Abstract

Manufacturing industry profoundly impact economic and societal progress. As being a commonly accepted term for research centers and universities, the Industry 4.0 initiative has received a splendid attention of the business and research community. Although the idea is not new and was on the agenda of academic research in many years with different perceptions, the term “Industry 4.0” is just launched and well accepted to some extend not only in academic life but also in the industrial society as well. While academic research focuses on understanding and defining the concept and trying to develop related systems, business models and respective methodologies, industry, on the other hand, focuses its attention on the change of industrial machine suits and intelligent products as well as potential customers on this progress. It is therefore important for the companies to primarily understand the features and content of the Industry 4.0 for potential transformation from machine dominant manufacturing to digital manufacturing. In order to achieve a successful transformation, they should clearly review their positions and respective potentials against basic requirements set forward for Industry 4.0 standard. This will allow them to generate a well-defined road map. There has been several approaches and discussions going on along this line, a several road maps are already proposed. Some of those are reviewed in this paper. However, the literature clearly indicates the lack of respective assessment methodologies. Since the implementation and applications of related theorems and definitions outlined for the 4th industrial revolution is not mature enough for most of the reel life implementations, a systematic approach for making respective assessments and evaluations seems to be urgently required for those who are intending to speed this transformation up. It is now main responsibility of the research community to developed technological infrastructure with physical systems, management models, business models as well as some well-defined Industry 4.0 scenarios in order to make the life for the practitioners easy. It is estimated by the experts that the Industry 4.0 and related progress along this line will have an enormous effect on social life. As outlined in the introduction, some social transformation is also expected. It is assumed that the robots will be more dominant in manufacturing, implanted technologies, cooperating and coordinating machines, self-decision-making systems, autonom problem solvers, learning machines, 3D printing etc. will dominate the production process. Wearable internet, big data analysis, sensor based life, smart city implementations or similar applications will be the main concern of the community. This social transformation will naturally trigger the manufacturing society to improve their manufacturing suits to cope with the customer requirements and sustain competitive advantage. A summary of the potential progress along this line is reviewed in introduction of the paper. It is so obvious that the future manufacturing systems will have a different vision composed of products, intelligence, communications and information network. This will bring about new business models to be dominant in industrial life. Another important issue to take into account is that the time span of this so-called revolution will be so short triggering a continues transformation process to yield some new industrial areas to emerge. This clearly puts a big pressure on manufacturers to learn, understand, design and implement the transformation process. Since the main motivation for finding the best way to follow this transformation, a comprehensive literature review will generate a remarkable support. This paper presents such a review for highlighting the progress and aims to help improve the awareness on the best experiences. It is intended to provide a clear idea for those wishing to generate a road map for digitizing the respective manufacturing suits. By presenting this review it is also intended to provide a hands-on library of Industry 4.0 to both academics as well as industrial practitioners. The top 100 headings, abstracts and key words (i.e. a total of 619 publications of any kind) for each search term were independently analyzed in order to ensure the reliability of the review process. Note that, this exhaustive literature review provides a concrete definition of Industry 4.0 and defines its six design principles such as interoperability, virtualization, local, real-time talent, service orientation and modularity. It seems that these principles have taken the attention of the scientists to carry out more variety of research on the subject and to develop implementable and appropriate scenarios. A comprehensive taxonomy of Industry 4.0 can also be developed through analyzing the results of this review.

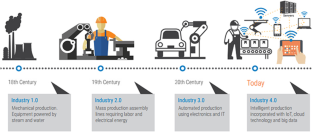

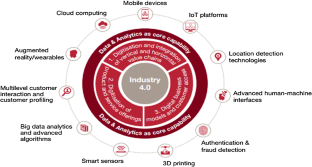

Reproduced with permission from BCMCOM (2017)

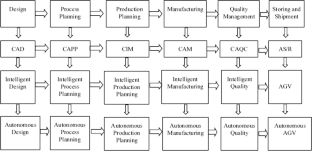

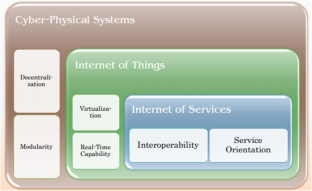

Reproduced with permission from Oztemel (2010)

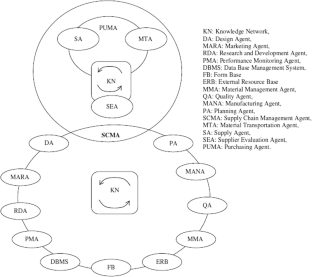

Reproduced with permission from Oztemel and Tekez (2009a)

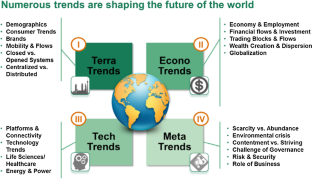

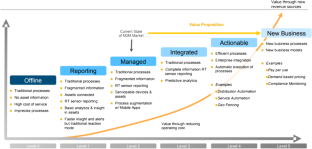

Reproduced with permission from Boston Consulting Group (2016)

Reproduced with permission from Lichtblau et al. (2016)

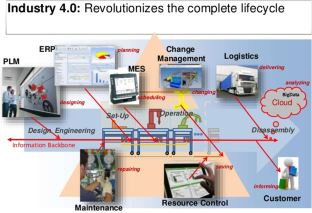

Reproduced with permission from GTAI (2017)

Reproduced with permission from Remon (2017)

Reproduced with permission from Jaehne and KalalChelvan (2017)

Reproduced with permission from Gaurav (2017)

Similar content being viewed by others

References

Aalaei, A., & Davoudpour, H. (2016). Revised multi-choice goal programming for incorporated dynamic virtual cellular manufacturing into supply chain management: A case study. Engineering Applications of Artifical Intelligence,47, 3–15.

Abdoa, J., & Demerjianb, J. (2017). Evaluation of mobile cloud architectures. Pervasive and Mobile Computing,39, 284–303.

Aburaia, M., Markl, E., & Stuje, K. (2015). New concept for design and control of 4 axis robot using the additive manufacturing technology. Procedia Engineering,100, 1364–1369.

Accenture. (2016). Industry 4.0 revolution report. https://www.accenture.com/us-en/insight-digital-industry-impact. Available on August 28, 2017.

Accorsi, R., Bortolini, M., Baruffaldi, G., Pilati, F., & Ferrari, E. (2017). Internet-of-things paradigm in food supply chains control and management. Procedia Manufacturing,11, 889–895.

Ackermann, R. (2013). M2M, internet of things and industry 4.0—An industry perspective. http://www.acatech.de/fileadmin/user_upload/Baumstruktur_nach_Website/Acatech/root/de/Material_fuer_Sonderseiten/Second_German-Indian-Workshop/India_01_13_Industrie40_m2m_Ackermann_SAP.pdf. Available on August 28, 2017.

Addo-Tenkorang, R., & Helo, P. T. (2016). Big data applications in operations/supply-chain management: A literature review. Computers & Industrial Engineering,101, 528–543.

Adeyeri, S., Kanisuru, M., Khumbulani, M., & Olukorede T. (2015). Integration of agent technology into manufacturing enterprise: A review and platform for industry 4.0. In Proceedings of the 2015 international conference on industrial engineering and operations management Dubai, United Arab Emirates (UAE) (pp. 1625–1635).

Agency, M. (2008). The medical products agency’s working group on medical information systems. National Board of Health and Welfare in the regulations on quality management systems in health care. https://lakemedelsverket.se/upload/foretag/medicinteknik/en/Medical-Information-Systems-Report_2009-06-18.pdf. Available on August 22, 2017.

Ahmed, E., & Kohno, R. (2017). Error control coding and decoding with medical QoS constraints for Wban end to end connection via UMTS channel. ICT Express. https://doi.org/10.1016/j.icte.2018.01.016.

AIR-LIQUIDE. (2016). https://www.airliquide.com/media/france-air-liquide-plant-future-project-certified-technological-showcase-industry-future-alliance. Available on August 30, 2017.

Akoka, J., Wattiau, I., & Laoufi, N. (2016). Research on big data—A systematic mapping study. Neurocomputing,2, 1023–1041.

Al-Ali, A., & Aburukba, R. (2015). Role of internet of things in the smart grid technology. Journal of Computer and Communications,3, 229–233.

Alam, K., & Saddik, A. (2015). C2PS: A digital twin architecture reference model for the cloud-based cyber-physical system. IEEE Access,5, 25–35.

Alanso-Martin, F., Castro, A., Malfaz, M., & Castillo, J. (2017). Identification and distance estimation of users and objects by means of electronic beacons in social robotics. Expert Systems with Applications,86, 247–257.

Alatoibi, Y. (2016). Business process modelling challenges and solutions: A literature review. Journal of Intelligent Manufacturing,27, 701–723.

Alayaa, M., Banouara, D., Monteila, S., Chassota, Z., & Drira, T. (2014). OM2M: Extensible ETSI-compliant M2M service platform with self-configuration capability. Computer Science,32, 1079–1086.

Albert, A., Bartosz, G., Tobias, P., Viktoriia, B., & Tobias, S. (2016). Procedure for defining the system of objectives in the initial phase of an industry 4.0 project focusing on intelligent quality control systems. Reconfigurable & Virtual Production,52, 262–267.

Albodour, R., James, A., & Yaacob, N. (2015). QoS within business grid quality of service (BGQoS). Future Generation Computer Systems,50, 22–37.

Aleina, S. C., Viola, N., Fusara, R., Saccoccia, G., & Vercella, V. (2018). Using the ESA exploration technology roadmaps in support of new mission concepts and technology prioritization. Acta Astronautica. https://doi.org/10.1016/j.actaastro.2018.04.035.

Al-Fuqaha, A., Guizani, M., Mohammadi, M., Aledhari, M., & Ayyash, M. (2015). Internet of things: A survey on enabling technologies, protocols and applications. IEEE Communications Surveys and Tutorials,17(4), 2347–2376.

Alharthi, A., Krotov, V., & Bowman, M. (2017). Adressing bariers to big data. Business Horizons,60, 285–292.

Alkhamisi, A., & Monowar, M. (2013). Rise of augmented reality: Current and future application areas. International Journal of Internet and Distributed Systems,1, 25–34.

