Abstract

The results are presented from an experimental study to investigate three-dimensional turbulence structure profiles, including turbulence intensity and Reynolds stress, of different non-uniform open channel flows over smooth bed in subcritical flow regime. In the analysis, the uniform flow profiles have been used to compare with those of the non-uniform flows to investigate their time-averaged spatial flow turbulence structure characteristics. The measured non-uniform velocity profiles are used to verify the von Karman constant κ and to estimate sets of log-law integration constant Br and wake parameter П, where their findings are also compared with values from previous studies. From κ, Br and П findings, it has been found that the log-wake law can sufficiently represent the non-uniform flow in its non-modified form, and all κ, Br and П follow universal rules for different bed roughness conditions. The non-uniform flow experiments also show that both the turbulence intensity and Reynolds stress are governed well by exponential pressure gradient parameter β equations. Their exponential constants are described by quadratic functions in the investigated β range. Through this experimental study, it has been observed that the decelerating flow shows higher empirical constants, in both the turbulence intensity and Reynolds stress compared to the accelerating flow. The decelerating flow also has stronger dominance to determine the flow non-uniformity, because it presents higher Reynolds stress profile than uniform flow, whereas the accelerating flow does not.

Similar content being viewed by others

1 Introduction

The analysis of flow turbulence is commonly performed on the time-averaged velocity, turbulence intensity and Reynolds stress in two-dimensional (2D) flow domain [19]. However, studying 3D flow characteristics can provide more descriptive flow information about its turbulence structure, which is useful for various hydraulic engineering applications. The time-averaged flow velocity is often reproduced by logarithmic profile that is normalised by the wall shear velocity. To systematically represent flow velocity, the Prandtl van Karman type velocity distribution’s logarithmic-wall law was utilised by Keulegan [10] in his investigation on rectangular open channel flow. To improve Keulegan’s study, Coles [6] proposed the log-wake law with a wake correction to more precisely represent velocity distribution at the outer flow region where the ratio of flow vertical location to full flow depth (z/h) is bigger than 0.2. Coles’ method has been proven to give better accuracy compared to the log-wall law, as concluded by Song and Graf [29] and Dey and Raikar [7]; as well as in the modified log-wake law study by Yang [32].

The turbulence structure, including the time-averaged turbulence intensity and Reynolds stress, is produced from the Reynolds decomposed elements of instantaneous flow velocity. The same as the velocity log profile, the wall shear velocity is often used to normalise the turbulence intensity and Reynolds stress. This normalisation allows the turbulence representation in a scale benchmarked by the wall value so to permit comparison between different data sets collected under different hydraulic and wall boundary conditions. There are several ways to determine the shear velocity [27], in which two common approaches are: (1) the extrapolation method from the measured Reynolds stress profile, and (2) the energy gradient method. These methods have been shown to give reasonable estimation of the wall shear velocity [7, 28] providing that the wall boundary is relatively uniform through longitudinal space, i.e. particularly suitable for smooth bed flows. In comparison, the Reynolds stress profile extrapolation method has been found to be more prone to error as it is more dependent to the near bed/inner flow region measurements. For the measuring technique utilised in this study, Acoustic Doppler Velocimeter (ADV), the quality of the measured signal-to-noise ratio (SNR) can be sensitive to the reflective signals from wall boundary [35]. On the other hand, the energy gradient method involves the use of basic flow parameters, such as the hydraulic radius and bed slope; hence it is more error-resistant in calculating shear velocity [24, 25].

