Abstract

The life of an electrical transformer is mainly determined by that of its cellulosic solid insulation. The analysis of the chemical markers of cellulose degradation dissolved in oil is a simple and economical way to indirectly characterize the insulating paper. Methanol, a marker that is intimately linked to the rupturing of 1,4-β-glycosidic bonds of cellulose, has been observed together with ethanol during laboratory ageing experiments. Regardless of the simulated ageing conditions (temperature, humidity, air), the ratio of methanol to ethanol concentration is always higher than one (unity). However, in approximately 10 % of transformer oil samples, the ethanol generation is higher than that of methanol. In this study, thermal degradation by pyrolysis is coupled with gas chromatography/mass spectrometry to assess the volatile by-products generated at high temperatures with emphasis on methanol/ethanol generation. Some cellulose model compounds were also pyrolyzed and thermally aged in oil. The results showed that the generation of ethanol from paper pyrolysis is always smaller than for methanol, but it only occurs at temperatures higher than 300 °C. However, thermal ageing of levoglucosan in oil generates a massive amount of ethanol compared to methanol regardless of the conditions (temperature, humidity, air, nitrogen, acidity). The hypothesis that ethanol is a by-product of cellulose degradation through levoglucosan as an intermediary in power transformers is proposed. The presence of ethanol during transformer oil analysis is of high interest because it can be related to a thermal fault or hot spot within the solid insulation.

Similar content being viewed by others

Introduction

Cellulosic insulation materials in the form of insulation paper, pressboard and transformer boards are widely used in oil-filled power transformers. Their intrinsic mechanical and electrical properties together with their abundance and straightforward use in the manufacturing process have made them a universal choice. A typical power transformer contains around 12,000 kg of cellulose per 40,000 kg of oil and operates at temperatures ranging from 60 to 105 °C (Emsley 1994; Jalbert et al. 2007, 2009). In open-breathing equipment, 1 % moisture and 3.5 % oxygen content are expected. Cellulose degradation is an important parameter for determining the end of life of a transformer. The combined action of temperature, oxygen and moisture causes the oil and the oil-impregnated insulation material to decompose and to generate gaseous decomposition products dissolved in the mineral oil. This degradation causes a loss of mechanical properties of the cellulose insulation and could ultimately result in a loss of the equipment due to a short-circuit between conductors. Therefore, it is essential to monitor cellulose degradation in order to ensure proper transformer operation. However, directly evaluating the condition of cellulose insulation in a working transformer, e.g. through a measurement of the degree of polymerization (DPv), is difficult and impractical. Such direct evaluation would require shutting down, opening, and untanking the transformer to finally be able to collect representative samples of insulating paper. Indirect evaluation, which consists of sampling the transformer oil, is simple, economical and non-intrusive.

The cellulose degradation products are generated by hydrolysis, oxidation and thermal degradation. These mechanisms are not independent of each other; they could coexist and even be in competition inside a transformer (Emsley and Stevens 1994). Some of the first efforts aimed at identifying indirect indicators of cellulose degradation, “chemical markers,” included determining carbon oxide and carbon dioxide levels (Kelly 1980; Tamura et al. 1981) along with a family of furanic compounds such as 5-hydroxymethyl-2-furaldehyde, furfuryl alcohol, 2-furaldehyde, 2-acetyl furan, and 5-methyl-2-furaldehyde present in oil (Burton et al. 1984; Unsworth and Mitchell 1990). Nonetheless, it has been reported that the presence of carbon oxides might not only be specific to paper degradation but also to oil ageing (Blue et al. 1998; Levchik et al. 1998). The presence of furanic compounds has been shown to be more specific to paper degradation. However, their instability, trace occurrence, humidity dependence, and possible derivation from other paper components hamper their use as universal indicators of cellulose degradation (Emsley 1994; Lundgaard et al. 2004).

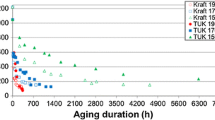

Recent studies indicate the presence of methanol (MeOH) and ethanol (EtOH) during the ageing of oil-impregnated paper which could be serve as chemical markers (Jalbert et al. 2007; Ryadi et al. 2011; Rodriguez-Celis et al. 2012). For the first time, a linear relationship between the generated methanol and depolymerization of cellulose (rupture of 1,4-β-glycosidic bonds) was established (Jalbert et al. 2007). Later on, kinetic studies of the degradation of standard wood kraft and thermally upgraded insulating paper provided additional confirmation that methanol originates from the cellulose chopped-end chains (Gilbert et al. 2008, 2009; Jalbert et al. 2015). New studies have confirmed the applicability of methanol as a new marker for paper degradation in power transformers (Schaut et al. 2011; Jalbert et al. 2012a) and an analytical methodology is available for the determination of these two alcohols in transformer oil, with detection limits in the low ng g−1 concentration level (Jalbert et al. 2012b).