Alkoc, E., & Erbatur, F. (1997). Productivity improvement in concreting operations through simulation models. Building Research and Information,25(2), 83–95.

Amatoa, F., & Moscato, F. (2017). Exploiting cloud and workflow patterns for the analysis of composite cloud services. Future Generation Computer Systems,67, 255–265.

Anderl, R. (2014). Industries 4.0-advanced engineering of smart products and smart production. In 19th International seminar on high technology, technological innovations in the product development, Piracicaba, Brazil. https://www.researchgate.net/publication/270392830_Industrie_40_-_Advanced_Engineering_of_Smart_Products_and_Smart_Production_09_October_2014. Available on December 28, 2017.

Andrade, A., Pereira, A., Walter, S., Almeida, R., Loureiro, R., Compagna, D., et al. (2014). Bridging the gap between robotic technology and health care. Biomedical Signal Processing and Control,10, 65–78.

Angeles, R. (2005). RFID technologies: Supply-chain applications and implementation issues. Information Systems Management,22, 51–65.

Ângelo, A., Barata, J., da Cunha, P. R., & Almeida, V. (2017). Digital transformation in the pharmaceutical compounds supply chain: Design of a service ecosystem with e-labeling. In European, Mediterranean, and Middle Eastern conference on information systems (pp. 307–323).

Anitha, R., & Mukherjee, S. (2017). ‘MaaS’: Fast retrieval of E-file in cloud using metadata as a service. Journal of Intelligent Manufacturing,28, 1871–1891.

ARIZ. (2017). https://www.festo.com/group/en/cms/12690.htm. Available on August 30, 2017.

Armentia, A., Gangoiti, U., Orive, D., & Marcos, M. (2017). Dynamic QoS management for flexible multimedia applications. IFAC PapersOnLine,50, 5920–5925.

Atanasov, I., Nikolov, A., Pencheva, E., Dimova, R., & Ivanov, M. (2015). An approach to data annotation for internet of things. International Journal of Information Technology and Web Engineering (IJITWE),10(4), 1–19.

Atif, Y., Dinga, J., & Jeusfelda, M. A. (2016). Internet of things approach to cloud-based smart car parking. Computer Science,98, 193–198.

Atzori, L., Morabito, G., & Lera, A. (2017). Understanding the internet of things: Definition. Ad Hoc Networks,56, 122–140.

AWS. (2017). https://aws.amazon.com/iot-platform/. Available on August 30, 2017.

Azevedo, P., Azevedo, C., & Romão, M. (2014). Application integration: Enterprise resource planning (ERP) systems in the hospitality industry. Procedia Technology,16, 52–58.

Backhaus, J., & Reinhart, G. (2017). Digital description of products, processes and resources for task-oriented programming of assembly systems. Journal of Intelligent Manufacturing,28, 1787–1800.

Badawi, H., Dong, H., & El Saddika, Abdulmotaleb. (2017). Mobile cloud-based physical activity advisory system using biofeedback sensors. Future Generation Computer Systems,66, 59–70.

Bagheri, B., Yang, S., Kao, H. A., & Lee, J. (2015). Cyber-physical systems architecture for selfaware machines in industry 4.0 environment. IFAC-PapersOnLine,48(3), 1622–1627.

Baheti, R., & Gill, H. (2011). Cyber-physical systems. The İmpact of Control Technology,12, 161–166.

Balina, S., Baumgarte, D., & Salna, E. (2017). Cloud based cross-system integration for small and medium-sized enterprises. Computer Science,104, 127–132.

Bartezzaghi, E., & Ronchi, S. (2003). Internet supporting the procurement process lessons from four case studies. Integrated Manufacturing Systems,14, 632–641.

Bauer, W., Schlund, S., Marrenbach, D., & Ganschar, O. (2014). Industry 4.0—Volkswirtschaftliches Potenzial für Deutschland, BITKOM company. http://www.produktionsarbeit.de/content/dam/produktionsarbeit/de/documents/Studie-Industrie-4-0-Volkswirtschaftliches-Potential-fuer-Deutschland.pdf. Available on August 28, 2017 (in German).

Bauernhansl, T. (2014). Die vierte Industrylle Revolution. Der Weg in ein wertschaffendes Produktionsparadigma,4, 3–35. (in German).

Bauernhansl, T., ten Hompel, M., & Vogel-Heuser, B. (Eds.) (2014). Industry 4.0 in Produktion, Automatisierung und Logistik. Anwendung, Technologien und Migration 8, 30–40 (in German).

Baygin, M., Yetis, H., Karakose, M., & Akin, E. (2016). An effect analysis of industry 4.0 to higher education. In 2016 15th international conference on information technology based higher education and training (ITHET), July 10–12, 2017, Ohrid, Macedonia.

BCMCOM. (2017). Industry 4.0 technologies for new trends and developments for industry delivering quality. http://www.bcmcom.com/solutions_application_industry40.htm. Available on August 28, 2017.

Beckera, T., & Sterna, H. (2016). Future trends in human work area design for cyber-physical production systems. Procedia CIRP,57, 404–409.

Bellini, P., Bruno, I., Cenni, D., & Nesi, P. (2017). Managing cloud via smart cloud engine and knowledge base. In 2015 IEEE 8th international conference on cloud computing (CLOUD), 27 June–2 July 2015, New York, NY, USA.

Bello, O., Zeadally, S., & Badra, M. (2017). Network layer inter-operation of device-to-device communication technologies in internet of things (IoT). Ad Hoc Networks,57, 52–62.

Bently, C. (2016). The manufacturer industry 4.0 UK readiness report. Oracle Company Report. https://www.oracle.com/webfolder/s/delivery_production/docs/FY16h1/doc19/Industry-Report.pdf. Available on August 28, 2017.

Bergera, C., Heesa, A., Braunreuthera, S., & Reinharta, G. (2016). Characterization of cyber-physical sensor systems. Manufacturing System,41, 638–643.

Berryman, D. (2012). Augmented reality: A review. Medical Reference Services Quarterly,31(2), 212–218.

Bertacchini, F., Bilotta, E., & Pantano, P. (2017). Shopping with a robotic companion. Computers in Human Behavior,77, 382–395.

Biral, A., Centenaro, M., Zanella, A., Vangelista, L., & Zorzi, M. (2015). The challenges of M2M massive access in wireless cellular networks. Digital Communications and Networks,1(1), 1–19.

BMBF. (2014). Bundesministerium für Bildung und Forschung, 2014: Zukunftsbild Industry 4.0. http://www.bmbf.de/pubRD/Zukunftsbild_Industry_40.pdf. Available on August 28, 2017 (in German).

Boston Consulting Group. (2016). Industry 4.0: The future of productivity and growth in manufacturing industries. https://www.bcgperspectives.com/content/articles/engineered_products_project_business_industry_40_future_productivity_growth_manufacturing_industries/?chapter=4#chapter4_section2. Available on August 28, 2017.

Bourke, R., & Mentis, M. (2014). An assessment framework for inclusive education: Integrating assessment approaches. Assesment in Education,21(4), 384–397.

Bouwers, E., & Vis, R. (2009). Multidimensional software monitoring applied to ERP. Electronic Notes in Theoretical Computer Science,233, 161–173.

Boveta, G., & Hennebertb, J. (2013). Energy-efficient optimization layer for event-based communications on Wi-Fi thing. Computer Science,19, 256–264.

Bower, M., Howe, C., McCredie, N., Robinson, A., & Grover, D. (2014). Augmented reality in education—Cases, places and potentials. Educational Media International,51(1), 1–15.

Brandmeier, M., Bognera, E., Brossoga, M., & Frankea, J. (2016). Product design improvement through knowledge feedback of cyber-physical systems. Procedia CIRP,50, 186–191.

Brennera, A., & Hummela, V. (2016). A seamless convergence of the digital and physical factory aiming in personalized Product Emergence Process (PPEP) for smart products within ESB Logistics Learning Factory at Reutlingen University. Procedia CIRP,54, 227–232.

Brettel, M., Klein, M., & Friederichsen, N. (2016). The relevance of manufacturing flexibility int he context of industries 4.0. Procedia CIRP,41, 105–110.

Brioto, M., Hoque Z., Steinke R., & Willner A. (2016). Towards programmable fog nodes in smart factories. In 2016 IEEE 1st international workshops on foundations and applications of self systems, Augsburg, Germany, 12–16 September 2016.

Brunete, A., Gambao, E., Koskinen, J., Heikkila, T., Kaldestad, K., Tyapin, I., et al. (2017). Hard material small-batch industrial machining robot. Robotics and Computer-Integrated Manufacturing. https://doi.org/10.1016/j.rcim.2017.11.004.

Bryner, M. (2012). Smart manufacturing: The next revolution. CEP Magazine,7, 1090–1098.

Bui, D., Yoon, Y., Huh, E., Jun, S., & Lee, S. (2013). Energy efficiency for cloud computing system based on predictive optimization. Journal of Parallel and Distributed Computing,102, 103–114.

Bungart, S. (2014). Industrial internet versus industry 4.0. Produktion—Technik und Wirtschaft für die deutsche Industry. Retrieved from http://www.produktion.de/automatisierung/industrial-internet-versus-Industry-4-0/print. Available on August 28, 2017.

Bunse, B. (2016). Industry: Based on “German Industry 4.0” report. Journal of Applied Business and Economics,18, 40–50.

Bürger, T., & Tragl, K. (2014). SPS-Automatisierung mit den Technologien der IT-Welt verbinden. Technologien und Migration (pp. 559–569) (in German).

Burke, M., Quigley, N., & Speed, C. (2013). The internet of things: Pink jumpers and Hungarian eggs in digital spaces. Procedia Computer Engineering,9, 152–157.

Calderona, M., Delgadilloa, S., & Antonio, J. (2016). A more human-centric Internet of Things with temporal and spatial context. Computer Science,83(2016), 553–559.

Candra, S. (2012). ERP implementation success and knowledge capability. International Congress on Interdisciplinary Business and Social Science,65, 141–149.

Canedoa, A., & Richterb, J. (2014). Architectural design space exploration of cyber-physical systems using the functional modeling compiler. Engineering Services,21, 46–51.

