Abstract

The objective of this paper is to present an integrated approach using the Taguchi method (TM), grey relational analysis (GRA) and a neural network (NN) to optimize the weld bead geometry in a novel gas metal arc (GMA) welding process. The TM is first used to construct a database for the NN. The GRA is adopted to solve the problem of multiple performance characteristics in a GMA welding process using activating flux. The grey relational grade obtained from the GRA is used as the output of the back-propagation (BP) NN. Then, a NN with the Levenberg-Marquardt BP (LMBP) algorithm is used to provide the nonlinear relationship between welding parameters and grey relational grade of each weldment. The optimal parameters of the novel GMA welding process were determined by simulating parameters using a well-trained BPNN model. Experimental results illustrate the proposed approach.

Similar content being viewed by others

References

Balasubramanian M., Jayabalan V., Balasubramanian V. (2007) Response surface approach to optimize the pulsed current gas tungsten arc welding parameters of Ti-6Al-4V Titanium alloy. Metals and Materials International 13(4): 335–344

Benyounis, K. Y., Olabi, A. G., & Hashmi, M. S. J. (2005). Optimizing the laser-welded butt joints of medium carbon steel using RSM. Journal of Materials Processing Technology, 164–165, 986–989.

Coit D. W., Jacson B. T., Smith A. E. (1998) Static neural network process model: Considerations and cases studies. International Journal of Product Research 36(11): 2953–2967

Demuth H., Beale M. (1998) Neural network toolbox-for use with MATLAB. The Math Works Inc, Natick, MA, USA

Deng J. (1989) Introduction to grey system. Journal of Grey System 1(1): 1–24

Funahashi K. (1989) On the approximate realization of continuous mapping by neural network. Neural Network 2: 183–192

Hagan M. T., Demuth H., Beale M. (1996) Neural network design. PWS Publishing Co, Boston, MA, USA

Hagan M. T., Menhaj M. B. (1994) Training feed forward networks with marquatdt algorithm. IEEE Transactions on Neural Networks 5(6): 989–993

Hsiao Y. F., Tarng Y. S., Huang W. J. (2008) Optimization of plasma arc welding parameters by using the Taguchi method with the grey relational analysis. Materials and Manufacturing Processes 23: 51–58

Hsiang S. H., Kuo J. L., Yang F. Y. (1999) Using artificial neural networks to investigate the influence of temperature on hot extrusion of AZ61 magnesium alloy. Journal of Intelligent Manufacture 10: 73–79

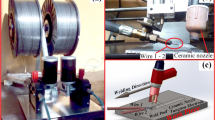

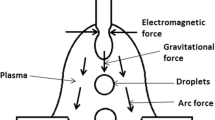

Huang H. Y. (2010) Effects of activating flux on the welded joint characteristics in gas metal arc welding. Materials and Design 31: 2488–2495

Karadeniz K., Ozsarac U., Yildiz C. (2007) The effect of process parameters on penetration in gas metal arc welding processes. Materials and Design 28: 649–656

Khaw J. F. C., Lim B. S., Lim L. E. N. (1995) Optimal design of neural networks using Taguchi method. Neurocomputing 7: 225–245

Kim I. S., Jeong Y. J., Lee C. W. (2003) Prediction of welding parameters for pipeline welding using an intelligent system. International Journal Advance Manufacture Technology 22: 713–719

Lin J. L., Lin C. L. (2002) The use of the orthogonal array with grey relational analysis to optimize the electrical discharge machining process with multiple performance characteristics. International Journal of Machine Tools & Manufacture 42: 237–244

Lucas W., Howse D. (1996) Activating flux-increasing of performance and productivity of the TIG and plasma processes. Welding & Metal Fabrication 64(1): 11–17

Nagesh D. S., Datta G. L. (2002) Prediction of weld bead geometry and penetration in shielded metal-arc welding using artificial neural networks. Journal of Materials Processing Technology 123: 303–312

Pan L. K., Wang C. C., Wei S. L., Sher H. F. (2007) Optimizing multiple quality characteristics via Taguchi method-based grey analysis. Journal of Materials Processing Technology 182: 107–116

Ross P. J. (1988) Taguchi techniques for quality engineering. McGraw-Hill, New york

Su C. T., Chiang T. L. (2003) Optimizing the IC wire bonding process using a neural networks/genetic algorithms approach. Journal of Intelligent Manufacture 14: 229–238

Taguchi G. (1993) Taguchi methods: Design of experiments. American Supplier Institute Inc, Dearborn, MI, USA

Tarng Y. S., Wu J. L., Yeh S. S., Juang S. C. (1999) Intelligent modeling and optimization of the gas tungsten arc welding process. Journal of Intelligent Manufacture 10: 73–79

Yu J. C., Chen X. X., Hung T. R., Thibault F. (2004) Optimization of extrusion blow molding processes using soft computing and Taguchi’s method. Journal of Intelligent Manufacture 15: 625–634

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper has not been published elsewhere nor has it been submitted for publication elsewhere.

Rights and permissions

About this article

Cite this article

Lin, HL. The use of the Taguchi method with grey relational analysis and a neural network to optimize a novel GMA welding process. J Intell Manuf 23, 1671–1680 (2012). https://doi.org/10.1007/s10845-010-0468-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-010-0468-2