Abstract

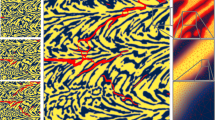

A numerical model and computational procedure for static recrystallization are developed using a phase-field method coupled with crystal-plasticity theory. In this model, first, the microstructure and dislocation density during the deformation process of a polycrystalline metal are simulated using a finite element method based on strain-gradient crystal-plasticity theory. Second, the calculated data are mapped onto the regular grids used in the phase-field simulation. The stored energy is calculated from the dislocation density and is smoothed to avoid computational difficulty. Furthermore, the misorientation required for nucleation criteria is calculated at all grid points. Finally, phase-field simulation of the nucleation and growth of recrystallization is performed using the mapped data. By performing a series of numerical simulations based on the proposed numerical procedure, it has been confirmed that the recrystallization microstructure can be reproduced from the deformation microstructure.

Similar content being viewed by others

References

Raabe, D.: Computational Materials Science. Federal Republic of Germany (1998)

Humphreys, F.J., Hatherly, M.: Recrystallization and Related Annealing Phenomena, 2nd edn. Elsevier (2004)

Srolovitz, D.J., Grest, G.S., Anderson, M.P.: Computer simulation of recrystallization—I. Homogeneous nucleation and growth. Acta metal. 34, 1833–1845 (1986)

Hesselbarth, H.W., Gobel, I.R.: Simulation of recrystallization by cellular automata. Acta Metall. Mater. 39, 2135–2143 (1991)

Miodownik, M.A.: A review of microstructural computer models used to simulate grain growth and recrystallisation in aluminium alloys. J. Light Metals 2, 125–135 (2002)

Raabe, D.: Scaling Monte Carlo kinetics of the Potts model using rate theory. Acta Mater. 48, 1617–1628 (2000)

Rollet, A.D., Raabe, D.: A hybrid model for mesoscopic simulation of recrystallization. Comp. Mate. Sci. 21, 69–78 (2001)

Kobayashi, R.: Modeling and numerical simulations of dendritic crystal growth. Physica D 63, 410–423 (1993)

Warren, J.A., Boettinger, W.J.: Prediction of dendritic growth and microsegregation patterns in a binary alloy using the phase-field method. Acta Metal. 43, 689 (1995)

Kobayashi, R., Warren, J.A., Carter, W.C.: A continuum model of grain boundaries. Physica D 140, 141–150 (2000)

Chen, L.-Q., Yang, W.: Computer simulation of the domain dynamics of a quenched system with a large number of nonconserved order parameters: The grain-growth kinetics. Phy. Rev. B 50, 15752–15756 (1994)

Steinbach, I., Pezzolla, F.: A generalized field method for multiphase transformations using interface fields. Physica D 134, 385–393 (1999)

Kobayashi, R., Giga, Y.: Equations with singular diffusivity. J. Statistical Physics 95, 1187–1220 (1999)

Xiao, N., Tong, M., Lan, Y., Li, D., Li, Y.: Coupled simulation of the influence of austenite deformation on the subsequent isothermal austenite-ferrite transformation. Acta Meter. 54, 1265–1278 (2006)

Lan, Y.J., Xiao, N.M., Li, D.Z., Li, Y.Y.: Mesoscale simulation of deformed austenite decomposition into ferrite by coupling a cellular automaton method with a crystal plasticity finite element model. Acta Meter. 53, 991–1003 (2005)

Higa, Y., Sawada, Y., Tomita, Y.: Computational simulation of characteristic length dependent deformation behavior of polycrystalline metals. Trans. JSME A69, 523–529 (in Japanese) (2003)

Peirce, D., Shih, C.F., Needleman, A.: A tangent modulus method for rate dependent solids. Comput. Struc. 18, 875–887 (1984)

Hutchinson, J.W.: Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. London. Series A 348, 101–127 (1976)

Pan, J., Rice, J.R.: Rate sensitivity of plastic flow and implications for yield-surface vertices. J. Solids Struct. 19, 973–987 (1983)

Ohashi, T.: Numerical modelling of plastic multislip in metal crystals of f.c.c. type. Philos. Magaz. A 70, 793–803 (1994)

Warren, J.A., Kobayashi, R., Lobkovskey, A.E., Carter, W.C.: Extending phase field models of solidification to polycrystalline materials. Acta Mater. 51, 6035–6058 (2003)

Warren, J.A., Carter, W.C., Kobayashi, R.: A phase field model of the impingement of solidifying particles. Physica A 261, 159–166 (1998)

Takaki, T., Fukuoka, T., Tomita, Y.: Phase-field simulation during directional solidification of a binary alloy using adaptive finite element method. J. Crys. Growth 283, 263–278 (2005)

Nakamachi, E., Ariyoshi, T., Kobayashi, Y., Hirose, M., Morimoto, H.: SEM-EBSD experimental and finite element analyses of plastic deformation induced crystal rotation of pure aluminium single crystals. Trans. Japan Soc. Mech. Eng. A 69, 817–822 (2003)

Kuo, C.-M., Chu, H.-H.: Plastic deformation mechanism of pure aluminum at low homologous temperatures. Mate. Sci. Eng. A 409, 59–66 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Takaki, T., Yamanaka, A., Higa, Y. et al. Phase-field model during static recrystallization based on crystal-plasticity theory. J Computer-Aided Mater Des 14 (Suppl 1), 75–84 (2007). https://doi.org/10.1007/s10820-007-9083-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10820-007-9083-8