Carboneras, M., Insa, C., & Salort, E. (2003). ERP implementation in the stone industry: Special difficulties and solutions in the production area. In Emerging technologies and factory automation, 2003. Proceedings. ETFA’03. IEEE conference. Lisbon, Portugal.

Carniani, E., Darenzo, D., Lazouski, A., Martinelli, A., & Mori, P. (2016). Usage control on cloud systems. Future Generation Computer Systems,63, 37–55.

Carrera, C., & Asensio, C. (2016). Landscape interpretation with augmented reality and maps to improve spatial orientation skill. Journal of Geography in Higher Education,41(1), 119–133.

Carstensen, J., Carstensen, T., Pabs, M., Schulz, F., Friederichs, J., Aden, S., et al. (2016). Condition monitoring and cloud-based energy analysis for autonomous mobile manipulation—Smart factory concept with LUHbots. Procedia Technology,26(2016), 560–569.

Chang, H., Kim, J., & Park, J. (2014). IT convergence security. Journal of Intelligent Manufacturing,25, 213–215.

Chang, H., Ma, J., Loke, S., Zimmermann, H., & Li, Z. (2012). Intelligent ubiquitous IT policy and its industrial services. Journal of Intelligent Manufacturing,23, 913–915.

Chang, V., Ramachandranb, M., Wills, G., Walters, R., Li, C., & Watters, P. (2016). Editorial for FGCS special issue: Big Data in the cloud. Future Generation Computer Systems,65, 73–75.

Chatterjee, S. (2015). ERP failure in developing countries: A case study in India. In India conference (INDICON), 2015 Annual IEEE, 17–20 December 2015, New Delhi, India.

Chelloug, S. (2015). Energy-efficient content-based routing in internet of things. Journal of Computer and Communications,3, 9–20.

Chen, G., & Liu, Y. (2012). Performance evaluation of ERP implementation based on uncertainty measurement theory. In 2012 International conference on information management, innovation management and industrial engineering, 20–21 October 2012, Sanya, China.

Chen, G., & Wang, J. (2010). Analysis on performance evaluation system of ERP implementation. In 2010 International conference of information science and management engineering, 7–8 August 2010, China.

Chen, T. C. (2018). Cloud intelligence in manufacturing. Journal of Intelligent Manufacturing,28, 1057–1059.

Chen, T., & Chiu, M. (2017). Development of a cloud-based factory simulation system for enabling ubiquitous factory simulation. Robotics and Computer-Integrated Manufacturing,45, 133–143.

Chen, T., & Wu, C. (2017). A new cloud computing method for establishing asymmetric cycle time intervals in a wafer fabrication factory. Journal of Intelligent Manufacturing,28, 1095–1107.

Chen, X., Zhao, Y., Zhang, C., Wang, X., & Chen, L. (2018). Robot needle-punching for manufacturing composite preforms. Robotics and Computer-Integrated Manufacturing,50, 132–139.

Chen, X., & Jin, Z. (2012). Research on key technology and applications for internet of things. Physics Procedia,33(2012), 561–566.

Cheng, G., Lıu, L., & Quıang, Z. (2016). Industry 4.0 development and application of intelligent manufacturing. In 2016 International conference on information system and artificial intelligence, 24–26 June 2016, Hong Kong, China.

Cheng-Yu, W., Pi-Cheng, T., & Chyun-Chau, F. (2010). Development of an automatic arc welding system using an adaptive sliding mode control. Intelligent Manufacturing,21(4), 355–362.

Chi, X., Zhang, J., & Ma, L. (2011). Queuing theory based service performance evaluation under H2H and M2M blending traffic arriving. Procedia Environmental Science,11(Part A), 478–485.

Chien, C., Gen, M., & Shi, Y. (2014). Manufacturing intelligence and innovation for digital manufacturing and operational excellence. Journal of Intelligent Manufacturing,25, 845–847.

Chlen, C., Kim, K., Liu, B., & Gen, M. (2012). Advanced decision and intelligence technologies for manufacturing and logistics. Journal of Intelligent Manufacturing,22, 2133–2135.

Chu, C., Weidong, L., & Jiao, R. (2013). Design chain management: bridging the gap between engineering and management. Journal of Intelligent Manufacturing,24, 541–544.

Cooper, S. (2017). Designing a UK industrial strategy for the age of industry 4.0. Rethink Manufacturing (pp. 1–27).

Corcio, M. (2016). Manufacturing intelligence, group manager: Automation, MES & Electricity. http://www.iiconsortium.org/smart-factory-forum/MIGUEL-CORCIO-Keynote_IIC-MC-Smart_Manufacturing.pdf. Available on August 28, 2017.

Dagli, C. (2016). Engineering cyber physical systems: Applying theory to practice. Procedia Computer Science,95, 7–8.

Daim, T., Yoon, B., Linderberg, J., Grizzi, R., & Estep, J. (2018). Strategic roadmapping of robotics echnologies for the power industry: A multicriteria technology assessment. Technological Forecasting and Social Change,131, 49–66.

Damle, A., Damle, R., Flahive, J., Schlussel, A. T., Davids, J., Sturrock, P. R., et al. (2017). Diffusion of technology: Trends in robotic-assisted colorectal surgery. The American Journal of Surgery,214, 820–824.

Dasgupta, A., Nagaraj, R., & Nagamani, K. (2016). An internet of things platform with Google. Journal of Software Engineering and Applications,9, 291–295.

Davali, I., Belli, L., Cilfone, A., & Ferrari, G. (2016). Integration of Wifi mobile nodes in a web of things tested. ICT Express,2(3), 96–99.

Dechene, D., & Shami, A. (2013). Energy efficient QoS constrained scheduler for SC-FDMA uplink. Physical Communication,8, 81–90.

Decker, M., Fischer, M., & Ott, I. (2017). Service robotics and human labor: A first technology assessment of substitution and cooperation. Robotics and Autonomous Systems,87, 348–354.

DEF. (2016). https://www.economie.gouv.fr/files/files/PDF/web-dp-indus-ang.pdf. Available on August 30, 2017.

Deja, M., & Siemiaatkowski, M. (2013). Feature-based generation of machining process plans for optimised parts manufacture. Journal of Intelligent Manufacturing,24, 831–846.

Dener, M., & Bostancıoğlu, C. (2015). Smart technologies with wireless sensor networks. Social and Behavioral Sciences,195, 1915–1921.

Deng, G., Chen, D., & Yao, M. (2015). Value structure analysis for cloud service ecosystem. International Journal of Services, Technology and Management,21(4/5/6), 228–237.

Ding, L., Liu, Y., Han, B., & Zhang, S. (2017a). HB-file: An efficient and effective high-dimensional big data storage structure based on US-ELM. Proceedings of ELM,1, 489–500.

Ding, Y., Yaoa, G., & Haoa, K. (2017b). Fault-tolerant elastic scheduling algorithm for workflow in cloud systems. Future Generation Computer Systems,393, 47–65.

Do, H., Minh, P., Sheng, W., Yang, D., & Liu, M. (2018). RiSH: A robot-integrated smart home for elderly care. Robotics and Autonomous Systems,101, 74–92.

Dong, H.-S. (2016). Anatomy of big data developmental process. Telecommunication Policy,40(9), 837–854.

Drath, H., & Horch, A. (2014). Industry 4.0: Hit or hype? Industry forum. IEEE Industrial Electronics Magazine,8(2), 56–58.

Du, C., Tan, L., & Dong, Y. (2015). Period selection for integrated controller tasks in cyber physical systems. Aeronautics China,28(3), 894–902.

Du, Z., He, L., Chen, Y., Xiao, Y., Gao, P., & Wang, T. (2017). Robot cloud: Bridging the power of robotics and cloud computing. Future Generation Computer Systems,74, 337–348.

Duan, Q. (2017). Cloud service performance evaluation: status, challenges, and opportunities—A survey from the system modeling perspective. Computer Science,3(2), 101–111.

Dudek, J., Auersperg, J., Pantou, R., & Rzepka, S. (2015). Thermal and mechanical behavior of an RFID based smart system embedded in a transmission belt determined by FEM simulations for industry 4.0 applications. In 2015 16th international conference on Fraunhofer ENAS, 19–22 April 2015, Budapest, Hungary.

Dworschak, B., & Zaiser, H. (2014). Competencies for cyber-physical systems in manufacturing—First findings and scenarios. Procedia CIRP,25, 345–350.

EEF. (2017). The 4th industrial revolution—A primer for manufacturers. Technical report, EEF the manufacturers Organization, UK.

e-factory. (2017). https://tr3a.mitsubishielectric.com/fa/tr/solutions/efactory. Available on August 30, 2017.

Elmangousha, A., Coricib, A., Steinkeb, R., Coricib, M., & Magedanz, T. (2015). A framework for handling heterogeneous M2M traffic. Procedia Computer Science,63, 112–119.

Elmonem, M. A., Geith, M., Nasr, E., & Geith, M. (2017). Benefits and challenges of cloud ERP systems—A systematic literature review. Future Computing and Informatics Journal,1(1–2), 1–9.

Elmonem, M., Nasr, E., & Geith, M. (2016). Benefits and challenges of cloud ERP systems: A systematic literature view. Future Computing and Informatics Journal,1(1–2), 1–9.

Elragal, A. (2014). ERP and big data: The inept couple. Procedia Technology,16, 242–249.

Enget, K. (2016). A big data case. Journal of Accounting Education,39, 1–84.

ENTOC. (2017). https://www.festo.com/group/en/cms/12827.htm. Available on August 30, 2017.

EPRS. (2015). http://www.europarl.europa.eu/RegData/etudes/BRIE/2015/568337/EPRS_BRI(2015)568337_EN.pdf. Available on August 30, 2017.

Epstein, B., & Givoni, M. (2016). Analyzing the gap between the QOS demanded by PT users and QOS supplied by service operators. Transportation Research Part A,94, 622–637.

Ermilova, E., & Afsarmanesh, E. (2007). Modeling and management of profiles and competencies in VBEs. Intelligent Manufacturing,18, 561–586.

Erol, S., Jäger, A., Hold, P., Ott, K., & Sihn, W. (2016). Tangible industry 4.0: A scenario-based approach to learning for the future of production. Procedia CIRP,54, 13–18.

