Abstract

The paper presents an analysis of test results by Frequency Domain Spectroscopy (FDS) of the loss tangent (tgδ) in electrotechnical pressboard impregnated with insulating oil and containing nanoparticles of water depending on the frequency of alternating current, sample temperature and degree of moisture. We found tgδ reduction in areas of low and ultra-low frequency. It is associated with relaxation due to the hopping conductivity (tunnelling) of electrons between moisture nanoparticles occurring in the cellulose impregnated with insulating oil. In frequency areas close to the local minimum of tgδ and higher, relaxation does not depend on the moisture content and is associated with other polar molecules which are part of the cellulose. We developed a new method converting experimental frequency dependence of the loss angle tangent, measured by the FDS method to the reference temperature of 293 K (20 °C), using the exponential dependence of the relaxation time on the temperature, was developed. The activation energy of the relaxation time was determined based on the loss angle tangent of moist electrotechnical pressboard impregnated with insulating oil. It was found that the variation in moisture content in the composite cellulose–mineral oil–water nanoparticles do not cause changes in the activation energy of the relaxation time. The conversion of experimental frequency dependence of the loss angle tangent determined by the FDS method to the reference temperature of 293 K (20 °C) eliminates the temperature dependence in the areas of ultra-low and low frequencies occurring in the runs made directly on the basis of the measurement results. After calculating the frequency dependence of the loss angle tangent to the reference temperature, all that remains is its dependence on the moisture content.

Similar content being viewed by others

Introduction

For about a 100 years cellulose in the form of paper and electrotechnical pressboard, impregnated with insulation oil, has been the primary insulation material used for the production of high-power transformers. The main source of damp in the cellulose is the moisture penetrating to the transformer from the outside, which is dissolved in transformer oil. Water is then supplied through the oil to the cellulose and is absorbed by it, because the solubility of water in cellulose is more than a thousand times higher than in transformer oil (Oommen 1983). Besides, during many years of use paper-oil insulation is subject to aging in which cellulose depolymerisation processes occur (Jalbert et al. 2015; Gilbert et al. 2010) as a result of which the water molecules are precipitated directly in the fibers of cellulose. Both of these factors result in the fact that during long-term operation the moisture content in the composite cellulose–mineral oil gradually increases from a starting level of about 0.8 wt% to a level even higher than 5 wt%. As stated in Żukowski et al. (2015b), the water in the cellulose precipitates in the form of nanoparticles with a size of about 2.32 nm, containing approximately 220 molecules of water. This is consistent with the conditions sufficient for the formation of nanoparticles (Pogrebnjak and Beresnev 2012; Pogrebnjak et al. 2009, 2011), namely oil and water do not enter into chemical reactions, water is not soluble in oil, and the flow surface of water is much larger than that of insulating oil. This causes the water nanodrops to take the form of balls, which protects a minimum of surface energy. This means that during its operation the insulation of power transformers is converted from the composite cellulose-oil into the composite cellulose-oil–water nanoparticles (Żukowski et al. 2015b).

This means that it should be possible to accurately determine the moisture level of the solid component of power transformer insulation. To determine the moisture content in the paper-oil insulation of hermetic power transformers, non-destructive electrical methods are frequently used. These methods fall into two basic groups—measurements in the time domain, such as the method RVM (Return Voltage Measurement) (Saha 2003; Dey et al. 2010) and PDC (Polarisation Depolarisation Current) (Saha and Purkait 2004; Wolny and Kedzia 2010) and measurements in the frequency domain or e.g. FDS (Frequency Domain Spectroscopy) (Zhang et al. 2014; Jaya et al. 2013).

