Abstract

Advanced ceramic materials with complex design have become inseparable from the current engineering applications. Due to the limitation of traditional ceramic processing, ceramic additive manufacturing (AM) which allows high degree of fabrication freedom has gained significant research interest. Among these AM techniques, low-cost robocasting technique is often considered to fabricate complex ceramic components. In this work, aqueous ceramic suspension comprising of commercial nano-sized yttria-stabilized zirconia (YSZ) powder has been developed for robocasting purpose. Both fully and partially stabilized YSZ green bodies with complex morphologies were successfully printed in ambient conditions using relatively low-solid-content ceramic suspensions (<38 vol%). The sintered structures were able to retain the original morphologies with >94% of the theoretical density despite its high linear shrinkage (up to 33%). The microstructure analysis indicated that dense fully and partially stabilized YSZ with grain size as small as 1.40 ± 0.53 and 0.38 ± 0.10 μm can be obtained, respectively. The sintered partially stabilized YSZ solid and porous mesh samples (porosity of macro-pores >45%) exhibited hardness up to 13.29 GPa and flexural strengths up to 242.8 ± 11.4 and 57.3 ± 5.2 MPa, respectively. The aqueous-based ceramic suspension was also demonstrated to be suitable for the fabrication of large YSZ parts with good repeatability.

Similar content being viewed by others

References

Belmonte M (2006) Advanced ceramic materials for high temperature applications. Adv Eng Mater 8(8):693–703

Kelly JR, Denry I (2008) Stabilized zirconia as a structural ceramic: an overview. Dent Mater 24(3):289–298

Gautam C, Joyner J, Gautam A, Rao J, Vajtai R (2016) Zirconia based dental ceramics: structure, mechanical properties, biocompatibility and applications. Dalton Trans 45(48):19194–19215

Park J-S, Kim H, Kim I-D (2014) Overview of electroceramic materials for oxide semiconductor thin film transistors. J Electroceram 32(2):117–140

Schlordt T, Schwanke S, Keppner F, Fey T, Travitzky N, Greil P (2013) Robocasting of alumina hollow filament lattice structures. J Eur Ceram Soc 33(15–16):3243–3248

Manicone PF, Rossi Iommetti P, Raffaelli L (2007) An overview of zirconia ceramics: basic properties and clinical applications. J Dent 35(11):819–826

Zhao S, Xiao W, Rahaman MN, O’Brien D, Seitz-Sampson JW, Sonny Bal B (2017) Robocasting of silicon nitride with controllable shape and architecture for biomedical applications. Int J Appl Ceram Technol 14(2):117–127

Cai K, Román-Manso B, Smay JE, Zhou J, Osendi MI, Belmonte M, Miranzo P (2012) Geometrically complex silicon carbide structures fabricated by robocasting. J Am Ceram Soc 95(8):2660–2666

Chen Z, Song X, Lei L, Chen X, Fei C, Chiu CT, Qian X, Ma T, Yang Y, Shung K, Chen Y, Zhou Q (2016) 3D printing of piezoelectric element for energy focusing and ultrasonic sensing. Nano Energy 27:78–86

Tuttle BA, Smay JE, Cesarano J, Voigt JA, Scofield TW, Olson WR, Lewis JA (2001) Robocast Pb(Zr0.95Ti0.05)O3 ceramic monoliths and composites. J Am Ceram Soc 84(4):872–874

Jakus AE, Taylor SL, Geisendorfer NR, Dunand DC, Shah RN (2015) Metallic architectures from 3D-printed powder-based liquid inks. Adv Func Mater 25(45):6985–6995

Wei X, Nagarajan RS, Peng E, Xue J, Wang J, Ding J (2016) Fabrication of YBa2Cu3O7−x (YBCO) superconductor bulk structures by extrusion freeforming. Ceram Int 42(14):15836–15842

Tsampas MN, Sapountzi FM, Vernoux P (2015) Applications of yttria stabilized zirconia (YSZ) in catalysis. Catal Sci Technol 5(11):4884–4900