Esfahbodi, A., Zhang, Y., & Watson, G. (2016). Sustainable supply chain management in emerging economies: Trade-offs between environmental and cost performance. International Journal of Production Economics,181, 350–366.

ESIMA. (2017). Industry 4.0 project. https://www.esima-projekt.de/. Available on August 28, 2017 (in Germany).

Eslava, H., Rojas, L., & Pereira, R. (2014). Implementation of machine-to-machine solutions using MQTT protocol in internet of things (IoT) environment to improve automation process for electrical distribution substations in Colombia. Journal of Power and Energy Engineering,3, 92–96.

Evans, A., & Annunziata, B. (2012). Industrial internet: Pushing the boundaries of minds and machines. https://www.ge.com/docs/chapters/Industrial_Internet.pdf. Available on May 28, 2017.

Fallera, C., & Feldmüllera, D. (2015). Industry 4.0 learning factory for regional SMEs. In The 5th conference on learning factories 2015 (Vol. 32, pp. 88–91).

Fanjiang, Y., Syu, Y., & Kuo, J. (2016). Search based approach to forecasting QoS attributes of web services using genetic programming. Information and Software Technology,80, 158–174.

Fariss, M., Asaidi, H., & Bellouki, M. (2018). Comparative study of skyline algorithms for selecting Web Services based on QoS. The First International Conference On Intelligent Computing in Data Sciences,127, 408–415.

Feldmann, A. (2011). A strategic perspective on plants in manufacturing networks. Division of Production Economics Department of Management and Engineering, Vol. 1, pp. 581–583. ISBN: 978-91-7393-134-2.

Filaretov, V. F., & Pryyanichnikov, V. E. (2015). Autonomous mobile university robots AMUR: Technology and applications to extreme robotics. Procedia Engineering,100, 269–277.

Filippi, S., & Barattin, D. (2012). Classification and selection of prototyping activities for interaction design. Intelligent Information Management,4, 147–156.

Finin, T., Labrou, Y., & Mayfied, J. (1995). KQML as an agent communication language. In J. M. Bradshaw (Ed.), Software agents. Cambridge: MIT Press. ISBN 9780262522342.

Flammini, E., & Sisinni, E. (2012). Wireless sensor networking in the internet of things and cloud computing era. Procedia Engineering,87(2014), 672–679.

Fleisch, E., Weinberger, M., & Wortmann, F. (2014). Business models and the internet of things. Bosch IoT Lab Whitepaper, University of St. Gallen. http://cocoa.ethz.ch/downloads/2014/10/2090_EN_Bosch%20Lab%20White%20Paper%20GM%20im%20IOT%201_2.pdf. Available on May 28, 2017.

Flores-Abad, A., Ma, Q., Pham, K., & Ulrich, S. (2014). A review of space robotics technologies for on-orbit servicing. Progress in Aerospace Sciences,68, 1–26.

Foehr, M., Vollmar, J., Calà, A., Leitão, P., Karnouskos, S., & Colombo A. W. (2017). Engineering of next generation cyber-physical automation system architectures. In MultiDisciplinary Engineering for Cyber-Physical Production Systems, pp. 185–206. https://doi.org/10.1007/978-3-319-56345-9_8.

Foerstl, K., Azadegan, A., Leppelt, T., & Hartmann, E. (2015). Drivers of supplier sustainability: Moving beyond compliance to commitment. Journal of Supply Chain Management,51(1), 67–92.

Forti, T., & Munteanub, V. (2017). Topics in cloud incident management. Future Generation Computer Systems,72, 163–164.

Foster, K., Smith, G., Ariyachandra, T., & Frolick, M. (2015). Business intelligence competency center: Improving data and decisions. Information Systems Management,32(3), 229–233.

Framinan, J., & Pierreval, H. (2012). Special issue on pull strategies in manufacturing systems and supply chains: Recent advances. Journal of Intelligent Manufacturing,23, 1–3.

Francis, H., & Kusiak, A. (2017). Prediction of engine demand with a data-driven approach. Procedia Computer Science,103, 28–35.

Friedberg, I., McLaughlin, K., Smith, P., Laverty, D., & Seze, S. (2016). STPA-SafeSec: Safety and security analysis for cyber-physical systems. Journal of Information Security and Applications,2(2), 123–133.

FUSION. (2016). http://fusion-edu.eu/FUSION/. Available on August 30, 2017.

Gabrel, V., Manouvrier, M., Moreau, K., & Murat, C. (2018). QoS-aware automatic syntactic service composition problem: Complexity and resolution. Future Generation Computer Systems,80, 311–321.

Gaikwad, P. P., Gabhane, J. P., & Golait, S. S. (2015). A survey based on Smart Homes system using Internet-of-Things. In Computation of power, energy information and communication (ICCPEIC) (pp. 0330–0335).

Gajos, K., Weisman, L., & Shrobe, H. (2001). Design principles for resource management systems for intelligent spaces. International Workshop on Self-Adaptive Software,36, 198–215.

Galaske, N., & Anderl, R. (2016). Disruption management for resilient processes in cyber-physical production systems. Procedia CIRP,50, 442–447.

Gao, Y., Yang, T., & Bo, H. (2014). Improving the transmission reliability in smart factory through spatial diversity with ARQ. In IEEE/CIC international conference on communication in China, 27–29 July 2016, Chengdu, China.

Gash, D., Ariyachandra, T., & Frolick, M. (2011). Looking to the clouds for business intelligence. Journal of Internet Commerce,10(4), 261–269.

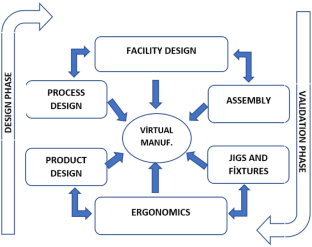

Gaurav, D. (2017). What is the difference between digital manufacturing and virtual manufacturing, Quora. https://www.quora.com/What-is-the-difference-between-Digital-Manufacturing-and-Virtual-Manufacturing. Available on August 28, 2017.

Gawanda, H., & Roya, K. (2015). Online monitoring of a cyber physical system against control aware cyber attacks. Engineering Services,70, 238–244.

Gay, S., & Nieuwoudt, L. (2010). Results of a trade simulation model for the South African fresh orange industry. Agrekon,38(4), 707–715.

Ge, M., Hong, J., Guttman, W., & Kim, D. (2014). A framework for automating security analysis of the internet of things. Procedia Technology,83, 12–27.

Geeta, R. B., Totad, G., Reddy, P., & Shobha, R. B. (2015). Big data structure and usage mining coalition. International Journal of Services, Technology and Management,21(6), 252–271.

Gelbmann, U., & Hammerl, B. (2015). Integrative re-use systems as innovative business models for devising sustainable product–service-systems. Journal of Cleaner Production,97, 50–60.

Gen, M., & Hwang, H. (2011). Advanced models and optimization in manufacturing and logistics systems. Journal of Intelligent Manufacturing,22, 343–344.

German Ministry of Education. (2016). Industry 4.0 platform, recommendations of industry 4.0 applications. http://www.din.de/blob/65354/f5252239daa596d8c4d1f24b40e4486d/roadmap-i4-0-e-data.pdf. Available on August 28, 2017.

Gharbic, G., Guermoucheb, N., & Monteil, T. (2014). Timed verification of machine-to-machine communications. Procedia Computer Science,32, 1071–1078.

Giasiranis, S., & Sofos, L. (2016). Production and evaluation of educational material using augmented reality for teaching the module of “representation of the information on computers” in junior high school. Creative Education,7, 1270–1291.

Giusto, D., Lera, A., Morabito, G., & Atzori, L. (Eds.) (2010). The internet of things: 20th Tyrrhenian workshop on digital communications. Springer. ISBN-10: 1441916733.

Gjeldum, N., Mladineoa, M., & Vezaa, I. (2016). Transfer of model of innovative smart factory to croatian economy using lean learning factory. Procedia CIRP,54, 158–163.

Gökalp, M., Kayabay, K., Akyol, M., Eren, E., & Kocyigit. A. (2016). Big data for industry 4.0: A conceptual framework. In 2016 International conference on computational science and computational intelligence, 15–17 December 2016, Las Vegas, NV, USA.

Golova, N., & Rönnbäck, L. (2016). Big data normalization for massively parallel processing database. Computer Standard,54(Part 2), 86–93.

Golparvar-Fard, M., Peña-Mora, F., & Savarese, S. (2009). D4AR—A 4-dimensional augmented reality model for automating construction progress monitoring data collection, processing and communication. Journal of Information Technology in Construction,14, 81–97.

Gonzales-Coma, J. P., Joham, M., Castro, P., & Castedo, L. (2018). QoS constrained power minimization in the multiple stream MIMO broadcast channel. Signal Processing,143, 48–55.

Gorecky, D., Schmitt, M., Loskyll, M., & Zühlke, D., (2014). Human–machine-interaction in the industry 4.0 era. In 12th IEEE international conference on industrial informatics (INDIN) (pp. 289–294).

Granell, C., Havlik, D., Schade, S., Sabeur, Z., Delaney, C., Pielorz, J., et al. (2016). Future internet technologies for environmental applications. Enviromental Modelling and Software,78, 1–15.

Greenyera, J., Gritznera, D., Katzb, G., Marronb, A., Gladea, N., Gutjahra, T., et al. (2016). Distributed execution of scenario-based specifications of structurally dynamic cyber-physical systems. Engineering Services,26, 552–559.

Grzenda, M., Bustillo, A., & Zawistowski, P. (2012). A soft computing system using intelligent imputation strategies for roughness prediction in deep drilling. Intelligent Manufacturing Systems,23(5), 1733–1743.

GTAI. (2017). Industries 4.0, http://www.gtai.de/GTAI/Navigation/EN/Invest/Industries/Industrie-4-0/Industrie-4-0/industrie-4-0-what-is-it.html#overviewAnker. Available on November 11, 2017.

Gubbi, J., Buyya, R., Marusic, S., & Palaniswami, M. (2013). Internet of Things (IoT): A vision, architectural elements, and future directions. Future Generation Computer Systems,29, 1645–1660.

