Abstract

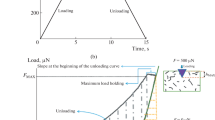

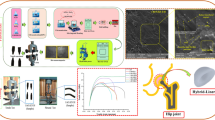

Ultra-high molecular weight polyethylene (UHMWPE)-based conductive nanocomposites with reduced percolation and tunable piezoresistive behavior were prepared via solution mixing followed by compression molding using carbon nanotubes (CNT) and graphene nanoplatelets (GNP). The effect of varying wt% of GNP with fixed CNT content (0.1 wt%) on the mechanical, electrical, thermal and piezoresistive properties of UHMWPE nanocomposites was evaluated. The combination of CNT and GNP enhanced the dispersion in UHMWPE matrix and lowered the probability of CNT aggregation as GNP acted as a spacer to separate the entanglement of CNT with each other. This has allowed the formation of an effective conductive path between GNP and CNT in UHMWPE matrix. The thermal conductivity, degree of crystallinity and degradation temperature of the nanocomposites increased with increasing GNP content. The elastic modulus and yield strength of the nanocomposites were improved by 37% and 33%, respectively, for 0.1/0.3 wt% of CNT/GNP compared to neat UHMWPE. The electrical conductivity was measured using four-probe method, and the lowest electrical percolation threshold was achieved at 0.1/0.1 wt% of CNT/GNP forming a nearly two-dimensional conductive network (critical value, t = 1.20). Such improvements in mechanical and electrical properties are attributed to the synergistic effect of the two-dimensional GNP and one-dimensional CNT which limits aggregation of CNTs enabling a more efficient conductive network at low wt% of fillers. These hybrid nanocomposites exhibited strong piezoresistive response with sensitivity factor of 6.2, 15.93 and 557.44 in the linear elastic, inelastic I and inelastic II regimes, respectively, for 0.1/0.5 wt% of CNT/GNP. This study demonstrates the fabrication method and the self-sensing performance of CNT/GNP/UHMWPE nanocomposites with improved properties useful for orthopedic implants.

Similar content being viewed by others

References

Kurtz SM (2009) UHMWPE biomaterials handbook. 2nd ed. Academic Press, Boston, pp 1–6. https://doi.org/10.1016/B978-0-12-374721-1.00001-8

Bi S, Liu M, Shen J, Hu XM, Zhang L (2017) Ultrahigh self-sensing performance of geopolymer nanocomposites via unique interface engineering. ACS Appl Mater Interfaces 9(14):12851–12858. https://doi.org/10.1021/acsami.7b00419

Chung DDL (2007) Damage detection using self-sensing concepts. Proc Inst Mech Eng Part G: J Aerosp Eng 221(4):509–520

Chung D (2012) Carbon materials for structural self-sensing, electromagnetic shielding and thermal interfacing. Carbon 50(9):3342–3353

Gupta TK, Kumar S, Khan AZ, Varadarajan KM, Cantwell WJ (2018) Self-sensing performance of MWCNT-low density polyethylene nanocomposites. Mater Res Express 5:015703. https://doi.org/10.1088/2053-1591/aa9f9e

Liu H, Gao J, Huang W, Dai K, Zheng G, Liu C, Shen C, Yan X, Guo J, Guo Z (2016) Electrically conductive strain sensing polyurethane nanocomposites with synergistic carbon nanotubes and graphene bifillers. Nanoscale 8(26):12977–12989. https://doi.org/10.1039/c6nr02216b

Dai H, Wong EW, Lieber CM (1996) Probing electrical transport in nanomaterials: conductivity of individual carbon nanotubes. Science 272(5261):523–526

Treacy MJ, Ebbesen T, Gibson J (1996) Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 381(6584):678–680

Arif MF, Kumar S, Shah T (2016) Tunable morphology and its influence on electrical, thermal and mechanical properties of carbon nanostructure-buckypaper. Mater Des 101:236–244. https://doi.org/10.1016/j.matdes.2016.03.122

Berber S, Kwon Y-K, Tománek D (2000) Unusually high thermal conductivity of carbon nanotubes. Phys Rev Lett 84(20):4613–4616

