Abstract

Despite their advances and numerous benefits, metal powder-bed additive manufacturing (AM) processes still suffer from the high chances of defect formation and a need for improved quality. This work develops an online monitoring system for quality of fusion and defect formation in every layer of the laser powder-bed fusion process using computer vision and Bayesian inference. An imaging setup is developed that for the first time allows capturing in-situ (during the build) images from every layer that visualize detailed layer defects and porosity. A database of camera images from every layer of AM parts made with various part quality was created that is the first visual labeled dataset from in-situ visual images of the powder-bed AM (also visualizing detailed layer features). The dataset is used in training-based classification to detect layers or sub-regions of the layer with low quality of fusion or defects. Features are carefully selected based on physical intuition into the process and extracted from the images of the various types of builds. A Bayesian classifier is developed and trained to classify the quality of the build that signifies the defective and unacceptable build layers or regions. The results can be used for quasi-real-time (layer-wise) process control, further process decisions, or corrective actions.

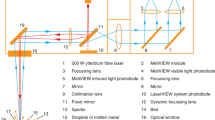

(Reproduced with permission from Gong et al. (2014))

Similar content being viewed by others

References

Aminzadeh, M., & Kurfess, T. (2015a). In-situ monitoring of dimensional accuracy in additive manufacturing by layerwise detection of geometric errors. In Proceedings of the ASPE spring topical meetings. American Society of Precision Engineering.

Aminzadeh, M., & Kurfess, T. (2015b). Layerwise automated visual inspection in laser powder-bed additive manufacturing. In ASME 2015 international manufacturing science and engineering conference (pp. V002T004A011-V002T004A011). American Society of Mechanical Engineers.

Aminzadeh, M., & Kurfess, T. (2016a). Vision-based inspection system for dimensional accuracy in powder-bed additive manufacturing. In ASME 2016 international manufacturing science and engineering conference. American Society of Mechanical Engineers.

Aminzadeh, M. & Kurfess, T. (2016b). In-situ quality inspection of laser powder-bed fusion using high-resolution visual camera images. In Paper presented at the solid freeform fabrication 2016: Proceedings of the 26th annual international solid freeform fabrication symposium—an additive manufacturing conference.

Bayle, F., & Doubenskaia, M. (2008). Selective laser melting process monitoring with high speed infra-red camera and pyrometer. Fundamentals of Laser Assisted Micro- and Nanotechnologies, 6985, 98505–98505. https://doi.org/10.1117/12.786940.

Berger, J. O. (2013). Statistical decision theory and Bayesian analysis. Berlin: Springer.

Boddu, M. R., Landers, R. G., & Liou, F. W. (2001). Control of laser cladding for rapid prototyping—A review. In Solid freeform fabrication symposium proceedings (pp. 6–8).

Brundage, M. P., Kulvatunyou, B., Ademujimi, T., & Rakshith, B. (2017). Smart manufacturing through a framework for a knowledge-based diagnosis system. In ASME 2017 12th international manufacturing science and engineering conference collocated with the JSME/ASME 2017 6th international conference on materials and processing (pp. V003T004A012-V003T004A012). American Society of Mechanical Engineers.

Cai, B., Huang, L., & Xie, M. (2017). Bayesian networks in fault diagnosis. IEEE Transactions on Industrial Informatics, 13, 2227–2240.

Clark, D., Sharples, S. D., & Wright, D. C. (2011). Development of online inspection for additive manufacturing products. Insight-Non-destructive Testing and Condition Monitoring, 53(11), 610–613. https://doi.org/10.1784/insi.2011.53.11.610.

Craeghs, T., Bechmann, F., Berumen, S., & Kruth, J. P. (2010). Feedback control of layerwise laser melting using optical sensors. In Laser assisted net shape engineering 6, proceedings of the lane 2010, part 2, 5 (pp. 505–514). https://doi.org/10.1016/j.phpro.2010.08.078.

Craeghs, T., Clijsters, S., Yasa, E., Bechmann, F., Berumen, S., & Kruth, J. P. (2011a). Determination of geometrical factors in layerwise laser melting using optical process monitoring. Optics and Lasers in Engineering, 49(12), 1440–1446. https://doi.org/10.1016/j.optlaseng.2011.06.016.

Craeghs, T., Clijsters, S., Yasa, E., & Kruth, J.-P. (2011b). Online quality control of selective laser melting. In 20th solid freeform fabrication (SFF) symposium, Austin, Texas.

Das, S. (2003). Physical aspects of process control in selective laser sintering of metals. Advanced Engineering Materials, 5(10), 701–711. https://doi.org/10.1002/adem.200310099.

De Silva, N., & Jayamanne, D. (2016). Computer-aided medical diagnosis using bayesian classifier-decision support system for medical diagnosis. International Journal of Multidisciplinary Studies, 3(2), 91–97.