Gudfinnsson, K., Strand, M., & Berntsson, M. (2015). Analyzing business intelligence maturity. Journal of Decision Systems,24(1), 37–54. https://doi.org/10.1080/12460125.2015.994287.

Guide, V. D. R., Jr., & Van Wassenhove, L. N. (2009). OR FORUM—The evolution of closedloop supply chain research. Operations Research,57(1), 10–18.

Gunasekaran, A., & Kobu, B. (2007). Performance measures and metrics in logistics and supply chain management: A review of recent literature (1995–2004) for research and applications. International Journal of Production Research,45(12), 2819–2840.

Guo, K., Liang, Z., Tang, Y., & Chi, T. (2016). SOR: An optimized semantic ontology retrieval algorithm for heterogeneous multimedia big data. International Journal of Information,4, 25–35.

Guoa, Z., Zhanga, Z., & Li, W. (2012). Establishment of intelligent identification management platform in railway logistics system by means of the internet of things. Procedia Engineering,29, 726–730.

Gupta, M., & George, J. (2016). Toward the development of a big data analytics capability. Information Management,53(8), 1049–1064.

Gursoy, M. C., Qiao, D., & Velipasalar, S. (2008). Analysis of energy efficiency in fading channels under QoS constraints. IEEE Transactions on Wireless Communications,8, 1276–1536.

Haddara, M., & Elragal, A. (2015). The readiness of ERP systems for the factory of the future. Procedia Computer Science,64, 721–728.

Haquea, S., & Aziz, S. (2013). False alarm detection in cyber-physical systems for healthcare applications. Engineering Services,5, 54–61.

Hardy, K., & Maurushat, A. (2016). Opening up government data for Big Data analysis and public benefit. Journal of Business Research,33(1), 30–37.

Hartunga, R., Hakanssonb, A., & Moradianc, E. (2015). A prescription for cyber physical systems. Manufacturing System,5, 4–9.

Hashem, I., Chang, V., Anuar, N., Adewole, K., Yaquub, I., Gani, A., et al. (2016). The role of big data in smart city. International Journal of information,36(5), 748–758.

Hassanalieragh, M., Page, A., Soyata, T., Sharma, G., Aktas, M., Mateos, G., et al. (2015). Health monitoring and management using Internet-of-Things (IoT) sensing with cloud-based processing: Opportunities and challenges. In IEEE international conference on services computing (SCC) (pp. 285–292).

Hayyolalam, V., & Kazem, A. (2018). A systematic literature review on QoS-aware service composition and selection in cloud environment. Journal of Network and Computer Applications,110, 52–74.

Hazen, B., Boone, C., Farmer, L. A., & Ezell, J. (2014). Data quality for data science, predictive analytics, and big data in supply chain management: An introduction to the problem and suggestions for research and applications. Internal Journal of Production,154, 72–80.

Hazen, B. T., Skipper, J. B., Ezell, J. D., & Boone, C. A. (2016). Big Data and predictive analytics for supply chain sustainability: A theory-driven research agenda. Computers & Industrial Engineering,101, 592–598.

He, J., Chen, H., & Hu, F. (2015). ERP: An enhanced read policy for HDFS to improve read performance for files under construction. In 2015 IEEE international conference on progress in informatics and computing (PIC), 18–20 December 2015, Nanjing, China.

He, K., & Li, X. (2016). A quantitative estimation technique for welding quality using local mean decomposition and support vector machine. Journal of Intelligent Manufacturing,27, 525–533.

Hea, Y., Chena, L., & Wang, L. (2016). An improved direct anonymous attestation scheme for M2M networks. Computer Science,15, 1481–1486.

Hecklau, F., Galeitzkea, M., Flachsa, S., & Kohl, H. (2015). Holistic approach for human resource management in industry 4.0. In Conference on learning factories, 10–11 October 2009, Changsha, Hunan, China.

Heng, S., Slomka, L., Ag, D. B., & Hoffmann, R. (2014). Industry 4.0. Upgrading of Germany’s industrial capabilities on the horizon. Frankfurt am Main: Deutsche Bank Research. SSRN: https://ssrn.com/abstract=2656608.

Henriques, C. I., Sobreiro, V. A., & Kimura, H. (2018). Science and technology park: Future challenges. Technology in Society,53, 144–160.

Heragu, S., & Kusiak, A. (1987). Analysis of expert systems in manufacturing design. IEEE Transactions on Systems, Man, and Cybernetics,17(6), 898–912.

Hermann, M., Tobias, P., & Otto, B. (2016). Design principles for industry 4.0 scenarios. http://www.thiagobranquinho.com/wp-content/uploads/2016/11/Design-Principles-for-Industrie-4_0-Scenarios.pdf. Available on August 28, 2017.

Herron, J. (2016). Augmented reality in medical education and training. Journal of Electronic Resources in Medical Libraries,13(2), 51–55.

Herterich, M., Uebernickel, F., & Brenner, W. (2015). The impact of cyber-physical systems on industrial services in manufacturing. Procedia CIRP,30, 323–328.

Higashinoa, W., Capretz, M., & Bittencourt, L. (2017). CEPSim: Modelling and simulation of complex event processing systems in cloud environments. Future Generation Computer Systems,65, 122–139.

Hofmann, E., & Rüsch, M. (2017). Industry 4.0 and the current status as well as future prospects on logistics. Computers in Industry,89, 23–34.

Holm, A., Wang, L., & Brewster, R. (2016). Localizing operators in the smart factory: A review of existing techniques and systems. In 2016 International symposium on flexible automation, 1–3 August 2016, Cleveland, Ohio, USA.

Hong, E.-K., Baek, J., Jang, Y., Na, J., & Kim, K. (2017). QoS-guaranteed scheduling for small cell networks. ICT Express. https://doi.org/10.1016/j.icte.2017.11.017.

Hossain, M. S., & Muhammad, G. (2016). Cloud-assisted industrial internet of things (iiot)—Enabled framework for health monitoring. Computer Networks,101, 192–202.

Houda, K., & Lakel, R. (2015). Synchronized communication in a set of autonomous mobile robots using bluetooth technology. Procedia Computer Science,73, 154–161.

Hsiao, M. (2018). A conceptual framework for technology-enabled and technology dependent user behavior toward device mesh and mesh app. Future Business Journal,4, 130–138.

Hu, T., Xiao, M., Hu, C., Gao, G., & Wang, B. (2017). A QoS-sensitive task assignment algorithm for mobile crowdsensing. Pervasive and Mobile Computing,41, 333–342.

Huang, C., Liang, W., & Yi, S. (2017). Cloud-based design for disassembly to create environmentally friendly products. Journal of Intelligent Manufacturing,28, 1203–1218.

Hubert, C., & Chan, Y. (2015). Internet of things business models. Journal of Service Science and Management,50, 1020–1030.

Huckle, S., Bhattacharya, R., White, M., & Beloff, N. (2016). Internet of things blockchain, shared economy applications. Procedia Computer Science,98(2016), 461–466.

Hufnagel, J., & Vogel-Heuser, B. (2015). Data integration in manufacturing industry model-based integration of data distributed from ERP to PLC. In 13th International conference on industrial informatics (INDIN), 22–24 July 2015, Cambridge, UK.

Hwang, G., Lee, J., Park, J., & Chang, T. (2016). Developing performance measurement system for Internet of Things and smart factory environment. International Journal of Production Research,55(9), 2590–2602.

I4MTS. (2016). http://www.the-mtc.org/pdf/Industry-4-Report-2016-e.pdf. Available on August 30, 2017.

Iavazzo, C., & Gkegkes, I. (2017). Cost–benefit analysis of robotic surgery in gynaecological oncology. Best Practice & Research Clinical Obstetrics and Gynaecology,45, 7–18.

ICV. (2016). International controller association report. http://integratedreporting.org/wp-content/uploads/2013/08/137_International-Controller-Association-Discussion-Paper.pdf. Available on August 28, 2017.

Iera, A., Floerkemeier, C., Mitsugi, J., & Morabito, G. (2010). The internet of things. IEEE Wireless Communications,17, 8–9.

Ignaccolo, M. (2003). A simulation model for airport capacity and delay analysis. Transportation Planning and Technology,26(2), 135–170.

IIC. (2016). http://www.process-worldwide.com/usa-industry-40-the-american-way-a-536602/. Available on August 30, 2017.

Ince, H., Imamoglu, S. Z., Keskin, H., Akgun, A., & Efe, M. A. (2013). The impact of ERP systems and supply chain management practices on firm performance: Case of Turkish companies. International Strategic Management Conference,99, 1124–1133.

Inderfurth, K., de Kok, A. G., & Flapper, S. D. P. (2001). Product recovery in stochastic remanufacturing systems with multiple reuse options. European Journal of Operational Research,133, 130–152.

INESA. (2016). http://journal.jp.fujitsu.com/en/2016/10/31/01/. Available on August 30, 2017.

InGlobe. (2017). http://www.inglobetechnologies.com/smart-manufacturing-ar-industry-4-0. Available on August 30, 2017.

Intel IOT Report. (2016). Developing solutions for the internet of things. http://www.intel.com/content/dam/www/public/us/en/documents/white-papers/developing-solutions-for-iot.pdf. Available on August 28, 2017.

Iqbal, A., Zhang, H., Kong, L., & Hussain, G. (2015). A rule-based system for trade-off among energy consumption, tool life, and productivity in machining process. Journal of Intelligent Manufacturing,26, 1217–1232.

Issa, H., Regenbrecht, H., & Hale, R. (2012). Augmented reality applications in rehabilitation to improve physical outcomes. Physical Therapy Reviews,17(1), 16–28.

Ivanov, D., Dolgui, A., Sokolov, B., & Ivanova, M. (2015). A dynamic model and an algorithm for short term supply chain scheduling in the smart factory industry 4.0. International Journal of Production Research,54(2), 386–402.

Jäckel, M., Falk, T., & Landgrebe, D. (2016). Concept for further development of self-pierce riveting by using cyber physical systems. Procedia CIRP,44, 293–297.

Jaehne, J., & KalalChelvan, S. (2017). Towards a connected world of supply chain—Industry 4.0 presentation. https://www.slideshare.net/sarathygurushankar1/shaping-towards-a-connected-world-of-supply-chain-industrie-40. Available on August 22, 2017.