Yu A, Ramesh P, Sun X, Bekyarova E, Itkis ME, Haddon RC (2008) Enhanced thermal conductivity in a hybrid graphite nanoplatelet—carbon nanotube filler for epoxy composites. Adv Mater 20(24):4740–4744. https://doi.org/10.1002/adma.200800401

Danafar F, Fakhru’l-Razi A, Salleh MAM, Biak DRA (2009) Fluidized bed catalytic chemical vapor deposition synthesis of carbon nanotubes. Chem Eng J 155(1–2):37–48. https://doi.org/10.1016/j.cej.2009.07.052

Ranjith Kumar VSN, Kumar S, Pal G, Shah T (2016) High-ampacity overhead power lines with carbon nanostructure-epoxy composites. J Eng Mater Technol 138:041018–041026. https://doi.org/10.1115/1.4034095

Kumar S, Pal G, Shah T (2017) High performance overhead power lines with carbon nanostructures for transmission and distribution of electricity from renewable sources. J Clean Prod 145:180–187. https://doi.org/10.1016/j.jclepro.2017.01.053

Samad MA, Sinha SK (2011) Mechanical, thermal and tribological characterization of a UHMWPE film reinforced with carbon nanotubes coated on steel. Tribol Int 44(12):1932–1941. https://doi.org/10.1016/j.triboint.2011.08.001

Bakshi SR, Tercero JE, Agarwal A (2007) Synthesis and characterization of multiwalled carbon nanotube reinforced ultra high molecular weight polyethylene composite by electrostatic spraying technique. Compos A Appl Sci Manuf 38(12):2493–2499. https://doi.org/10.1016/j.compositesa.2007.08.004

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2004) Electric field effect in atomically thin carbon films. Science 306(5696):666–669. https://doi.org/10.1126/science.1102896

Cui Y, Kundalwal SI, Kumar S (2016) Gas barrier performance of graphene/polymer nanocomposites. Carbon 98:313–333. https://doi.org/10.1016/j.carbon.2015.11.018

Gupta TK, Kumar S (2018) Fabrication of carbon nanotube/polymer nanocomposites. Carbon nanotube-reinforced polymers: from nanoscale to macroscale. Elsevier, Amsterdam, pp 61–81

Ruan SL, Gao P, Yang XG, Yu TX (2003) Toughening high performance ultrahigh molecular weight polyethylene using multiwalled carbon nanotubes. Polymer 44(19):5643–5654. https://doi.org/10.1016/S0032-3861(03)00628-1

Liu T, Eyler A, Zhong W-H (2016) Simultaneous improvements in wear resistance and mechanical properties of UHMWPE nanocomposite fabricated via a facile approach. Mater Lett 177:17–20. https://doi.org/10.1016/j.matlet.2016.04.072

Gao J-F, Li Z-M, Q-j Meng, Yang Q (2008) CNTs/UHMWPE composites with a two-dimensional conductive network. Mater Lett 62(20):3530–3532. https://doi.org/10.1016/j.matlet.2008.03.053

Ren P-G, Di Y-Y, Zhang Q, Li L, Pang H, Li Z-M (2012) Composites of ultrahigh-molecular-weight polyethylene with graphene sheets and/or MWCNTs with segregated network structure: preparation and properties. Macromol Mater Eng 297(5):437–443. https://doi.org/10.1002/mame.201100229

Hu N, Masuda Z, Yan C, Yamamoto G, Fukunaga H, Hashida T (2008) The electrical properties of polymer nanocomposites with carbon nanotube fillers. Nanotechnology 19:215701. https://doi.org/10.1088/0957-4484/19/21/215701

Eslami H, Behrouz M (2014) Molecular dynamics simulation of a polyamide-66/carbon nanotube nanocomposite. J Phys Chem C 118:9841–9851. https://doi.org/10.1021/jp501672t

Pal G, Kumar S (2016) Modeling of carbon nanotubes and carbon nanotube–polymer composites. Prog Aerosp Sci 80:33–58. https://doi.org/10.1016/j.paerosci.2015.12.001

Pal G, Kumar S (2016) Multiscale modeling of effective electrical conductivity of short carbon fiber-carbon nanotube-polymer matrix hybrid composites. Mater Des 89:129–136. https://doi.org/10.1016/j.matdes.2015.09.105

Pal G, Kumar S (2018) Mechanical properties of isolated carbon nanotube. Carbon nanotube-reinforced polymers: from nanoscale to macroscale. Elsevier, Amsterdam, pp 173–199