As a rule, the basis for the analysis is the Debye dielectric relaxation model (Jonscher 1983), which however has several features that are not confirmed experimentally. Namely, under for the pulsation ω = 2πf smaller than the reverse of the relaxation time τ (ω < 1/τ) in this model, there is a quadratic dependence of the conductivity on the frequency. In the damp pressboard impregnated with insulation oil this dependence is weaker than square (Żukowski et al. 2015c). Another drawback of Debye’s model is the reduction of dielectric permittivity in a square frequency function. Measurements of dielectric permittivity of impregnated pressboard with a certain moisture content prove that these relationships are weaker (Żukowski et al. 2016). In order to justify the presence of weaker than square dependences on the frequency conductivity and dielectric permittivity, a number of empirical models (Cole and Cole 1941, 1942; Havriliak and Havriliak 1997) were developed.

The most important drawback of both the Debye model (Jonscher 1983) and empirical models (Cole and Cole 1941, 1942; Havriliak and Havriliak 1997) is that while aiming at the electric field frequency to zero (DC voltage), conductivity also decreases to zero. This is contrary to the previously known measurement results which within ultra low frequencies exhibit a limit (DC) value of conductivity.

In (Żukowski et al. 2014, 2015b) it was found that the conductivity in the composite cellulose–mineral oil–water nanoparticles is done by hopping (tunnelling) of electrons between wells of potential, produced by water nanodrops. The well an electron jumped out of becomes positively charged, while the one it jumped into obtains a negative charge. This means that an electric dipole is formed as a result of such hopping. This causes a rise in the static dielectric permittivity above the values characteristic for a material containing no potential wells (Zukowski et al. 1991, 1997). In the case of polarisation and conductivity induced by electron tunnelling between the wells of potential an important parameter of phenomena is relaxation time τ. This is the time since the inception of the dipole until the return of the electron to the well from which it started its jump (the lifetime of the dipole).

Studies (Zukowski et al. 1997; Kołtunowicz et al. 2013; Żukowski et al. 2015a) present a model of hopping electron transfer (tunnelling) for direct and alternating current. Under this model, in the case of a hopping of a charge in the area of low pulsation value of ω ≪ 1/τ conductivity is a constant value (DC conductivity). In the intermediate frequency range of ω ~ 1/τ there is an increase in conductivity. In the area of high frequency (ω > 1/τ) conductivity ceases to grow and strives to achieve a constant value.

It can be seen from the model that in the area of intermediate frequency ω ~ 1/τ conductivity can be described by the formula:

where σ(ω)—conductivity; ω = 2πf—pulsation; f—frequency; α—frequency coefficient.

The rate of increase in conductivity in this frequency region is weaker than the square one: α < 2.

Experimental verification of the model, made for semiconductors containing wells of potential and composite nanoparticles of metallic phase in dielectric matrices (Svito et al. 2014) showed compatibility of the measurement results of AC conductivity and permittivity with the model of hopping electron transfer (tunneling) for direct and alternating current.

In (Żukowski et al. 2014, 2015c, 2016) for the analysis of relaxation processes of the DC conductivity and permittivity of the AC conductivity in the composite cellulose–mineral oil–water nanoparticles a new approach is used, based on taking into account the occurrence of an hopping exchange (tunnelling) of electrons between wells of potential generated by the water nanoparticles. It was agreed that in the composite cellulose–mineral oil–water nanoparticles there are complex depenednces of AC conductivity and dielectric permittivity on temperature, frequency and moisture, which are reviewed in studies (Żukowski et al. 2015c, 2016). However, the application of the AC conductivity and dielectric permittivity to assess the moisture level of the solid insulation of power transformers requires fairly complex calculations of the measured frequency resistance and capacitance, taking into account the geometric dimensions of the insulation.

From the point of view of application in estimating the moisture level in the solid insulation component the most suitable seems to be the tangent of the loss angle. This is due to the fact that this value is given directly by most meters intended for measurement by the FDS method.

The aim of this study was to evaluate the effect of moisture on the frequency and temperature dependences of the loss angle tangent of the composite cellulose–mineral oil–water nanoparticles.

