Abstract

Fire hazard is one of the main risks associated to fuel storage tanks in petroleum and in the petrochemical industries. Such a hazard includes pool fires in the storage tanks or in the bunds, fire propagation from the source tank to target tanks both in absence and in presence of wind, and also the cascading/domino effect due to confined and unconfined vapour cloud explosion and or BLEVE associated with the source tank. In the present work, a radiation shield of flowing water has been introduced at a distance from the source fuel storage tank to prevent the domino effect originating from this source tank, under fire, to the target fuel storage tanks in a tank farm. A simple one dimensional model has been developed from the steady state energy balance to simulate the safe distances (i.e. rim–rim distance) between fuel storage tanks containing class-I fuel (e.g. gasoline), both in presence and absence of a water-shield under no-wind and cross-wind conditions. The model predictions have shown that the maximum safe inter-tank separation distance of 28.42 m is anticipated at a wind velocity of 6 m/s, compared to 16.34 m in no-wind condition, beyond which the centroid of the parallelepiped (a solid-flame geometry) falls outside the base of the tilted flame geometry causing flattening of flame and a very sluggish increase in the flame tilt angle as the inverse of the Richardson number in the presence of wind velocity vector increases. Furthermore, the present one dimensional mathematical model has also been extended to show that introduction of a water-shield with an appropriate thickness (δopt) is able to prevent the propagation of radiation heat flux under both no-wind and cross-wind conditions to a much lower distance close to 8.34 m between tanks (measured from the centre of the source tank), than those predicted from the existing empirical models; viz. Point Source model and Shokrie-Beyler’s model.

Similar content being viewed by others

References

Abbasi MH, Benhelal E, Ahmad A (2014) Designing an optimal safe layout for a fuel storage tanks farm : case study of Jaipur Oil Depot. Int J Chem Mol Nucl Mater Metall Eng 8:147–155

Bariha N, Srivastava VC, Mishra IM (2016) Theoretical and experimental studies on hazard analysis of LPG/LNG release: a review Center for Chemical Process Safety. Rev Chem Eng 33:387–432. https://doi.org/10.1515/revce-2016-0006

Necci A, Argenti F, Landucci G, Cozzani V (2014) Accident scenarios triggered by lightning strike on atmospheric storage tanks. Reliab Eng Syst Saf 127:30–46. https://doi.org/10.1016/j.ress.2014.02.005

Sengupta A, Gupta AK, Mishra IM (2011) Engineering layout of fuel tanks in a tank farm. J Loss Prev Process Ind 24:568–574

Benedetti RP (2016) Flammable and combustible liquids code. National Fire Protection Association, Quincy

Gorjipour S, Anvaripour B (2014) Safe distance from pools fires in NGL storage tanks in stagnant Air. Int J Basic Sci Appl Res 3:777–780

Beer T (1991) The interaction of wind and fire. Bound-Layer Meteorol 54:287–308

Lautkaski R (1992) Validation of flame drag correlations with data from large pool fires. J Loss Prev Process Ind 5:175–180. https://doi.org/10.1016/0950-4230(92)80021-Y

Jiang P, Lu SX (2016) Pool fire mass burning rate and flame tilt angle under crosswind in open space. Procedia Eng 135:260–273. https://doi.org/10.1016/j.proeng.2016.01.122

Lam CS, Weckman EJ (2015) Wind-blown pool fire, part I: experimental characterization of the thermal field. Fire Saf J 75:1–13. https://doi.org/10.1016/j.firesaf.2015.04.009

Lam CS, Weckman EJ (2015) Wind-blown pool fire, part II: comparison of measured flame geometry with semi-empirical correlations. Fire Saf J 78:130–141. https://doi.org/10.1016/j.firesaf.2015.08.004

Hu L, Liu S, Xu Y, Li D (2011) A wind tunnel experimental study on burning rate enhancement behavior of gasoline pool fires by cross air flow. Combust Flame 158:586–591. https://doi.org/10.1016/j.combustflame.2010.10.013

Hu L, Wu L, Liu S (2013) Flame length elongation behavior of medium hydrocarbon pool fires in cross air flow. Fuel 111:613–620. https://doi.org/10.1016/j.fuel.2013.03.025

Hu L, Liu S, Wu L (2013) Flame radiation feedback to fuel surface in medium ethanol and heptane pool fires with cross air flow. Combust Flame 160:295–306. https://doi.org/10.1016/j.combustflame.2011.11.008

