Abstract

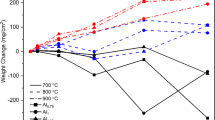

This study deals with the effect of the annealing temperature on the pitting corrosion resistance of UNS S32750 submerged-arc welded joints. In a companion article (Part I), the influence of post-weld annealing temperature on microstructure evolution and chemical composition of austenite and ferrite was analyzed; this study can thus be considered directly connected with the previous one. The pitting corrosion resistance of the heat-treated welded joints was evaluated by using both electrochemical measurements and ASTM G48 standard gravimetric tests; examinations of initiation sites of pitting attack were carried out in order to correlate the experimental data obtained in this study with the predicted pitting corrosion behavior obtained by using the results described in Part I. Generally, the post-weld annealing treatment enhances the pitting corrosion resistance of UNS S32750 welded joints. By using PREN analysis of single phases, a correlation between the chemical composition evolution of ferrite and austenite and the experimental pitting behavior of the welded joints was found, in relation to welding and post-welding heat treatment temperature. In particular, an exponential relationship between PREN of weaker phase and pitting potential in 3.5% NaCl solution at 80 °C for the weld metal was obtained. The most favorable annealing temperature for the analyzed welded joints was found to be 1100 °C.

Similar content being viewed by others

References

Nilsson JO (1992) Mater Sci Technol 8:685

Atamert S, King JE (1991) Acta Metall Mater 39(3):273

Bonollo F, Tiziani A, Ferro P (2009) Advances in duplex stainless steels, chap 4. ISTE LTD, London

Tavares SSM, Pardal JM, Lima LD, Bastos IN, Nascimento AM, de Souza JA (2007) Mater Charact 58:610

Taban E (2008) J Mater Sci 43:4309. doi:10.1007/s10853-008-2632-z

Sathiya P, Aravindan S, Soundararajan R, Noorul Haq A (2009) J Mater Sci 44:114. doi:10.1007/s10853-008-3098-8

Migiakis K, Papadimitriou GD (2009) J Mater Sci 44:6372. doi:10.1007/s10853-009-3878-9

Ogawa T, Koseki T (1989) Weld J 68:181

Liao J (2001) ISIJ Int 41(5):460

Liou H-Y, Hsieh R-I, Tsai W-T (2002) Mater Chem Phys 74:33

Nilsson JO, Karlsson L, Anderson JO (1995) Mater Sci Technol 11:276

Kwok CT, Fong SL, Cheng FT, Man HC (2006) J Mater Process Technol 176:168

Kordatos JD, Fourlaris G, Papadimitriou G (2001) Scripta Mater 44:401

Bautista A, Blanco G, Velasco F, Martinez MA (2007) Constr Build Mater 21:1267

Garzon CM, Serna CA, Brandi SD, Ramirez AJ (2007) J Mater Sci 42:9021. doi:10.1007/s10853-007-1881-6

Sun Z, Kuo M, Annergren I, Pan D (2003) Mater Sci Eng A356:274

Muthupandi V, Bala Srinivasan P, Seshadri SK, Sundaresan S (2003) Mater Sci Eng A358:9

Ferro P, Tiziani A, Bonollo F (2008) Weld J 87:298

Pohjanne P, Carpén L, Hakkarainen T, Kinnunen P (2008) J Constr Steel Res 64:1325

Herbsleb G (1982) Werkst Korros 33:334

Lorenz K, Medawar G (1969) Thyssen Forschung 1:97

Dölling R, Neubert V, Knoll P (1991) In: Proceedings of the duplex stainless steels conference, vol 91. Beaune, France, pp 1341–1351

Vannevik H, Nilsson JO, Frodigh J, Kangas P (1996) ISIJ Int 36(7):807

Weber L, Uggowitzer PJ (1998) Mater Sci Eng A 242:222

Bernhardsonn S (1991) In: Proceedings of the duplex stainless steels conference, vol 185. Beaune, France

Tuck CDS, Sykes JM, Garfias-Mesias LF (1994) In: 4th International conference of duplex stainless steels, Glasgow, paper 15

Tan H, Jiang Y, Deng B, Sun T, Xu J-L, Li J (2009) Mater Charact. doi:10.1016/j.matchar.2009.04.009

Van Bennekom A (1998) Steel World 54

Garfias-Mesias LF, Sykes JM, Tuck CDS (1996) Corros Sci 38:1319

Vannevik H, Nilsson JO, Frodigh J, Kangas P (1996) ISIJ Int 36:807

Annual book of ASTM standards, ASTM G48-03, 2003, ASTM

Deng B, Jiang Y, Gong J, Zhong C, Gao J, Li J (2008) Electrochim Acta 53:5220

Merello R, Botana FJ, Botella J, Matres MV, Marcos M (2003) Corros Sci 45:909

Batista SRF, Kuri SE (2004) Methods Mater 51(3):205

Acknowledgements

The authors gratefully acknowledge the experimental support provided by Mr. Giacomo Mazzacavallo, Dr. Enrico Della Rovere, and Dr. Vincenzo Grassi. Special thanks are also due to Rivit S.p.A. (Caltrano, VI—Italy) for the materials supply and welding.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cervo, R., Ferro, P., Tiziani, A. et al. Annealing temperature effects on superduplex stainless steel UNS S32750 welded joints. II: pitting corrosion resistance evaluation. J Mater Sci 45, 4378–4389 (2010). https://doi.org/10.1007/s10853-010-4311-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4311-0