Abstract

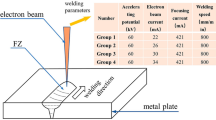

The electron beam (EB) welding process is used to weld any metal that can be arc welded with equal or superior weld quality. EB welding is carried out in a high-purity vacuum environment, which results in freedom from impurities such as oxides and nitrides. Thus, pore-free joints can readily be achieved in metallic materials, such as Al-alloys and Ti-alloys. However, autogenous EB welding of some aluminium alloys leads to a significant strength reduction (undermatching) in the fusion zone due to the loss of strengthening phases. For such Al-alloys, the local microstructure-property relationships should be established to satisfy the service requirement of a welded component with strength undermatching. Autogenous EB welding was performed on 5 mm thick aluminium alloy 7020 plate. Microstructural characterization of the weld metals was made by optical and scanning electron microscopy. Extensive microhardness measurements were conducted in the weld regions of the joints which exhibited a hardness loss in the fusion zone due to the loss of strengthening phases. Tensile properties of the joints were determined by testing flat transverse tensile specimens at room temperature without machining the weld profiles. Furthermore, elastic-plastic fracture toughness tests (CTOD) were carried out on the base material and welded joints at room temperature.

Similar content being viewed by others

References

Kuo S (1986) Welding research council bulletin, no. 320, WRC, New York

Çam G, Koçak M (1998) Sci Technol Welding Joining 3(4):159

Çam G, dos Santos JF, Koçak M (1997) Laser and electron beam weldability of Al-alloys: literature review. GKSS 97/E/25, GKSS Research Center, Geesthacht, Germany, IIW Doc. IX-1896-98

Çam G, Koçak M (1998) Int Mater Rev 43(1):1

Olson DL et al (eds) (1993) ASM handbook: welding, brazing, and soldering, vol 6. ASM International, Materials Park, Ohio

Murphy JL, Huber RA, Lever WE (1990) Weld J Res Suppl 69(4):125s

Cieslak MJ, Fuerschbach PW (1988) Metall Trans B 19B:319

Petrov DA (1993) In: Petzow G, Effenberg G (eds) Ternary alloys, vol. 7. VHC Publishers, New York, p 57

Rao SRK et al (2005) Mater Charact 55:345

Çam G et al (1999) J Sci Technol Welding Joining 4(5):317

Çam G et al (2000) Practical Metallography 37(2):59, also available as GKSS Report, GKSS 2000/9, GKSS Research Center, Geesthacht, Germany, 2000

Acknowledgements

This work is a part of the Brite Euram ASPOW project (BRPR95-0021). Authors wish to thank the European Commission for the financial support. Thanks are also due to Mr. S. Riekehr, Mr. H. Mackel, and Mr. V. Ventzke for their assistance in conducting the experimental work. They would also like to thank Mr. G. Jennequin and Mr. P. Gonthier-Maurin of CNIM, La Seyne-Sur-Mer Cedex, France, where electron beam welding was performed.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Çam, G., Koçak, M. Microstructural and mechanical characterization of electron beam welded Al-alloy 7020. J Mater Sci 42, 7154–7161 (2007). https://doi.org/10.1007/s10853-007-1604-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1604-z