Abstract

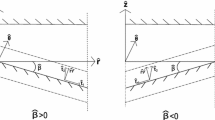

A modified Reynolds equation for compressible flow is used to model the dynamics of pressurised air bearings in a simplified axisymmetric geometry. The formulation incorporates the effect of centrifugal inertia for high-speed operation. A steady-state analysis is presented with a fixed rotor–stator clearance. The load-carrying capacity of the bearing is assessed for both inward and outward pressurisation and the air-flow characteristics are seen to depend on the level and direction of pressurisation. A critical shaft speed is identified that maintains no-net flow by balancing inertia and pressurisation effects. The nonlinear air–rotor–stator dynamics are investigated by modelling the axial stator position using a spring–mass–damper system coupled to the air-film dynamics. Solutions are presented to illustrate the effect of various frequencies and amplitudes of forcing for a range of rotation speeds. The time-averaged axial force and mass flow of air are used as characteristic measures of bearing performance, and further numerical results are presented as part of a parameter space analysis. Using the method of arc-length continuation key measures of the numerical solutions are tracked for changing values of the physical parameters. The minimum rotor–stator clearance is used to evaluate the limit of stable periodic operation without resonant stator dynamics and incorporating high operating speeds.

Similar content being viewed by others

References

San Andrés L, Kim TH, Ryu H, Chirathadam TA, Hagen K, Martinez A, Rice B, Niedbalski N, Hung W, Johnson M (2009) Gas bearing technology for oil-free turbomachinery—research experience for undergraduate (REU) program at Texas A&M. In: Proceedings of ASME Turbo Expo 2009: power for land, sea and air

Munson J, Pecht G (1992) Development of film riding face seals for a gas turbine engine. Tribol Trans 35: 65–70

Malanoski SB, Waldron W (1973) Experimental investigation of air bearings for gas turbine engines. Tribol Trans 16: 4–297303

Zirkelback N, San Andrés L (1999) Effect of frequency excitation on force coefficients of spiral groove gas seals. J Tribol 121: 853–863

Sayma AI, Bréard C, Vahdati M, Imregun M (2002) Aeroelasticity analysis of air-riding seals for aero-engine applications. J Tribol 124: 607–616

Etsion I (1982) Dynamic analysis of noncontacting face seals. Trans ASME 104: 460–468

Fourka M, Tian Y, Bonis M (1996) Prediction of the stability of air thrust bearings by numerical, analytical and experimental methods. Wear 198: 1–6

Taylor G, Saffman PG (1957) Effects of compressibility at low Reynolds number. J Aeronaut Sci 24: 553–562

Langlois WE (1962) Isothermal squeeze-films. Q Appl Math 20: 131–150

Stolarski TA, Chai W (2006) Load-carrying capacity generation in squeeze-film action. Int J Mech Sci 48: 736–741

Salbu EOJ (1964) Compressible squeeze-films and squeeze bearings. J Basic Eng 86: 355–366

Hasegawa E, Izuchi H (1982) Inertia effects due to lubricant compressibility in a sliding externally pressurized gas bearing. Wear 80: 207–220

Stolarski TA, Chai W (2008) Inertia effect in squeeze-film air contact. Tribol Int 41: 716–723

Stolarski TA, Chai W (2006) Self-levitating sliding air contact. Int J Mech Sci 48: 601–620

Brunetière N, Tournerie B (2006) The effect of inertia on radial flows—application to hydrostatic seals. J Tribol 128: 566–574

Garratt JE, Cliffe KA, Hibberd S, Power H (2010) A compressible flow model for the air–rotor–stator dynamics of a high-speed squeeze-film thrust bearing. J Fluid Mech 655: 446–471

Brunetière N, Tournerie B, Frêne J (2002) Influence of fluid flow regime on performances of non-contacting liquid face seals. J Tribol 214: 515–523

Minikes A, Bucher I (2003) Coupled dynamics of a squeeze-film levitated mass and a vibrating piezoelectric disc: numerical analysis and experimental study. J Sound Vib 263: 241–268

Abramovitz M, Stegun I (1964) Handbook of mathematical functions with formulas, graphs, and mathematical tables. Dover, New York, p 228

Bender CM, Orszag SA (1999) Advanced mathematical methods for scientists and engineers—asymptotic methods and perturbation theory. Springer, New York, p 253

Garratt JE, Cliffe KA, Hibberd S, Power H (2011) A numerical scheme for solving the periodically forced Reynolds equation. Int J Numer Methods Fluids 67:559–580. doi:10.1002/fld.2373

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Garratt, J.E., Hibberd, S., Cliffe, K.A. et al. Centrifugal inertia effects in high-speed hydrostatic air thrust bearings. J Eng Math 76, 59–80 (2012). https://doi.org/10.1007/s10665-011-9527-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10665-011-9527-8