Although there are many studies that promote the use of methanol as a marker of early stage paper degradation, the mechanism responsible for ethanol production in transformer oil is not yet understood. Both alcohols have been observed as products of the ageing of both standard Kraft and upgraded papers, regardless of the ageing conditions (temperature, humidity, air, etc.). Typically, during laboratory paper ageing at temperatures <210 °C and during the routine analysis of transformer oil, the concentration of methanol is always higher than for ethanol, which is generated at a lower rate than methanol but stabilized at about the same time (Jalbert et al. 2007, 2015; Ryadi et al. 2011). This probably corresponds to an ordinary ageing where acid hydrolysis is the predominant reaction pathway. The reverse tendency, EtOH > MeOH, has only been reported in 10 % of real transformer samples (Ryadi et al. 2011) regardless of transformer design (core vs. shell) and not during the routine analysis of transformer oil.

To gain a better understanding of this behavior, this paper further investigates cellulose degradation at higher temperatures in an effort to grasp the ethanol versus methanol formation from insulating paper in power transformers. This particular generation of ethanol might become a new diagnosis tool of a specific solid insulation event in the transformer.

Since cellulose is the major component of cell walls in plants, there is great interest in cellulose pyrolysis for biomass conversion. Cellulose pyrolysis has been also widely studied for the chemical utilization of wood pyrolysis products and fire-related issues. Cellulose pyrolysis reactions usually take place at temperatures higher than 250–300 °C; at lower temperatures there is water elimination, the formation of some double bonds, and cross-linking reactions. Various paths to account for the products of cellulose pyrolysis have been reported in the literature (Shafizadeh and Fu 1973; Piskorz et al. 1986; Funazukuri et al. 1988; Emsley and Stevens 1994; Perveen et al. 2008). Perhaps the most widely accepted pyrolysis mechanism consists of an activation step without weight loss followed by up to three competing irreversible first-order reactions which lead to weight loss (Piskorz et al. 1986; Diebold 1994). The first of these reactions (Diebold mechanism) involves the depolymerization of cellulose which consists of the splitting of glycosidic bonds to yield volatile products (primary vapors). The second reaction could form directly secondary gases, and the third reaction involves dehydration which yields char and water (Diebold 1994). Dehydration is important at low temperatures and slow heating rates while depolymerization becomes significant at higher temperatures, short times, and high heating rates (Piskorz et al. 1986). In a recent publication (Lin et al. 2009), the authors present a mechanism that consists in a series of reactions instead of three parallel pathways. They suggest that cellulose becomes “active” followed by decomposition into anhydro-oligosaccharides and then to levoglucosan formation. The latter undergoes dehydration and isomerization to form other molecules that could later form volatiles, carbon monoxides and char. The authors indicate that depolymerization occurs at temperatures as low as 100–150 °C.

In this study, pyrolysis was coupled with gas chromatography/mass spectrometry (GC/MS) for a quick and efficient identification of the volatile pyrolysis products. Only flash pyrolysis is considered, which involves heating rates in milliseconds. The fast pyrolysis of paper was carried out using a commercial instrument with mg sample capacity under an inert gas atmosphere (He). The goal of this work is to determine if ethanol is a by-product of pyrolysis and to identify thermal degradation products that could serve as indicators of localized high temperature of the solid insulation (hot-spots) in power transformers. The pyrolysis results are compared with thermal ageing of some cellulose model compounds (glucose, levoglucosan and cellobiose).

Experimental section

Chemicals

A standard 100 % wood kraft insulating paper, Munskjö electrical grade (Munskjö, Stockholm, Sweden) with a thickness of 45–55 μm and average viscometric degree of polymerization (DPv) of ~1200, was used in the experiments. Pyrolysis samples were prepared by slicing the paper into 1.0 × 0.2-cm strips. Each strip had an approximate weight of 1 mg. The paper samples were placed in a vacuum desiccator containing anhydrous calcium sulfate (Drierite) prior to pyrolysis.

Methanol extra dry 99.9 % (Acros Organics BVBA, Geel, Belgium), ethanol 99.9 % (Les Alcools de Commerce, Montréal, Canada) and cellulose model compounds d-(+)-cellobiose, d-(+)-glucose and 1,6-anhydro-β-d-glucose (levoglucosan), all products from Sigma-Aldrich Canada Ltd. (Oakville, Canada), were also used in the experiments. Inhibited electrical insulating oil, LuminolTM TR-i (Petro-Canada Lubricants Inc, Mississauga, Canada) was used in the thermal ageing experiments.