Kim K, Regan W, Geng B, Alemn B, Kessler BM, Wang F, Crommie MF, Zettl A (2010) High-temperature stability of suspended single-layer graphene. Phys Status Solidi (RRL) Rapid Res Lett 4(11):302–304

Dresselhaus MS, Dresselhaus G, Saito R, Jorio A (2005) Raman spectroscopy of carbon nanotubes. Phys Rep 409(2):47–99. https://doi.org/10.1016/j.physrep.2004.10.006

Briscoe BJ, Pelillo E, Sinha SK (1996) Scratch hardness and deformation maps for polycarbonate and polyethylene. Polym Eng Sci 36(24):2996–3005

Pak SY, Kim HM, Kim SY, Youn JR (2012) Synergistic improvement of thermal conductivity of thermoplastic composites with mixed boron nitride and multi-walled carbon nanotube fillers. Carbon 50(13):4830–4838. https://doi.org/10.1016/j.carbon.2012.06.009

Zabihi Z, Araghi H (2016) Effect of functional groups on thermal conductivity of graphene/paraffin nanocomposite. Phys Lett A 380(45):3828–3831. https://doi.org/10.1016/j.physleta.2016.09.028

Zabihi Z, Araghi H (2017) Effective thermal conductivity of carbon nanostructure based polyethylene nanocomposite: influence of defected, doped, and hybrid filler. Int J Therm Sci 120:185–189. https://doi.org/10.1016/j.ijthermalsci.2017.06.010

Yu A, Ramesh P, Sun X, Bekyarova E, Itkis ME, Haddon RC (2008) Enhanced thermal conductivity in a hybrid graphite nanoplatelet–carbon nanotube filler for epoxy composites. Adv Mater 20:4740–4744. https://doi.org/10.1002/adma.200800401

Wunderlich B (1973) Thermal analysis of polymers. J Therm Anal 5(1):117–136

Lahiri D, Dua R, Zhang C, de Socarraz-Novoa I, Bhat A, Ramaswamy S, Agarwal A (2012) Graphene nanoplatelet-induced strengthening of ultrahigh molecular weight polyethylene and biocompatibility in vitro. ACS Appl Mater Interfaces 4(4):2234–2241. https://doi.org/10.1021/am300244s

Mironi-Harpaz I, Narkis M (2001) Thermoelectric behavior (PTC) of carbon black-containing TPX/UHMWPE and TPX/XL-UHMWPE blends. J Polym Sci Part B: Polym Phys 39(12):1415–1428. https://doi.org/10.1002/polb.1113

Khanam PN, Ponnamma D, Al-Madeed MA (2015) Electrical properties of graphene polymer nanocomposites. In: Sadasivuni KK, Ponnamma D, Kim J, Thomas S (eds) Graphene-based polymer nanocomposites in electronics. Springer, pp 25–47. https://doi.org/10.1007/978-3-319-13875-6_2

Oskouyi ABSU, Mertiny P (2014) Tunneling conductivity and piezoresistivity of composites containing randomly dispersed conductive nano-platelets. Mater Chem Phys 7(4):2501–2521

Zabihi Z, Araghi H (2016) Monte Carlo simulations of effective electrical conductivity of graphene/poly(methyl methacrylate) nanocomposite: landauer-Buttiker approach. Synth Met 217:87–93. https://doi.org/10.1016/j.synthmet.2016.03.024

Grossiord N, Loos J, Regev O, Koning CE (2006) Toolbox for dispersing carbon nanotubes into polymers to get conductive nanocomposites. Chem Mater 18(5):1089–1099. https://doi.org/10.1021/cm051881h

Bauhofer WKJ (2009) A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos Sci Technol 69(10):1486–1498

Acknowledgements

The authors would like to thank to Abu Dhabi Education Council (ADEC) for providing the research Grant (EX2016-000006) through “the ADEC Award for Research Excellence (A2RE) 2015.”

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gupta, T.K., Choosri, M., Varadarajan, K.M. et al. Self-sensing and mechanical performance of CNT/GNP/UHMWPE biocompatible nanocomposites. J Mater Sci 53, 7939–7952 (2018). https://doi.org/10.1007/s10853-018-2072-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2072-3