Abstract

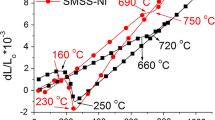

Supermartensitic steels are a new class of martensitic stainless steels developed to obtain higher corrosion resistance and better toughness through the reduction of carbon content, and addition of Ni and Mo. They were developed to more critical applications or to improve the performance obtained with conventional grades AISI 410, 420, and 431. In this study, the influences of the tempering parameters on the microstructure, mechanical properties (hardness and toughness), and sensitization of a Ti-alloyed supermartensitc stainless steel were investigated. The material showed temper embrittlement in the 400–600 °C range, as detected by low temperature (−46 °C) impact tests. The degree of sensitization measured by double loop reactivation potentiodynamic tests increased continuously with the increase of tempering temperature above 400 °C. Healing due to Cr diffusion at high tempering temperatures was not observed. Double tempered specimens showed high amounts (>20%) of reverse austenite but their toughness were similar to specimens single tempered at 625 and 650 °C.

Similar content being viewed by others

References

Olden V, Thaulow C, Johnsen R (2008) Mater Des 29:1934

Kondo K, Ueda M, Oawa K, Amaya H, Hirata H, Takabe H (1999) In: Supermartensitic stainless steels ‘99’, Belgium, p 11

Rodrigues CAD, di Lorenzo PL, Sokolowski A, Barbosa CA, Tremiliosi-Filho G, Rollo JMAD (2006) In: 17th Congresso Brasileiro de Engenharia e Ciência dos Materiais, Foz do Iguaçu, p 2695

Rodrigues CAD, Lorenzo PLD, Sokolowski A, Barbosa CA, Rollo JMAD (2007) Mater Sci Eng A 460–461:149

Pickering FB (1978) Physical metallurgy and the design of steels. Applied Science Publishers Ltd, London

ASM (1994) ASM speciality handbook. ASM International, Materials Park

Čihal V, Štefec R (2001) Electrochim Acta 46:3867

Folkhard E (1984) Welding metallurgy of stainless steels. Springer-Verlag/Wien, New York

SM A (1987) ASM metals handbook, vol 12, Fractography. ASM International, Materials Park

API Recommended Practice 571 (2003) Damage mechanisms affecting fixed equipment in the refining industry, Section 4: general damage mechanisms—all industries. Americam Petroleum Institute, Washington DC

Prohaska M, Kanduth H, Mori G, Grill R, Tischler G (2010) Corros Sci 52(5):1582

Lopez N, Cid M, Puiggali M, Azkarate I, Pelayo A (1997) Mater Sci Eng A 229(1–2):123

Cullity BD (1978) Elements of X-ray diffraction. Addison Wesley Publishing Company, Reading

Leffer B (2010) Stainless steels and their properties. Available in https://doi.org/www.outokumpu.com/files/Group/HR/Documents/STAINLESS20.pdf. Accessed 27 Nov 2010

Tavares SSM, da Silva FJ, Scandian C, da Silva GF, Abreu HFG (2010) Corros Sci 52(11):3835

Carrouge D (2011) software MAP_STEEL_AC1TEMP, Phase transformation group, University of Cambridge, Department of Materials Science and Metallurgy. https://doi.org/www.msm.cam.ac.uk/map/steel/programs/ac1new.html. Accessed 4 Apr 2011

Gesnouin C, Hazarabedian A, Bruzzoni P, Ovejero-Garcia J, Bilmes P, Llorente C (2004) Corros Sci 46:1633

Bilmes PD, Solari M, Lorente CL (2001) Mater Charact 46:285

Nakagawa N, Miyazaki T (1999) J Mater Sci 34:3901. doi:https://doi.org/10.1023/A:1004626907367

Moura V, Kina AY, Tavares SSM, Lima LD, Mainier FB (2008) J Mater Sci 43:536. doi:https://doi.org/10.1007/s10853-007-1785-5

Kina AY, Tavares SSM, Souza JA, Abreu HFG (2008) J Mater Process Technol 199:391

Acknowledgement

The authors acknowledge the Brazilian research agencies (CAPES, FAPERJ and CNPq) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

da Silva, G.F., Tavares, S.S.M., Pardal, J.M. et al. Influence of heat treatments on toughness and sensitization of a Ti-alloyed supermartensitic stainless steel. J Mater Sci 46, 7737–7744 (2011). https://doi.org/10.1007/s10853-011-5753-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5753-8