Hu L, Liu S, De Ris JL, Wu L (2013) A new mathematical quantification of wind-blown flame tilt angle of hydrocarbon pool fires with a new global correlation model. Fuel 106:730–736. https://doi.org/10.1016/j.fuel.2012.10.075

Hu L, Hu J, Liu S, Tang W, Zhang X (2015) Evolution of heat feedback in medium pool fires with cross air flow and scaling of mass burning flux by a stagnant layer theory solution. Proc Combust Inst 35:2511–2518. https://doi.org/10.1016/j.proci.2014.06.074

Hu L, Kuang C, Zhong X, Ren F, Zhang X, Ding H (2017) An experimental study on burning rate and flame tilt of optical-thin heptane pool fires in cross flows. Proc Combust Inst 36:3089–3096. https://doi.org/10.1016/j.proci.2016.08.021

Hu L (2017) A review of physics and correlations of pool fire behaviour in wind and future challenges. Fire Saf J 91:41–55. https://doi.org/10.1016/j.firesaf.2017.05.008

Fan CG, Tang F (2017) Flame interaction and burning characteristics of abreast liquid fuel fires with cross wind. Exp Therm Fluid Sci 82:160–165. https://doi.org/10.1016/j.expthermflusci.2016.11.010

Khakzad N, Khan F, Amyotte P, Cozzani V (2014) Risk management of domino effects considering dynamic consequence analysis. Risk Anal 34:1128–1138. https://doi.org/10.1111/risa.12158

Khakzad N, Reniers G (2015) Using graph theory to analyze the vulnerability of process plants in the context of cascading effects. Reliab Eng Syst Saf 143:63–73. https://doi.org/10.1016/j.ress.2015.04.015

Santos S, Landesmann A (2014) Thermal performance-based analysis of minimum safe distances between fuel storage tanks exposed to fi re. Fire Saf J 69:57–68. https://doi.org/10.1016/j.firesaf.2014.08.010

Rebec A, Kolˇ J, Pleˇ P (2016) Fires in storages of LFO : Analysis of hazard of structural collapse of steel-aluminium containers. J Hazard Mater 306:367–375. https://doi.org/10.1016/j.jhazmat.2015.12.006

Sullivan AL, Ellis PF, Knight IK (2003) A review of radiant heat flux models used in bushfire applications. Int J Wildl Fire 12:101–110. https://doi.org/10.1071/WF02052

Zárate L, Arnaldos J, Casal J (2008) Establishing safety distances for wildland fires. Fire Saf J 43:565–575. https://doi.org/10.1016/j.firesaf.2008.01.001

Sudheer S, Prabhu SSV (2013) Characterization of open pool fires and study of heat transfer in bodies engulfed in pool fires. https://www.iitb.ac.in/~sudheer/files/thesis_ssr_2013.pdf. Accessed 3 Jan 2018

Drysdale D (1999) An introduction to fire dynamics, 2nd edn. Wiley, Hoboken

Bariha N, Mani I, Chandra V (2016) Fire and explosion hazard analysis during surface transport of liquefied petroleum gas (LPG): a case study of LPG truck tanker accident in Kannur, Kerala, India. J Loss Prev Process Ind 40:449–460. https://doi.org/10.1016/j.jlp.2016.01.020

Koseki H (1999) Large scale pool fires: results of recent experiments. In: Fire safety science sixth international symposium, pp 115–132

Heskestad G (1984) Engineering relations for fire plumes. Fire Saf J 7:25–32. https://doi.org/10.1016/0379-7112(84)90005-5

Cengel YA, Klein S, Beckman W (2002) Heat transfer: a practical approach. McGraw Hill Education, New York

Churchill SW, Chu HHS (1975) Correlating equations for laminar and turbulent free convection from a vertical plate. Int J Heat Mass Transf 18:1323–1329. https://doi.org/10.1016/0017-9310(75)90243-4

Babrauskas V (1983) Estimating large pool fire burning rates. Fire Technol 19:251–261. https://doi.org/10.1007/BF02380810

Kodur VKR, Harmathy TZ (2016) Properties of building materials. In: Hurley MJ et al (eds) SFPE handbook of fire protection engineering. Springer, New York. https://doi.org/10.1007/978-1-4939-2565-0_9

Thomas PH (1963) The size of flame from natural fires. Proc Combust Inst 9:844–859

Wade DD (2013) Flame descriptors. SFE fact sheet 2013–6, Southern fire exchange, 2 p