Accelerating [5] and decelerating flows [9, 22, 32] were studied to understand the characteristics of non-uniform flow. The strategy adopted for the analysis of non-uniform time-averaged velocity and turbulence characteristics was usually based on comparison to the uniform flow profiles [9, 33]. Nezu et al. [18] first suggested the representation of non-uniform flow characteristics using the indication of streamwise pressure gradient. According to their study, due to the existence of the pressure gradient in the non-uniform flows, the velocity distribution should be characterised by non-constant wake parameter Π and log-law integration constant Br. Kironoto and Graf [14] and Song and Chiew [28] further detailed the change of Br and Π values using a pressure gradient parameter β, which is defined by

where h is the water flow depth, τo is the bed shear stress, and \( \partial P/\partial x \) is the flow pressure gradient. The work on β-effects on flow non-uniformity has been further expanded in the study by Onitsuka et al. [22]. All these studies showed that the non-uniform flow turbulence intensity and Reynolds stress can be well-represented by expression of β.

In this study, we attempt to compare the non-uniform flow turbulence patterns in subcritical flow regime over smooth bed. It aims to investigate the non-uniformity impact to the time-averaged spatial flow velocity, turbulence intensity and Reynolds stress profiles and to find their respective relationship to flow pressure gradient. To this end, these non-uniform flow profiles are also compared with previous literature findings to investigate their flow properties and to identify the flow behaviour under different types of non-uniform flows (i.e. accelerating and decelerating flows). Compared to previous works, this study identifies clearer dominant characteristics between the tested accelerating and decelerating flows which can add to the existing knowledge and tests of the non-uniform flow.

2 Experimental description

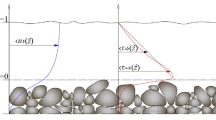

Figure 1 shows the general layout of the hydraulic flume used in this study. The experimental instrumentation and flow conditions are described in details here.

(re-adapted using similar figure to Fig. 1 at [25])

Sketch layout of the experimental flume with dimensions of 12.0 m × 0.5 m × 0.45 m

2.1 Experimental instrumentations

The flume presented in Fig. 1 has dimensions of 12 m × 0.50 m × 0.45 m, and it is a recently refurbished flume located at the Hydraulic Laboratory, University of Bradford [26]. The flume is operated by a circulating system, where the outlet discharge is directed into a filtering tank then to a water pump system to be re-circulated back into the flume. The flume consists of glass walls and a smooth stainless-steel base. A flat gate is located at the channel end to control the flow depth in the flume. Two parallel tracks are utilised on top of the flume for attaching measuring trolley used for holding and securing the ADV equipment.

The employed ADV has down-looking probes—product of the Nortek Ltd. (Vectrino ADV). It has a limitation of 5 cm measuring distance downward from the probe location, which restricts the data collection at 5 cm vertical distance near to the water flow free surface. The ADV is equipped with the four-probe-receiver, which can significantly reduce the noise signal of the measurements as compared with the three-probe-receiver ADV [3].

2.2 Experimental conditions

Table 1 presents a summary of all conditions in the hydraulically smooth uniform and non-uniform flow experiments conducted in this study. Besides the common parameters, the table also includes a roughness Reynolds number, Rek, to indicate and confirm the smooth bed property used in this study [34]. The velocity measurements for the non-uniform flows (Test 2, 3, 4 and 5) are taken at four streamwise locations (at 3, 5, 6 and 7 m from the flume inlet). For the uniform flow test (Test 1), the measurements are conducted at five different streamwise locations from upstream to downstream to ensure its uniformity characteristic. At each streamwise location, the velocity measurements are recorded at 15–20 vertical positions. Each sampling point can have a minimum sampling volume size of 1 mm3; however, for the measurement point that has low SNR ratio (lower than 18 dB), the sampling volume is increased. In all tests, all the point velocity measurements are conducted at a sampling frequency of 100 Hz for 5 min.

3 Uniform flow results and analysis

The normalised velocity profile for smooth bed uniform flow can be represented by the log-wake law originated from Prandtl–van Karman log velocity distribution as follows [19]

where \( u^{ + } = u\left( z \right)/u_{*} \), \( z^{ + } = \left( {u_{*} \cdot z} \right)/\nu \), z is the vertical distance, \( u\left( z \right) \) is flow velocity at distance z, \( u_{*} \) is the shear velocity, δ is the water depth where the maximum velocity occurs (in our case δ = h), and ν is the kinematic viscosity. In Eq. (2), the first two items on the right-hand side represent the log-wall law function and the inclusion of the last expression on the right-hand side provides the wake function to the log law.

