Abstract

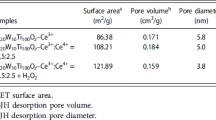

A series of cerium-tungsten oxide catalysts was prepared by the co-precipitation method and was evaluated for the selective catalytic reduction of NO x by ammonia (NH3-SCR) over a wide temperature range. These catalysts were characterized by BET, XRD, XPS and H2-TPR analyses. The experimental studies demonstrated that, among cerium-tungsten oxides, CeO2–WO3 with a Ce/W molar ratio of 3/2 exhibited the best activity toward NH3-SCR reactions, N2 selectivity and SO2 durability over a broad temperature range of 175–500 °C at a space velocity of 47,000 h−1. The strong interaction between Ce and W could be the main factor leading to the high activity of the CeO2–WO3 mixed oxide catalyst.

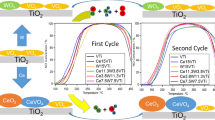

Graphical Abstract

A series of cerium-tungsten oxide catalysts was prepared by the co-precipitation method and was evaluated for the selective catalytic reduction of NO x by ammonia (NH3-SCR) over a wide temperature range. These catalysts were characterized by BET, XRD, XPS and H2-TPR analyses. The experimental studies demonstrated that, among cerium-tungsten oxides, CeO2–WO3 with a Ce/W molar ratio of 3/2 exhibited the best activity toward NH3-SCR reactions, N2 selectivity and SO2 durability over a broad temperature range of 175–500 °C at a space velocity of 47,000 h−1. The strong interaction between Ce and W could be the main factor leading to the high activity of the CeO2–WO3 mixed oxide catalyst.

a NO x conversion over pure CeO2, pure WO3 and CeO2–WO3 mixed oxides. b NO conversion as a function of time at 300 °C over CeO2/TiO2, CeO2–WO3/TiO2 and CeO2–WO3 catalyst in the presence of SO2

Similar content being viewed by others

References

Bosch H, Janssen F (1988) Catal Today 2:369

Schneider H, Scharf U, Wokaun A, Baiker A (1994) J Catal 146:545

Busca G, Lietti L, Ramis G, Berti F (1998) Appl Catal B 18:1

Dunn JP, Koppula PR, Stenger HG, Wachs IE (1998) Appl Catal B 19:103

Liu FD, He H, Zhang CB (2008) Chem Commun 17:2043

Xu WQ, Yu YB, Zhang CB, He H (2008) Catal Commun 9:1453

Gao X, Jiang Y, Zhong Y, Luo ZY, Cen KF (2010) J Hazard Mater 174:734

Shen YS, Zhu SM, Qiu T, Shen SB (2009) Catal Commun 11:20

Si ZC, Weng D, Wu XD, Li J, Li G (2010) J Catal 271:43

Qi GS, Yang RT (2004) J Phys Chem B 108:15738

Long RQ, Yang RT (2000) Appl Catal B 27:87

Reddy BM, Khan A, Yamada Y, Kobayashi T, Loridant S, Volta JC (2003) J Phys Chem B 107:162

Xu WQ, He H, Yu YB (2009) J Phys Chem C 113:4426

Chen L, Li JH, Ge MF, Zhu RH (2010) Catal Today 153:77

Chen L, Li JH, Ge MF (2010) Environ Sci Technol 44:9590

Marrero-Lo′pez D, Canales-Va′zquez J, Zhou WZ, Irvine JTS, Nu′n˜ez P (2006) J Solution Chem 179:278

Mamede AS, Payen E, Grange P, Poncelet G, Ion A, Alifanti M, Pârvulescu VI (2004) J Catal 223:1

Noronha FB, Fendley EC, Soares RR, Alvarez WE, Resasco DE (2001) Chem Eng J 82:21

He H, Dai HX, Au CT (2004) Catal Today 90:245

Baek Y, Yong K (2007) J Phys Chem C 111:1213

Leftheriotis G, Papaefthimiou S, Yianoulis P, Siokou A (2001) Thin Solid Films 384:298

Logie V, Maire G, Michel D, Vignes JL (1999) J Catal 188:90

Chen L, Li JH, Ge MF (2009) J Phys Chem C 113:21177

Wu ZB, Jin RB, Liu Y, Wang HQ (2008) Catal Commun 9:2217

Acknowledgments

This study was financially supported by the National Natural Science fund of China (Grant NO. 51078203) and the National High-Tech Research and Development (863) Program of China (Grant No. 2010AA065001 and 2010AA065002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, L., Li, J., Ablikim, W. et al. CeO2–WO3 Mixed Oxides for the Selective Catalytic Reduction of NO x by NH3 Over a Wide Temperature Range. Catal Lett 141, 1859–1864 (2011). https://doi.org/10.1007/s10562-011-0701-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-011-0701-4