Apparatus

A coil pyrolysis unit (CDS Pyroprobe 2000 and its CDS 1500 Interface) was connected to a split/splitless injector (50:1 at 250 °C) of a 6890 gas chromatograph (GC) equipped with a 5973 mass spectrometer (MS) operating at 70 eV ionization energy in the electron ionization mode (GC and MS both from Agilent Technologies). The chromatography separation was performed on a 60-m-DB-624 (Agilent J&W) column, 0.250 mm in diameter, with a film thickness of 1.4 µm. The gas carrier flow ranged from 1.2 to 1.5 mL min−1 and the column temperature from 25 to 260 °C. The mass spectrometer interface was maintained at 230 °C, with a mass range of m/z = 30–300 amu, and scanned in total ion count mode (TIC) at a rate of 5.10 scans per second. The pyrolyzer heating element was made of platinum wire formed into a coil approximately 15 mm in length by 3 mm in diameter. The integrated GC–MS data analysis software (MSD ChemStation v.E.02.00.493) allowed the ions of the unknown peaks to be matched to the ions of a NIST MS library (NIST11) installed on the system.

Measurements of the average viscometric degree of polymerization (DPv) were made based on ASTM standard D4243.

Pyrolysis procedure

Experiments were performed by bringing the CDS 1500 interface to the operating temperature (250 °C). Once this temperature was attained, samples of approximately 1 mg were introduced into the quartz tube (0.3 mm thick, 25 mm long), which was plugged with quartz wool and inserted into the coil probe. The use of quartz wool on both sides of the samples provides a surface area for the cellulose tar to collect before penetrating into the GC pneumatics (Wampler, personal communication). The quartz tube also allows samples to remain in the center of the tube to ensure reproducibility during the pyrolysis experiment. The probe is then inserted into the hot interface and sealed with the valve in the LOAD position. A purge flow of Helium gas at 20 mL min−1 was connected to the purge input of the interface. This flow is intended to remove the presence of air from the interface before pyrolysis, and siloxanes that could originate from the probe septum during the experiment (Wampler, personal communication). Thirty seconds after the sample is introduced into the interface, the valve is switched to the RUN position, and once the GC inlet pressure is stable, pyrolysis (at the desired temperature and duration) starts simultaneously with GC separation. Approximately a minute after pyrolysis, the sample is removed with the valve again set at LOAD. Due to the large amount of generated vapour, high injection split ratios are used in pyrolysis to limit the amount of sample going into the GC but also to sweep the sample out of the interface, thus minimizing carryover. The inlet liner (straight, ultra inert, 990 μL) was changed regularly to avoid cross-contamination.

Pyrolysis of the paper strips and solid cellulose model compounds was performed at different filament set-point temperatures (25 °C intervals from 250 to 475 °C) in triplicate. Each test corresponds to the 20-s pyrolysis of a single paper strip. The paper samples were weighed before and after pyrolysis. To assess the change of DPv during pyrolysis, multiple paper samples were pyrolyzed under the above conditions in order to gather enough sample weight for the DPv measurements (~100 mg).

Calibration curves for methanol and ethanol were prepared from aqueous solutions of 25–320 μg g−1. These solutions (1 μL) were injected into the GC.

Thermal ageing studies

These studies involved ageing 0.5 g of the studied material (cellobiose, glucose and levoglucosan) with 9 mL of oil placed in 20-mL glass ampoules. The ampoules were sealed and placed in an oven at constant temperature for 1 week (168 h). Two temperatures were chosen (60 and 130 °C) and studies were done in triplicate. Besides being aged in regular oil, levoglucosan was aged at 130 °C in water and in acidified oil (0.1 mg KOH g−1 oil) under air atmosphere, and in oil under nitrogen atmosphere. After the ageing period, the ampoules were opened and 5 mL of oil was analyzed for alcohol content by an in-house HS–GC–MS (Agilent Technologies) method (Jalbert et al. 2012a). The samples were also analyzed for 2-FAL using high-performance liquid chromatography (Agilent Technologies, 1100 Series) based on a method adapted from Lessard et al. 1995).

Viscometric degree of polymerization (DPv)

Measurements of the average DPv were made at IREQ based on ASTM standard D4243.

FTIR measurements

Fourier-transform infrared (FTIR) spectroscopy was performed on a Nicolet 4700 spectrometer (Thermo Electron Corporation, Madison, WI, USA) using the attenuated total reflection (ATR) accessory. The instrument resolution was 4 cm−1.

Safety considerations

Although no problems were encountered during the pyrolysis studies, appropriate safety measures are recommended when working with a high-temperature pyrolysis probe.

