Abstract

The microstructure with suitable boundary characters for superplasticity is summarized for the steels which consist of two phases, i.e., ferrite (bcc α) + austenite (fcc γ) or ferrite (α) + cementite (orthorhombic θ -Fe3C).

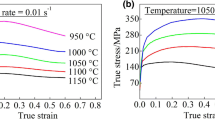

In (α + γ) duplex alloys, a conventional thermomechanical processing (solution treatment + heavy cold rolling + aging) produces the (α + γ) duplex structure through the competition of recovery/recrystallization of matrix and precipitation. In Fe-Cr-Ni (α + γ) duplex stainless steels with high γ fractions (40–50%), α matrix undergoes recovery to form α subgrain boundaries and γ phase precipitates on α subgrain boundaries with near Kurdjumov-Sachs relationship during aging. By warm deformation, the transition of α boundary structure from low-angle to high-angle type occurs by dynamic continuous recrystallization of α matrix and, simultaneously, coherency across α/γ boundary is lost. Contrarily, α phase first precipitates in deformed γ matrix in Ni-Cr-Fe based alloy during aging. Subsequently discontinuous recrystallization of γ matrix takes place and the (α + γ) microduplex structure with high-angle γ boundaries is formed. The formation of those high-angle boundaries in (α + γ) microduplex structure induces the high strain rate superplasticity.

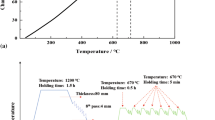

In an ultra-high carbon steel, when pearlite was austenitized in the (γ + θ) region, quenched and tempered at the temperature below A1, an (α + θ) microduplex structure in which most of α boundaries are of high-angle type is formed through the recovery of the fine (α ′ lath martensite + θ) mixture during tempering. Such (α + θ) microduplex structure with high angle α boundaries exhibits higher superplasticity than that formed by heavy warm rolling or cold rolling and annealing of pearlite which contains higher fraction of low angle boundaries.

Similar content being viewed by others

References

Y. Maehara, Trans. ISIJ 25 (1985) 69.

Y. Maehara and Y. Ohmori, Metall. Trans. A 18A (1987) 663.

H. W. Hayden, R. C. Gibson, H. F. Merrick and J. H. Brophy, Trans. ASM 60 (1967) 3.

J. Wadsworth and O. D. Sherby, J. Mater. Sci. 13 (1978) 2645.

K. Tsuzaki, H. Matsuyama, M. Nagao and T. Maki, Mater. Trans. JIM 31 (1990) 983.

T. Yamazaki, Y. Mizuno, T. Furuhara and T. Maki, Mater. Sci. Forum 304–306 (1999) 127.

T. Furuhara, Y. Mizuno and T. Maki, Mater. Trans. JIM 40 (1999) 815.

E. Sato, S. Furimoto, T. Furuhara, K. Tsuzaki and T. Maki, Mater. Sci. Forum 304–306 (1999) 133.

T. Furuhara, E. Sato, T. Mizoguchi, S. Furimoto and T. Maki, Mater. Trans. 43 (2002) 2455.

K. Ameyama, K. Murakami, T. Maki and I. Tamura, J. Jpn. Inst. Met. 49 (1985) 1045.

T. Maki, T. Furuhara and K. Tsuzaki, ISIJ Inter. 41 (2001) 571.

K. Tsuzaki, Huang Xiaoxu and T. Maki, Acta Metall. Mater. 44 (1996) 4491.

S. Hashimoto, F. Moriwaki, T. Mimaki, S. Miura in “Superplasticity in Advanced Materials,” edited by S. Hori, M. Tokizane, N. Furushiro (The Japan Society for Research on Superplasticity, 1991) p. 23.

O. D. Sherby, B. Walser, C. M. Young and E. M. Cady, Scripta Metall. 9 (1975) 569.

B. Walser and O. D. Sherby, Metall. Trans. A 10A (1979) 1461.

O. D. Sherby, T. Oyama, D. W. Kum, B. Walser and J. Wadsworth, J. Metals 37 (1985) 50.

D. R. Lesure, C. M. Syn, A. Goldberg, J. Wadsworth and O. D. Sherby, J. Metals 45 (1993) 40.

T. Oyama, O. D. Sherby, J. Wadsworth and B. Warser, Scripta Metall. 18 (1984) 799.

K. Seto, T. Kato and H. Abe, Mat. Res. Symp. Proc. 196 (1990) 99.

T. Mizoguchi, T. Furuhara, T. Maki, in Proc. Int. Symp. on Ultra-Fine Grained Steels (ISIJ, 2001), 198.

S. Tagashira, K. Sakai, T. Furuhara and T. Maki, ISIJ Inter. 40 (2000) 1149.

T. Maki, K. Tsuzaki and I. Tamura, Trans. ISIJ 20 (1980) 207.

T. Maki, S. Morito, T. Furuhara, in Proc. 19th ASM Heat Treat. Soc. Conf. (ASM International, Materials Park, OH, 2000) p. 631.

A. Ohmori, S. Torizuka, K. Nagai, K. Yamada and Y. Mukaigo, Tetsu-to-Hagane 88 (2002) 857.

G. Kelly, H. Beladi and P. D. Hodgson, ISIJ Inter. 42 (2002) 1585.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Furuhara, T., Maki, T. Grain boundary engineering for superplasticity in steels. J Mater Sci 40, 919–926 (2005). https://doi.org/10.1007/s10853-005-6510-7

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-6510-7