Abstract

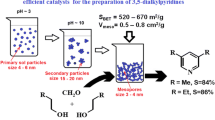

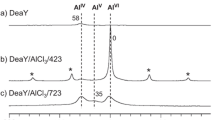

The development of solid strong base catalysts utilizable in green but acidic medium of scCO2 is reviewed. The strong base sites on mesoporous alumina and sulfated mesoporous alumina that had been generated by severe treatment at 773 K under vacuum (10−4 Torr) were not neutralized by the compressed Lewis acidic molecules of CO2, promoting a representative strong base-catalyzed reaction of the Tishchenko reaction as well as a typical base-catalyzed reaction of the Knoevenagel reaction in scCO2. Infrared spectroscopy of the adsorbed pyrrole, temperature-programmed desorption of CO2, and the poisoning by a very weak Brönsted acid of methanol have revealed that the average strengths of the base sites on mesoporous alumina and sulfated mesoporous alumina are weaker than that on conventional γ-alumina like JRC-ALO-4, but that they have a small number of strong base sites which function even in scCO2 medium. It was found that the addition of a slight amount of THF cosolvent into scCO2 remarkably accelerates the Tishchenko reaction over sulfated mesoporous alumina; the reaction rate in the scCO2–THF medium was 1.5-fold and 2-fold faster than those in ordinary organic solvents such as benzene and THF and that in pure scCO2, respectively. The unique structures of mesoporous alumina and sulfated mesoporous alumina have been fully characterized by N2 adsorption–desorption measurements and XRD analyses.

Similar content being viewed by others

Notes

The present authors synthesized mesoAl2O3 as follows. Into a polypropylene vessel containing a stirring bar were added Al(O-sec-Bu)3 (21.9 g, 89.0 mmol), 1-propanol (120 g, 2.00 mol), and deionized water (5.15 g, 286 mmol), followed by vigorous stirring at room temperature. After 1 h, a solution of lauric acid (5.40 g, 27.0 mmol) in 1-propanol (17.5 g, 290 mmol) was added under vigorous stirring, and the mixture was further stirred vigorously at room temperature for 24 h. The resulting white liquid was placed in a 300-mL autoclave, and heated at 383 K for 48 h without stirring to afford a white precipitate. The precipitate was washed on a filter paper with a large amount of ethanol, and dried at room temperature under an N2 flow. The white solid thus obtained was heated from room temperature to 873 K at a ramping rate of 10 K min−1 under an N2 flow, and then calcined under an air flow at 873 K for 5 h to burn out the organic species to give pure mesoAl2O3. After several repetitions of the synthesis, it was found that the synthesized mesoAl2O3 had the surface areas in the range of 471–523 m2 g−1.

Preparation method of mesoAl 2 O 3 /SO 2− 4 -I and -II. To a mixture of Al(O-sec-Bu)3 (21.9 g, 89.0 mmol) and 1-propanol (120 g, 2.00 mol) was added deionized water (5.15 g, 286 mmol) containing 96% H2SO4 (0.1 g, 1 mmol and 0.2 g, 2 mmol for mesoAl2O3/SO 2−4 -I and -II, respectively). The resultant solution was vigorously stirred for 1 h at room temperature. Lauric acid (5.40 g, 27.0 mmol) in 1-propanol (17.5 g, 290 mmol) was then added, and the mixture was further stirred for 24 h at room temperature. The resulting white liquid was placed in a 300-mL autoclave and heated at 383 K for 48 h without stirring to afford a white precipitate. The precipitate was washed on a filter paper with a large amount of ethanol, and dried at room temperature under an N2 flow. The white solid thus obtained was heated from room temperature to 873 K at a ramping rate of 10 K min−1 under an N2 flow, and calcined under an air flow at 873 K for 5 h to burn out the organic species to yield mesoAl2O3/SO 2−4 -I or -II. Preparation method of mesoAl 2 O 3 /SO 2− 4 -III. A mixture of Al(O-sec-Bu)3 (19.5 g, 79.0 mmol), Al2(SO4)3 (1.7 g, 5.0 mmol), 1-propanol (120 g, 2.00 mol), and deionized water (5.15 g, 286 mmol) was vigorously stirred for 1 h at room temperature. Lauric acid (5.40 g, 27.0 mmol) in 1-propanol (17.5 g, 290 mmol) was then added, and the resulting mixture was further stirred for 24 h at room temperature. The resulting white liquid was placed in a 300-mL autoclave and heated at 383 K for 48 h without stirring to afford a white precipitate. The precipitate was washed on a filter paper with a large amount of ethanol, and dried at room temperature under an N2 flow. The white solid thus obtained was heated from room temperature to 873 K at a ramping rate of 10 K min−1 under an N2 flow, and calcined under an air flow at 873 K for 5 h to burn out the organic species to give mesoAl2O3/SO 2−4 -III.