Jannsenn, M., Voort, H., & Wahyudi, A. (2017). Factors influencing big data decision making quality. Journal of Business Research,70, 338–345.

Jararweha, Y., Al-Ayyoub, M., Darabseh, A., Benkhelifa, E., Vouk, M., & Rindos, A. (2017). Software defined cloud: Survey, system and evaluation. Future Generation Computer Systems,58, 56–74.

Jatzkowskia, J., & Kleinjohanna, B. (2016). Towards self-reconfiguration of real-time communication within cyber-physical systems. Manufacturing Systems,15, 54–61.

Jayanthi, S., Roth, V., Kristal, M., & Venu, L. (2009). Strategic resource dynamics of manufacturing firms. Management Science,55(6), 1060–1076.

Jeang, A. (2015a). Robust product design and process planning in using process capability analysis. Intelligent Manufacturing Systems,26(3), 459–470.

Jeang, A. (2015b). Robust product design and process planning in using process capability analysis. Journal of Intelligent Manufacturing,26, 459–470.

Jeng, T., Tzeng, S., Tseng, C., & Liu, Y. (2016). The design and fabrication of a temperature diagnosis system for the intelligent rotating spindle of industry 4.0. Smart Science,4, 38–43.

Jernigan, D., Fernandez, S., Pensyl, R., & Shangping, L. (2009). Digitally augmented reality characters in live theatre performances. International Journal of Performance Arts and Digital Media,5(1), 35–49.

Jeschke, S., Brecher, C., Meisen, T., Özdemir, D., & Eschert, T. (2017). Industrial internet of things and cyber manufacturing systems. In Industrial internet of things, international publishing (pp. 3–19).

Ji, Z., Ganchev, I., O’Droma, M., Zhao, L., & Zhang, X. (2014). A cloud-based car parking middleware for IoT-based smart cities: Design and implementation. Sensors,14, 22372–22393.

Jianjuna, S., Xub, W., Jizhenc, G., & Yangzhou, C. (2016). The analysis of traffic control cyber-physical systems. Social and Behavioral Science,96, 2487–2496.

Jiao, B., Zhou, Y., Du, J., Huang, C., Wang, J., & Li, B. (2015). A heuristic nonlinear operator for the aggregation of incomplete judgment matrices in group decision making. Journal of Intelligent Manufacturing,26, 1253–1266.

Jing, Q., Vasilakos, A. V., Wan, J., Lu, J., & Qiu, D. (2014). Security of the internet of things: Perspectives and challenges. Wireless Networks,20, 2481–2501.

Johansson, B., Alajbegovic, A., & Alexopoulos, V. (2015). Cloud ERP adoption opportunities and concerns: The role of organizational size, system sciences (HICSS). In 2015 48th Hawaii international conference on system sciences (pp 1530–1605), 5–8 January 2015, Kauai, HI, USA.

Jones, A., Vidalis, S., & Abouzakhar, N. (2016). Information security and digital forensics in the world of cyber physical systems. In 2016 Eleventh international conference on digital information management (ICDIM), 19–21 September, Porto, Portugal.

Jourdan, Z., Rainer, K., & Marshall, T. (2008). Business intelligence: An analysis of the literature. Information Systems Management,25(2), 121–131.

Junghanns, P., Fabian, B., & Ermakova, T. (2016). Engineering of secure multi-cloud storage. Computers in Industry,83, 108–120.

Kagermann, H. (2014). Chancen von Industry 4.0 nutzen. In Bauernhansl, T., M. ten Hompel and B. Vogel-Heuser, Vol. 4, pp. 603–614 (in German).

Kagermann, H., Lukas, W., & Wahlster, W. (2011). Industry 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. Industryllen Revolution. VDI nachrichten, Vol. 13, pp. 1090–1100.

Kagermann, H., Wahlster, W., & Helbig, J. (2013). Recommendations for implementing the strategic initiative Industry 4.0. Final report of the industry 4.0 working group, http://www.acatech.de/fileadmin/user_upload/Baumstruktur_nach_Website/Acatech/root/de/Material_fuer_Sonderseiten/Industrie_4.0/Final_report__Industrie_4.0_accessible.pdf. Available on August 22, 2017.

Kaidanren. (2016). Toward realization of the new economy and society. Japan Business Federation (p. 8). http://www.keidanren.or.jp/en/policy/2016/029_outline.pdf. Available on August 22, 2017.

Karakus, M., & Durresi, A. (2017). Quality of service (QoS) in software defined networking (SDN): A survey. Journal of Network and Computer Applications,80, 200–218.

Kba, S. (2015). Cloud based health system. Computer Science,18, 989–1000.

Ke, Y., Wang, P., Chen, Y., Gu, B., Qi, H., Zhou, P., et al. (2015). Concurrent mental activities affect ERPs and impair performance of ERP-spellers. In 2015 7th International IEEE/EMBS conference on neural engineering (NER), 22–24 April 2015, Montpellier, France.

Kermorgant, O. (2018). A magnetic climbing robot to perform autonomous welding in the shipbuilding industry. Robotics and Computer Integrated Manufacturing,53, 178–186.

Khan, R., Khan, S. U., Zaheer, R., Khan, S. (2012). Future internet: The internet of things architecture, possible applications and key challenges. In 10th International conference on frontiers of information technology (FIT) (pp. 257–260).

Kiel, D., Arnold, C., & Voigt, K. I. (2017). The influence of the Industrial Internet of Things on business models of established manufacturing companies—A business level perspective. Technovation,68, 4–19.

Kim, H., Lee, S., Park, H., & Lee, G. (2005). A model for a simulation-based shipbuilding system in a shipyard manufacturing process. International Journal of Computer Integrated Manufacturing,18(6), 427–441.

Kim, J., Kim, H., Lakshmanan, K., & Rajkumar, R. R. (2013). Parallel scheduling for cyber-physical systems: Analysis and case study on a self-driving car. In Proceedings of the ACM/IEEE 4th international conference on cyber-physical systems (pp. 31–40).

Kim, J., Lee, S., Seo, J., & Kamat, V. (2018). Modular data communication methods for a robotic excavator. Automation in Construction,90, 166–177.

Kim, W., & Jo, O. (2015). Cost-optimized configuration of computing instances for large sized cloud systems. Computer Science,5, 20–30.

Kim, Y., & Suzuki, K. (2015). Social context representation in product-service systems with internet of things. Open Journal of Social Sciences,3, 187–193.

Kirthica, S., & Sridhar, R. (2016). CIT: A cloud inter-operation toolkit to enhance elasticity and tolerate shut down of external clouds. Journal of Network and Computer Applications,85, 32–46.

Klaus, H. (2016). Siemens industry 4.0 report for german industry and applications. On the way industry 4.0. https://www.siemens.com/press/pool/de/events/2015/digitalfactory/2015-04-hannovermesse/presentation-e.pdf. Available on August 22, 2017.

Klimeš, J. (2014). Using formal concept analysis for control in cyber-physical systems. Engineering Services,69, 1518–1522.

Kokuryo, D., Kaihara, T., Suginouchi, S., & Kuik, S. (2016). A study on value co-creative design and manufacturing system for tailor-made rubber shoes production. In 2016 International symposium on flexible automation, 1–3 August 2016, Ohio, USA.

Kolberg, D., Berger, C., Pirvu, B., Franke, M., & Michniewicz, J. (2016). Insights from a framework for designing cyber-physical systems in production environments. Procedia CIRP,57, 32–37.

Koo, D., Piratla, K., & Matthews, J. (2015). Towards sustainable water supply: Schematic development of big data collection using internet of things. Procedia Computer Engineering,4, 45–55.

Koseleva, N., & Ropaite, G. (2017). Big data in building energy efficiency: Understanding of big data and main challenges. Procedia Engineering,172(2017), 544–549.

Kothandaraman, D., & Chellappan, C. (2016). Direction detecting system of indoor Smartphone users using BLE in IoT. Circuits and Systems,7, 1492–1503.

Kowalska, M., Pazdzior, M., & Maziopa, A. (2018). Erratum to: Implementation of QFD method in quality analysis of confectionery products. Journal of Intelligent Manufacturing,29, 449–450.

Kozhirbayev, Z., & Sinnott, R. (2017). A performance comparison of container-based technologies for the cloud. Future Generation Computer Systems,68, 175–182.

Krawatzeck, R., & Dinter, B. (2015). Agile business intelligence: Collection and classification of agile business intelligence actions by means of a catalog and a selection guide. Information Systems Management,32(3), 177–191.

Kumar, J., & Zaveri, M. (2016). Hierarchical clustering for dynamic and heterogeneous internet of things. Computer Science,93, 276–282.

Kurth, M., & Syleyer, C. (2016). Smart factory and education. In 2016 IEEE 11th conference on industrial electronics and applications (ICIEA) (pp. 110–119), 5–7 June 2016, Hefei, China.

Kusiak, A. (2009). Short-term prediction of wind farm power: A data mining approach. Wind Energy Journal,12(3), 275–293.

Kusiak, A. (2012). A data-mining approach to monitoring wind turbines. Transactions on Sustainable Energy,3(1), 150–165.

Kusiak, A. (2013). Innovation: The living laboratory perspective. Computer-Aided Design and Applications,4(6), 196–206.

Kusiak, A. (2017a). Smart manufacturing. International Journal of Production Research. https://doi.org/10.1080/00207543.2017.1351644.

Kusiak, A. (2017b). Smart manufacturing must embrace big data. Nature,544(7648), 23–25.

Kusiak, A., Zheng, H., & Song, Z. (2010). Power optimization of wind turbines with data mining and evolutionary computation. Renewable Energy,35(3), 695–702.

Kyriazisa, D., & Varvarigoua, T. (2013). Smart, autonomous and reliable Internet of Things. Computer Science,21(2013), 442–448.

Lakhmi, C. J., & Nguyen, N. T. (2009). Knowledge processing and decision making in agent-based systems. Berlin: Springer. ISBN 978-3-540-88048-6.

Lakshimi, R., Babu, S., & Bhalaji, N. (2017). Analysis of clustered QoS routing protocol for distributed wireless sensor network. Computers & Electrical Engineering,64, 173–181.