Devi PS, Sharma AD, Maiti HS (2004) Solid oxide fuel cell materials: a review. Trans Indian Ceram Soc 63(2):75–98

Porter DL, Evans AG, Heuer AH (1979) Transformation-toughening in partially-stabilized zirconia (PSZ). Acta Metall 27(10):1649–1654

Durá OJ, López de la Torre MA, Vázquez L, Chaboy J, Boada R, Rivera-Calzada A, Santamaria J, Leon C (2010) Ionic conductivity of nanocrystalline yttria-stabilized zirconia: grain boundary and size effects. Phys Rev B 81(18):184301

Shanti NO, Hovis DB, Seitz ME, Montgomery JK, Baskin DM, Faber KT (2009) Ceramic laminates by gelcasting. Int J Appl Ceram Technol 6(5):593–606

Hotza D, Greil P (1995) Review: aqueous tape casting of ceramic powders. Mater Sci Eng A 202(1):206–217

Mohd Foudzi F, Muhamad N, Bakar Sulong A, Zakaria H (2013) Yttria stabilized zirconia formed by micro ceramic injection molding: rheological properties and debinding effects on the sintered part. Ceram Int 39(3):2665–2674

Lewis JA, Smay JE, Stuecker J, Cesarano J (2006) Direct ink writing of three-dimensional ceramic structures. J Am Ceram Soc 89(12):3599–3609

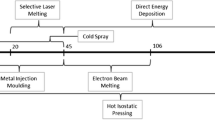

Travitzky N, Bonet A, Dermeik B, Fey T, Filbert-Demut I, Schlier L, Schlordt T, Greil P (2014) Additive manufacturing of ceramic-based materials. Adv Eng Mater 16(6):729–754

Zocca A, Colombo P, Gomes CM, Günster J (2015) Additive manufacturing of ceramics: issues, potentialities, and opportunities. J Am Ceram Soc 98(7):1983–2001

Qian B, Shen Z (2013) Laser sintering of ceramics. J Asian Ceram Soc 1(4):315–321

Manogharan G, Kioko M, Linkous C (2015) Binder jetting: a novel solid oxide fuel-cell fabrication process and evaluation. JOM 67(3):660–667

Halloran JW (2016) Ceramic stereolithography: additive manufacturing for ceramics by photopolymerization. Annu Rev Mater Res 46(1):19–40

Allahverdi M, Danforth SC, Jafari M, Safari A (2001) Processing of advanced electroceramic components by fused deposition technique. J Eur Ceram Soc 21(10–11):1485–1490

Lu X, Lee Y, Yang S, Hao Y, Evans JRG, Parini CG (2009) Fine lattice structures fabricated by extrusion freeforming: process variables. J Mater Process Technol 209(10):4654–4661

Maazouz Y, Montufar EB, Guillem-Marti J, Fleps I, Ohman C, Persson C, Ginebra MP (2014) Robocasting of biomimetic hydroxyapatite scaffolds using self-setting inks. J Mater Chem B 2(33):5378–5386

Mason MS, Huang T, Landers RG, Leu MC, Hilmas GE (2009) Aqueous-based extrusion of high solids loading ceramic pastes: process modeling and control. J Mater Process Technol 209(6):2946–2957

Scheithauer U, Schwarzer E, Richter H-J, Moritz T (2015) Thermoplastic 3D printing—an additive manufacturing method for producing dense ceramics. Int J Appl Ceram Technol 12(1):26–31

Vaidyanathan R, Walish J, Lombardi JL, Kasichainula S, Calvert P, Cooper KC (2000) The extrusion freeforming of functional ceramic prototypes. JOM 52(12):34–37