Results and discussion

Normalization of pyrolysis temperatures

As indicated in the experimental section, the set-point temperature is the nominal temperature of the platinum filament calibrated by the manufacturer. The heat is initially transferred from the filament to the quartz tube and then to the paper sample. Therefore, a difference between the real pyrolysis temperature and the nominal filament temperature (set-point) is expected due to heat transfer losses. It has been reported that this difference becomes significant for pyrolysis experiments <5 s long (Funazukuri et al. 1987). The instrument manufacturer (CDS Analytical Inc.) indicates that the real pyrolysis temperature depends on sample size and type, and it is approximately 100 °C lower than the filament set-point temperature. The manufacturer also mentions that the observed difference is smaller at lower set-point temperatures. Studies on the heating characteristics of filament-type pyrolysis instruments are available in the literature (Inger 1980; Funazukuri et al. 1987). A temperature standardization procedure based on the ratio of isoprene/dipentene, two degradation products from the pyrolysis of Kraton, is available for flash pyrolysis (Levy and Walker 1984). However, this methodology has been proposed for experiments where the pyrolysis temperatures are higher than 600 °C.

During the weight loss experiments, we observed that our samples started to exhibit a significant weight loss at set-point temperatures above 350 °C. However, most pyrolysis studies of cellulose report weight loss at temperatures as low as 300 °C (Moldoveanu 1998), which is in agreement with a thermogravimetric analysis (TGA) of a similar insulation paper, Munskjö TH70. To estimate and make adjustments for differences between the filament set-point and the real pyrolysis temperatures, TGA data were compared with the remaining weight after paper pyrolysis. A plot of these temperature differences (not shown) for the same final weight versus the filament set-point temperatures yielded a linear correlation which was used to make corrections for the real pyrolysis temperature. This difference increased with temperature; for example, an experiment at a set-point temperature of 350 °C corresponded to a pyrolysis at 310 °C. From this point onward, the corrected temperature will be referred to as the pyrolysis temperature.

Changes in weight, degree of polymerization and FTIR characterization

The percentage weight loss was calculated as the difference in sample weight after pyrolysis divided by the initial weight and multiplied by 100. Figure 1 presents the weight lost during the pyrolysis experiments as a function of temperature. This weight loss behaviour, which corresponds to a pure pyrolytic ageing mechanism, differs from the trend observed for a similar standard Kraft paper, aged in oil. In Table 4 of their study (Jalbert et al. 2015) these authors show that after 14 h of ageing at 210 °C, a DPv of 133 was reached with an observable weight loss of only 1 %. It was noted by these authors that a pyrolysis-like mechanism in conjunction with acid hydrolysis was present in their ageing systems. Conversely, when only pyrolysis is present, weight loss shows an exponential increase with temperature. Figure 2 shows the changes in the physical appearance of the paper specimens before and after pyrolysis. As seen in this figure, there is a gradual increase of dark-brown coloring, and starting at 320 °C the remaining paper is black and extremely fragile and brittle.

The DPv accounts for the number of polymerized glucose rings. New cellulosic paper has a DPv of ~1200; a value of 150–200 indicates the end of its useful life where the transformer’s paper has no mechanical strength left resulting in a possible fault if mechanical stress occurs. The average number of cellulose scissions is calculated as DPv_initial/DPv_final − 1. Figure 3 presents the changes in DPv and the number of scissions with the increasing pyrolysis temperature. In our experiments, depolymerization is already present, with 50 % of its original value at 250 °C, and it probably starts at a lower temperature. In this figure, it is possible to observe that there are three trends during the decrease of DPv with pyrolysis temperature. First, there is an attenuation of DPv at temperatures below 300 °C, which corresponds to a minimum change of weight and appearance of the paper. Since 250 °C is the first studied degradation temperature, it is not possible to determine the role of the weak links (~4 % of initial DPv) during pyrolysis. This value was determined after a paper reduction treatment with borane tert-butylamine complex (TBAB) (Bicchieri et al. 1999). From 290 to 320 °C, there is a rapid decrease of DPv, the weight starts decreasing, and the damage in the paper is more evident. At approximately 320 °C, the DPv of the paper is already below 170, its LODP (levelling-off degree of polymerization) (Gilbert et al. 2009). Once the LODP is attained, the decrease of DPv seems to continue at a lower pace, while the weight loss keeps increasing and the paper is completely carbonized.

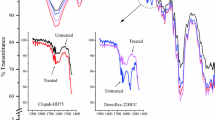

Mid-FTIR spectroscopy is used to monitor the structural and chemical changes in cellulose during pyrolysis. Figure 4 presents a superposition of FTIR spectra for Munskjö pyrolyzed at 310 and 330 °C and compared to a new paper. The most marked variation is the decrease in intensity of the O–H stretch hydrogen-bonded band at around 3300 cm−1 and the C–O stretch for secondary alcohols band at 1050 cm−1, which indicates dehydration when compared to new paper. The band at 1640 cm−1 found in the new paper disappeared. This band corresponds to the bending vibration of adsorbed water molecules that typically masks the conjugated C=O band (Łojewska et al. 2005). At higher pyrolysis temperatures, two new bands are better defined at 1590 and 1700 cm−1, which correspond to C=C and C=O stretching, respectively. However, the glucose ring stretch bands at 890 and 1110 cm−1 are still present. Our FTIR findings are in agreement with a study of cellulose char in anaerobic conditions from 190 to 390 °C (Pastorova et al. 1994).