Lasi, H., Fettke, P., Kemper, G., Feld, T., & Hoffmann, M. (2014). Industry 4.0: Bedarfssog und Technologiedruck als Treiber der vierten Industrillen Revolution. The İnternational Journal of Wirtschaftsinformatik,56, 261–264. (in German).

Layuan, L., & Chunlin, L. (2002). A multicast routing protocol supporting multiple QoS constraints. In 10th IEEE international conference on networks (Vol. 2). https://doi.org/10.1109/icon.2002.1033285.

Lee, A. (2008). Cyber physical systems: Design challenges. In 11th IEEE symposium on object oriented real-time distributed computing (ISORC), 5–7 May 2008, Orlando, FL, USA.

Lee, D. (2014). Robots in the shipbuilding industry. Robotics and Computer-Integrated Manufacturing,30, 442–450.

Lee, H., Leu, J., & Huang, Y. (2015c). Implementation of enterprise resource planning using the value engineering and system dynamics methods. In 2015 2nd International conference on information science and control engineering (ICISCE), 24–26 April 2015, Shanghai, China.

Lee, J., & Shin, K. (2017). Development and use of a new task model for cyber-physical systems: A real-time scheduling perspective. Journal of System,126, 45–56.

Lee, J., Ardakani, H., Yang, S., & Bagheri, B. (2015a). Industrial big data analytics and cyber-physical systems for future maintenance & service innovation. Procedia CIRP,38, 3–7.

Lee, J., Bagheri, B., & Kao, H. (2015b). A cyber systems architecture for industry 4.0 based manufacturing systems. Manufacturing Letters,3, 18–23.

Lee, J., Kao, H. A., & Yang, S. (2014). Service innovation and smart analytics for industry 4.0 and big data environment. Procedia Cirp,16, 3–8.

Lee, J., & Lapira, E. (2014). Industry 4.0 environment. Asset Condition Management,15, 54–61.

Lee, J., Lapira, E., Bagheri, B., & Kao, H. A. (2013). Recent advances and trends in predictive manufacturing systems in big data environment. Manufacturing Letters,1(1), 38–41.

Lee, H., Yoo, S., & Kim, Y. (2016). An energy management framework for smart factory on context awareness. In 18th International conference on advanced communication technology (ICACT), 31 January–3 February 2016, Pyeongchang, South Korea.

Lei, C., Wan, K., & Man, K. (2013). Developing a smart learning environment in universities via cyber-physical systems. Information Technology and Quantitative Management,17, 583–585.

Leloglu, E. (2017). A review of security concerns in internet of things. Journal of Computer and Communications,5, 121–136.

Leppelt, T., Foerstl, K., Reuter, C., & Hartmann, E. (2013). Sustainability management beyond organizational boundaries–sustainable supplier relationship management in the chemical industry. Journal of Cleaner Production,56, 94–102.

Li, B., Song, A. M., & Song, J. (2012). A distributed QoS-constraint task scheduling scheme in cloud computing environment: Model and algorithm. Advances in information Sciences and Service Sciences (AISS),4, 283–291.

Li, G., Zhang, D., Zheng, K., Ming, X., Pan, H., & Jiang, K. (2013). A kind of new multicast routing algorithm for application of internet of things. Journal of Applied Research and Technology,11(4), 578–585.

Li, J., Xie, T., & Du, S. (2011). Requirements analysis on flexibility of ERP system of medium and small publishers. Procedia Engineering,15, 5493–5497.

Li, Z., Shen, H., Li, H., Xia, G., Gamba, P., & Zhang, L. (2017). Multi-feature combined cloud and cloud shadow detection in GaoFen-1 wide field of view imagery. Remote Sensing of Environment,191, 342–358.

Lia, B., & Yub, B. (2011). Research and application on the smart home based on component technologies and Internet of Things. Procedia Engineering,15, 2087–2092.

Liang, H., & Du, Y. (2017). Dynamic service selection with QoS constraints and inter-service correlations using cooperative coevolution. Future Generation Computer Systems,76, 119–135.

Lian-yue, W. (2012). Think of construction lean SCM based on IOT. In IEEE Symposium on Robotics and Applications (ISRA) (pp. 436–438).

Liao, T. (2015). Augmented or admented reality? The influence of marketing on augmented reality technologies. Information, Communication and Society,18(3), 310–326.

Liao, Y., Deschamps, F., Loures, E., & Ramos, L. (2017). Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. International Journal of Production Research,55(12), 3609–3629.

Lichtblau, K., Stıch, V., Bertenrath, R., Blum, R., Bleider, M., Millack, A., et al. (2016). IMPULS, Industry 4.0 readiness, VDMA. http://industrie40.vdma.org/documents/4214230/5356229/Industrie%204.0%20Readiness%20Study%20English.pdf/f6de92c1-74ed-4790-b6a4-74b30b1e83f0. Available on August 28, 2017.

Lilis, G., Conus, G., Asadi, N., & Kayal, M. (2017). Towards the next generation of intelligent building: An assessment study of current automation and future IoT based systems with a proposal for transitional design. Sustainable Cities and Society,28, 473–481.

Lim, M. K., Tseng, M. L., Tan, K. H., & Bui, T. D. (2017). Knowledge management in sustainable supply chain management: Improving performance through an interpretive structural modelling approach. Journal of Cleaner Production,162, 806–816.

Lin, T., Chen, M., Yang, D., & Chen, Y. (2016). New method for industry 4.0 machine status prediction—A case study with the machine of a spring factory. In 2016 International computer symposium, 15–17 December 2016, Chiayi, Taiwan.

Lin, Y. C., Hung, M. H., Huang, H. C., Chen, C. C., Yang, H. C., Hsieh, Y. S., et al. (2017a). Development of advanced manufacturing cloud of things (AMCoT)—A smart manufacturing platform. IEEE Robotics and Automation Letters,2, 1809–1816.

Lin, D., Lee, C., Lau, H., & Yang, Y. (2017c). Strategic response to Industry 4.0: An empirical investigation on the Chinese automotive industry. Industrial Management & Data Systems, 118(3), 589–605.

Lin, B., Lin, F., & Tung, L. (2016b). The roles of 5G mobile broadband in the development of IoT, big data, cloud and SDN. Communications and Network,8, 9–21.

Lin, C., Wnag, K., & Deng, G. (2017b). A QoS-aware routing in SDN hybrid networks. Procedia Computer Science,110, 242–249.

Linton, J. D., Klassen, R., & Jayaraman, V. (2007). Sustainable supply chains: An introduction. Journal of operations management,25, 1075–1082.

Liu, D., & Hu, X. (2006). Firm real-time system scheduling based on a novel QoS constraint. IEEE Transactıons on Computers,55, 1–14.

Liu, J., & Tonga, W. (2012). Device service networks maintenance based on components migration in the internet of things. Procedia Engineering,29, 3418–3423.

Liu, M., Ma, J., Lin, L., Ge, M., Wang, Q., & Liu, C. (2017b). Intelligent assembly system for mechanical products and key technology based on internet of things. Journal of Intelligent Manufacturing,28(2), 271–299.

Liu, X., Guo, X., Chen, L., Zhou, Y., & Xin, C. (2014). The use of three-dimensional integrated design system in smart substation design. Journal of Power and Energy Engineering,2, 632–638.

Liu, Z., Choo, K. K. R., & Zhao, M. (2017a). Practical-oriented protocols for privacy-preserving outsourced big data analysis: Challenges and future research directions. Computers and Security,69, 97–113.

Lokers, R., Knapen, K., Sander, J., Randen, Y., & Jansen, J. (2016). Analysis of big data technologies for use in agro-environmental science. Modelling Software,4, 1090–1105.

Lom, M., Pribyl, O., & Svitek, M. (2016). Industry 4.0 as a part of smart cities. Smart Cities Symposium, 26–27 May 2016, Prague, Czech Republic.

Longo, F., Nicoletti, L., & Padovano, A. (2017). Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Computers & Industrial Engineering,113, 144–159.

Lorenc, A., & Szkoda, M. (2015). Customer logistic service in the automotive industry with the use of the SAP ERP system. In 2015 4th International conference on advanced logistics and transport (ICALT), 20–22 May 2015, Valenciennes, France.

Loseto, G., Ieva, S., Gramegna, F., Ruta, M., Scioscia, F., & Sciascio, E. (2016). Linking the web of things: LDP-CoAP mapping. Computer Science,83, 1182–1187.

Lucke, A. (2008). Manufacturing systems and technologies for the new frontier. In The 41st CIRP conference on manufacturing systems, Tokyo, Japan (Vol 2, pp. 115–118).

Maansman, J., Böcker, S., Rettberg, F., Wietfeld, C., & Rehtanz, C. (2014). Renewable energies in smart factories with electric vehicle fleets. In 49th International universities power engineering conference (UPEC), Cluj-Napoca, Romania.

Macabee, S., Landis, R., & Burke, M. (2017). Inductive reasoning: The promise of big data. Human Resource Management,27(2), 277–290.

Machowiak, W. (2012). Risk management—Unappreciated instrument of supply chain strategy. LogForum,8, 277–285.

Madani, S. R., & Rasti-Barzoki, M. (2017). Sustainable supply chain management with pricing, greening and governmental tariffs determining strategies: A game-theoretic approach. Computers & Industrial Engineering,105, 287–298.

Magdić, J., & Car, Z. (2013). A company model supporting ERP and CRM software development and implementation processes. In 12th International conference on telecommunications (ConTEL), 26–28 June 2013, Zagreb, Croatia.

Majeed, A. A., & Rupasinghe, T. D. (2017). Internet of things (IoT) embedded future supply chains for industry 4.0: An assessment from an ERP-based fashion apparel and footwear industry. International Journal of Supply Chain Management,6, 25–40.

Marron, J. S. (2014). Big data in context and robustness against heterogeneity. Computer Science,2, 73–80.

Martin, P., & Dantan, J. (2011). Virtual manufacturing: Prediction of work piece. International Journal of Computer Integrated Manufacturing,24, 620–626.

Martinez, G., & Munizaga, M. (2016). Workshop 5 report: Harnessing big data. Research in Transportation economics,59, 236–241.

