Abstract

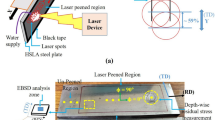

Pure mechanical and thermo-mechanical laser shock processing treatments have been carried out on an AISI 316L stainless steel. Surface properties, mostly mechanical and metallurgical modifications, were analysed at different scales: a local scale using the nano-indentation technique and AFM analysis, and a more macroscopic scale, using microhardness, optical microscopy and residual stress determinations. After a pure mechanical laser-peening treatment, a significant improvement in the pitting corrosion resistance (+0.1 V) was observed in 0.05 M NaCl. This improvement was attributed to the combined effects of compressive residual stresses and work-hardening, and, in turn, to a mechano-electrochemical phenomenon by which a modification of cathodic reactions occurs during electrochemical tests. For the surface treated by thermo-mechanical laser peening (combination of a surface ablation and shock waves), a tendency for decreasing resistance against pitting corrosion was shown, and attributed to the processing-specific surface texture (ablation craters), which made the material susceptible for the creation of occluded cells.

Similar content being viewed by others

Notes

Laboratoire pour l’Utilisation des Lasers Intenses, UMR 7605 CNRS, 91128 Palaiseau cedex, France.

References

Pan Q, Hang W, Song R, Zhou Y, Zhang G (1998) Surface Coating Technol 102:245

Kwok C, Man H, Cheng F (1998) Surface Coating Technol 99:295

Clauer AH (1981) In: Shock waves and high strain rate phenomena in metals. Plenum Press, New York, p 675

Obata M, Kubo T, Sano Y (2000) Zairyo 49(2):193

Peyre P, Scherpereel X, Berthe L, Carboni C, Fabbro R, Beranger G, Lemaitre C (2000) Mater Sci Eng 280(2):294

Krauβ M, Herzog R, Scholtes B (2001) Z Metallkd 92(8):910

Braham C, Perrais J, Ledion J (1994) 2ème Colloque Européen “Corrosion Dans Les Usines Chimiques Et Parachimiques’’. 206ème Manifestation Fec, Grenoble (Fr)

Ben Rhouma A, Braham C, Fitzpatrick ME (2001) J Mater Eng Perf 10:507

Ke R, Alkire R (1995) J Electrochem Soc 142(12):4056

Carboni C (2002) Doctoral Thesis, University of Technology of Compiègne, Fr

Carboni C, Peyre P, Fregonese M, Mazille H (2001) In: Jeandin M, Sudarshan T (eds) Proceedings of surface modifications technologies XIV (Smt14), Paris, Sept. 2000. ASM, p 381

Fabbro R, Fournier J, Ballard P, Devaux D, Virmont J (1990) J Appl Phys 68:775

Schmidt-Uhlig T (2000) Epj Appl Phys 9(3):235

Seo M, Chiba M (2001) Electrochim Acta 47:319

Lu J (2005) In: Lu J (ed) Handbook on residual stress measurements, 2nd edn. SEM

Gutman EM (1994) Mechanochemistry of solid surfaces, Ed. World Scientific Publishers, Singapore

Vignal V, Valot C, Oltra R, Verneau M, Coudreuse L (2002) Corros Sci 44(7):1477

Kamachi Mudali U, Katada Y (2001) Electrochim Acta 46:3735

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peyre, P., Carboni, C., Forget, P. et al. Influence of thermal and mechanical surface modifications induced by laser shock processing on the initiation of corrosion pits in 316L stainless steel. J Mater Sci 42, 6866–6877 (2007). https://doi.org/10.1007/s10853-007-1502-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1502-4