For the von Karman constant κ in Eq. (2), relatively consistent values have been found in different literature studies. A range of κ = 0.40–0.42 was proposed for the flows over smooth bed investigated by Coles [6] and Cardoso et al. [4]; while, similar value (κ = 0.40) was also suggested for the rough bed flow by Song et al. [30]. More recently, Auel et al. [2] summarised from various smooth and rough bed flow studies that κ = 0.385–0.435, universally. For the log-law integration constant Br of smooth bed uniform flows, it was proposed as Br = 4.9 in Mellor and Gibson [15], and Anwar and Atkins [1]; and Br = 5.1 in Coles [6], and Cardoso et al. [4]. In comparison to different rough bed flow studies (i.e. Br = 8.47 ± 0.90 in [13]; Br = 8.42 ± 0.22 in [30]; and Br = 7.80 ± 0.37 in [7]), the smooth bed flow was found to have lower Br value.

For the wake parameter П, different estimations were made in various literature studies for the smooth bed uniform flow. In those studies, some have suggested higher values, namely Nezu and Rodi [20]—П = 0.20; while others proposed lower values, namely Kirkgoz [11]—П = 0.10, Steffer et al. [31]—П = 0.08–0.15, and Cardoso et al. [4]—П = 0.079 ± 0.093. When compared to rough bed flow studies, i.e. Π = 0.09 by Kironoto and Graf [13], Π = 0.08 by Song et al. [30], and Π = 0.110 ± 0.026 by Dey and Raikar [7], Π does not show separate distinct values for flow over different bed roughness.

3.1 Discussion

In Fig. 2, the u+ distribution profiles for Test 1 are used to empirically verify κ, and to calculate Br and П constants appeared in Eq. (2). The shear velocity in this test has been obtained using the bed shear stress calculated from the uniform pressure gradient approach as follows

where g is the gravitational acceleration, R is the hydraulic radius, and So is the bed slope. The measurements at five different locations across up- to downstream for Test 1 show the unchanged coefficient values of κ, Br and П to be 0.43, 4.7, and 0.0754, respectively. These parameters are found to give consistent values with most of the other smooth bed uniform flow studies discussed in this section; however, 0.43 is found to be at the higher end of κ range proposed by Auel et al. [2].

To carry out the turbulence structure analysis, the 3D turbulence intensities for Test 1 are investigated. The well-known theory of Nezu [16] has been employed to express the 3D turbulence intensities in exponential form as follows

where u′, v′ and w′ represent the velocity fluctuations in 3D streamwise, lateral and vertical directions, respectively, and D1, D2, D3, λ1, λ2 and λ3 are all empirical constants for the 3D turbulence intensities. It can be observed from Fig. 3 that the measured turbulence intensity profiles (symbols) at all five measured locations correspond reasonably with Eqs. (4)–(6) (lines) in which their regression coefficients R2 falls between 0.75 and 0.83. For the lateral turbulence intensity profile, Papanicolaou and Hilldale [23] reported that D2 and λ2 should be slightly larger than D3 and λ3, which is in agreement with our finding. All turbulence intensity empirical constants from this study have been compared to literature findings in Table 2. The measured streamwise and vertical profiles in this study are slightly higher than others’ data presented in Table 2, which is resulted from the higher u* = 2.83 cm/s employed in this study. This finding shows that even in hydraulically smooth flow condition the wall shear stress may affect turbulence intensity profiles within a high flow depth in streamwise and vertical directions provided that R and h are not large. Auel et al. [2] has consistently suggested this same conclusion in their supercritical flow tests with relatively small R and h settings.

