Abstract

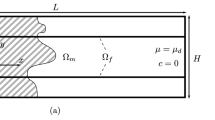

In this paper, we have developed a linear stability analysis to predict the formation of necking instabilities in porous ductile plates subjected to dynamic biaxial stretching. The mechanical behavior of the material is described with the Gurson–Tvergaard–Needleman constitutive relation for progressively cavitating solids (Gurson 1977; Tvergaard 1981, 1982; Tvergaard and Needleman 1984) which considers the voids to be spherical and the matrix material isotropic with yielding defined by the von Mises (1928) criterion. The analytical model is formulated in a two-dimensional framework in which the multiaxial stress state that develops inside the necked region is approximated with the Bridgman (1952) correction factor, superimposing a hydrostatic stress state to the uniform stress field that develops in the plate before localization. As opposed to the linear stability models published so far to model dynamic necking in ductile plates, which consider the material to be fully dense and incompressible, the approach developed in this paper provides new insights into the interplay between porosity and inertia on plastic localization. In addition, the predictions of the theoretical model for the critical strain leading to necking formation have been compared with unit-cell finite element calculations performed in ABAQUS/Explicit (2019). Satisfactory quantitative and qualitative agreement has been found between the theoretical and the computational approach for loading paths ranging from plane strain tension to nearly equibiaxial tension, loading rates varying from 100 to \(10{,}000~\text {s}^{-1}\), and different values of the initial void volume fraction ranging from 0.01 to 0.1. Both analytical and finite element results suggest that the influence of porosity on necking localization increases, due to voids coalescence, as the loading rate increases and the loading path approaches equibiaxial tension. The original formulation developed in this paper serves as a basis for analytically modeling the dynamic formability of porous ductile plates, and it can be readily extended to consider more complex porous plasticity theories, e.g. constitutive models which consider the anisotropy of the material (Benzerga and Besson 2001) and/or voids with different shapes (Gologanu et al. 1993; Monchiet et al. 2008).

Similar content being viewed by others

References

ABAQUS/Explicit (2019) Abaqus Explicit v6.19 User’s Manual, version 6.19 Edition. ABAQUS Inc., Richmond, USA

Aboulkhair NT, Everitt NM, Ashcroft I, Tuck C (2014) Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit Manuf 1–4:77–86 (inaugural Issue)

Altynova M, Hu X, Daehn GS (1996) Increased ductility in high velocity electromagnetic ring expansion. Metall Trans A 27:1837–1844

Audoly B, Hutchinson JW (2016) Analysis of necking based on a one-dimensional model. J Mech Phys Solids 97:68–91 (sI:Pierre Suquet Symposium)

Audoly B, Hutchinson JW (2019) One-dimensional modeling of necking in rate-dependent materials. J Mech Phys Solids 123:149–171 (the N.A. Fleck 60th Anniversary Volume)

Banabic D, Barlat F, Cazacu O, Kuwabara T (2010) Advances in anisotropy and formability. Int J Mater Form 3:165–189

Benzerga AA, Besson J (2001) Plastic potentials for anisotropic porous solids. Eur J Mech A Solids 20(3):397–434

Bridgman PW (1952) Studies in large plastic flow and fracture, with special emphasis on the effects of hydrostatic pressure, vol 1. McGraw-Hill Book Company Inc, New York

Brunet M, Morestin F (2001) Experimental and analytical necking studies of anisotropic sheet metals. J Mater Process Technol 112(2):214–226

Cazacu O, Plunkett B, Barlat F (2006) Orthotropic yield criterion for hexagonal closed packed metals. Int J Plast 22(7):1171–1194

Chou PC, Carleone J (1977) The stability of shaped-charge jets. J Appl Phys 48(10):4187–4195

Considère A (1885) Mémoire sur l’emploi du fer et de l’acier dans les constructions. Ann. Ponts et Chaussées 9:574–775