Analysis of dielectric losses in the composite cellulose–mineral oil–water nanoparticles

Preliminary analysis will be done for a sample of impregnated pressboard with the moisture of X = 4 wt%. The relationship tgδ(f) for the temperature of 293 K (Fig. 1) was determined on the basis of the measurement results presented in (Ekanayake et al. 2006). The tgδ(f) dependencies (Fig. 1) for the measurement temperatures of 323 K and 353 K were determined on the basis of the measurement data presented in (Walczak et al. 2006). In references (Ekanayake et al. 2006; Walczak et al. 2006) studies were carried out for pressboard samples with various degrees of moisture and subsequently aged for about half a year at room temperature in order to achieve a thermodynamic equilibrium between pressboard, oil insulation and moisture.

As can be seen from Fig. 1, in the area of ultra-low and low-frequency pressboard impregnated with the moisture content of X = 4 wt% there are very high values of tgδ(f), even more than 10. As mentioned above, this is to do with the formation of electric dipoles as a result of the hopping exchange of electrons between the water nanoparticles. With increasing frequencies above approximately f = 102 Hz, the values of tgδ(f) decrease and reach a minimum, the position of which depends on the measurement temperature. The values of tgδ(f) at a minimum are relatively weakly dependent on temperature. In the frequency range above the minimum the values of tgδ(f) begin to rise.

Figure 1 also shows that the increase in measurement temperature causes a shift of the tgδ(f) characteristics into the higher frequency range. This effect is due to the acceleration with an increase in temperature of the relaxation processes of the dipoles resulting from the hopping exchange of electrons between the water nanodrops. This phenomenon can be taken into account by describing the temperature changes of the relaxation time by using the formula (Psarras et al. 2003; Kudryashov et al. 2012):

where τ(T)—relaxation time; τ0—a constant value; ΔE(τ)—activation energy of the relaxation time; k—Boltzmann constant; T—temperature.

To determine the value of the activation energy of the relaxation time at each of the dependences of Fig. 1, one should select the characteristic point of the waveforms obtained at different temperatures.

However, as can be seen from Fig. 1, the measurement points, determined experimentally, are located relatively rarely, with the step of Δlogf = 0.333, that is three points per decade. This is related to the need for a considerable time to perform each measurement in the range of ultra-low frequency of the order of (10−4–10−3) Hz. Accordingly, the accuracy of determining the position of the characteristic point, and consequently the activation energy values ΔE(τ) directly from the experimental data is very low.

In order to improve the accuracy of the position of the characteristic point we used a new procedure for the polynomial approximation, prepared and presented in (Żukowski et al. 2015c). The results of these calculations of frequency permittivity dependences are shown in Fig. 1 with the step of Δlogf = 0.01 in the form of small dots, which practically form continuous lines.

As can be seen from Fig. 1, the new way of polynomial approximation of dielectric permittivity applied in our study to the composite cellulose–mineral oil–water nanoparticles perfectly clearly shows waveforms obtained by experiment in the entire frequency range measured. This is also confirmed by the values of the determination coefficient R2 approaching very closely the value of one, and amounting to 0.99999, 0.99996 and 0.99923 for the measured and approximated tgδ(f) waveforms, for measurement temperatures of 293, 323 and 353 K respectively.

The characteristic point in the waveforms presented in Fig. 1 is a local minimum present in the frequency range above 102 Hz. The location of this f min point was chosen as a reference point in order to convert waveforms obtained at any temperature to the temperature of 293 K adopted in electrical engineering as a reference. Waveforms for temperatures other than the reference temperature 293 K are moved by means of the relaxation time τ, calculated from formula (2) to the temperature of 293 K. The calculation results are shown in Fig. 2.

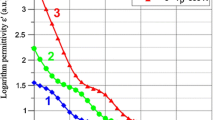

The approximation of the tgδ(f) dependence on frequency for impregnated pressboard with the water content of X = 4 wt%. The shift along the horizontal axis is aimed at aligning the positions of the minima for temperatures 323 and 353 K with the minimum for the reference temperature of 293 K. Measurement temperatures: 1 293 K, 2 323 K, 3 353 K

As can be seen from Fig. 2, the shifted of the waveforms, carried out in such a way that the positions of the minima of the waveforms tgδ(f) overlap, results in the fact that the only overlapping in the waveforms is that of the minimum points. The remaining areas of the tgδ(f) dependences do not overlap. This means that the choice of the f min position as a reference point was not hit.