Measured normalised flow turbulence intensity profiles at five different streamwise locations (Test 1—uniform flow). Symbols: measurements; line: exponential law fits from Nezu [16]

4 Non-uniform flow results and analysis

The non-uniform flow, which is characterised by the existence of a streamwise pressure gradient, has also been investigated. Four separate flow tests (Tests 2–5) have been carried out during this study. Tests 2–4 have accelerating flow characteristics; while Test 5 presents the decelerating flow characteristics. Table 3 describes the recorded depth-averaged velocity along the streamwise flow direction; while Fig. 4 shows the measured flow depths across the channel for each test. All tested flows in this study have aspect ratio between 3.57 and 6.33 (recorded from 0.5 m upstream to 11.5 m downstream of the channel). For the non-uniform flow, its pressure gradient is represented by

where ρ is the density of water, and dh/dx is the flow streamwise water level gradient.

The pressure gradient parameter β [determined by Eq. (1) using pressure gradient in Eq. (7)] was utilised to calculate the change of velocity and turbulence structure for non-uniform flow in Song et al. [30], Kironoto and Graf [14] and Song and Chiew [28]. For uniform flow, β has a constant value of − 1; whereas for the non-uniform flow, β is non-constant (as suggested by [2, 14, 28]). As both Br and П of the non-uniform flow are in the function of β, the non-uniform flow’s log-wake law should therefore be expressed as

4.1 Discussion

Figures 5, 6, 7 and 8 show the comparisons between the log-wake law and experimental data for Tests 2–5. The measurements correspond to the log-wake law. The shear velocity for the non-uniform flow can be calculated using the energy gradient method as follows

where Fr is the Froude number. This method was proven in Pu et al. [25] and Pu [24] to accurately compute the non-uniform flow’s shear velocity. As it is derived from the basic flow principle, its parameters can be measured with much less uncertainty. In Table 4, the shear velocity calculated by the energy gradient method have been compared to those found by the Reynolds stress profile method. The Reynolds stress profile method calculates \( u_{*} \) by relating the bed shear stress expression of \( - \;\overline{u'w'} \) to an expression of \( u_{*}^{2} (1 - z/\delta ) \). Both methods have the calculated \( u_{*} \) in good agreement with each other. The values of all the empirical κ, Br and П constants for Test 2–5 are also presented in Table 4. These values have been used to produce Fig. 9, where the accelerating flow falls in the region of β < − 1; while the decelerating flow falls in the region of β > − 1.

From the results at Figs. 5, 6, 7 and 8, an analysis has been conducted to find out the influence of non-uniformity towards log-wake law. To this end, Fig. 9 is produced to investigate the impact of non-uniformity on κ, Br and П constants. The measurements in Fig. 9a show that the von Karman constant κ remains unchanged across the investigated β range at about 0.43 with regression coefficient R2 of 0.92 compared to measured data, and this consistency remains for both accelerating and decelerating flow tests. The constant κ = 0.43 is also within the κ range proposed in Auel et al. [2]. In Fig. 9b, this study’s Br remains constant at around Br = 8.1 with regression coefficient R2 of 0.84 compared to measured data. When compared to rough bed non-uniform flow Br, such as 8.5 proposed by Kironoto and Graf [14] and 8.21–8.61 proposed by Song and Chiew [28], Br proposed in this study agrees well with them. In their rough bed flow’s log-wake law, their utilised parameter z+ was affected by bed roughness. This comparison shows the universality of non-uniform flow Br in different bed roughness. Figure 9c shows that the wake parameter П is varying with β in non-uniform flows. The experimental data here is compared with non-uniform flow formulae proposed for the smooth bed flow by Nezu et al. [18] and for the rough bed flow by Kironoto and Graf [14], in which the data shows reasonably good agreement with both formulae. This comparison further suggests that the β-expression of П should be universal for both hydraulically rough and smooth non-uniform flows. From these κ, Br and П findings, it can be concluded that the log-wake law can sufficiently represent the non-uniform flow without needing any modification. The detailed analysis also reveals that all κ, Br and П follow universal rules for different bed roughness conditions.