Leu MC, Deuser BK, Tang L, Landers RG, Hilmas GE, Watts JL (2012) Freeze-form extrusion fabrication of functionally graded materials. CIRP Ann Manuf Technol 61(1):223–226

de Hazan Y, Thänert M, Trunec M, Misak J (2012) Robotic deposition of 3d nanocomposite and ceramic fiber architectures via UV curable colloidal inks. J Eur Ceram Soc 32(6):1187–1198

Faes M, Valkenaers H, Vogeler F, Vleugels J, Ferraris E (2015) Extrusion-based 3D printing of ceramic components. Procedia CIRP 28:76–81

Feilden E, Blanca EG-T, Giuliani F, Saiz E, Vandeperre L (2016) Robocasting of structural ceramic parts with hydrogel inks. J Eur Ceram Soc 36(10):2525–2533

Lu X, Lee Y, Yang S, Hao Y, Ubic R, Evans JRG, Parini CG (2008) Fabrication of electromagnetic crystals by extrusion freeforming. Metamaterials 2(1):36–44

Lu X, Lee Y, Yang S, Hao Y, Evans JRG, Parini CG (2010) Solvent-based paste extrusion solid freeforming. J Eur Ceram Soc 30(1):1–10

Michna S, Wu W, Lewis JA (2005) Concentrated hydroxyapatite inks for direct-write assembly of 3-D periodic scaffolds. Biomaterials 26(28):5632–5639

Smay JE, Cesarano J, Lewis JA (2002) Colloidal inks for directed assembly of 3-D periodic structures. Langmuir 18(14):5429–5437

Garbe U, Randall T, Hughes C (2011) The new neutron radiography/tomography/imaging station DINGO at OPAL. Nucl Instrum Methods Phys Res Sect A 651(1):42–46

Lewis JA (2000) Colloidal processing of ceramics. J Am Ceram Soc 83(10):2341–2359

Moreno R (2012) Colloidal processing of ceramics and composites. Adv Appl Ceram 111(5-6):246–253

Hidber PC, Graule TJ, Gauckler LJ (1996) Citric acid—a dispersant for aqueous alumina suspensions. J Am Ceram Soc 79(7):1857–1867

Çınar S, Akinc M (2014) Ascorbic acid as a dispersant for concentrated alumina nanopowder suspensions. J Eur Ceram Soc 34(8):1997–2004

Stuecker JN, Cesarano Iii J, Hirschfeld DA (2003) Control of the viscous behavior of highly concentrated mullite suspensions for robocasting. J Mater Process Technol 142(2):318–325

Tekeli S (2007) The solid solubility limit of Al2O3 and its effect on densification and microstructural evolution in cubic-zirconia used as an electrolyte for solid oxide fuel cell. Mater Des 28(2):713–716

Tekeli S, Demir U (2005) Colloidal processing, sintering and static grain growth behaviour of alumina-doped cubic zirconia. Ceram Int 31(7):973–980

Houmard M, Fu Q, Genet M, Saiz E, Tomsia AP (2013) On the structural, mechanical, and biodegradation properties of HA/β-TCP robocast scaffolds. J Biomed Mater Res B Appl Biomater 101(7):1233–1242

Michorczyk P, Hedrzak E, Wegrzyniak A (2016) Preparation of monolithic catalysts using 3D printed templates for oxidative coupling of methane. J Mater Chem A 4(48):18753–18756

Saint Gobain. ZirPro CY3Z-P Technical Data Sheet. http://www.zirpro.com/zirconia-beads-powders/yttria-stabilized-zirconia

Acknowledgements

The authors would like to thank Saint Gobain ZirPro for providing the zirconia powders. This project is financially supported by Saint Gobain (R-284-000-140-597), NUS Strategic Research Fund R-261-509-001-646 and R-261-509-001-733 and NRF NRF-CRP16-2015-01 (R-284-000-159-281).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Peng, E., Wei, X., Garbe, U. et al. Robocasting of dense yttria-stabilized zirconia structures. J Mater Sci 53, 247–273 (2018). https://doi.org/10.1007/s10853-017-1491-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1491-x