JRC-ALO-2, -3, and -4 are the reference alumina catalysts provided by the Catalysis Society of Japan, and contain the following impurities. JRC-ALO-2: 0.03% Fe2O3, 0.22% SiO2, 0.04% Na2O, 1.72% SO 2−4 ; JRC-ALO-3: 0.01% Fe2O3, 0.01% SiO2, 0.3% Na2O, 0.01% TiO2; JRC-ALO-4: 0.01% Fe2O3, 0.01% SiO2, 0.01% Na2O.

Thomas Swan & Co. Ltd. (UK) has successfully developed a large-scale continuous-flow reactor system for heterogeneous catalytic reactions in scCO2 under the direction of Prof. Dr. Poliakoff (Nottingham University, UK). The detailed information is available via the internet, see http://www.thomas-swan.co.uk/index.html.

Since the Knoevenagel reaction proceeds very rapidly over the activated MgO and aluminas under solvent-free condition, we could not avoid the “neat” reaction that had taken place before the introduction of liqCO2 into the autoclave. The amount of 3 that were formed before starting the reactions under scCO2 condition were 0.33, 0.10, and 0.10 mmol for MgO, JRC-ALO-4, and mesoAl2O3, respectively.

See footnote 3

The visual inspections were carried out using a 10-mL autoclave equipped with sapphire windows. In the absence of a catalyst, a freshly distilled compound (4 or 5) and compressed CO2 were stirred with or without a cosolvent under the described conditions. After 15 min, the inside of the vessel was visually observed.

References

(a) G. Ertl, H. Knözinger and J. Weitkamp, The Handbook of Heterogeneous Catalysis (Wiley-VCH, Weinheim, 1997); (b) G.W. Kabalka and R.M. Pagni, Tetrahedron 53 (1997) 7999; (c) P. Euzen, P. Raybaud, X. Krokidis, H. Toulhoat, J.-L. Le Loarer, J.-P. Jolivet and C. Froidefond, in: Handbook of Porous Materials, eds. F. Schüth, K. Sing and J. Weitkamp (Wiley-VCH, Weinheim, 2002) p. 1591

C.H. Bartholomew and R.J. Farrauto, Fundamentals of Industrial Catalytic Process, 2nd ed. (Wiley, Hoboken, New Jersey, 2006) p. 260

(a) J. Čejka, Appl. Catal. A 254 (2003) 327 and references therein; (b) F. Vaudry, S. Khodabandeh and M.E. Davis, Chem. Mater. 8 (1996) 1451

L. Kaluža, M. Zdražil, N. Žilková, J. Čejka Catal. Commun. 3 (2002) 151

(a) M. Onaka and T. Oikawa, Chem. Lett. (2002) 850; (b) T. Oikawa, T. Ookoshi, T. Tanaka, T. Yamamoto and M. Onaka, Micropor. Mesopor. Mater. 74 (2004) 93; (c) T. Oikawa, Y. Masui, T. Tanaka, Y. Chujo and M. Onaka, J. Organomet. Chem. (in press)

(a) T. Seki and M. Onaka, Chem. Lett. 34 (2005) 262; (b) T. Seki and M. Onaka, J. Phys. Chem. B 110 (2006) 1240

T. Seki and M. Onaka, J. Mol. Catal. A (in press)

Y. Tanaka, A.S. Jursa, F.J. LeBlanc J. Chem. Phys. 32 (1960) 1199

Y. Yoshioka, H.F. Schaefer III J. Chem. Phys. 75 (1981) 1040

K. Wefers and C. Misra, Oxides and Hydroxides of Aluminum (Alcoa Laboratories, 1987)

S. Brunauer, P.H. Emmett, E. Teller J. Am. Chem. Soc. 60 (1938) 309

E.P. Barrett, L.G. Joyner, P.P. Halenda J. Am. Chem. Soc. 73 (1951) 373

D. Dollimore, G.R. Heal J. Appl. Chem. 14 (1964) 109

(a) G. Yamaguchi and H. Yanagida, Bull. Chem. Soc. Jpn. 35 (1962) 1896; (b) H. Yanagida and G. Yamaguchi, Bull. Chem. Soc. Jpn. 37 (1964) 1229; (c) H. Yanagida, H. Yamaguchi and J. Kubota, Bull. Chem. Soc. Jpn. 38 (1965) 2194