A relationship suggested by Nezu et al. [18] and Kironoto and Graf [14] has been employed in this study to represent the 3D non-uniform flow turbulence intensities as follows

where all the coefficients D1, D2, D3, λ1, λ2, and λ3 are in the function of β. Figures 10 and 11 are produced from the empirical coefficients in Eqs. (10)–(12), where the measured data are investigated across a range of β from accelerating to decelerating flow regimes. The thin dash-lines in Figs. 10 and 11 represent the uniform flow region at β = − 1. The proposed empirical quadratic relationships with β are presented in Eq. (13) for D1, D2 and D3 with regression coefficient R2 of 0.88, 0.85 and 0.84, respectively. In contrast, constant relationships can be seen for λ1, λ2, and λ3 (with regression coefficient R2 of 0.64, 0.61 and 0.61, respectively) as in Eq. (14).

Two points can be observed from Eqs. (13)–(14): (a) all D1, D2 and D3 have consistent tendency to decrease from higher values at decelerating flow region to lower values at accelerating flow region in the investigated β range; and (b) it is presented in Eq. (14) that λ1 > λ2 > λ3. These findings suggest that the decelerating flow has higher 3D turbulence intensity profiles than the accelerating flow; and the turbulence intensity characteristics are more dominantly dictated by the streamwise flow. The fitted relationships of Eqs. (13)–(14) also represent the uniform flow data well, suggesting they are working across both the uniform and non-uniform flows.

Further investigations of the measured non-uniform flow Reynolds stresses are conducted using the equation below (proposed by [12])

where Duw and λuw are the empirical constants for Reynolds stress profile. Figure 12 presents the measured Reynolds stress’ constants in Eq. (15), which their quadratic relationship with β is presented in Eqs. (16)–(17). In Fig. 12, the fitted Duw and λuw from the measured data have respective regression coefficient R2 of 0.76 and 0.58 when compared to Eqs. (16)–(17).

Theoretically for uniform flow, the Reynolds stress near bed should be almost equal to \( u_{*}^{2} \) where Duw = 1 (dotted line in Fig. 12a). From Fig. 12a, we can clearly observe that Duw remains around unity at the accelerating flow region (where β < − 1), which shows a close resemblance to the uniform flow characteristic. At the decelerating flow region, stronger non-uniformity characteristic has been observed where all the measurements are higher than the uniform flow’s Duw. This finding suggests that the decelerating flow is more influential in determining the non-uniform characteristic for Reynolds stress compared to the accelerating flow. This suggestion is further supported by the fact that three different strengths of accelerating pressure gradients were tested in this study (from β = − 2.6 to β = − 6.3) and none of them give significant alteration to Duw from uniform flow characteristic. In the full range of β, Duw shows a weak quadratic function suggesting its slow change across uniform and non-uniform flows. λuw is also found to be representable by a quadratic polynomial function with β in Eq. (17). However, unlike Duw in Eq. (17), λuw shows a stronger expression in β2 proposing its fast change across uniform and non-uniform flows. The non-constant λuw also displays different characteristic from the constant uniform flow’s λ1, λ2 and λ3.

As discussed above, by summarising the findings at Figs. 9, 10, 11 and 12 we can draw useful conclusions to the studied non-uniform flows. The insights gathered from these figures are also useful for hydraulic flow applications, such as flow through control structures which experiences rapidly varied flow between accelerating and decelerating features. For example, in flow phenomena passing weir or sluice, such as hydraulic jump or drop, sudden acceleration or deceleration in flow usually takes place. This rapid variation not only changes the flow characteristic but also affects other associated flow issues, i.e. sediment transport. Thus, a good understanding on accelerating and decelerating flows’ characteristics and their dominance features can help in design such structures, i.e. in controlling the flow turbulence within these structures.

