Abstract

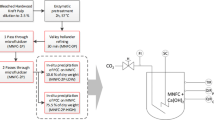

This paper demonstrates a way to utilize the rheological properties of high consistency microfibrillated and nanofibrillated cellulose (MFC and NFC) based furnishes for improved dewatering. This is relevant to a new manufacturing platform that is being developed to form composite webs from suitable mixtures of MFC or NFC, traditional pulp fibres and pigments. The studied furnishes were evaluated in the consistencies range of 5–15 % with an MCR 300 rheometer and an immobilization cell. This setup enables us to characterize the rheology of the samples before and during the dewatering process. Classical rheological methods are used to characterise MFC and NFC furnishes. Yield stress as an indicator of the flocculated network strength was found to increase with the consistencies, following the increase in elastic moduli, which indicated a gel-like strongly flocculated matrix. The shear thinning properties of furnishes are observed to follow the Oswald’s rheological model on a wide range of shear rates. It was found that when the MFC and NFC furnishes were dewatered under vacuum conditions, the final solids content was increased with application of shear. This behaviour is more pronounced for furnishes which contained the more swollen NFC (higher WRV, i.e. higher zeta potential). This effect is further exemplified by the change of the complex and dynamic viscosities during the dewatering. The shear rate, the fibre content, and the furnish consistencies were also found to influence the dewatering rate.

Similar content being viewed by others

References

Agoda-Tandjawa G, Durand S, Gaillard C, Garnier C, Doublier J- (2012) Rheological behaviour and microstructure of microfibrillated cellulose suspensions/low-methoxyl pectin mixed systems. Effect of calcium ions. Carbohydr Polym 87:1045–1057

Ayol A, Dentel SK, Filibeli A (2010) Rheological characterization of sludges during belt filtration dewatering using an immobilization cell. J Environ Eng 136:992–999

Barnes HA (2007) The ‘yield stress myth?’ paper—21 years on. Appl Rheol 17:43110-1-43100-5

Barnes H, Carnali J (1990) The vane-in-cup as a novel rheometer geometry for shear thinning and thixotropic materials. J Rheol 34:841

Beghello L, Eklund D (1999) Influence of the chemical environment on fibre flocculation. J Pulp Paper Sci 25:246–250

Björkman U (2005) Floc dynamics in flowing fibre suspensions. Nord Pulp Pap Res J 20:247–252

Blanco A, Negro C, Fuente E, Tijero J (2007) Rotor selection for a Searle-type device to study the rheology of paper pulp suspensions. Chem Eng Process 46:37–44

Chinga-Carrasco G, Kuznetsova N, Garaeva M, Leirset I, Galiullina G, Kostochko A, Syverud K (2012) Bleached and unbleached MFC nanobarriers: properties and hydrophobisation with hexamethyldisilazane. J Nanopart Res 14:1280

Dolz M, González F, Herráez M, Díez-Sales O (1994) The influence of starch on the rheological behaviour of microcrystalline cellulose hydrogels. J Dispersion Sci Technol 15:189–205

Dursun D, Dentel SK (2008) New rheological method to evaluate the dewaterability of biosolids. Proceedings of the water environment federation 2008:24–36

Gladman B, De Kretser R, Rudman M, Scales P (2005) Effect of shear on particulate suspension dewatering. Chem Eng Res Design 83:933–936

González I, Boufi S, Pèlach MA, Alcalà M, Vilaseca F, Mutjé P (2012) Nanofibrillated cellulose as paper additive in eucalyptus pulps. BioResources 7:5167–5180

Henriksson M, Henriksson G, Berglund L, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polymer J 43:3434–3441

Horvath AE, Lindström T (2007) The influence of colloidal interactions on fiber network strength. J Colloid Interface Sci 309:511–517

Hubbe MA, Heitmann JA (2007) Review of factors affecting the release of water from cellulosic fibers during paper manufacture. BioResources 2:500–533

Hubbe MA, Panczyk M (2007) Dewatering of refined, bleached hardwood kraftpulp by gravity, vacuum, and centrifugation with applied pressure part 2. Effects of wet-end additives. O Papel (Brazil) 68:88–100

Iotti M, Gregersen ØW, Moe S, Lenes M (2011) Rheological studies of microfibrillar cellulose water dispersions. J Polym Environ 19:137–145

Jäder J, Järnström L (2003) The influence of thickener addition on filter cake formation during dewatering of mineral suspensions. Appl Rheol 13:125–131

