Abstract

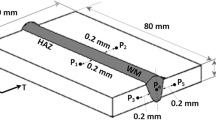

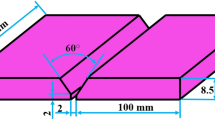

Welding of austenitic-ferritic stainless steels is a crucial operation and all the materials and parameters used in this process must be optimized in order to obtain the suitable corrosion and mechanical properties. Since a great part of super duplex stainless steels is used in very aggressive environment, their corrosion resistance, referred in particular to pitting and crevice corrosion, is an all-important facet in production and processing of this type of steels. Pitting corrosion resistance of super duplex stainless steels welded joints depends on several aspects: microstructure of the bead, elemental partitioning between ferrite and austenite, and the possible presence of secondary phases. For these reasons, a post-weld annealing is generally performed to homogenize the microstructure. The annealing temperature is the most important parameter to be optimized in this heat treatment. In the present work, a comparison between the as-welded and solution-treated joints is carried out. An effort has been made to correlate the main factors that affect pitting corrosion of the welded joints (microstructure, secondary phases, chemical composition of single phases) with the experimental data obtained from corrosion tests. In this first part of the work the results regarding microstructure and partitioning of elements are presented. The phase balance and the austenite morphology are locally upset during submerged-arc welding of UNS S32750. In the fusion zone, the two phases (ferrite and austenite) result to have approximately the same composition regarding Cr, Mo, and Ni content, while nitrogen is heavily concentrated in austenite. After annealing treatment, the austenite volume fraction increases and the partitioning ratios of elements reach the equilibrium values. The base material results to be less sensitive to annealing treatment than the fusion zone, and the partitioning of elements in the base material is in agreement with previous works reported in the literature.

Similar content being viewed by others

References

Nilsson JO (1992) Mater Sci Technol 8:685

Garcia-Garcia DM, Garcia-Anton J, Igual-Munoz A, Blasco-Tamarit E (2006) Corros Sci 48:2380

Perren RA, Suter TA, Uggowitzer PJ, Weber L, Magdowski R, Bohni H, Speidel MO (2001) Corros Sci 43:707

Perren RA, Suter T, Solenthaler C, Gullo G, Uggowitzer PJ, Bohni H, Speidel MO (2001) Corros Sci 43:727

Taban E (2008) J Mater Sci 43:4309. doi:10.1007/s10853-008-2632-z

Migiakis K, Papadimitriou GD (2009) J Mater Sci 44:6372. doi:10.1007/s10853-009-3878-9

Muthupandi V, Bala Srinivasan P, Seshadri SK, Sundaresan S (2003) Mater Sci Eng A358:9

Nowacki J, Rybicki P (2005) J Mater Process Technol 164–165:1082

Tavares SSM, Pardal JM, Lima LD, Bastos IN, Nascimento AM, de Souza JA (2007) Mater Charact 58:610

Atamert S, King JE (1992) Mater Sci Technol 8:896

Bonollo F, Tiziani A, Ferro P (2009) Advances in duplex stainless steels, chap 4. ISTE LTD, London

Nilsson JO, Karlsson L, Anderson JO (1995) Mater Sci Technol 11:276

Ferro P, Tiziani A, Bonollo F (2008) Weld J 87:298

Grong Ø (1997) Metallurgical modelling of welding. The Institute of Materials, Great Britain

Atamert S, King JE (1991) Acta Metall Mater 39:273

Weber L, Uggowitzer PJ (1995) Proceedings of international symposium on high performance steels for structural applications, ASM, Cleveland, pp 291–298

Ogawa T, Koseki T (1989) Weld J 68:181

Bonollo F, Gregori A, Tiziani A, Nilsson J-O (1998) A study on microstructural evolution of superduplex steels (SAF 2507) induced by isothermal heat treatment. Proceedings of 11th congress of the international federation for heat treatment and surface engineering, Associazione Italiana di Metallurgia, Milano, vol 3, pp 291–300

Liou H-Y, Hsieh R-I, Tsai W-T (2002) Mater Chem Phys 74:33

Nilsson JO, Wilson A (1993) Mater Sci Technol 9:545

Ha HY, Kwon HS (2007) Electrochem Acta 52:2175

Bonollo F, Tiziani A, Ferro P (2009) In: Alvarez-Armas I, Degallaix-Moreuil S (eds) Duplex stainless steels. ISTE LTD, London, p 143

Ramirez AJ, Lippold JC, Brandi SD (2003) Metall Mater Trans 34A:1575

Badji R, Bouadballah M, Bacroix B, Kahloun C, Bettahar K, Kherrouba N (2008) Mater Sci Technol A496:447

Tan H, Jiang Y, Deng B, Sun T, Xu J, Li J (2009) Mater Charact 60:1049. doi:10.106/j.matchar.2009.04.009

Weber L, Uggowitzer PJ (1998) Mater Sci Eng A 242:222

Charles J (1991) Physique 1:3

Liljas M (1994) The welding metallurgy of duplex stainless steels. Proceedings of duplex stainless steels 94, Glasgow, Scotland

Acknowledgements

The authors gratefully acknowledge the experimental support provided by Mr. Giacomo Mazzacavallo and Dr. Enrico Della Rovere. Special thanks are also due to Rivit S.p.A. (Caltrano, VI, Italy) for the materials supply and welding.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cervo, R., Ferro, P. & Tiziani, A. Annealing temperature effects on super duplex stainless steel UNS s32750 welded joints. I: microstructure and partitioning of elements. J Mater Sci 45, 4369–4377 (2010). https://doi.org/10.1007/s10853-010-4310-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4310-1