5 Measurement limitations and cautions

5.1 Flow regime

In present study, the main concentration is put on measuring the flow characteristics at centreline flow region. This is because when a flow is in ‘wide’ channel, i.e. with high width-to-flow-depth aspect ratio (b/h), velocity dip should not take place. This will cause the velocity and turbulence structure profiles to follow similar pattern regardless the measurements at centreline or region relatively nearer to sidewalls within the same longitudinal position.

There are several assumptions used in previous studies to describe the occurrence of velocity dip and the division between wide and narrow flows. Nezu and Nakagawa [19] described the b/h ratio of 4.0–5.0 as the threshold from narrow to wide open channel flow, where flow regime under this threshold limit can be impacted by velocity dip effect. However, studies focused on non-uniform flows, i.e. Graf and Song [8] and Song [27], found that for flows with and above aspect ratio of b/h = 3.5, no velocity dip was recorded, which suggested they possessed a wide open-channel flow characteristic. Auel et al. [2] also described that strong velocity dip occurred up to b/h < 3, and weak velocity dip can take place up to b/h < 5.0.

In this study, flows with minimum aspect ratio of b/h = 3.57 were tested. Our assumption for centreline data measurements was based on the tested aspect ratio would not cause dip phenomenon to the measured profile, which this assumption cannot be utilised if lower aspect ratio flows are going to be tested in any further work. In other words, if velocity dip caused by the secondary current from the side-walls takes place, then it can affect the measured data across channel width. For the flows with low aspect ratio, it will be essential to measure lateral flow profiles at various transverse locations within a longitudinal position to determine the effect from side-walls’ secondary current.

5.2 Flow non-uniformity

This study presents five flow tests for uniform, accelerating and decelerating flows to analyse their velocity and turbulence structure profiles. The uniform flow characteristic is utilised to compare with the non-uniform flow findings, in order to validate the proposed relationships in this study (i.e. at Figs. 10, 11). The measured data in this study are also used to perform analysis to identify the key behaviour of accelerating and decelerating flows. However due to this wide research topic, further studies will be needed to test and identify the wider range of flow non-uniformity in order to further explore present study’s findings. For example, more laboratory studies need to be conducted to provide more extreme non-uniform flow tests. More specifically, further tests with wider flow discharge and velocity ranges can create more extreme accelerating and decelerating flow conditions for advancing this study’s flow tests. The added flow tests should also concentrate on supercritical flow condition to add on to the current obtained subcritical flow knowledge. Within a flow, the higher velocity increment (for accelerating flow) and decrement (for decelerating flow) can also be tested to identify the flow impacts from more extreme non-uniformity. In turns of the flow measurements, to obtain better accuracy convergence for time-averaged data, an ADV with higher sampling frequency power can be used for recording longer sampling time’s data.

6 Conclusions

In this study, 3D turbulence characteristics of different accelerating and decelerating flows were investigated. Uniform flow test was also conducted for comparison to the non-uniform flows. The employed non-uniform flows measured a set of κ, Br and П. κ and Br for the non-uniform flows remained almost constant; while П was found to change in a linear relationship with the pressure gradient parameter β. Both κ and Br constants found from this study corresponded to previous studies suggested range, in which κ fell within the suggested range in Auel et al. [2] and Br showed similarity with the proposed values in rough bed flow studies by Kironoto and Graf [14] and Song and Chiew [28]. The Br finding further suggested its universality in different bed roughness conditions. The measured П was also found to correspond well to both smooth and rough bed flow formulae proposed by Nezu et al. [18] and Kironoto [12]; which suggested that П can be represented by universal rule for both rough and smooth bed non-uniform flows.