Jäder J, Järnström L, Engström G (2003) The immobilization cell revisited: prediction of dewatering kinetics and immobilised layer properties for coating colours. Nordic Pulp Paper Res J 18:382–387

Karppinen A, Vesterinen AH, Saarinen T, Pietikäinen P, Seppälä J (2011) Effect of cationic polymethacrylates on the rheology and flocculation of microfibrillated cellulose. Cellulose 18:1381–1390

Lasseuguette E, Roux D, Nishiyama Y (2008) Rheological properties of microfibrillar suspension of TEMPO-oxidized pulp. Cellulose 15:425–433

Lindström T, Carlsson G (1982) The effect of chemical environment on fiber swelling. Svensk Papperstindning-Nordisk Cellulosa 85:14–20

Mezger TG (2006) The rheology handbook: for users of rotational and oscillatory rheometers. Vincentz Network GmbH & Co KG, Hannover

Nakagaito AN, Fujimura A, Sakai T, Hama Y, Yano H (2009) Production of microfibrillated cellulose (MFC)-reinforced polylactic acid (PLA) nanocomposites from sheets obtained by a papermaking-like process. Compos Sci Technol 69:1293–1297

Ovarlez G, Rodts S, Chateau X, Coussot P (2009) Phenomenology and physical origin of shear localization and shear banding in complex fluids. Rheol Acta 48:831–844

Pajari H, Koskela H (2010) 9.2—Consolidation of coating colors—Experimental studies. 11th advanced coating fundamentals symposium proceedings: the latest advances in coating research and development: 347–359

Paradis MA, Genco JM, Bousfield DW, Hassler JC, Wildfong V (2002) Determination of drainage resistance coefficients under known shear rate. Tappi J 1:12–18

Puisto A, Illa X, Mohtaschemi M, Alava M (2012) Modeling the viscosity and aggregation of suspensions of highly anisotropic nanoparticles. Eur Phys J E 35:1–7

Pujara J, Siddiqui M, Liu Z, Bjegovic P, Takagaki S, Li P, Ramaswamy S (2008) Method to characterize the air flow and water removal characteristics during vacuum dewatering. Part II—analysis and characterization. Drying Technol 26:341–348

Raisanen KO, Paulapuro H, Karrila SJ (1995) The effects of retention aids, drainage conditions, and pretreatment of slurry on high-vacuum dewatering: a laboratory study. Tappi J 78:140–147

Ramaswamy S (2003) Vacuum dewatering during paper manufacturing. Drying Technol 21:685–717

Renardy M (2010) The mathematics of myth: yield stress behavior as a limit of non-monotone constitutive theories. J Non Newtonian Fluid Mech 165:519–526

Richmond F (2012) The coating of nanofibrillated cellulose onto paper using flooded and metered size press methods. 12PaperCon/Papers/12PAP18 aspx

Richmond, Finley-Co, Abert-Bousfield Douglas (2012) The coating of nanofibrillated cellulose onto paper using flooded and metered size press methods. 12 paperCon/Papcrs/12 PAP18 aspx

Saito T, Isogai A (2005) TEMPO-mediated oxidation of native cellulose. Appita Annual Conference 3:337–340

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2010) The effect of chemical composition on microfibrillar cellulose films from wood pulps: water interactions and physical properties for packaging applications. Cellulose 17:835–848

Subramanian R, Hiltunen E, Gane PAC (2011) Potential use of micro- and nano-fibrillated cellulose composites exemplified by paper. Cellulose fibers: bio-and nano-polymer composites. Green Chem Technol 121

Turbak AF, Snyder FW, Sandberg KR (1984) Microfibrillated cellulose—A new composition of commercial significance: TAPPI 1984, Conference Proceedings, Nonwovwns Symposium Notes, pp 115–123

Walls HJ, Caines SB, Sanchez AM, Khan SA (2003) Yield stress and wall slip phenomena in colloidal silica gels. J Rheol 47:847–868

Willenbacher N (2011) Novel approaches to explain the rheological properties of colloidal structures. Curr Opin Colloid Interface Sci 16:1–2

Willenbacher N, Hanciogullari H, Radle M (1999) New laboratory test to characterize immobilization and dewatering of paper coating colors. Tappi J 82:167–174

Wollny K (2001) New rheological test method to determine the dewatering kinetics of suspensions. Appl Rheol 11:197–202

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dimic-Misic, K., Puisto, A., Paltakari, J. et al. The influence of shear on the dewatering of high consistency nanofibrillated cellulose furnishes. Cellulose 20, 1853–1864 (2013). https://doi.org/10.1007/s10570-013-9964-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-9964-9