K. Tanabe, M. Misono, Y. Ono and H. Hattori, New Solid Acids and Bases (Kodansha-Elsevier, Tokyo, Amsterdam, Oxford, New York, Tokyo, 1989)

(a) K. Arata, Adv. Catal. 37 (1990) 165; (b) T. Jin, T. Yamaguchi and K. Tanabe, J. Phys. Chem. 90 (1986) 4794

M. Yada, S. Kuroki, M. Kuroki, K. Ohe and T. Kijima, Langmuir 18 (2002) 8714 and references therein

A.F. Bedilo, K.J. Klabunde J. Catal. 176 (1998) 448

U. Ciesla, S. Schacht, G.D. Stucky, K.K. Unger, F. Schüth Angew. Chem. Int. Ed. Engl. 35 (1996) 541

H. Hattori, Chem Rev 95 (1995) 537

(a) P.O. Scokart and P.G. Rouxhet, J. Chem. Soc., Faraday Trans. I 76 (1980) 1476; (b) D. Barthomeuf, J. Phys. Chem. 88 (1984) 42; (c) C. Binet, A. Jadi, J. Lamotte and J.C. Lavalley, J. Chem. Soc., Faraday Trans. 92 (1996) 123

P.E. Savage, S. Gopalan, T.I. Mizan, C.J. Martino, E.E. Brock AIChE J. 41 (1995) 1723

Reiews of homogeneous catalysis in scCO2: (a) P.G. Jessop, T. Ikariya and R. Noyori, Chem. Rev. 99 (1999) 475; (b) T. Ikariya and Y. Kayaki, Catal. Surv. Jpn. 4 (2000) 39

Reviews of heterogeneous catalysis in scCO2: (a) A. Baiker, Chem. Rev. 99 (1999) 453; (b) J.-D. Grunwaldt, R. Wandeler and A. Baiker, Catal. Rev.-Sci. Eng. 45 (2003) 1; (c) R. Amandi, J. Hyde and M. Poliakoff, in: Carbon Dioxide Recovery and Utilization, ed. M. Aresta (Kluwer Academic Publishers, Dordrecht, 2003) p. 169; (d) J.-D. Grunwaldt and A. Baiker, Phys. Chem. Chem. Phys. 7 (2005) 3526

R. Gilgen, R. Kleinrahm, W. Wagner J. Chem. Thermodyn. 24 (1992) 1243

V. Vesovic, W.A. Wakeham, G.A. Olchowy, J.V. Sengers, J.T.R. Watson, J. Millat, J. Phys. Chem. Ref. Data 19 (1990) 763

A. Fenghour, W.A. Wakeham, V. Vesovic J. Phys. Chem. Ref. Data 27 (1998) 31

J. Obriot, J. Ge, T.K. Bose, J.-M. St-Arnaud Fluid Phase Equilib. 86 (1993) 315

D.L. Goldfarb, D.P. Fernández, H.R. Corti Fluid Phase Equilib. 158–160 (1999) 1011

V.M. Shenai, B.L. Hamilton and M.A. Matthews, in: Supercritical Fluid Engineering Science: Fundamentals and Applications, Vol. 11, eds. E. Kiran and J.F. Brennecke (American Chemical Society, Washington, DC, 1993)

I. Komoto, S. Kobayashi J. Org. Chem. 69 (2004) 680

(a) O. Kröcher, R.A. Köppel and A. Baiker, Chem. Commun. (1996) 1497; (b) O. Kröcher, R.A. Köppel, M. Fröba and A. Baiker, J. Catal. 178 (1998) 284

M.G. Hitzler, F.R. Smail, S.K. Ross, M. Poliakoff Chem. Commun. (1998) 359

R. Amandi, P. Licence, S.K. Ross, O. Aaltonen, M. Poliakoff Org. Process. Res. Dev. 9 (2005) 451

(a) A.R. Tadd, A. Marteel, M.R. Mason, J.A. Davies and M.A. Abraham, J. Supercrit. Fluids 25 (2003) 183; (b) A.R. Tadd, A. Marteel, M.R. Mason, J.A. Davies and M.A. Abraham, Ind. Eng. Chem. Res. 41 (2002) 4514; (c) O. Hemminger, A. Marteel, M.R. Mason, J.A. Davies, A.R. Tadd and M.A. Abraham, Green. Chem. 4 (2002) 507

M.S. Schneider, J.-D. Grunwaldt, T. Bürgi, A. Baiker Rev. Sci. Instrum. 74 (2003) 4121

