Abstract

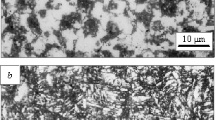

To minimize the distortion of bearing steel components during manufacturing processes, 100Cr6 steel (SAE 52100) has been produced by spray forming as an alternative approach to conventional continuous casting process. Material characteristics and distortion behaviour of the spray formed 100Cr6 steel were investigated in comparison with continuous cast material. The investigation showed that the spray formed 100Cr6 steel exhibited lower distortion potential than the conventional material due to much better metallurgical homogeneity.

Similar content being viewed by others

References

C. CUI, U. FRITSCHING, A. SCHULZ, K. BAUCKHAGE and P. MAYR, J. Mater. Sci. 39 (2004) 5639.

S. GUNNARSON, Härterei-Tech. Mitt. 46 (1991) 216.

E. BRINKSMEIER, A. WALTER, L. SÖLTER and L. NOWAG, ibid. 58 (2003) 266.

SFB570 “Distortion Engineering” Arbeits- und Ergebnisbericht 2001-2003, Research Reports to DFG (German Research Foundation), 2003, University of Bremen.

S. SEGERBERG and J. BODIN, in Proceedings of the Second International Conference on Quenching and the Control of Distortion, Cleveland, Nov. 1996, edited by G. E. Totten, M. A. H. Howes, S. J. Sjöstrom and K. Funatani (ASM International, Materials Park, OH, 1996) p. 69.

H. E. BOYER and P. R. CARY, in “Quenching and Control of Distortion” (ASM International, Materials Park, OH, 1998) p. 11.

J. G. ZHANG, D. S. SUN, H. S. SHI, H. B. XU, J. S. WU and X. F. WU, Mater. Sci. Eng. A 326 (2002) 20.

R. TINCHER, H. BOMAS and P. MAYR, ibid. 326 (2002) 11.

S. SPANIEL, “Einfluß der Prozeßparameter auf das Gefüge sprühkompaktierter Rund-und Flachprodukte aus C15, C105 und 100Cr6,” Ph. D. Thesis, University of Bremen, 2002, p. 72.

A. SCHULZ, V. UHLENWINKEL, C. BERTRAND, R. KOHLMANN, A. KULMBURG, A. OLDEWURTEL, R. SCHNEIDER and D. VIALE, Mater. Sci. Eng. A. 383 (2004) 58.

H. W. ZOCH, TH. LÜBBEN, F. HOFFMANN and P. MAYR, Härterei-Tech. Mitt. 49 (1994) 245.

B. GONDESEN, U. HECK, TH. LÜBBEN, U. FRITSCHING, F. HOFFMANN, K. BAUCKHAGE and P. MAYR, ibid. 53 (1998) 194.

R. KUSMIERZ, E. RENTSCH and E. BRINKSMEIER, ibid. 58 (2003) 276.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, C., Schulz, A., Fritsching, U. et al. Spray formed bearing steel insensitive to distortion. J Mater Sci 40, 1673–1680 (2005). https://doi.org/10.1007/s10853-005-0668-x

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-0668-x