Since these pyrolysis experiments at different temperatures were done at a constant time (20 s), it is not possible to elaborate on the cellulose degradation kinetics for each temperature. However, our findings confirm that dehydration and depolymerization play an important role and occur simultaneously during the range of studied temperatures.

Identification of pyrolysis products

When identifying potential chemical markers of cellulose degradation by accelerated ageing in oil, there is the limitation of the partitioning effect of these molecules in the two phases in contact (paper/oil), which causes signal fluctuations as there is an increase of oxidation products in the oil during the course of ageing. This partitioning effect is not an issue when working in pyrolysis mode. Moreover, the products identified by pyrolysis are readily available as they are generated just seconds before the beginning of the chromatographic separation and they are characteristic of the starting material, cellulose, since there is an absence of any other ageing matrix such as oil. The relative high pyrolysis temperatures could contribute to identifying the product characteristic of an unusual high temperature inside a transformer.

Table 1 lists the compounds identified during the paper pyrolysis experiments. The symbol √ indicates that the compound was present at the chosen temperature with a confidence level higher than 35 %. Although weight loss at 250, 275 and 288 °C was minimal (~5 %), the number of compounds for these temperatures increased significantly with the temperature. In general, the higher the pyrolysis temperature, the larger the number of molecules and their yields in the total ion chromatogram (TIC). As seen in this table, the identified molecules consisted of alcohols, carbonyl compounds, furans, acids, esters, and anhydrosugars, as well as other molecules such as sulfur dioxide, chloromethane and methanethiol. Most of these molecules are of the same type as those reported in the literature for cellulose pyrolysis (Moldoveanu 1998).

In field transformer analysis, is not rare to encounter methanol and ethanol (Ryadi et al. 2011). In a recent study (Rodriguez-Celis et al. 2012), some of these products (methanol, ethanol, furan, hydroxy-acetaldehyde, 2-methyl-furan and furfural) were identified in distribution and power transformer oil samples. Acetaldehyde, acetone and acetic acid were also present in the transformer oil but they are not exclusive to paper degradation (Rodriguez-Celis et al. 2012) as they are also products of oil degradation.

Methanol has already been reported in pyrolysis studies of microcrystalline cellulose (Funazukuri et al. 1987, 1988), wood pyrolysis at 250 °C (Degroot et al. 1988) and as a pyrolysis product (low yield) of 1,6-anhydro-α-d-glucopyranose (levoglucosan) at 600 °C (Shafizadeh 1982). It was also identified during the pyrolysis of lignin at 650 °C (Caballero et al. 1997), although the authors mentioned that its production decreases with increasing pyrolysis temperature. Although numerous studies are available on the enzymatic bioconversion of biomass into ethanol (Wayman et al. 1992; Srinivas et al. 1995; Oh et al. 1996; Rocha et al. 2013), references for ethanol, as a direct cellulose pyrolysis product, were not found. In a recent study (Jalbert et al. 2015) on the ageing of paper/oil systems at temperatures between 120 and 210 °C, ethanol is present as a degradation product; however, the ratio of methanol/ethanol concentrations is always higher than unity. Figure 5 shows the generation of these two alcohols with increasing pyrolysis temperature. The plotted signal corresponds to the integrated intensity for extracted ion m/z 31 normalized by the initial sample weight (~1 mg) as well as the number of moles of alcohol obtained per mass of paper. Methanol is observed at all the studied temperatures. Figure 5a shows two trends for methanol production. At temperatures lower than 300 °C, methanol is generated at a slower pace, but as the temperature increases, there is a more obvious generation. Even though ethanol is also identified during pyrolysis, its occurrence is only at set-point temperatures higher than 330 °C, ~DPv 100 (Fig. 5b) and its yield is lower than for methanol. Larger amounts of paper samples were pyrolyzed to confirm its appearance at only higher temperatures and not due to a lack of sensitivity at detection. Figure 6 shows the dependence of methanol on the number of chain-end groups in cellulose. The concentration of cellulose chains in the paper samples was calculated as suggested by Whitmore and Bogard (1994). For DPv values higher than the LODP, it is possible to model the first portion of the methanol relation within a linear function. A linear relationship between the broken cellulose chains and the amount of methanol has already been reported (Jalbert et al. 2007). Once the degradation has attained the LODP value, a downward curvature appears in the graphic, which could be explained by fewer methanol molecules produced once in the more stable crystalline region. Although a linear relationship exists between the generation of methanol and the concentration of broken bonds, the amount of methanol does not follow a 1:1 ratio with the concentration of chain-end groups, as demonstrated elsewhere (Jalbert et al. 2007, 2015; Gilbert et al. 2008, 2009). Since these experiments are performed without oil, methanol partition within the oil matrix is not responsible for its low production yield. This means that pyrolysis is not the preferred route of methanol formation since a higher yield was observed during accelerated paper ageing studies in oil.