Dariani BM, Liaghat GH, Gerdooei M (2009) Experimental investigation of sheet metal formability under various strain rates. Proc Inst Mech Eng B 223(6):703–712

Dudzinski D, Molinari A (1991) Perturbation analysis of thermoviscoplastic instabilities in biaxial loading. Int J Solids Struct 27:601–628

El Maï S, Mercier S, Petit J, Molinari A (2014) An extension of the linear stability analysis for the prediction of multiple necking during dynamic extension of round bar. Int J Solids Struct 51:3491–3507

Fressengeas C, Molinari A (1985) Inertia and thermal effects on the localization of plastic flow. Acta Metall 33:387–396

Fressengeas C, Molinari A (1994) Fragmentation of rapidly stretching sheets. Eur J Mech A 13:251–268

Gologanu M, Leblond J-B, Devaux J (1993) Approximate models for ductile metals containing non-spherical voids-case of axisymmetric prolate ellipsoidal cavities. J Mech Phys Solids 41(11):1723–1754

Golovashchenko SF, Gillard AJ, Mamutov AV (2013) Formability of dual phase steels in electrohydraulic forming. J Mater Process Technol 213(7):1191–1212

Grady DE, Benson DA (1983) Fragmentation of metal rings by electromagnetic loading. Experimental Mechanics 12:393–400

Guduru PR, Freund LB (2002) The dynamics of multiple neck formation and fragmentation in high rate extension of ductile materials. Int J Solids Struct 39:5615–5632

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth. Part I: yield criteria and flow rules for porous ductile media. ASME J Eng Mater Technol 99:2–15

Heidari L, Tangestani A, Hadianfard MJ, Vashaee D, Tayebi L (2020) Effect of fabrication method on the structure and properties of a nanostructured nickel-free stainless steel. Adv Powder Technol 31(8):3408–3419

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc Lond A 193:281–297

Hill R, Hutchinson J (1975) Bifurcation phenomena in the plane tension test. J Mech Phys Solids 23(4–5):239–264

Hu X, Daehn GS (1996) Effect of velocity on flow localization in tension. Acta Mater 44:1021–1033

Hutchinson JW, Neale KW, Needleman A (1978) Sheet necking-III. Strain-rate effects. In: Mechanics of sheet metal forming. Springer, Boston, MA, pp 269–285

Jacques N (2020) An analytical model for necking strains in stretched plates under dynamic biaxial loading. Int J Solids Struct 200–201:198–212

Karpp R, Simon J (1976) An estimate of the strength of a copper shaped charge jet and the effect of strength on the breakup of a stretching jet. US Army Ballistic Research Lab, BRL Report

Kuroda M, Tvergaard V (2000) Forming limit diagrams for anisotropic metal sheets with different yield criteria. Int J Solids Struct 37:5037–5059

Li F, Mo J, Li J, Zhao J (2017) Formability evaluation for low conductive sheet metal by novel specimen design in electromagnetic forming. Int J Adv Manuf Technol 88:1677–1685

Marvi-Mashhadi M, Vaz-Romero A, Sket F, Rodríguez-Martínez JA (2021) Finite element analysis to determine the role of porosity in dynamic localization and fragmentation: application to porous microstructures obtained from additively manufactured materials. Int J Plast 143:102999

Mercier S, Molinari A (2003) Predictions of bifurcations and instabilities during dynamic extensions. Int J Solids Struct 40:1995–2016

Mercier S, Granier N, Molinari A, Llorca F, Buy F (2010) Multiple necking during the dynamic expansion of hemispherical metallic shells, from experiments to modelling. J Mech Phys Solids 58:955–982

Mises RV (1928) Mechanik der plastischen formänderung von kristallen. ZAMM 8(3):161–185

Monchiet V, Cazacu O, Charkaluk E, Kondo D (2008) Macroscopic yield criteria for plastic anisotropic materials containing spheroidal voids. Int J Plast 24(7):1158–1189