Matena, V., Bures, T., Gerostathopoulos, I., & Hnetynka, P. (2016). Model problem and testbed for experiments with adaptation in smart cyber-physical systems. In Software engineering for IEEE/ACM, 11th international symposium on adaptive and self-managing systems (SEAMS), 16–17 May 2016, Austin, TX, USA.

Matutinovic, I., Salthe, S., & Ulanowicz, R. (2016). The mature stage of capitalist development: Models, signs, policy, implications. Structural Change and Economic Dynamics,39, 17–30.

Mawlawi, B., Dore, J., Lebedev, N., & Gorce, J. (2014). Performance evaluation of multiband CSMA/CA with RTS/CTS or M2M. In International conference on selected topics in mobile and wireless networking, Rome, Italy (Vol. 40, pp. 108–115).

Mayer, S., Verborgh, R., Kovatsch, M., & Mattern, F. (2016). Smart configuration on smart environments. IEEE Transactions on Automation Science and Engineering,13(3), 1247–1255.

McCullough, A., Gempesaw, C., Daniels, W., & Bacon, R. (2008). Simulating the economic viability of crawfish production: A two stage modeling approach. Aquaculture Economics and Management,5(2), 69–79.

Mckinsey. (2016). Industry 4.0: How to navigate digitization of the manufacturing sector. https://www.mckinsey.de/files/mck_industry_40_report.pdf. Available on August 22, 2017.

McKinsey. (2017). China develops from ‘sponge’ into innovation leader. https://www.your-bizbook.com/en/Club-China-News/mckinsey-china-develops-from-sponge-into-innovation-leader. Available on November 19, 2017.

Meddeb, M., Alaya, S., Monteil, T., Dhraief, A., & Drira, K. (2014). M2M platform with autonomic device management service. Computer Science,32, 1063–1070.

MESA. (2009). Smart manufacturing in industry 4.0 systems, mesa international report for industry 4.0 systems. http://www.mesa.org/en/resources/MESAWhitePaper52-SmartManufacturing-LandscapeExplainedShortVersion.pdf. Available on August 22, 2017.

MetamoFAB. (2017). https://www.festo.com/group/en/cms/10275.htm. Available on August 30, 2017.

Meziane, F., Vadera, S., Kobbacy, K., & Proudlove, N. (2014). Intelligent systems in manufacturing: Current developments and future prospects. Integrated Manufacturing Systems,11(4), 218–238.

Michniewicza, J., & Reinharta, G. (2016). Cyber-physical robotics—Automated analysis, programming and configuration of robot cells based on cyber-physical-systems. Engineering Services,15, 566–575.

Michona, E., Gossa, J., Genaud, S., Unbekandt, L., & Kherbache, V. (2017). Schlouder: A broker for IaaS clouds. Future Generation Computer Systems,69, 11–23.

Mikusz, M. (2014). Towards an understanding of cyber-physical systems as industrial software-product-service systems. Procedia CIRP,16, 385–389.

Miloslavskaya, N., & Tolstoy, A. (2017). Big data, fast data and data lake concepts. Procedia Engineering,88(2016), 300–305.

Ming, B., Shuo, T., Mingsan, M., Jiaojiao, J., & Weiyun, X. (2015). Big data applications in traditional Chinese medicine research. International Journal of Services, Technology and Management,21(4), 294–300.

Mirsanei, H. S., Zandieh, M., Moayed, M. J., & Khabbazi, M. R. (2011). A simulated annealing algorithm approach to hybrid flow shop scheduling with sequence-dependent setup times. Journal of Intelligent Manufacturing,22, 965–978.

Miškuf, M., & Zolotová, I. (2016). Comparison between multi-class classifiers and deep learning with focus on industry 4.0. Cybernetics & Informatics (pp. 1–5), 2–5 February 2016.

Mohammed, A., & Wang, L. (2018). Brainwaves driven human–robot collaborative assembly. CIRP Annals Manufacturing Technology,1781, 1–4.

Mokhtar, B., & Eltoweissy, M. (2017). Big data and semantics management system. Ad Hoc Networks,57, 32–51.

Monostori, L. (2014). Cyber-physical production systems: Roots, expectations and R&D challenges. Procedia CIRP,17, 9–13.

Monteiroa, V., Ferreirab, J., & Afonso, J. (2014). Smart platform towards batteries analysis based on internet-of-things. Procedia Computer Egineering,17(2014), 520–527.

Moon, S., Kang, S., Jeon, J., & Chun, I. (2016). Simulation modeling of sewing process, for evaluation, of production schedule in smart factory. In 2016 International conference on industrial engineering, management science and application (ICIMSA), 23–26 May 2016, Jeju, South Korea.

Moregård, A., Haubenwallera, A., & Vandikasb, K. (2015). Computations on the edge in the internet of things. Computer Science,52, 29–34.

Mourtzis, D., Zogopoulos, V., & Vlachou, E. (2017). Augmented reality application to support remote maintenance as a service in the robotics industry. Procedia CIRP,63, 46–51.

Mucci, H., Sharaf, M., & Weyns, D. (2016). Self-adaptation for cyber-physical systems: A systematic literature review. In 2016 IEEE/ACM 11th international symposium on software engineering for adaptive and self-managing systems (SEAMS), 16–17 May 2016, Austin, TX, USA.

Müller, R. (2016). Planning and developing cyber-physical assembly systems by connecting virtual and real worlds. Procedia CIRP,52, 35–40.

Munera, E., Luis, L., Lujan, P., Luis, J., Yagüe, P., Simo, J., et al. (2015). Control kernel in smart factory, environments, smart resources integration. In The 5th annual IEEE international conference on cyber technology in automation, 8–12 June 2015, Shenyang, China.

Murray, T. (1999). Authoring intelligent tutoring systems: An analysis of the state of the art. International Journal of Artificial Intelligence in Education,10, 98–129.

Nawrocki, P., & Reszelewski, W. (2017). Resource usage optimization in mobile cloud computing. Journal Computer Communications,99(C), 1–12.

Nazarko, L. (2017). Future-oriented technology assessment. Procedia Engineering,182, 504–509.

Negash, B., Rahmani, A., Westelund, T., Liljeberg, P., & Tenhunen, H. (2015). LISA: Lightweight internet of things service bus architecture. Computer Science,52(2015), 436–443.

Neisse, R., Steri, G., & Favino, I. (2014). A model based security toolkit for the IOT. In 9th International conference on availability, reliability and security (ARES), 8–12 September 2014, Fribourg, Switzerland (pp.78–87).

Netland, T. (2016). Augmented reality: Ready for manufacturing industries. Better Operations, The Routledge Companion to Lean Management. http://better-operations.com/2016/10/07/augmented-reality-manufacturing/. Available on August 28, 2017.

Nguyen, P., Shaukat, A., & Tao, Y. (2017). Model-based security engineering for cyber-physical systems: A systematic mapping study. Information Software,83, 116–135.

Ning, H., & Liu, H. (2012). Cyber-physical-social based security architecture for future internet of things. Advances in Internet of Things,2, 1–7.

Nishioka, Y. (2016). https://iv-i.org/en/docs/doc_160428_hannover.pdf. Available on August 30, 2017.

Nofal, M., & Yusof, Z. (2013). Integration of business intelligence and enterprice resource planning within organizations. Procedia Technology,11, 658–665.

Nordahla, M., & Magnussona, B. (2015). A lightweight data interchange format for Internet of Things in the PalCom middleware framework. Computer Science,56(2015), 284–291.

NTIO. (2017). Smart Cities Taiwan: Opportunities for Dutch companies. https://www.rvo.nl/sites/default/files/2017/05/taiwan-ambition-and-development-of-smart-citiesv2.pdf.

Nuñez, D., Fernández, G., & Luna, J. (2017). Cloud system. Procedia Computer Engineering,62, 149–164.

Oesterreich, D. T., & Teuteberg, F. (2016). Understanding the implications of digitalization and automation in the context of Industry 4.0. Computers in Industry,83, 121–139.

Ojha, T., Misra, S., & Raghuwanshi, N. (2017). Sensing-cloud: Leveraging the benefits for agricultural applications. Computers and Electronics in Agriculture,135, 96–107.

Olszak, C. (2016). Toward better understanding and use of business intelligence in organizations. Information Systems Management,32(2), 105–123.

Ong, S. K., Yuan, M. L., & Nee, A. Y. C. (2008). Augmented reality applications in manufacturing: A survey. International Journal of Production Research,46, 2707–2742.

Onime, C., & Abiona, O. (2016). 3D mobile augmented reality interface for laboratory experiments. International Journal of Communications, Network and System Sciences,9, 67–76.

OPAK. (2017). A industry 4.0 project “open engineering platform for autonomous mechatronic automation components in a function-oriented architecture”. https://www.automation.com/automation-news/industry/festo-to-demonstrate-opak-industry-40-research. Available on August 28, 2017.

Orasız, S., & Yörök, G. (2012). Key performance indicators used in ERP performance measurement applications. In IEEE 10th jubilee international symposium on intelligent systems and informatics (SISY) (pp.43–48), 20–22 September 2012, Subotica, Serbia.

Ospennikova, A., Ershov, M., & Iljin, I. (2015). Educational robotics as an inovative educational technology. Social and Behavioral Sciences,214, 18–26.

Ou, C. S., Liu, F. C., Hung, Y. C., & Yen, D. C. (2010). A structural model of supply chain management on firm performance. International Journal of Operations & Production Management,30, 526–545.

Oztemel, E. (2010). Intelligent manufacturing systems. In L. Benyoucef & B. Grabot (Eds.), Artificial intelligence techniques for networked manufacturing enterprises management, chapter 1. Berlin: Springer. ISBN 978-1-84996-118-9.

Oztemel, E. (2015). Special issue on “Current progress of intelligent technologies, for manufacturing society”. Journal of Intelligent Manufacturing,26, 959–960.

Oztemel, E., & Tekez, K. (2009a). A general framework of a reference model for intelligent integrated manufacturing systems (REMIMS). Engineering Applications of Artificial Intelligence,22(6), 855–864.

Oztemel, E., & Tekez, E. (2009b). Integrating manufacturing systems through knowledge exchange protocols within an agent based knowledge network. Robotics and Computer-Integrated Manufacturing,25(1), 235–245.