A family of anhydrosugars (1,4:3,6-dianhydro-α-d-glucopyranose, 2,3-anhydro-d-manossan, 1,6-anhydro-α-d-glucopyranose, and 1,6-anhydro-α-d-galactofuranose) was also observed during pyrolysis experiments. Among these by-products, the most recurrent one is 1,6-anhydro-α-d-glucopyranose, also known as levoglucosan, which was observed at temperatures above 290 °C in our experiments. Levoglucosan is the most common product of depolymerization by transglycosidation, which is considered the main initial reaction in cellulose pyrolysis (Moldoveanu 1998). It was observed during laboratory ageing of Kraft paper in oil at 150 °C by analysis of the aqueous extracts by ion chromatography (Lessard et al. 1996). Consequently, this molecule would be an ideal marker of cellulose thermal degradation. Unfortunately, it has a low solubility in oil and an analytical technique might not be sensitive enough to detect its presence at low concentrations. If generated in the transformer, it would have a higher affinity for the paper than for the oil, which would further hinder its detection. Therefore, this molecule was not observed during routine transformer oil analysis.

Thermal ageing studies in oil

To further investigate the origin of ethanol, powder samples of cellobiose, glucose and levoglucosan were aged in oil at 60 and 130 °C for 168 h. The results are shown in Table 2 as μmol of component per mol of starting material. Both alcohols were generated after cellobiose and levoglucosan ageing. However, during ageing of levoglucosan, the predominant product was ethanol with a concentration of 40 and 220 times higher than methanol at 60 and 130 °C, respectively. Further studies show that the generation of ethanol did not improve with water content, acidic conditions, and inert atmosphere (N2).

Based on our findings, we suspect that ethanol originates at higher cellulose pyrolysis temperatures and subsequently is a by-product of levoglucosan degradation, which is confirmed by the high yield of ethanol during levoglucosan ageing. In a field oil sample containing a higher ratio of ethanol than methanol (Rodriguez-Celis et al. 2012), the average DPv was close to 1100, which indicates that the cellulosic insulation is still in good shape. However, a close inspection of the transformer paper showed black “burnt” regions, which may not influence the overall DP results but indicates uneven heating of the paper. Therefore, ethanol could be a valuable chemical marker for indicating the existence of “hot spots”. To confirm this hypothesis, alcohol oil testing together with DPv post-mortem values from scrapped transformers will be needed. At this stage, we are not in position to explain the mechanism of ethanol formation from cellulose through levoglucosan. Work is in progress to identify the factors and conditions that contribute to its formation.

Conclusions

This study involves the generation and identification of by-products of standard Kraft paper pyrolysis in the range of 250–360 °C. It is observed that at pyrolysis temperatures lower than 300 °C, there is no appreciable weight change and the physical appearance of the paper is not affected. However, at these temperatures, there is already major polymer degradation since the DPv values had already decreased and there is a significant number of volatile products. As the pyrolysis temperatures increase, the weight loss, physical changes and number and amount of volatiles increase as well. Dehydration and depolymerization seem to occur simultaneously during pyrolysis. Since these pyrolysis experiments were done at a constant time, it is not possible to elaborate on the degradation kinetics and build a model to predict the end of life of the paper.

Some of these thermal degradation products were observed during field transformer oil analysis, which could become useful in the choice of cellulose thermal degradation markers. Methanol, a marker that is already in use, was observed at all the studied temperatures. However, its yield was not the expected 1:1 ratio with the concentration of cellulose scissions. This suggests that pyrolysis by itself is not the main route of methanol generation, and its production is enhanced under the acidic hydrolytic conditions found in accelerated ageing in oil. Ethanol, a molecule that was found together with methanol in field samples and is generated during the ageing of levoglucosan in oil in a higher quantity than methanol, was only present at higher pyrolysis temperatures. We suspect ethanol, as a chemical marker of cellulose degradation, could indicate the presence of uneven heating zones in the insulation, also known as hot-spots. Future studies would include various pyrolysis times per temperature and the effect of pyrolysis under reagent gases.