Figure 3 shows the approximated waveforms for all moisture contents from 1 to 4 wt%. For the measurement temperature of 293 K. As can be seen from Fig. 3, the log{tgδ(logf)} waveforms with the values of −2.2 to −0.3 with increasing moisture move parallel to each other into the area of higher frequency. This means that in this change area a tgδ relaxation occurs, associated with the hopping electron exchange (tunneling). With a further approximation to the log{tgδ(logf)} values towards a local minimum, the differences between the waveforms for different moisture contents decrease. However, after exceeding the minimum for X = 4 wt% the dependence of the log{tgδ(logf)} values on moisture disappears completely. This means that the relaxation associated with the hopping exchange of electrons (tunneling) between nanoparticles of moisture occurs in the frequency range below f min. In frequency areas close to the minimum and higher, relaxation associated with dipoles arising out of the hopping exchange of electrons between the water nanoparticles is virtually terminated. Similar results were obtained for pressboard with the moisture content of 1, 2, and 3 wt%. Therefore, we selected as a reference, just as in (Żukowski et al. 2015c, 2016), the inflection point on the log{tgδ(logf)} function, which, as can be seen from Fig. 1, lies in the frequency region much lower than the local minimum, i.e. in an area where there is a relaxation associated with dipoles arising in the hopping exchange of electrons between the nanoparticles of water.

In order to determine the position of the inflection points one should calculate the frequency coefficient α(f) in formula (1) (Kołtunowicz et al. 2013):

At inflection points α(f) achieves the maximum value αmax(f) or the minimum one αmin(f). On the basis of the approximated waveforms tgδ(f) (Fig. 1) and by using formula (3) the values of frequency coefficients α(f), shown in Fig. 4, were calculated. On the waveforms clear minima and maxima can be seen, the position of which corresponds to the inflection points.

The frequency dependences α(f) for impregnated pressboard with the water content of X = 4 wt%, calculated according to formula (4) for tgδ waveforms. Measurement temperatures: 1 T = 293 K, 2 323 K, 3 353 K. The continuous lines calculations using approximation polynomial in steps of 0.01

Taking as reference points on the dependences obtained at different temperatures the f min frequency values corresponding to the positions of right-hand-side local minima (for 293 K—approx −3.0, for 323 K—approx +0.5, for 353 K—approx +2.0) for which α(f min) = αmin(f), one can take into account the effect of temperature on relaxation time τ, given by formula (2):

When setting the f min(T) values for two measurement temperatures T 1 and T 2 and comparing formulas (4), recorded for these temperatures, we get the value of activation energy of the relaxation time:

From the waveforms α(f) shown in Fig. 4, the values of f min(T) were determined, then used as reference points to calculate the activation energy of the relaxation time according to formula (5). Since we had a choice of 3 measurement temperatures, using the three possible combinations of temperature pairs of (T 1 – T 2, T 2 – T 3, T 1 – T 3), for the pressboard with the water content of 4 wt% the mean value was obtained of the activation energy of the relaxation time for the pressboard of 4 w% moisture ΔE(τ) ≈ 0.9828 eV. Similar calculations were performed for the activation energy of pressboard impregnated with insulating oil and the moisture content of 1, 2 and 3 wt%. The values of the activation energy for each of the moisture content and their average values are shown in Table 1.

Using the resulting value of the activation energy of the relaxation time the approximated tgδ(f) values were converted to the reference temperature T 0 = 273 K (20 °C). Figure 5 shows an approximated dependences of the tangent of the loss angle of the composite cellulose–mineral oil–water nanoparticles with the moisture content of 1, 2, 3 and 4 wt% for the measurement temperatures of 293 K, 323 K and 353 K, shifted to the reference temperature of T 0 = 293 K (20 C) along the x-axis by the obtained average value of the activation energy of the relaxation time ΔE(τ) = 0.9778 ± 0.00951 eV, calculated for the entire pressboard population with different moisture contents (Table 1).