The experiments also showed that both non-uniform flow’s 3D turbulence intensities and Reynolds stress were governed relatively well by exponential equations, where their exponential constants were well-described by quadratic functions in the investigated β range. It was found that the decelerating flow showed higher turbulence intensity profile than the accelerating flow. For the accelerating flow tests, the normalised Reynolds stress distribution found to have similar magnitude (measured by coefficient Duw) to the uniform flow; whereas this Duw magnitude was deviated in the decelerating flow. From the finding of non-uniform flows’ turbulence intensity and Reynolds stress profiles, we can conclude that the decelerating flow has more dominant impact towards the flow’s non-uniformity than the accelerating flow, due to its greater influence to alter the flow’s turbulence structure. This has also been concluded from the comparison with the uniform flow profiles.

Abbreviations

- Br :

-

Log-law integration constant

- Duw :

-

Empirical exponential constants for Reynolds stress profile

- Fr:

-

Froude number

- g:

-

Gravitational acceleration

- h:

-

Water flow depth

- ks :

-

Nikuradse roughness

- P:

-

Pressure

- R:

-

Hydraulic radius

- Rek :

-

Roughness Reynolds number

- So :

-

Channel slope

- u:

-

Flow velocity

- u* :

-

Shear velocity

- u′:

-

Fluctuation of streamwise velocity

- v′:

-

Fluctuation of lateral velocity

- w′:

-

Fluctuation of vertical velocity

- x:

-

Longitudinal distance

- y:

-

Lateral distance

- z:

-

Vertical distance

- zo :

-

Reference zero-plane displacement level

- β:

-

Pressure gradient parameter

- δ:

-

Water depth where maximum velocity occurs

- κ:

-

Von Karman constant

- λuw :

-

Empirical exponential constant for Reynolds stress profile

- ν:

-

Kinematic viscosity

- П:

-

Wake parameter

- ρ:

-

Water density

- τo :

-

Bed shear stress

References

Anwar HO, Atkins R (1980) Turbulence measurements in simulated tidal flow. J Hydraul Div 106(8):1273–1289

Auel C, Albayrak I, Boes RM (2014) Turbulence characteristics in supercritical open channel flows: effects of Froude number and aspect ratio. J Hydraul Eng 140(4):04014004

Blanckaert K, Lemmin U (2006) Means of noise reduction in acoustic turbulence measurements. J Hydraul Res 44(1):1–15

Cardoso AH, Graf WH, Gust G (1989) Uniform flow in a smooth open channel. J Hydraul Res 27(5):603–616

Cardoso AH, Graf WH, Gust G (1991) Steady gradually accelerating flow in a smooth open channel. J Hydraul Res 29(4):525–543

Coles D (1956) The law of the wake in the turbulent boundary layer. J Fluid Mech 1(2):191–226

Dey S, Raikar RV (2007) Characteristics of loose rough boundary streams at near-threshold. J Hydraul Eng 133(3):288–304

Graf WH, Song T (1995) Bed-shear stress in non-uniform and unsteady open-channel flows. J Hydraul Res 33(5):699–704

Hoan NT, Booij R, Stive MJF, Verhagen HJ (2007) Decelerating open-channel flow in a gradual expansion. In: Proceedings of the fourth international conference on Asian and Pacific coasts, Nanjing, China, pp 902–915

Keulegan GH (1938) Laws of turbulent flow in open channels. J Res Natl Bur Stand 21:707–741

Kirkgoz MS (1989) Turbulent velocity profiles for smooth and rough open channel flow. J Hydraul Eng 115(11):1543–1561

Kironoto BA (1992) Turbulence characteristics of uniform and non-uniform, rough open-channel flow. PhD dissertation, École Polytechnique Fédérale De Lausanne, Swissland

Kironoto BA, Graf WH (1994) Turbulence characteristics in rough uniform open-channel flow. Proc Inst Civ Eng Water Marit Energy 106(4):333–344

Kironoto BA, Graf WH (1995) Turbulence characteristics in rough non-uniform open-channel flow. Proc Inst Civ Eng Water Marit Energy 112(4):336–348