Bejan A (2004) Convection heat transfer, 3rd edn. Wiley, Hoboken

Chun KR, Seban RA (1971) Heat transfer to evaporating liquid films. J Heat Transfer 93:391. https://doi.org/10.1115/1.3449836

Geankoplis CJ (1993) Transport processes and unit operations, 3rd edn. Prentice-Hall International Inc, Upper Saddle River

Hurley MJ, Gottuk D, Hall JR, Harada K, Kuligowski E, Puchovsky M, Torero J, Watts JM, Wieczorek C (2016) SFPE handbook of fire protection engineering, 5th edn. Springer, New York, pp 1–3493. https://doi.org/10.1007/978-1-4939-2565-0

Feingold A (1966) Radiant-interchange configuration factors between various selected plane surfaces. Proc R Soc A Math Phys Eng Sci 292:51–60. https://doi.org/10.1098/rspa.1966.0118

Holman JP (2010) Heat Transfer, 10th edn. McGraw Hill, New York. https://doi.org/10.1115/1.3246887

Koseki H, Yumoto T (1988) Air entrainment from heptane pool fires.pdf. Fire Technology

De Ris J (1979) Fire radiation—a review. In: Symposium (international) on combustion, pp 1003–1015. https://doi.org/10.1016/s0082-0784(79)80097-1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

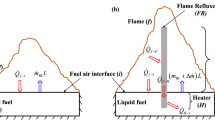

Within radiative regime, i.e. transfer of heat transport fluxes from the flame-front surfaces at x and x + ∆x (refer Fig. 1b) are dominantly by radiation; while the heat losses from the other surfaces of the elemental control volume can still be via convection and radiation (Sects. 2.1 and 2.2), the flame can be optically thick or thin depending on the pool diameter [33]. For pool diameter > 1 m with radiative flame give rise to optically thick flame [33]. Koseki [29] via experiments on large pool fires had concluded that large unconfined pool fires are predominantly in radiative regime. In the present scenario, we have considered a large 10 m diameter pool fire which is therefore, assumed to be in the radiative regime. The mean optical thickness of a flame is defined in terms of κβ, where κ is the absorption extinction coefficient and β is the mean beam length corrector [26, 27, 33]. While κ value for most of the fuel is documented in literature for pool fires with D ≥ 0.2 m, it had been argued that a “common β value does not emerge” for a given fuel and pool diameter and therefore, the κβ value is not unique [33]. Hence, while Babrauskas [33] reported the κβ value for gasoline pool fires of D ≥ 0.2 m to be 2.1 m−1; Sudheer et al. [26] reported κβ = 1.5 m−1. So we have calculated the κβ value for the present pool fire of D = 10 m containing gasoline; using the following relation, where \( \dot{m}^{\prime \prime } \) is the mass burning rate of the fuel (which can be obtained from pool diameter relationship [4, 27, 29, 33]) and \( \dot{m}_{\infty }^{\prime \prime } \) is a constant for a given fuel [33].

For gasoline (\( \dot{m}_{\infty }^{\prime \prime } = 0.055\;{\text{kg/m}}^{ 2} / {\text{s}} \), κ = 2 m−1 [33]) we have reported the κβ and the β values in Table 5 under both no-wind and windy conditions. The mass burning rate for each of the cases are also reported in the same table and are obtained from pool diameter relationship given in literature [27] under the no-wind condition; or by using Eq. (8) for windy conditions. Furthermore, the calculation of the optical depth (τ) have been performed using the Equation (33) [27, 44] and these values are also reported in Table 5:

where Vf is the volume of the flame geometry and Af is the surface area of the flame geometry. It is noted that the κβ value and the optical depth under no-wind condition for the present case is 0.1595 m−1 and 1.595, respectively. Following the argument on radiative regime pool fires with D > 1 m [33], τ = 1.595 is taken to be the optical thin limit for the gasoline pool fire and we also observe that for all windy conditions considered the corresponding optical depth values are greater than this limit. Therefore, the flame surface temperatures of the pool fires have been used to estimate the safe inter-tank distance in a gasoline tank farm for both no-wind and windy conditions. We also note an increase in the τ value with the increasing wind speed.

Rights and permissions

About this article

Cite this article

Sengupta, A. Optimal Safe Layout of Fuel Storage Tanks Exposed to Pool Fire: One Dimensional Deterministic Modelling Approach. Fire Technol 55, 1771–1799 (2019). https://doi.org/10.1007/s10694-019-00830-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-019-00830-y