After the shift we have three waveforms, for each moisture content and the three temperature measurements, running very close to one another (Fig. 5). The slight differences between them are for X = 4 wt% in the frequency range lower than log(f) = −1, 7 and fall within measurement uncertainty. In contrast, the differences occurring in the area above log(f) = +1, 3 are associated with the relaxation of polar molecules occurring in the structure of cellulose, i.e. particles other than nanoparticles of water. This means that the shift of the tgδ(f) dependences, measured at different temperatures, to the reference temperature of 293 K eliminates the temperature dependence in the frequency of 3 × 10−2 Hz < f < 3 × 101 Hz, where relaxation related to the dipoles arising in the hopping exchange of electrons between the water nanoparticles. After moving in this frequency area there remains only the dependence of the waveforms on the moisture of the composite cellulose–mineral oil–water nanoparticles. This means that by choosing any point on the tgδ(f) waveform in the frequency range of 3 × 10−2 Hz < f < 3 × 101 Hz we can analyse the impact of moisture on the tgδ value.

This means that the activation energy of the dielectric loss does not depend on the moisture content in the frequency region where there occurs relaxation associated with dipoles, arising from the hopping charge exchange between the nanoparticles of water, arising in the composite cellulose–mineral oil.

Figure 5 shows that the values of tgδ in this frequency range, shifted to the reference temperature of 293 K, depend exclusively on the moisture content.

This fact can serve as a basis to develop a new method of determining the moisture content in the component of solid paper-oil insulation.

Figure 5 also shows that in the frequency range above f min the tgδ(f) waveforms for different moisture contents measured at the temperature of 293 K perfectly overlap. Waveforms for the temperatures of 323 and 353 K behave in a similar way. This means that in this frequency range pressboard moisture does not affect the tgδ(f > f min) dependences. It can be deduced that the tgδ(f) dependences at frequencies above f min are due to intensified relaxation processes in this area, associated with particles other than the nanoparticles of water, i.e. with polar molecules contained in the cellulose structure (Linhjell et al. 2007; Ek et al. 1997).

Conclusions

Analysis of the frequency dependences of the tangent values of the loss angle of the composite cellulose–mineral oil–water nanoparticles showed that in areas of ultra-low and low frequency dielectric relaxation dipoles occurred as a result from the tunnelling of electrons between the nanoparticles of water. In this frequency region the increasing moves the tgδ(f) waveforms to the area of higher frequency due to the temperature changes in the relaxation time.

It was found that the variation in moisture content in the composite cellulose–mineral oil–water nanoparticles do not cause changes in the activation energy of the relaxation time for tgδ in the areas of ultra-low and low frequencies.

The activation energy of the relaxation time tgδ was determined, its value for the composite cellulose–mineral oil–water nanoparticles with the moisture content of 1–4 wt% is ΔE(τ) ≈ (0.9777 ± 0.00036) eV.

It was found that the tgδ(f) waveforms obtained at different measurement temperatures, when shifted to the reference temperature of 293 K, perfectly overlap in the areas of ultra-low and low frequencies. There occurs relaxation associated with dipoles arising in the hopping exchange of electrons between the nanoparticles of water. In this frequency area, after moving the waveforms to the reference temperature, all that remains is their dependence on the moisture content of the composite cellulose–mineral oil–water nanoparticles. This could serve as a basis for developing a new method of determining the moisture content in the component of solid paper-oil insulation.

In frequency areas close to the minimum and higher the relaxation is not due to the presence of moisture in the pressboard. The value tgδ in this frequency area is only determined by temperature.