Mellor GL, Gibson DM (1966) Equilibrium turbulent boundary layers. J Fluid Mech 24(2):225–253

Nezu I (1977) Turbulent structure in open channel flows. PhD dissertation, Department of Civil Engineering, Kyoto University, Japan. (in Japanese)

Nezu I, Azuma R (2004) Turbulence characteristics and interaction between particles and fluid in particle-laden open channel flows. J Hydraul Eng 130(10):988–1001

Nezu I, Kadota A and Nakagawa H (1994) Turbulent structures in accelerating and decelerating open-channel flows with laser Doppler anemometers. In: Proceedings of ninth congress APD-IAHR, Singapore, pp 413–420

Nezu I, Nakagawa H (1993) Turbulent open-channel flows. IAHR monograph. A. A. Balkema, Rotterdam

Nezu I, Rodi W (1986) Open-channel flow measurements with a laser Doppler anemometer. J Hydraul Eng 112(5):335–355

Noguchi K, Nezu I (2009) Particle-turbulence interaction and local particle concentration in sediment-laden open-channel flows. J Hydro Environ Res 3:54–68

Onitsuka K, Akiyama J, Matsuoka S (2009) Prediction of velocity profiles and Reynolds stress distributions in turbulent open-channel flows with adverse pressure gradient. J Hydraul Res 47(1):58–65

Papanicolaou AN, Hilldale R (2002) Turbulence characteristics in gradual channel transition. J Hydraul Eng 128(9):948–960

Pu JH (2015) Turbulence modelling of shallow water flows using Kolmogorov approach. Comput Fluids 115:66–74

Pu JH, Shao S, Huang Y (2014) Numerical and experimental turbulence studies on shallow open channel flows. J Hydro Environ Res 8:9–19

Pu JH, Wei J, Huang Y (2017) Velocity distribution and 3D turbulence characteristic analysis for flow over water-worked rough bed. Water 9:668. https://doi.org/10.3390/w9090668

Song T (1994) Velocity and turbulence distribution in non-uniform and unsteady open-channel flow. PhD thesis, École Polytechnique Fédérale De Lausanne, Switzerland

Song T, Chiew YM (2001) Turbulence measurement in nonuniform open-channel flow using acoustics Doppler velocimeter (ADV). J Eng Mech 127(3):219–232

Song T, Graf WH (1996) Velocity and turbulence distribution in unsteady open-channel flows. J Hydraul Eng 122(3):141–154

Song T, Graf WH, Lemmin U (1994) Uniform flow in open channels with movable gravel bed. J Hydraul Res 32(6):149–173

Steffer PM, Rajaratnam N, Peterson AW (1985) LDA measurements in open channel. J Hydraul Eng 111(1):119–130

Yang SQ (2009) Velocity distribution and wake-law in gradually decelerating flows. J Hydraul Res 47(2):177–184

Yang SQ, Lee JW (2007) Reynolds shear stress distributions in a gradually varied flow in a roughened channel. J Hydraul Res 45(4):462–471

Yang SQ, Yu H, Dharmasiri N (2011) Flow resistance over fixed roughness elements. J Hydraul Res 49(2):257–262

Yu G, Tan SK (2006) Errors in bed shear stress as estimated from vertical velocity profile. J Irrig Drain Eng 132(5):490–497

Acknowledgements

The first and fourth authors acknowledge the support of the Major State Basic Research Development Grant No. 2013CB036402. The support from the Major State Basic Research Development Program (973 program) of China is also greatly appreciated. Comments and suggestions made by anonymous reviewers have greatly improve the quality of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Pu, J.H., Tait, S., Guo, Y. et al. Dominant features in three-dimensional turbulence structure: comparison of non-uniform accelerating and decelerating flows. Environ Fluid Mech 18, 395–416 (2018). https://doi.org/10.1007/s10652-017-9557-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10652-017-9557-5