Abstract

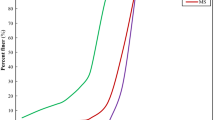

The practice of soil treatment using cement and zeolite is an approach that can be widely used in soil stabilization particularly in road construction, as a support layer for shallow foundations, to strengthen slopes, and to prevent sand liquefaction. The present research intends to quantify the impact of both amounts of cement and zeolite, porosity index, porosity/cement and porosity/SiO2 and Al2O3 particles ratio on zeolite cemented sand mixtures by the assessment of unconfined compressive strength (UCS). A program of unconfined compression tests considering three distinct porosity ratio, four cement contents (2, 4, 6 and 8%) and six different percent of cement replacement by zeolite (0, 10, 30, 50, 70 and 90%) is performed in this study. Results indicate that cement replaced by zeolite at optimum proportion of 30%, the value of improved UCS of the cement sand specimens due to zeolite and cement chemical properties are exploited. Increasing cement content and porosity of the compacted mixture, the efficiency of using zeolite rises. In this paper, it has been shown that for the zeolite–cement–sand mixtures, UCS increases via cement content (C) raise and porosity (η) reduction and a power function is well-adapted to fit both UCS-C and UCS-η. Finally, key parameter SiO2 and Al2O3 particles as active particles (AP) introduced and six UCS-AP diagrams are drawn, any of which is traced to a specific amount of zeolite. Afterwards, UCS is plotted against 1/AP and η/AP which is regarded as a controlling parameter of UCS. As a consequence, for each of the zeolite–cement–sand mixtures studied, a target UCS value could be obtained using a specific correlation (1.5E8 η-1.713AP1.424, R2 = 0.982) by porosity reductions, cement content rises and zeolite variations. This experimental research and key parameter AP will introduce an acceptable description of the mechanical parameters which are extensively used in the subgrade and foundation designs.

Similar content being viewed by others

Abbreviations

- UCS:

-

Unconfined compressive strength

- η:

-

Porosity

- Cc:

-

Coefficient of curvature

- Cu:

-

Coefficient of uniformity

- Z:

-

Replaced zeolite content

- C:

-

Cement content

- Gs :

-

Specific gravity

- Si :

-

Initial setting time

- Ss :

-

Specific surface

References

C ASTM (2002) 150 Standard specification for Portland cement. Annu B ASTM Stand, vol 4

Canpolat F, Yılmaz K, Köse MM, Sümer M, Yurdusev MA (2004) Use of zeolite, coal bottom ash and fly ash as replacement materials in cement production. Cem Concr Res 34(5):731–735

Consoli NC, Foppa D, Festugato L, Heineck KS (2007) Key parameters for strength control of artificially cemented soils. J Geotech Geoenviron Eng 133(2):197–205

D ASTM (2000) 2166 (1985) Standard test method for unconfined compressive strength of cohesive soil. In: American society for testing and materials, vol 100

Ladd R (1978) Preparing test specimens using undercompaction. Geotech Test J 1(1):16–23

Li G-Z, Feng N-Q, Zang X-W (1990) High-strength and flowing concrete with a zeolitic mineral admixture. Cem Concr Aggreg 12(2):61–69

Mola-Abasi H, Shooshpasha I (2016) Influence of zeolite and cement additions on mechanical behavior of sandy soil. J Rock Mech Geotech Eng 8(5):746–752

Mola-Abasi H, Shooshpasha I (2017) Polynomial models controlling strength of zeolite-cement-sand mixtures. Sci Iran Trans A Civ Eng 24(2):526

Mola-Abasi H, Kordtabar B, Kordnaeij A (2016) Effect of natural zeolite and cement additive on the strength of sand. Geotech Geol Eng 34(5):1539–1551

Mola-Abasi H, Kordtabar B, Kordnaeij A (2017) Parameters controlling strength of zeolite–cement–sand mixture. Int J Geotech Eng 11(1):72–79

Poon CS, Lam L, Kou SC, Lin ZS (1999) A study on the hydration rate of natural zeolite blended cement pastes. Constr Build Mater 13(8):427–432

Yılmaz B, Uçar A, Öteyaka B, Uz V (2007) Properties of zeolitic tuff (clinoptilolite) blended Portland cement. Build Environ 42(11):3808–3815

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mola-Abasi, H., Khajeh, A. & Semsani, S.N.S. Porosity/(SiO2 and Al2O3 Particles) Ratio Controlling Compressive Strength of Zeolite-Cemented Sands. Geotech Geol Eng 36, 949–958 (2018). https://doi.org/10.1007/s10706-017-0367-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-017-0367-9