References

Cole KS, Cole RH (1941) Dispersion and absorption in dielectrics—I. Alternating current characteristics. J Chem Phys 9(341):341–352. doi:10.1063/1.1750906

Cole KS, Cole RH (1942) Dispersion and absorption in dielectrics—II. Direct current characteristics. J Chem Phys 10(98):98–105. doi:10.1063/1.1723677

Dey D, Chatterjee B, Chakravorti S, Munshi S (2010) Importance of denoising in dielectric response measurements of transformer insulation: an uncertainty analysis based approach. Measurement 43(1):54–66

Ek R, Hill M, Newton JM (1997) Low frequency dielectric spectroscopy characterization of microcrystalline cellulose, tablets and paper. J Mater Sci 32(18):4807–4814

Ekanayake C, Gubanski SM, Graczkowski A, Walczak K (2006) Frequency response of oil impregnated pressboard and paper samples for estimating moisture in transformer insulation. IEEE Trans Power Deliv 21(3):1309–1317

Gilbert R, Jalbert J, Duchesne S, Tétreault P, Morin B, Denos Y (2010) Kinetics of the production of chain-end groups and methanol from the depolymerization of cellulose during the ageing of paper/oil systems. Part 2: thermally-upgraded insulating papers. Cellulose 17(2):253–269

Havriliak S Jr, Havriliak SJ (1997) Dielectric and mechanical relaxation in materials. Analysis, interpretation and application to polymers. Hanser Publishers, Vienna, New York

Jalbert J, Rodriguez-Celis E, Duchesne S, Morin B, Ryadi M, Gilbert R (2015) Kinetics of the production of chain-end groups and methanol from the depolymerization of cellulose during the ageing of paper/oil systems. Part 3: extension of the study under temperature conditions over 120 C. Cellulose 22(1):829–848. doi:10.1007/s10570-014-0516-8

Jaya M, Geißler D, Leibfried T (2013) Accelerating dielectric response measurements on power transformers—Part I: a frequency-domain approach. IEEE Trans Power Deliv 28(3):1469–1473

Jonscher AK (1983) Dielectric relaxation in solids. Chelsea Dielectrics Press, London

Kołtunowicz TN, Fedotova JA, Zhukowski P, Saad A, Fedotov A, Kasiuk JV, Larkin AV (2013) Negative capacitance in (FeCoZr)-(PZT) nanocomposite films. J Phys D Appl Phys 46(12):125304

Kudryashov MA, Mashin AI, Logunov AA, Chidichimo G, De Filpo G (2012) Frequency dependence of the electrical conductivity in Ag/PAN nanocomposites. Tech Phys 57(7):965–970

Linhjell D, Lundgaard L, Gäfvert U (2007) Dielectric response of mineral oil impregnated cellulose and the impact of aging. IEEE Trans Dielectr Electr Insul 14(1):156–169

Oommen TV (1983) Moisture equilibrium in paper oil systems. In: Proceedings of the 16th electrical/electronics insulation conference, October 3–6, Chicago, IL, pp 162–166

Pogrebnjak AD, Beresnev VM (2012) Nanocoatings, nano-systems, nanotechnologies. Bentham Science, Oak Park

Pogrebnjak AD, Danilionok MM, Uglov VV, Erdybaeva NK, Kirik GV, Dub SN, Rusakov VS, Shypylenko AP, Zukowski PV, Tuleushev YZ (2009) Nanocomposite protective coatings based on Ti-N-Cr/Ni-Cr-B-Si-Fe, their structure and properties. Vacuum 83(1):S235–S239. doi:10.1016/j.vacuum.2009.01.071

Pogrebnjak AD, Shpak AP, Kirik GV, Erdybaeva NK, Il’yashenko MV, Dem’yanenko AA, Kunitskii YuA, Kaverina ASh, Baidak VS, Makhmudov NA, Zukowski PV, Komarov FF, Beresnev VM, Ruzimov ShM, Shypylenko AP (2011) Multi layered nano-microcomposite Ti-Al-N/TiN/Al2O3 coatings. Their structure and properties. Acta Phys Pol A 120(1):94–99