Fang, T., Jafari, M. A., Safarai, A., & Danforth, S. C. (1999). Statistical feedback control architecture for layered manufacturing. Journal of Materials Processing & Manufacturing Science, 7(4), 391–404.

Foster, B., Reutzel, E., Nassar, A., Hall, B., Brown, S., & Dickman, C. (2015). Optical, layerwise monitoring of powder bed fusion. In 26th International solid freeform fabrication symposium, Austin, TX.

Gong, H. (2013). Generation and detection of defects in metallic parts fabricated by selective laser melting and electron beam melting and their effects on mechanical properties. https://doi.org/10.18297/etd/515

Gong, H., Rafi, K., Gu, H., Starr, T., & Stucker, B. (2014). Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes. Additive Manufacturing, 1, 87–98.

Gong, H., Rafi, K., Karthik, N., Starr, T., & Stucker, B. (2013). Defect morphology in Ti–6Al–4V parts fabricated by selective laser melting and electron beam melting. In 24rd Annual international solid freeform fabrication symposium—An additive manufacturing conference, Austin, TX, August, 2013 (pp. 12–14).

Gu, D., & Shen, Y. (2009). Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Materials & Design, 30(8), 2903–2910.

Islam, M., Purtonen, T., Piili, H., Salminen, A., & Nyrhila, O. (2013). Temperature profile and imaging analysis of laser additive manufacturing of stainless steel. Lasers in Manufacturing (Lim 2013), 41, 828–835. https://doi.org/10.1016/j.phpro.2013.03.156.

Jacobsm, J. Z., hlen, Kleszczynski, S., Schneider, D., & Witt, G. (2013). High resolution imaging for inspection of laser beam melting systems. In 2013 IEEE international instrumentation and measurement technology conference (I2MTC), 6–9 May 2013 (pp. 707–712). https://doi.org/10.1109/I2MTC.2013.6555507.

Kleszczynski, S., Joschka, Z. J., & Sehrt, J. T. (2012). Error detection in laser beam melting systems by high resolution imaging. In Proceedings of the twenty third annual international solid freeform fabrication symposium.

Kleszczynski, S., zur Jacobsmühlen, J., Sehrt, J. T., & Witt, G. (2013). Mechanical properties of laser beam melting components depending on various process errors. In Digital product and process development systems (pp. 153–166). Berlin: Springer.

Kruth, J.-P., Badrossamay, M., Yasa, E., Deckers, J., Thijs, L., & Humbeeck, J. V. (2010). Part and material properties in selective laser melting of metals. In 16th International symposium on electromachining, Chicago.

Kruth, J.-P., Mercelis, P., Vaerenbergh, J. V., & Craeghs, T. (2007). Feedback control of selective laser melting. In The 3rd international conference on advanced research in virtual and rapid prototyping (pp. 521–527).

Kruth, J. P., Levy, G., Klocke, F., & Childs, T. H. C. (2007). Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Annals—Manufacturing Technology, 56(2), 730–759.

Modi, S., Lin, Y., Cheng, L., & Zhang, W. J. (2011). A socially inspired framework for human state inference using expert opinion integration. IEEE Transactions on Mechatronics, 16(5), 874–878.

Prabhu, A. W. (2014). Improving fatigue life of LENS deposited Ti–6Al–4V through microstructure and process control. Columbus: The Ohio State University.

Sauvola, J., & Pietikäinen, M. (2000). Adaptive document image binarization. Pattern Recognition, 33(2), 225–236.

Shapiro, L. G., & Stockman, G. C. (2001). Computer Vision. London: Prentice Hall.

Tchangani, A. P. (2004). Decision-making with uncertain data: Bayesian linear programming approach. Journal of Intelligent Manufacturing, 15(1), 17–27.

Thijs, L., Verhaeghe, F., Craeghs, T., Humbeeck, J. V., & Kruth, J.-P. (2010). A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Materialia, 58(9), 3303–3312.

zur Jacobsmühlen, J., Kleszczynski, S., Witt, G., & Merhof, D. (2015). Elevated region area measurement for quantitative analysis of laser beam melting process stability. In 26th International solid freeform fabrication symposium, Austin, TX.

Acknowledgements

The authors would like to thank the Edison Welding Institute for funding this research and providing the equipment and support for conducting this work. This work was fulfilled under project “Measurement Science for Advanced Manufacturing” (MSAM) supported by the National Institute of Standards and Technology (NIST).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aminzadeh, M., Kurfess, T.R. Online quality inspection using Bayesian classification in powder-bed additive manufacturing from high-resolution visual camera images. J Intell Manuf 30, 2505–2523 (2019). https://doi.org/10.1007/s10845-018-1412-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-018-1412-0