N’souglo KE, Srivastava A, Osovski S, Rodríguez-Martínez JA (2018) Random distributions of initial porosity trigger regular necking patterns at high strain rates. Proc R Soc A 474:20170575

N’souglo KE, Rodríguez-Martínez JA, Cazacu O (2020) The effect of tension-compression asymmetry on the formation of dynamic necking instabilities under plane strain stretching. Int J Plast 128:102656

N’souglo KE, Jacques N, Rodríguez-Martínez JA (2021) A three-pronged approach to predict the effect of plastic orthotropy on the formability of thin sheets subjected to dynamic biaxial stretching. J Mech Phys Solids 146:104189

Rodríguez-Martínez JA, Molinari A, Zaera R, Vadillo G, Fernández-Sáez J (2017) The critical neck spacing in ductile plates subjected to dynamic biaxial loading: on the interplay between loading path and inertia effects. Int J Solids Struct 108:74–84

Rodríguez-Martínez JA, Cazacu O, Chandola N, N’souglo KE (2021) Effect of the third invariant on the formation of necking instabilities in ductile plates subjected to plane strain tension. Meccanica 1–30

Shenoy V, Freund L (1999) Necking bifurcations during high strain rate extension. J Mech Phys Solids 47(11):2209–2233

Stören S, Rice J (1975) Localized necking in thin sheets. J Mech Phys Solids 23:421–441

Tvergaard V (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17(4):389–407

Tvergaard V (1982) On localization in ductile materials containing spherical voids. Int J Fract 18(4):237–252

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32:157–169

Walsh J (1984) Plastic instability and particulation in stretching metal jets. J Appl Phys 56(7):1997–2006

Wood WW (1967) Experimental mechanics at velocity extremes–very high strain rates. Exp Mech 7:441–446

Xavier M, Czarnota C, Jouve D, Mercier S, Dequiedt JL, Molinari A (2020) Extension of linear stability analysis for the dynamic stretching of plates: spatio-temporal evolution of the perturbation. Eur J Mech A 79:103860

Xavier M, Mercier S, Czarnota C, El Mai S, Jouve D, Dequiedt JL, Molinari A (2021) Extension of 1D linear stability analysis based on the bridgman assumption. applications to the dynamic stretching of a plate and expansion of a ring. Int J Solids Struct 217–218:215–227

Zaera R, Rodríguez-Martínez JA, Vadillo G, Fernández-Sáez J, Molinari A (2015) Collective behaviour and spacing of necks in ductile plates subjected to dynamic biaxial loading. J Mech Phys Solids 85:245–269

Zheng X, N’souglo KE, Rodríguez-Martínez JA, Srivastava A (2020) Dynamics of necking and fracture in ductile porous materials. J Appl Mech 87(4):041005

Zhou F, Molinari JF, Ramesh KT (2006) An elasto-visco-plastic analysis of ductile expanding ring. Int J Impact Eng 33:880–891

Funding

The research leading to these results has received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme. Project PURPOSE, grant agreement 758056.

Author information

Authors and Affiliations

Contributions

MAK: Conceptualization; Data curation; Formal analysis; Investigation; Software; Validation; Writing—original draft. KEN: Conceptualization; Data curation; Formal analysis; Investigation; Methodology; Software; Supervision; Validation; Writing—original draft; Writing—review and editing. JAR-M: Conceptualization; Formal analysis; Funding acquisition; Investigation; Methodology; Project administration; Resources; Supervision; Validation; Visualization; Writing—original draft; Writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Supplementary material

In the following link we provide access the codes developed in Wolfram Mathematica to compute the stability analysis results presented in Sect. 3: https://doi.org/10.21950/2XVATI.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, M.A., N’souglo, K.E. & Rodríguez-Martínez, J.A. A new analytical model to predict the formation of necking instabilities in porous plates subjected to dynamic biaxial loading. Int J Fract 232, 181–198 (2021). https://doi.org/10.1007/s10704-021-00599-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-021-00599-8