J.-D. Grunwaldt, M. Ramin, M. Rohr, A. Michailowski, G.R. Patzke, A. Baiker Rev. Sci. Instrum. 76 (2005) 54104

(a) E. Knoevenagel, Ber. 31 (1898) 2596; (b) O. Doebner, Ber. 33 (1900) 2140; (c) G. Jones, Org. React. 15 (1967) 204; (d) B.K. Wilk, Tetrahedron 53 (1997) 7097

(a) R.W. Hein, M.J. Astle and J.R. Shelton, J. Org. Chem. 26 (1961) 4874; (b) L. Land, D. Haidukewych and R.J. Dolinski, J. Org. Chem. 31 (1966) 1272; (c) F. Texier-Boullet and A. Foucaud, Tetrahedron Lett. 23 (1982) 4927; (d) J. Muzart, Synthesis (1982) 60; (e) H. Moison, F. Texier-Boullet and A. Foucaud, Tetrahedron 43 (1987) 537; (f) A. Corma, V. Fornés, R.M. Martín-Aranda, H. García and J. Primo, Appl. Catal. 59 (1990) 237; (g) I. Rodriguez, H. Cambon, D. Brunel and M. Laspéras, J. Mol. Catal. A 130 (1998) 195; (h) C.F. Linares, M.R. Goldwasser, F.J. Machado, A. Rivera, G. Rodríguez-Fuentes and J. Barrault, Micropor. Mesopor. Mater. 41 (2000) 69; (i) A. Corma, V. Fornés, R.M. Martín-Aranda and F. Rey, J. Catal. 134 (1992) 58; (j) E. Angeletti, C. Canepa, G. Martinetti and P. Venturello, J. Chem. Soc., Perkin Trans. I (1989) 105; (k) B.M. Choudary, M.L. Kantam, P. Sreekanth, T. Bandopadhyay, F. Figueras and A. Tuel, J. Mol. Catal. A 142 (1999) 361; (l) Y.V. Rao and B.M. Choudary, Synth. Commun. 21 (1991) 1163; (m) M.A. Aramendia, V. Borau, C. Jimenez, J.M. Marinas and F.J. Romero, Chem. Lett. (1995) 279; (n) S. Ernst, M. Hartmann, S. Sauerbeck and T. Bongers, Appl. Catal. A 200 (2000) 117; (o) Y. Kubota, Y. Nishizaki and Y. Sugi, Chem. Lett. (2000) 998; (p) Y. Goa, P. Wu and T. Tatsumi, J. Catal. 224 (2004) 107

(a) M.B. Smith and J. March, March’s Advanced Organic Chemistry: Reactions, Mechanisms, and Structure, 5th ed. (Wiley-InterScience, New York, 2001) p. 1225; (b) M. Zhang, A.-Q. Zhang and Z.-H. Deng, J. Chem. Res. (2005) 69

N.D. Parkyns, J. Chem. Soc. A (1969) 410

H. Tsuji, A. Okamura-Yoshida, T. Shishido, H. Hattori, Langmuir 19 (2003) 8793

(a) W.C. Child and H. Adkins, J. Am. Chem. Soc. 47 (1925) 798; (b) I. Lin and A.R. Day, J. Am. Chem. Soc. 74 (1952) 5133; (c) T. Saegusa and T. Ueshima, J. Org. Chem. 33 (1968) 3310; (d) Mechanistic consideration: Y. Ogata and A. Kawasaki, Tetrahedron 25 (1969) 929; (e) Recent review of Tishchenko reaction: T. Seki, T. Nakajo and M. Onaka, Chem. Lett. 35 (2006) 824

K. Tanabe, K. Saito J. Catal. 35 (1974) 247

(a) T. Seki and H. Hattori, Chem. Commun. (2001) 2510; (b) T. Seki, H. Tachikawa, T. Yamada and H. Hattori, J. Catal. 217 (2003) 117

A. Fürstner, D. Koch, K. Langemann, W. Leitner, C. Six Angew. Chem. Int. Ed. Engl. 36 (1997) 2466

Author information

Authors and Affiliations

Corresponding author

Additional information

Tsunetake Seki is a Research Fellow of the Japan Society for the Promotion of Science.

Rights and permissions

About this article

Cite this article

Seki, T., Onaka, M. Heterogeneous strong base catalysis in supercritical carbon dioxide by mesoporous alumina and sulfated mesoporous alumina. Catal Surv Asia 10, 138–150 (2006). https://doi.org/10.1007/s10563-006-9013-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10563-006-9013-x