References

Bicchieri M, Bella M, Semetilli F (1999) A quantitative measure of borane tert-butylamine complex effectiveness in carbonyl reduction of aged papers. Restaurator 20:22–29. doi:10.1515/rest.1999.20.1.22

Blue R, Uttamchandani D, Farish O (1998) Infrared detection of transformer insulation degradation due to accelerated thermal aging. IEEE Trans Dielectr Electr Insul 5:165–168. doi:10.1109/94.671924

Burton PJ, Graham J, Hall AC, Laver JA, Oliver AJ (1984) Recent developments by CEGB to improve the prediction and monitoring of transformer performance. Presented at the CIGRE conference, Paris, France, September 1984

Caballero JA, Font R, Marcilla A (1997) Pyrolysis of Kraft lignin: yields and correlations. J Anal Appl Pyrol 39:161–183. doi:10.1016/S0165-2370(96)00965-5

CDS Analytical Inc. Operating Manual for Pyroprobe 1000, 2000, AS 2500

Degroot WF, Pan W-P, Rahman MD, Richards GN (1988) First chemical events in pyrolysis of wood. J Anal Appl Pyrol 13:221–231. doi:10.1016/0165-2370(88)80024-X

Diebold JP (1994) A unified, global model for the pyrolysis of cellulose. Biomass Bioenergy 7:75–85. doi:10.1016/0961-9534(94)00039-V

Emsley AM (1994) The kinetics and mechanisms of degradation of cellulosic insulation in power transformers. Polym Degrad Stab 44:343–349. doi:10.1016/0141-3910(94)90093-0

Emsley AM, Stevens GC (1994) Kinetics and mechanisms of the low-temperature degradation of cellulose. Cellulose 1:26–56. doi:10.1007/BF00818797

Funazukuri T, Hudgins RR, Silveston PL (1987) Product distribution for flash pyrolysis of cellulose in a coil pyrolyzer. J Anal Appl Pyrol 10:225–249. doi:10.1016/0165-2370(87)80005-0

Funazukuri T, Hudgins RR, Silveston PL (1988) Product yield correlations for cellulose flash pyrolysis. J Anal Appl Pyrol 13:103–122. doi:10.1016/0165-2370(88)80051-2

Gilbert R, Jalbert J, Tétreault P, Morin B, Denos Y (2008) Kinetics of the production of chain-end groups and methanol from the depolymerization of cellulose during the ageing of paper/oil systems. Part 1: standard wood kraft insulation. Cellulose 16:327–338. doi:10.1007/s10570-008-9261-1

Gilbert R, Jalbert J, Duchesne S, Tétreault P, Morin B, Denos Y (2009) Kinetics of the production of chain-end groups and methanol from the depolymerization of cellulose during the ageing of paper/oil systems. Part 2: thermally-upgraded insulating papers. Cellulose 17:253–269. doi:10.1007/s10570-009-9365-2

Inger E (1980) Determination of the temperature—time profile of filament pyrolyzers. J Anal Appl Pyrol 2:187–194. doi:10.1016/0165-2370(80)80030-1

Jalbert J, Gilbert R, Tétreault P, Morin B, Lessard-Déziel (2007) Identification of a chemical indicator of the rupture of 1,4-β-glycosidic bonds of cellulose in an oil-impregnated insulating paper system. Cellulose 14:295–309. doi:10.1007/s10570-007-9124-1

Jalbert J, Lacasse R, EL Khakani MA, Gilbert R (2009) Pulsed KrF excimer laser induced degradation of cellulose based insulating paper. Cellulose 16:863–876. doi:10.1007/s10570-009-9293-1

Jalbert J, Gilbert R, Denos Y, Gervais P (2012a) Methanol: a novel approach to power transformer asset management. IEEE Trans Power Deliv. doi:10.1109/TPWRD.2012.2185957

Jalbert J, Duchesne S, Rodriguez-Celis E, Tétreault P, Collin P (2012b) Robust and sensitive analysis of methanol and ethanol from cellulose degradation in mineral oils. J Chromatogr A 1256:240–245. doi:10.1016/j.chroma.2012.07.069

Jalbert J, Rodriguez-Celis E, Duchesne S, Morin B, Ryadi M, Gilbert R (2015) Kinetics of the production of chain-end groups and methanol from the depolymerization of cellulose during the ageing of paper/oil systems. Part 3: extension of the study under temperature conditions over 120 °C. Cellulose 22:829–848. doi:10.1007/s10570-014-0516-8

Kelly JJ (1980) Transformer fault diagnosis by dissolved-gas analysis. IEEE Trans Ind Appl IA-16:777–782. doi:10.1109/TIA.1980.4503871

Lessard MC, Lamarre C, Gendron A, Massé M (1995) Determination of paper degradation by-products by direct injection on an HPLC column. Presented at the conference on electrical insulation and dielectric phenomena, Virginia, USA, October 1995, 230–234. doi:10.1109/CEIDP.1995.483705

Lessard MC, Van Nifterik L, Masse M, Penneau JF, Grob R (1996) Thermal aging study of insulating papers used in power transformers. Presented at the conference on electrical insulation and dielectric phenomena, San Francisco, USA, October 1996, 20–23. doi:10.1109/CEIDP.1996.564642

Levchik S, Scheirs J, Camino G, Tumiatti W, Avidano M (1998) Depolymerization processes in the thermal degradation of cellulosic paper insulation in electrical transformers. Polym Degrad Stab 61:507–511. doi:10.1016/S0141-3910(97)00249-8