Psarras GC, Manolakaki E, Tsangaris GM (2003) Dielectric dispersion and ac conductivity in iron particles loaded polymer composites. Compos Part A Appl S 34(12):1187–1198

Saha T (2003) Review of time-domain polarization measurements for assessing insulation condition in aged transformers. IEEE Trans Power Deliv 18(4):1293–1300

Saha TK, Purkait P (2004) Investigation of polarization and depolarization current measurements for the assessment of oil-paper insulation of aged transformers. IEEE Trans Dielectr Electr Insul 11(1):144–154

Svito I, Fedotov AK, Koltunowicz TN, Zhukowski P, Kalinin Y, Sitnikov A, Czarnacka K, Saad A (2014) Hopping of electron transport in granular Cux(SiO2)1−x nanocomposite films deposited by ion-beam sputtering. J Alloys Compd 615(1):S371–S374

Walczak K, Graczkowski A, Gielniak J, Morańda H, Mościcka-Grzesiak H, Ekanayake C, Gubański S (2006) Dielectric frequency response of cellulose samples with various degree of moisture content and aging. Prz Elektrotechn 1:264–267 (in Polish)

Wolny S, Kedzia J (2010) The assessment of the influence of temperature of selected parameters of the approximation method of depolarization current analysis of paper–oil insulation. J Non-Cryst Solids 356(11–17):809–814

Zhang T, Li X, Lv H, Tan X (2014) Parameter identification and calculation of return voltage curve based on FDS data. IEEE Trans Appl Supercon 24(5):9002405

Zukowski PW, Kantorow SB, Kiszczak K, Maczka D, Stelmakh VF, Rodzik A, Czarnecka-Such E (1991) Study of dielectric function of silicon irradiation with great dose of neutrons. Phys Status Solidi A 128(2):K117–K121

Zukowski PW, Rodzik A, Shostak YA (1997) Dielectric constant and AC conductivity of semi-insulating Cd1−xMnxTe semiconductors. Semiconductors 31(6):610–614

Żukowski P, Kołtunowicz TN, Kierczyński K, Subocz J, Szrot M, Gutten M (2014) Assessment of water content in an impregnated pressboardbased on DC conductivity measurements. Theoretical assumptions. IEEE Trans Dielectr Electr Insul 21(3):1268–1275

Żukowski P, Kołtunowicz TK, Boiko O, Bondariev V, Czarnacka K, Fedotova JA, Fedotov AK, Svito IA (2015a) Impedance model of metal-dielectric nanocomposites produced by ion-beam sputtering in vacuum and its experimental verification for thin films of (FeCoZr) x (PZT)(100−x). Vacuum 120:37–43. doi:10.1016/j.vacuum.2015.04.035

Żukowski P, Kołtunowicz TN, Kierczyński K, Subocz J, Szrot M (2015b) Formation of water nanodrops in cellulose impregnated with insulating oil. Cellulose 22(1):861–866. doi:10.1007/s10570-015-0543-0

Żukowski P, Kołtunowicz TN, Kierczyński K, Subocz J, Szrot M, Gutten M, Sebok M, Jurcik J (2015c) Analysis of AC conductivity in wet oil-impregnated insulating paper. IEEE Trans Dieltr Electr Insul 22(4):2156–2164

Żukowski P, Kołtunowicz TN, Kierczynski K, Rogalski P, Subocz J, Szrot M, Gutten M, Sebok M, Jurcik J (2016) Permittivity of a composite of cellulose, mineral oil and water nanoparticles: theoretical assumptions. Cellulose 23(1):175–183. doi:10.1007/s10570-015-0797-6

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Żukowski, P., Kołtunowicz, T.N., Kierczyński, K. et al. Dielectric losses in the composite cellulose–mineral oil–water nanoparticles: theoretical assumptions. Cellulose 23, 1609–1616 (2016). https://doi.org/10.1007/s10570-016-0934-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0934-x