, Martens S, Ong WL, Ranganathan N (2006) High-performance flow-focusing geometry for spontaneous generation of monodispersed droplets. Lab Chip 6:1073–1079

Acknowledgments

This study was supported by the Japan Society for the Promotion of Science, Tokyo (the invitation fellowship of Dr. Goran Vladisavljević ID No. L-05555), and by the Food Nanotechnology Project of the Ministry of Agriculture, Forestry and Fisheries of Japan.

Author information

Authors and Affiliations

Corresponding authors

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Vladisavljević, G.T., Kobayashi, I. & Nakajima, M. Effect of dispersed phase viscosity on maximum droplet generation frequency in microchannel emulsification using asymmetric straight-through channels. Microfluid Nanofluid 10, 1199–1209 (2011). https://doi.org/10.1007/s10404-010-0750-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-010-0750-9