Levy EJ, Walker JQ (1984) The model molecular thermometer: a standardization method for pyrolysis gas chromatography. J Chromatogr Sci 22:49–55. doi:10.1093/chromsci/22.2.49

Lin Y-C, Cho J, Tompsett GA, Westmoreland PR, Huber GW (2009) Kinetics and mechanism of cellulose pyrolysis. J Phys Chem C 113:20097–20107. doi:10.1021/jp906702p

Łojewska J, Miśkowiec P, Łojewski T, Proniewicz LM (2005) Cellulose oxidative and hydrolytic degradation: in situ FTIR approach. Polym Degrad Stab 88:512–520. doi:10.1016/j.polymdegradstab.2004.12.012

Lundgaard LE, Hansen W, Linhjell D, Painter TJ (2004) Aging of oil-impregnated paper in power transformers. IEEE Trans Power Deliv 19:230–239. doi:10.1109/TPWRD.2003.820175

Moldoveanu S (1998) Analytical pyrolysis of natural organic polymers, 1st edn. Elsevier, Amsterdam

Oh K-K, Kim T-Y, Jeong Y-S, Hong S-I (1996) Bioconversion of cellulose to ethanol by the temperature optimized simultaneous saccharification and fermentation. Renew Energy 9:962–965. doi:10.1016/0960-1481(96)88440-0

Pastorova I, Botto RE, Arisz PW, Boon JJ (1994) Cellulose char structure: a combined analytical Py–GC–MS, FTIR, and NMR study. Carbohydr Res 262:27–47. doi:10.1016/0008-6215(94)84003-2

Perveen S, Hussain Z, Khan KM (2008) Comparison of the pyrolysates of glucose, sucrose, starch and cellulose. J Chem Soc Pak 30:142–146

Piskorz J, Radlein D, Scott DS (1986) On the mechanism of the rapid pyrolysis of cellulose. J Anal Appl Pyrol 9:121–137. doi:10.1016/0165-2370(86)85003-3

Rocha NR de AF, Barros MA, Fischer J, Filho UC, Cardoso VL (2013) Ethanol production from agroindustrial biomass using a crude enzyme complex produced by Aspergillus niger. Renew Energy 57:432–435. doi:10.1016/j.renene.2013.01.053

Rodriguez-Celis E, Jalbert J, Duchesne S, Noirhomme B, Lessard MC, Ryadi M (2012) Chemical markers use for diagnosis and life estimation of power transformers, a preliminary study of their origins. Presented at the CIGRE Canada conference, Montreal, Canada, September 2012

Ryadi M, Tanguy A, Jalbert J, Rajotte C (2011) Alcohols based ageing chemical markers for the diagnosis of transformer cellulosic insulation. Presented at the CIGRE A2 and D1 Joint Colloquium PS2-0-4, Kyoto, Japan, September 2011

Schaut A, Autru S, Eeckhoudt S (2011) Applicability of methanol as new marker for paper degradation in power transformers. IEEE Trans Dielectr Electr Insul 18:533–540. doi:10.1109/TDEI.2011.5739459

Shafizadeh F (1982) Introduction to pyrolysis of biomass. J Anal Appl Pyrol 3:283–305. doi:10.1016/0165-2370(82)80017-X

Shafizadeh F, Fu YL (1973) Pyrolysis of cellulose. Carbohydr Res 29:113–122. doi:10.1016/S0008-6215(00)82074-1

Srinivas D, Jagannadha Rao K, Théodore K, Panda T (1995) Direct conversion of cellulosic material to ethanol by the intergeneric fusant Trichoderma reesei QM 9414/Saccharomyces cerevisiae NCIM 3288. Enzyme Microbial Technol 17:418–423. doi:10.1016/0141-0229(94)00093-7

Tamura R, Anetai H, Ishii T, Kawamura T (1981) Diagnosis of ageing deterioration of insulating paper. Trans Inst Electr Eng Jpn 101:30–36

Unsworth J, Mitchell F (1990) Degradation of electrical insulating paper monitored with high performance liquid chromatography. IEEE Trans Electr Insul 25:737–746. doi:10.1109/14.57098

Wayman M, Chen S, Doan K (1992) Bioconversion of waste paper to ethanol. Process Biochem 27:239–245. doi:10.1016/0032-9592(92)80024-W

Whitmore PM, Bogaard J (1994) Determination of the cellulose scission route in the hydrolytic and oxidative degradation of paper. Restaurator 15:26–45. doi:10.1515/rest.1994.15.1.26

Acknowledgments

The authors would like to express their gratitude to V. Caisse, J. Courval and M. Bouaffi from IREQ for their valuable technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rodriguez-Celis, E.M., Duchesne, S., Jalbert, J. et al. Understanding ethanol versus methanol formation from insulating paper in power transformers. Cellulose 22, 3225–3236 (2015). https://doi.org/10.1007/s10570-015-0693-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0693-0